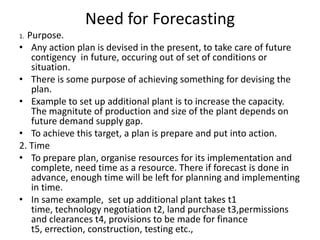

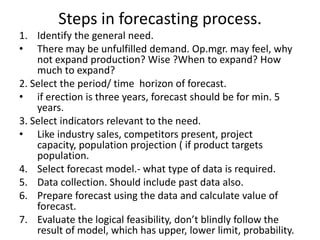

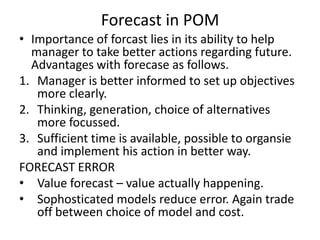

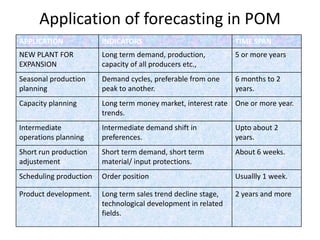

Operation management relies on forecasting to plan for future contingencies. Forecasting involves using past data and indicators to estimate future events, allowing sufficient time to develop plans and implement them. It provides managers information to set clear objectives and focus on alternatives. The forecasting process involves identifying needs, selecting a time horizon and relevant indicators, choosing a forecasting model, collecting data, preparing the forecast, and evaluating the results. Forecasting is applied in areas like new plant expansion, production planning, capacity planning, and product development to estimate indicators over various time spans from weeks to years into the future. Accurate forecasting helps managers make better informed decisions.