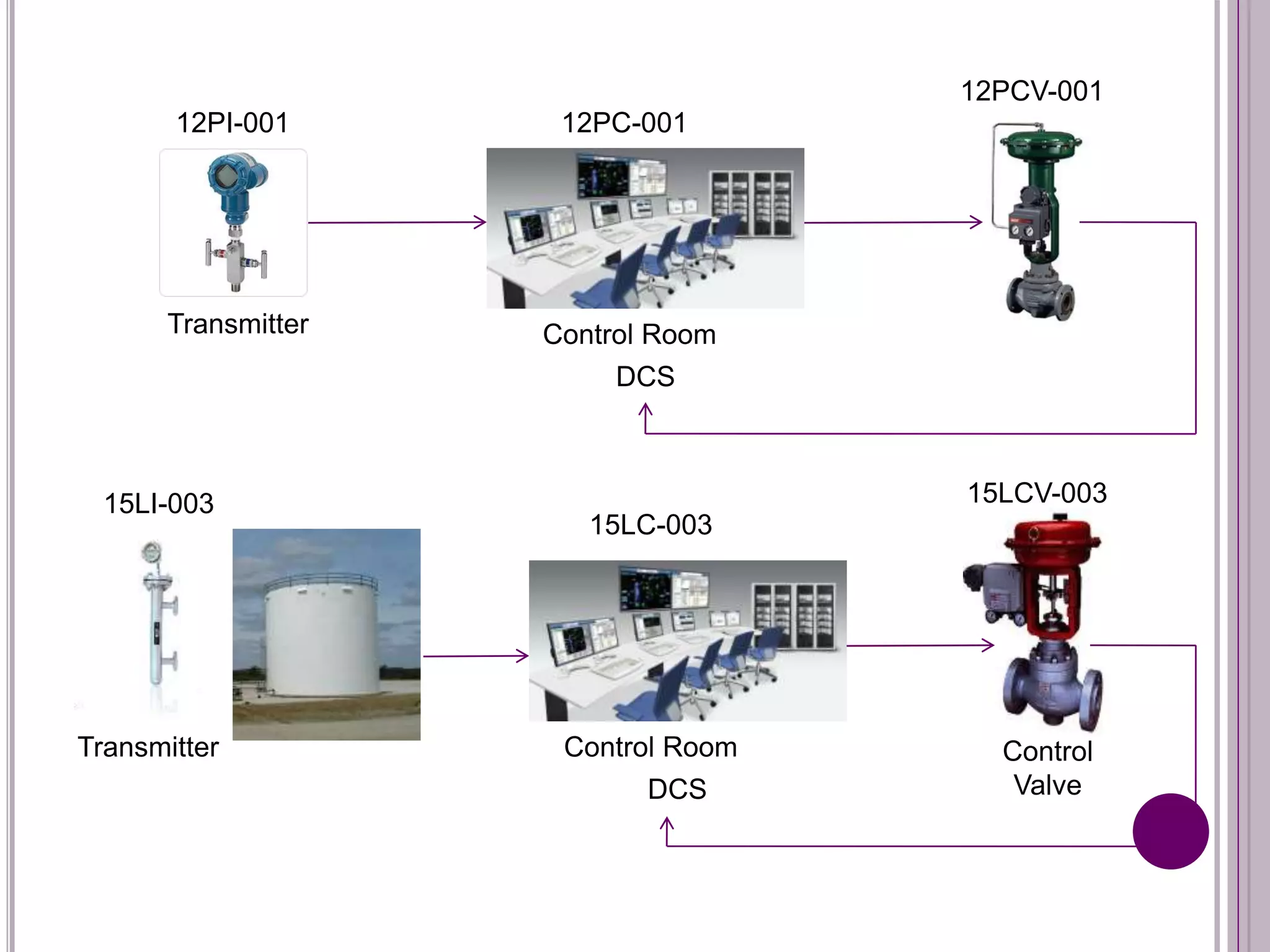

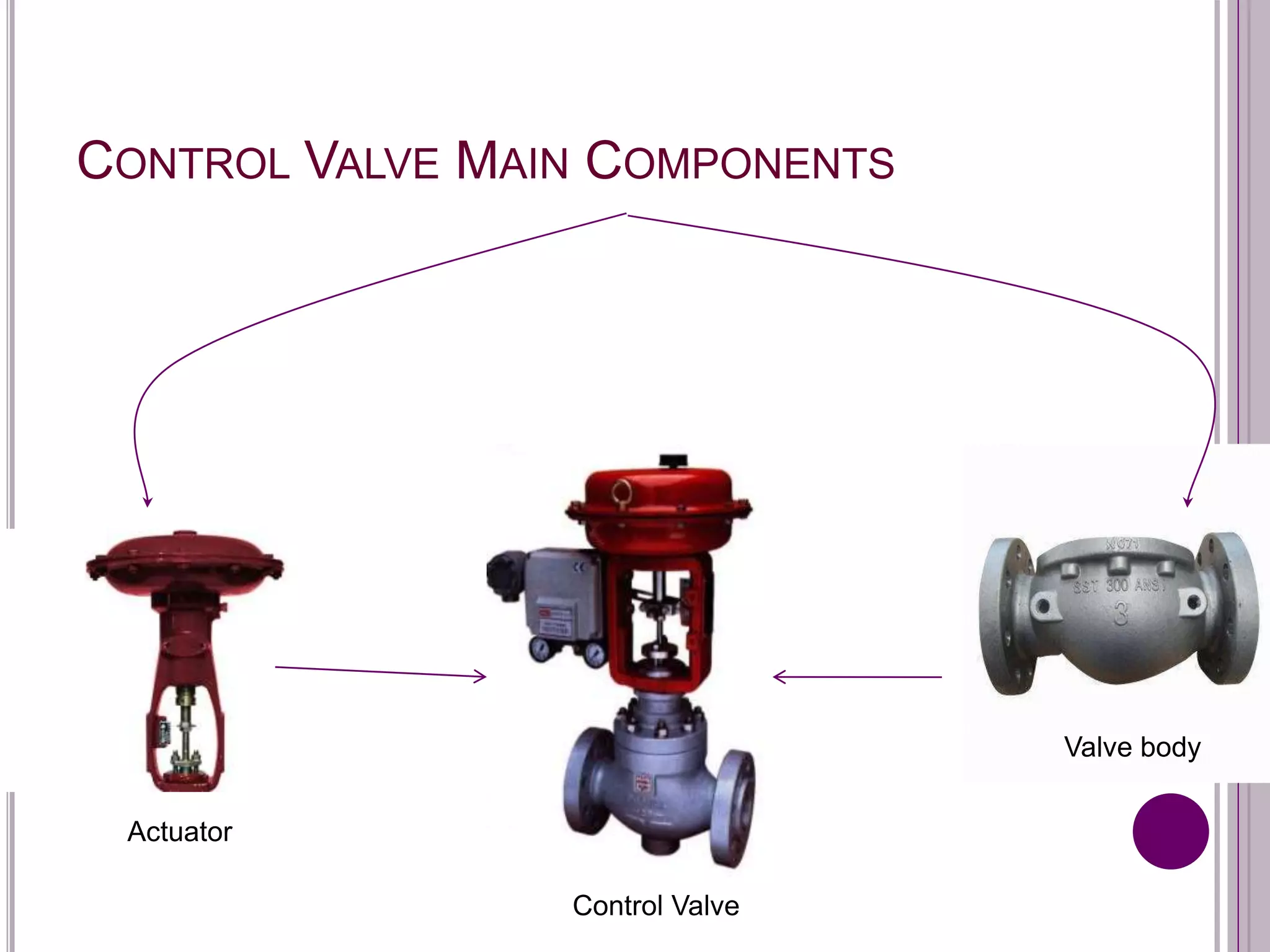

