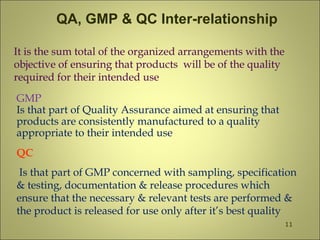

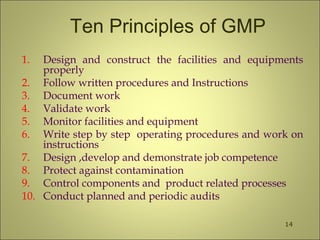

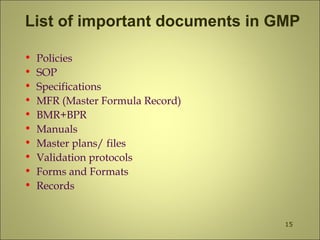

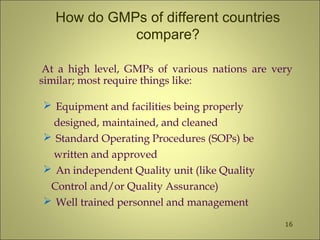

This document discusses Good Manufacturing Practices (GMP) and current Good Manufacturing Practices (cGMP). It defines GMP as ensuring products are consistently manufactured and controlled to quality standards for their intended use. cGMP emphasizes that expectations are dynamic and current. Quality is defined as a product's fitness for purpose. GMP is designed to minimize risks that cannot be eliminated through testing, such as contamination or incorrect labeling. Adhering to GMP is important to ensure medicines contain the proper ingredients and doses. The document outlines key aspects of GMP, including facilities, equipment, documentation, validation, training, and audits.