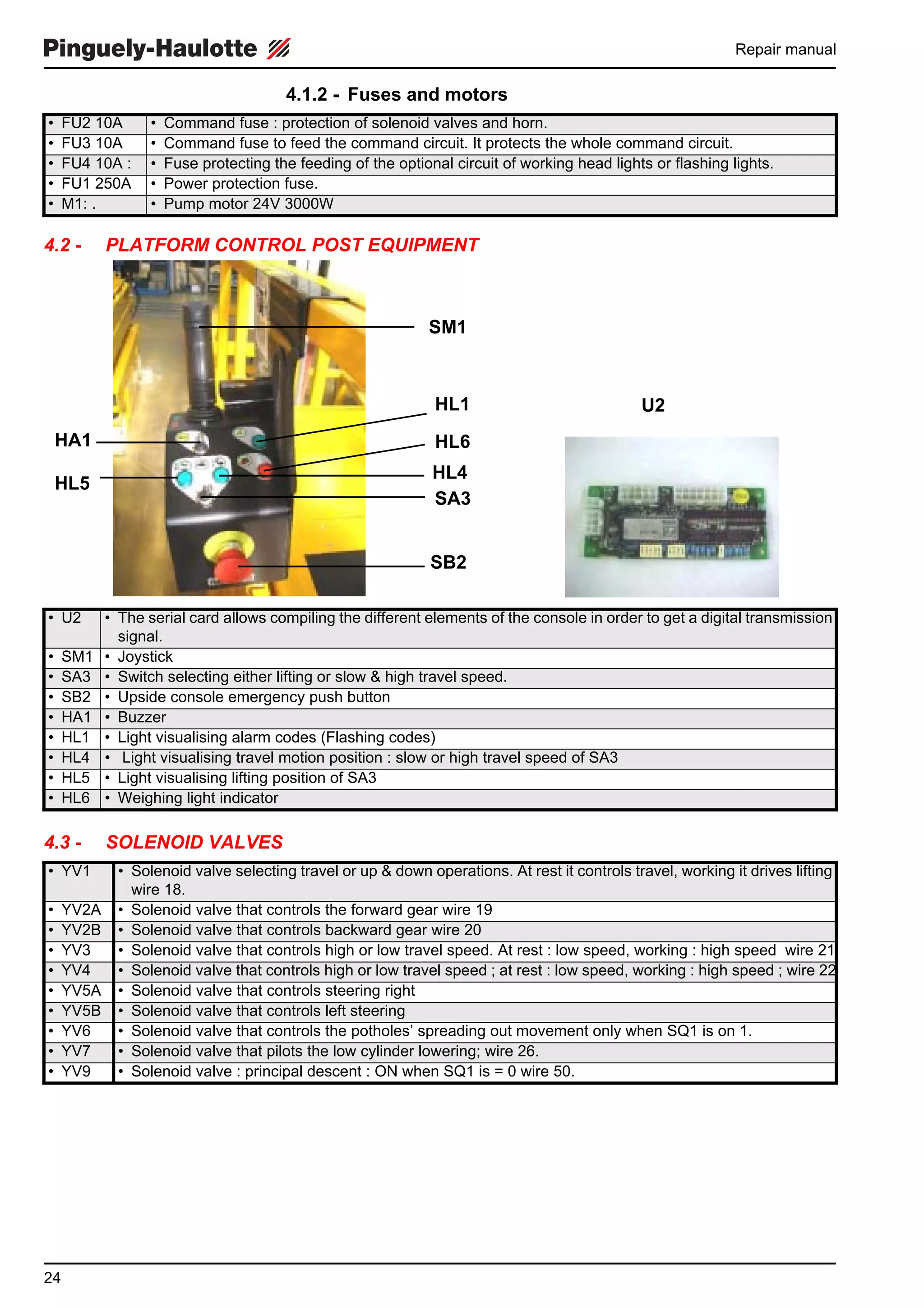

This document provides safety recommendations and maintenance instructions for self-propelled scissor lift platforms. It outlines general warnings, residual risks, safety recommendations for operators and use of the machine. It also describes the machine specifications, components, hydraulic and electrical systems. Maintenance procedures are presented, including preventative maintenance sheets. Failure detection flowcharts are provided to troubleshoot operational incidents. The document aims to help maintenance personnel safely service and repair the machine.