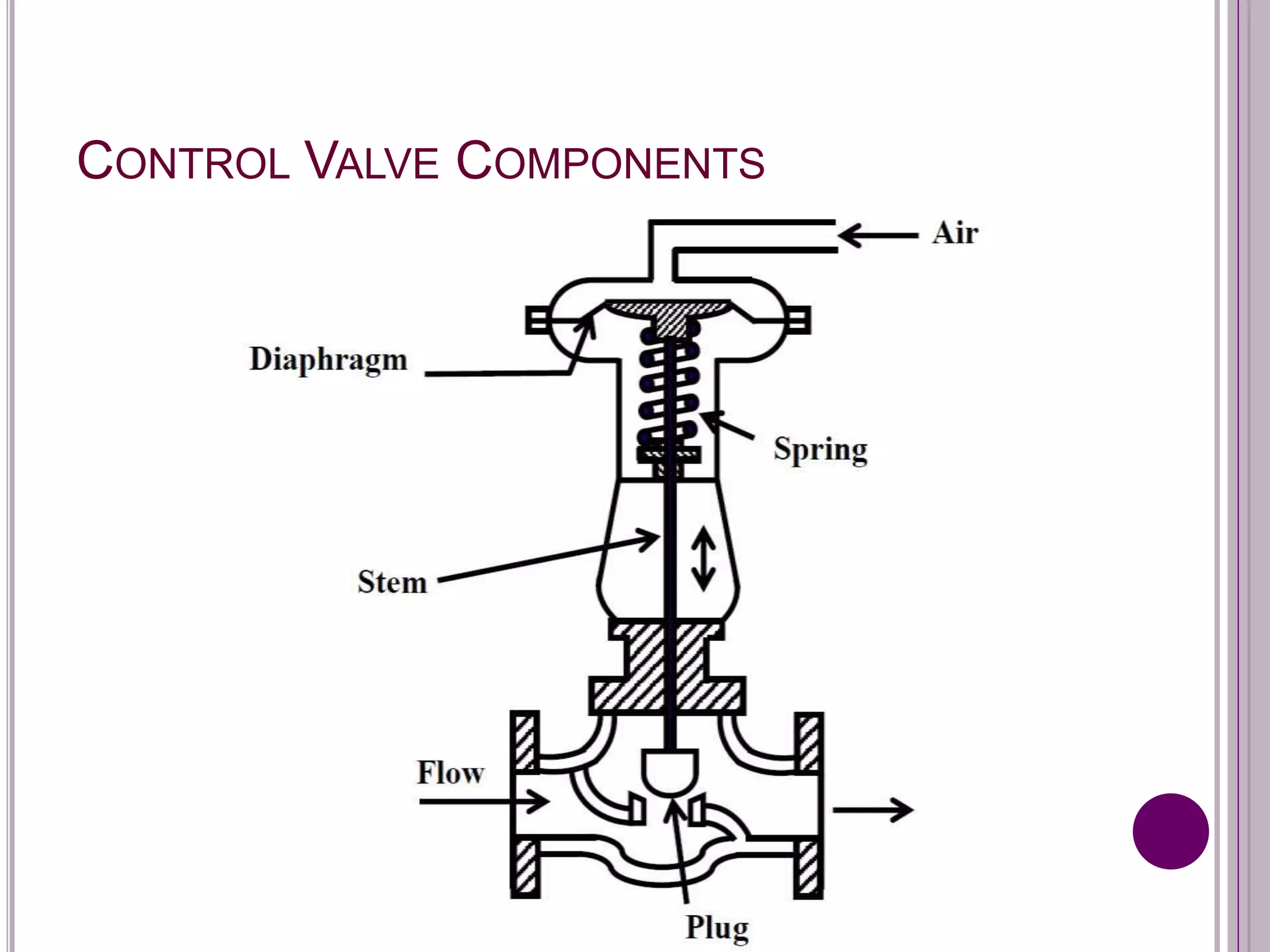

