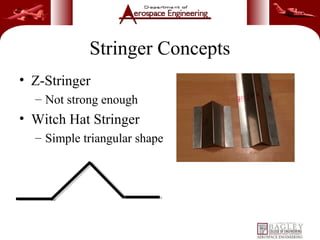

The document summarizes a panel project involving the design, optimization, manufacturing, and testing of stringer concepts for panels. It describes exploring a Z-stringer and witch hat stringer design. The team agreed on design parameters like a 90 degree web angle and adjusted the height at the expense of width for optimization. The final design is specified with dimensions. Testing showed discrepancies with the original dimensions likely due to coding errors, manufacturing tolerances, and plastering issues. Lessons learned included scheduling, measuring twice, alternative solutions, and checking work. The design was successful overall despite challenges.