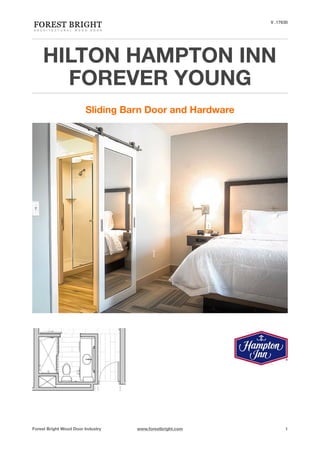

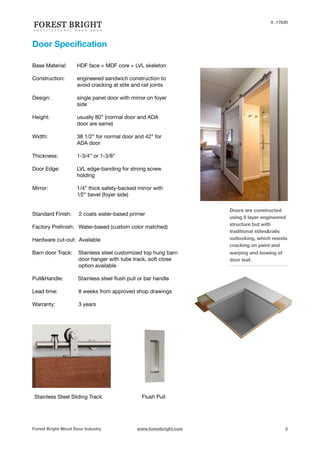

This document provides specifications for a sliding barn door and hardware from Forest Bright Wood Door Industry. It details the materials used in constructing the engineered wood doors including an HDF face, MDF core, and LVL skeleton. It also lists dimensions for height, width, thickness and finishes. Hardware options are outlined including stainless steel barn door tracks with soft close and pull and handle options. A lead time of 8 weeks from approved drawings is noted along with a 3 year warranty. Contact information is provided for the business development team to discuss hospitality, US architectural, sliding door or global architectural projects.