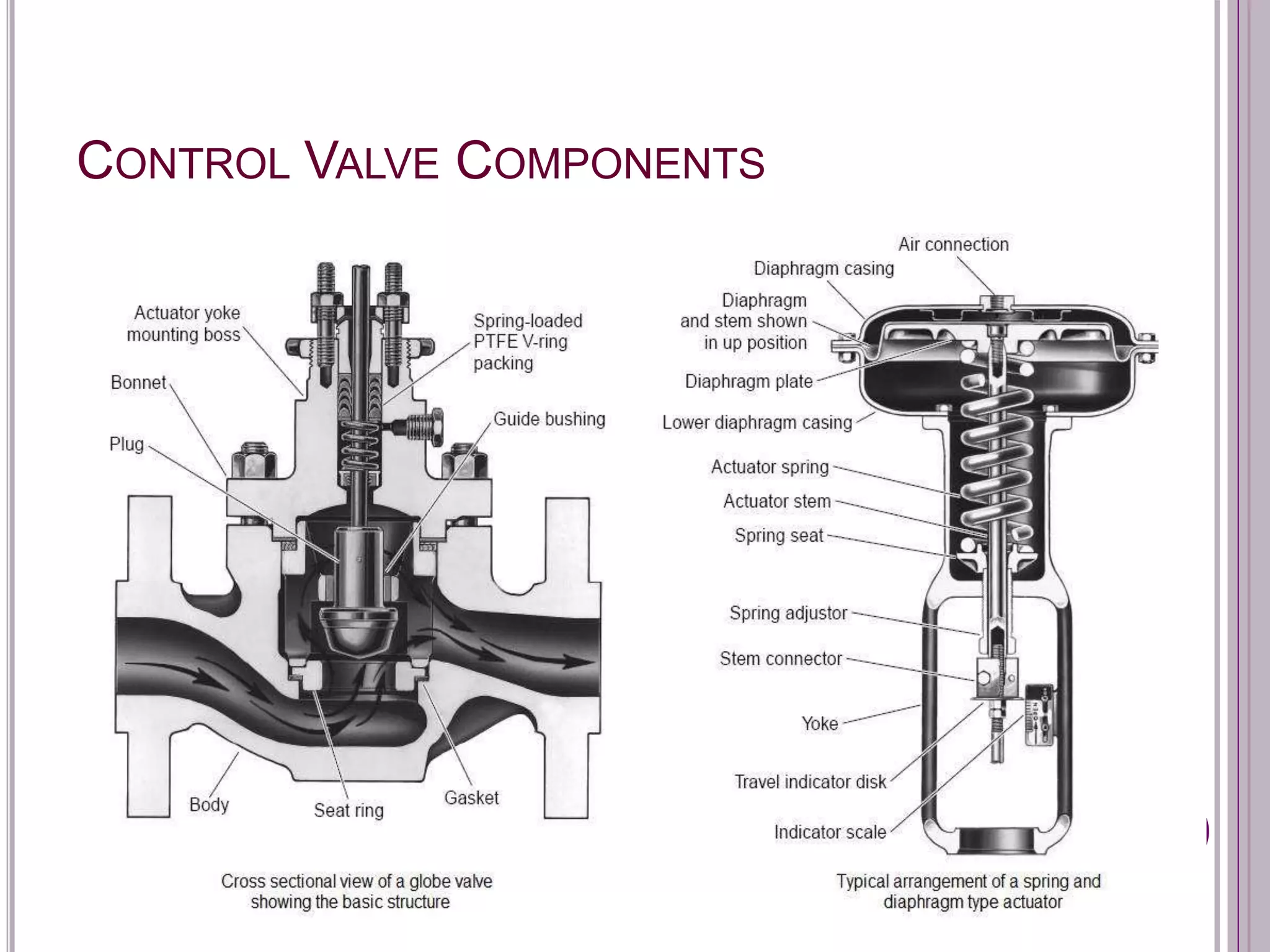

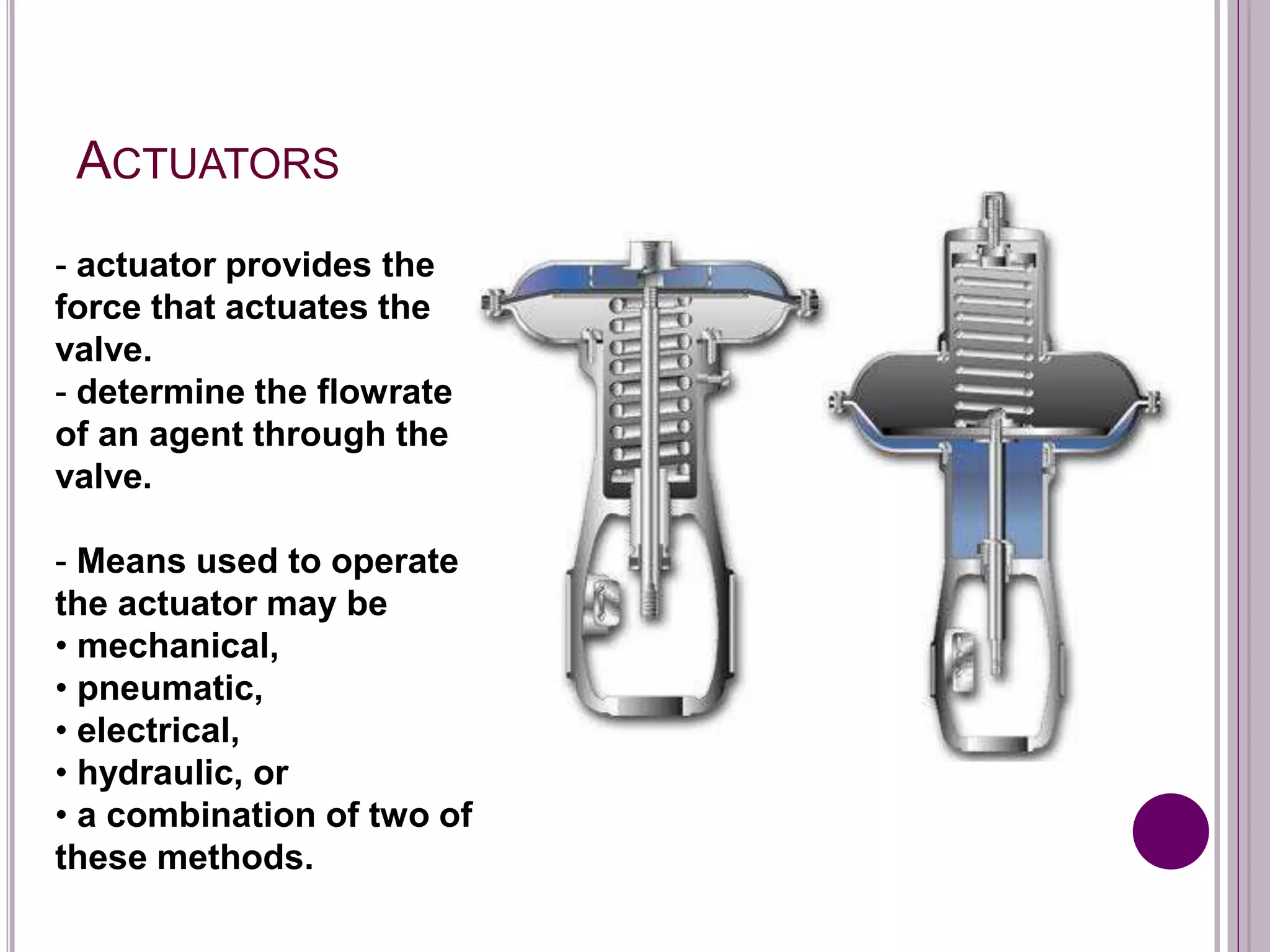

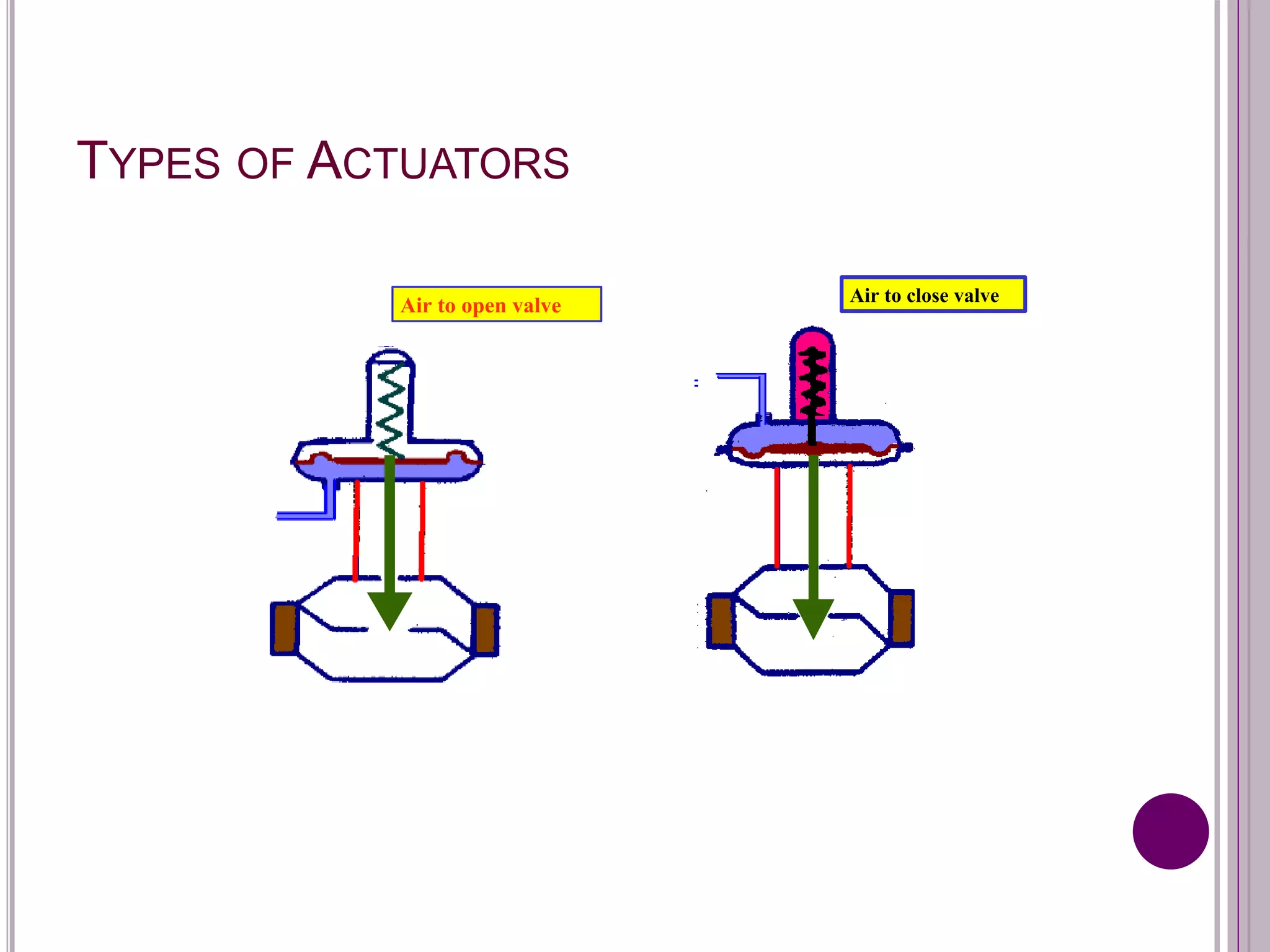

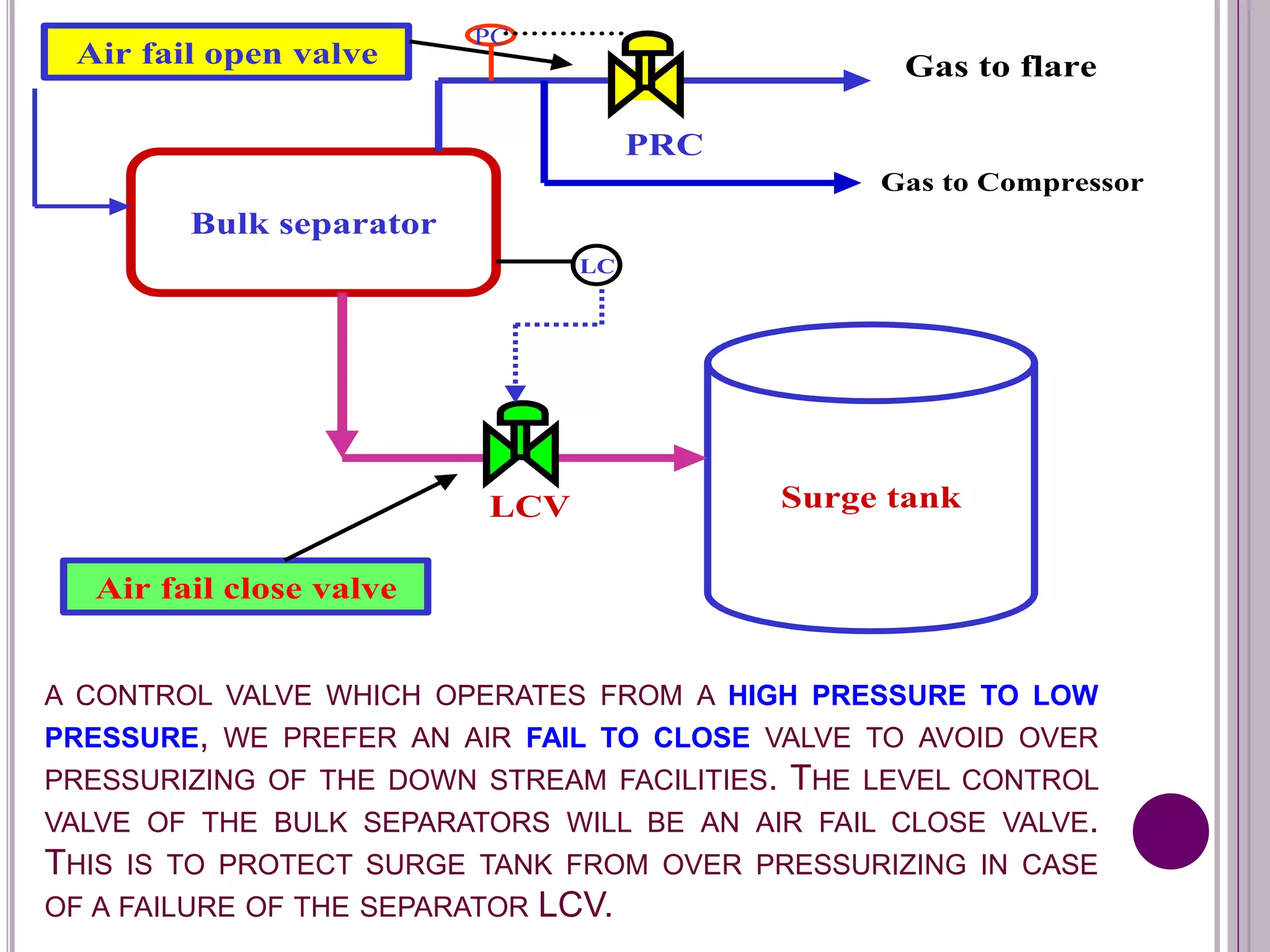

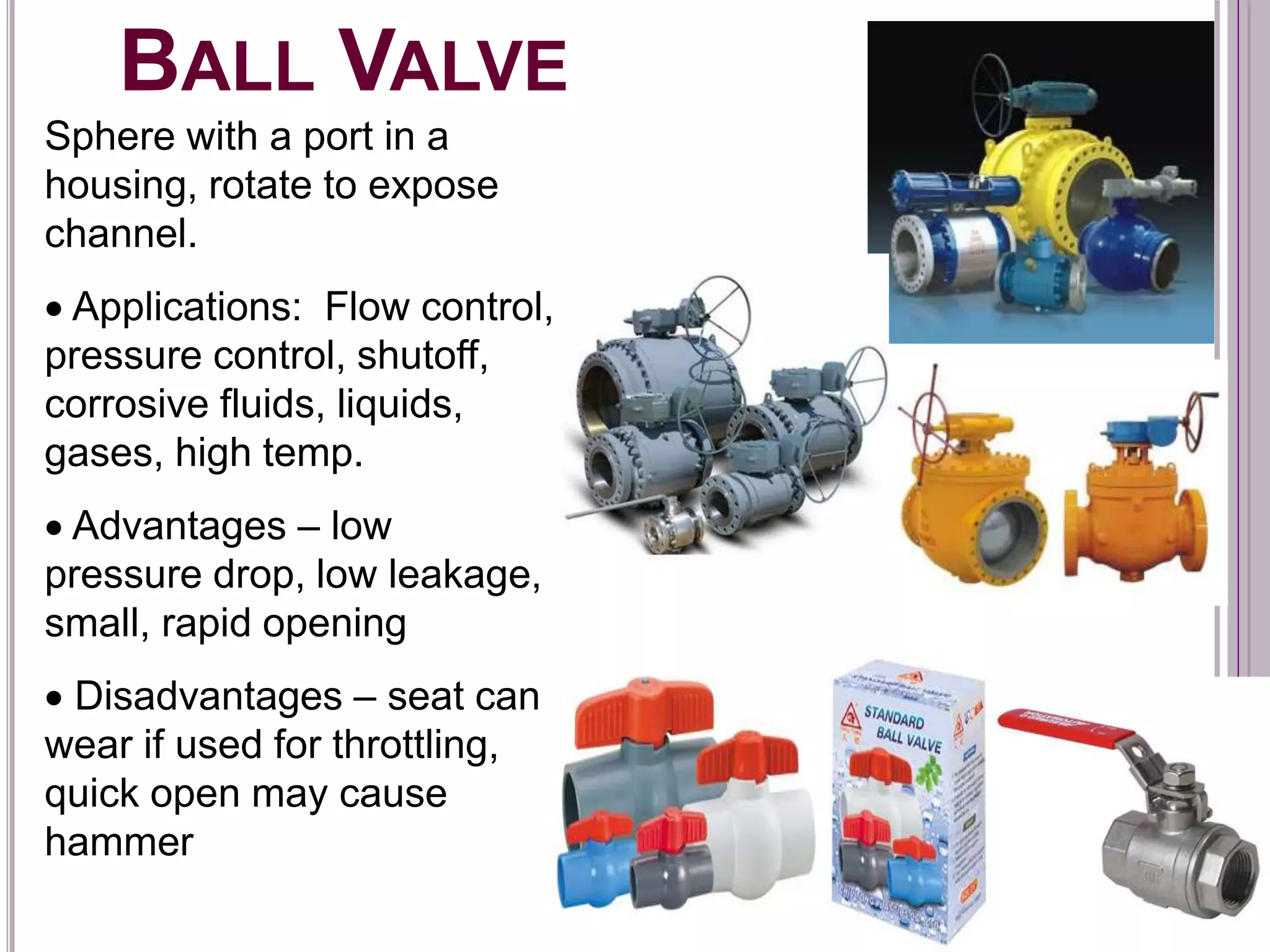

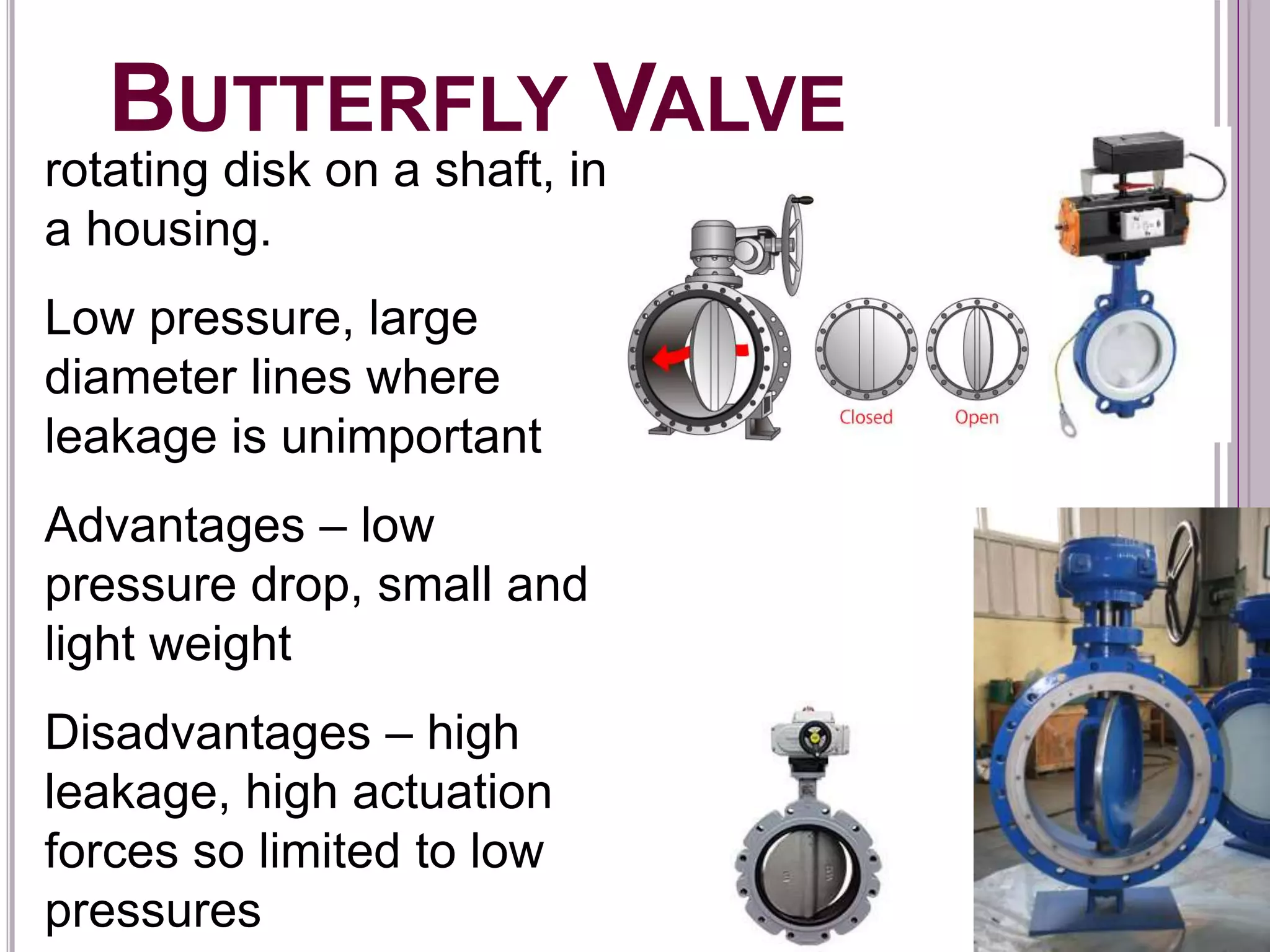

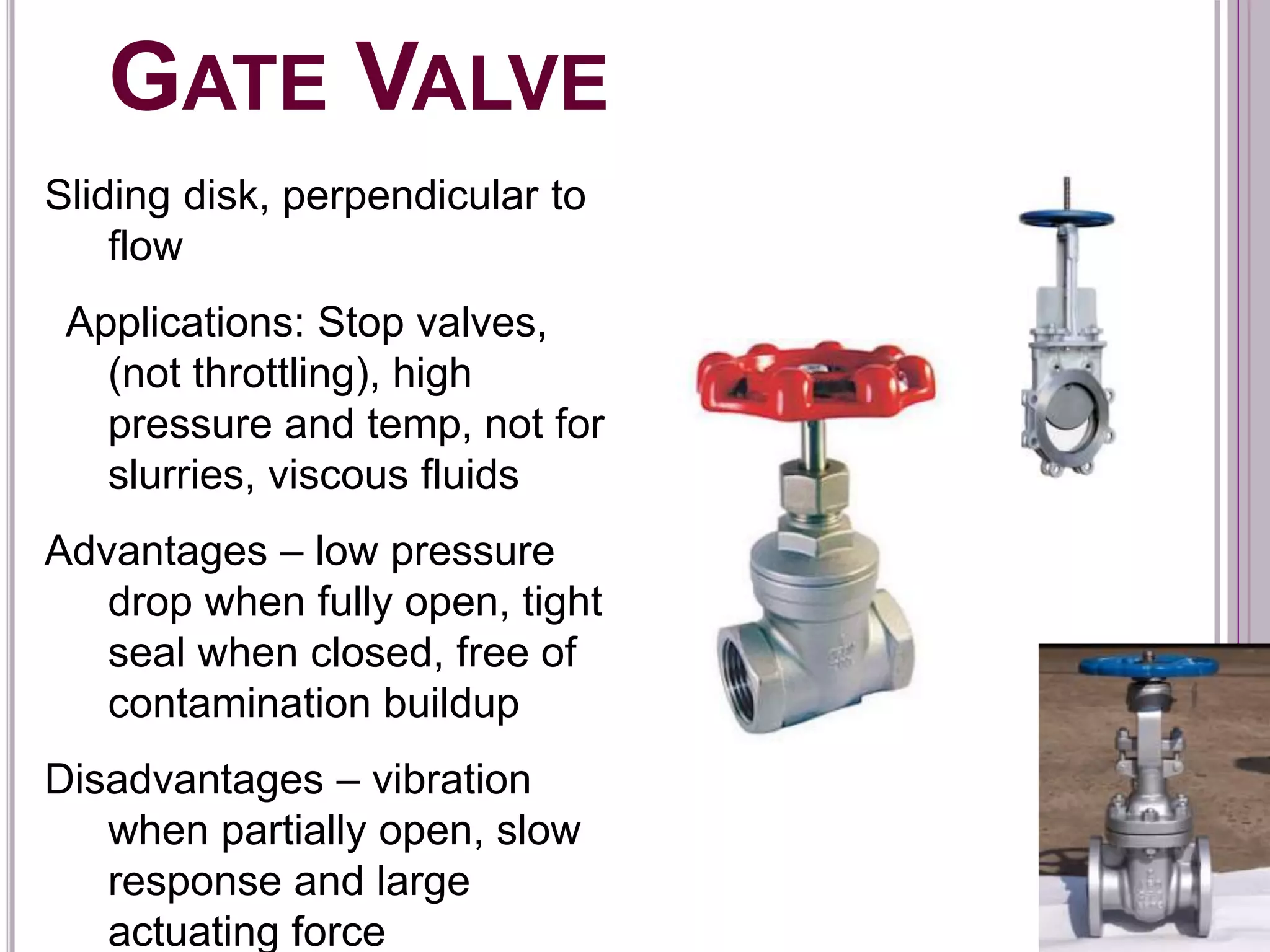

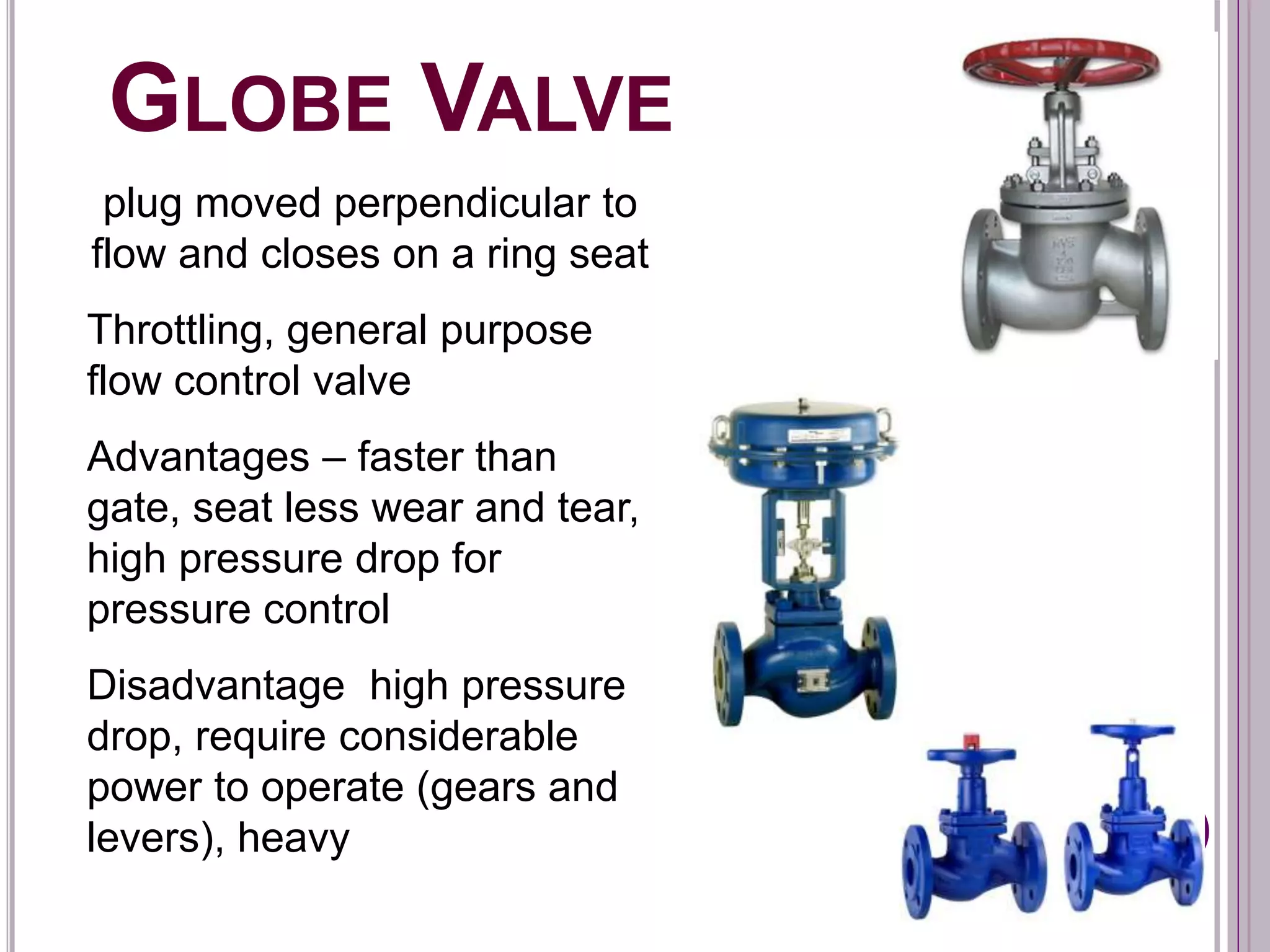

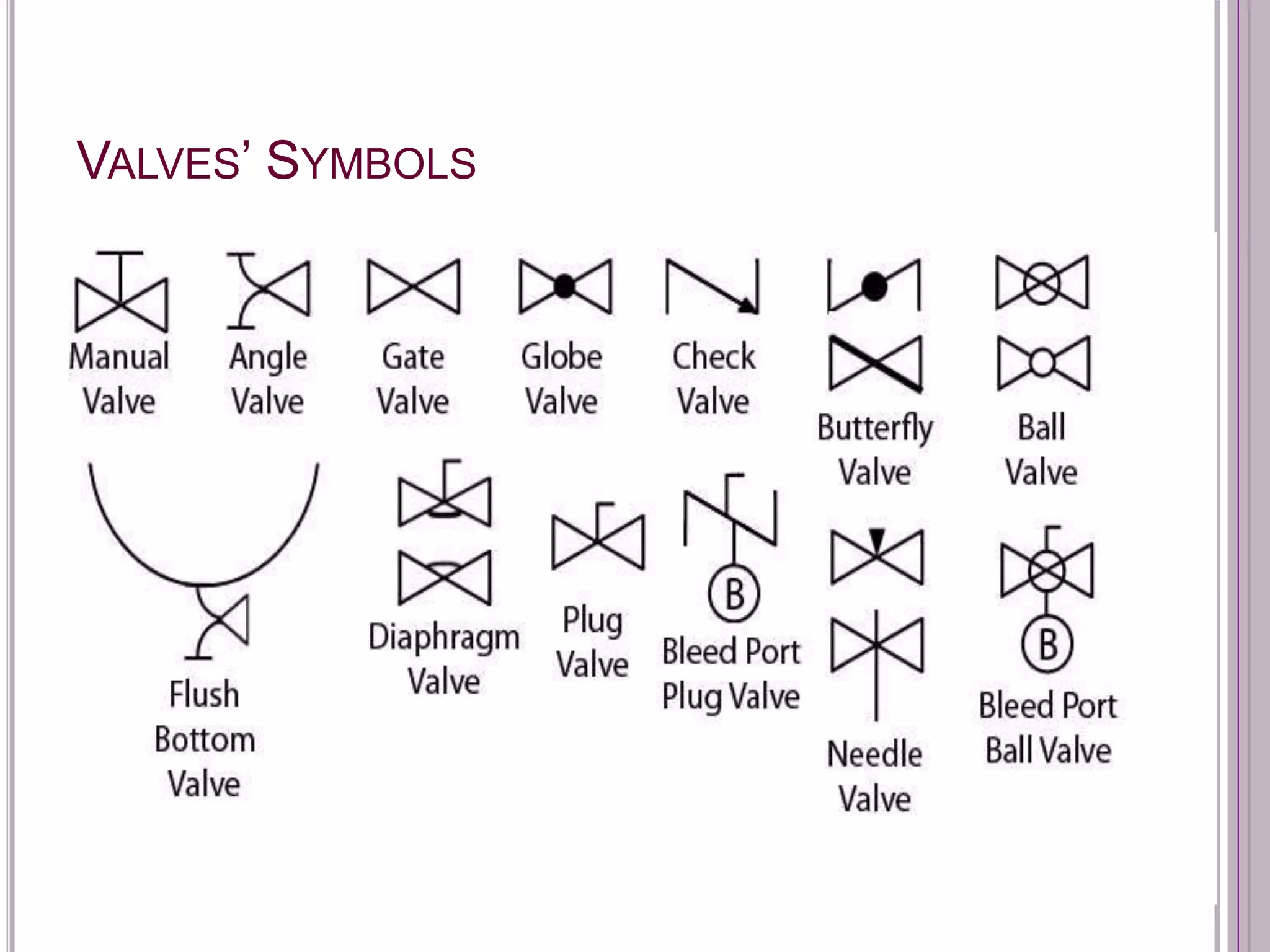

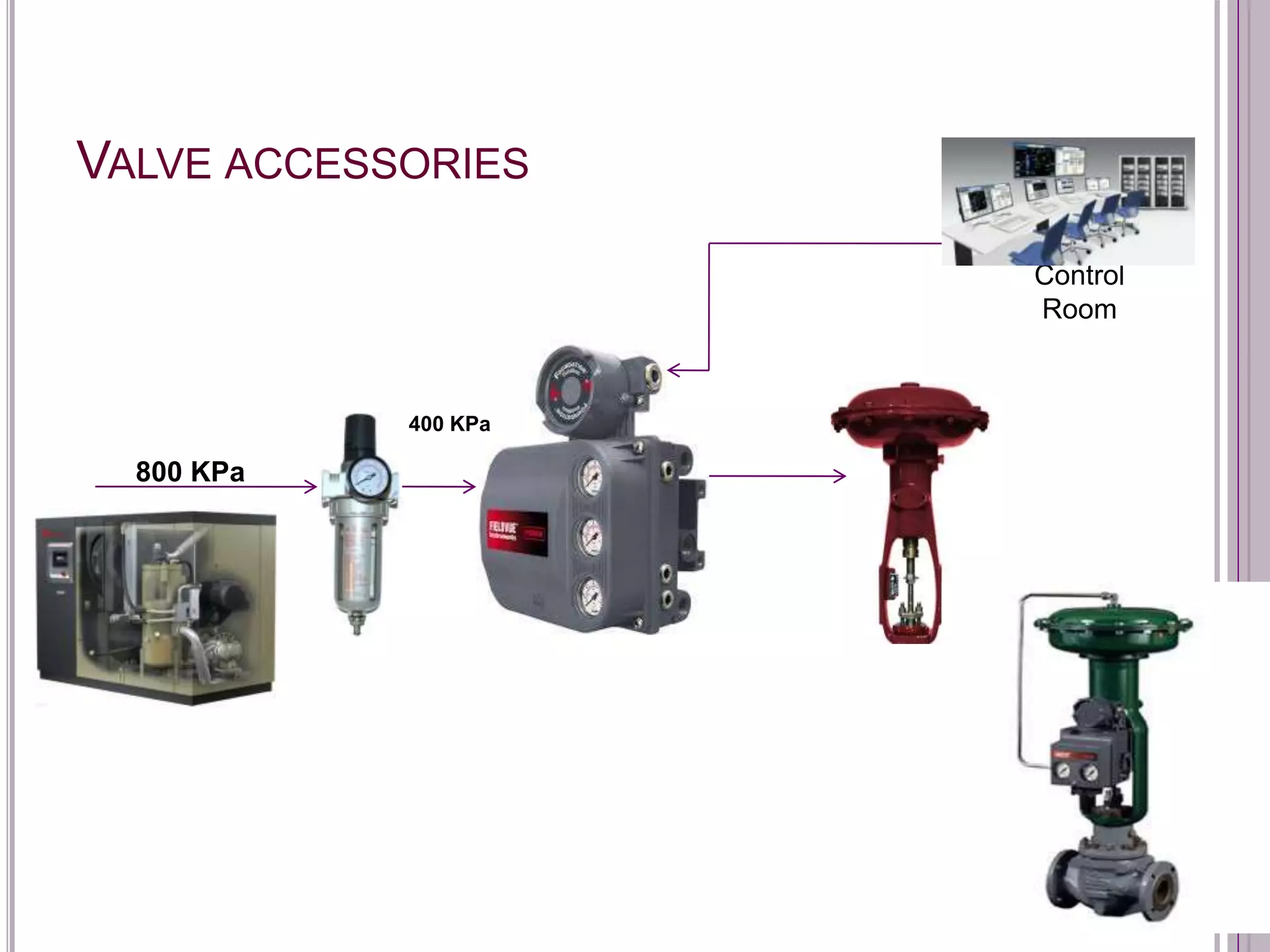

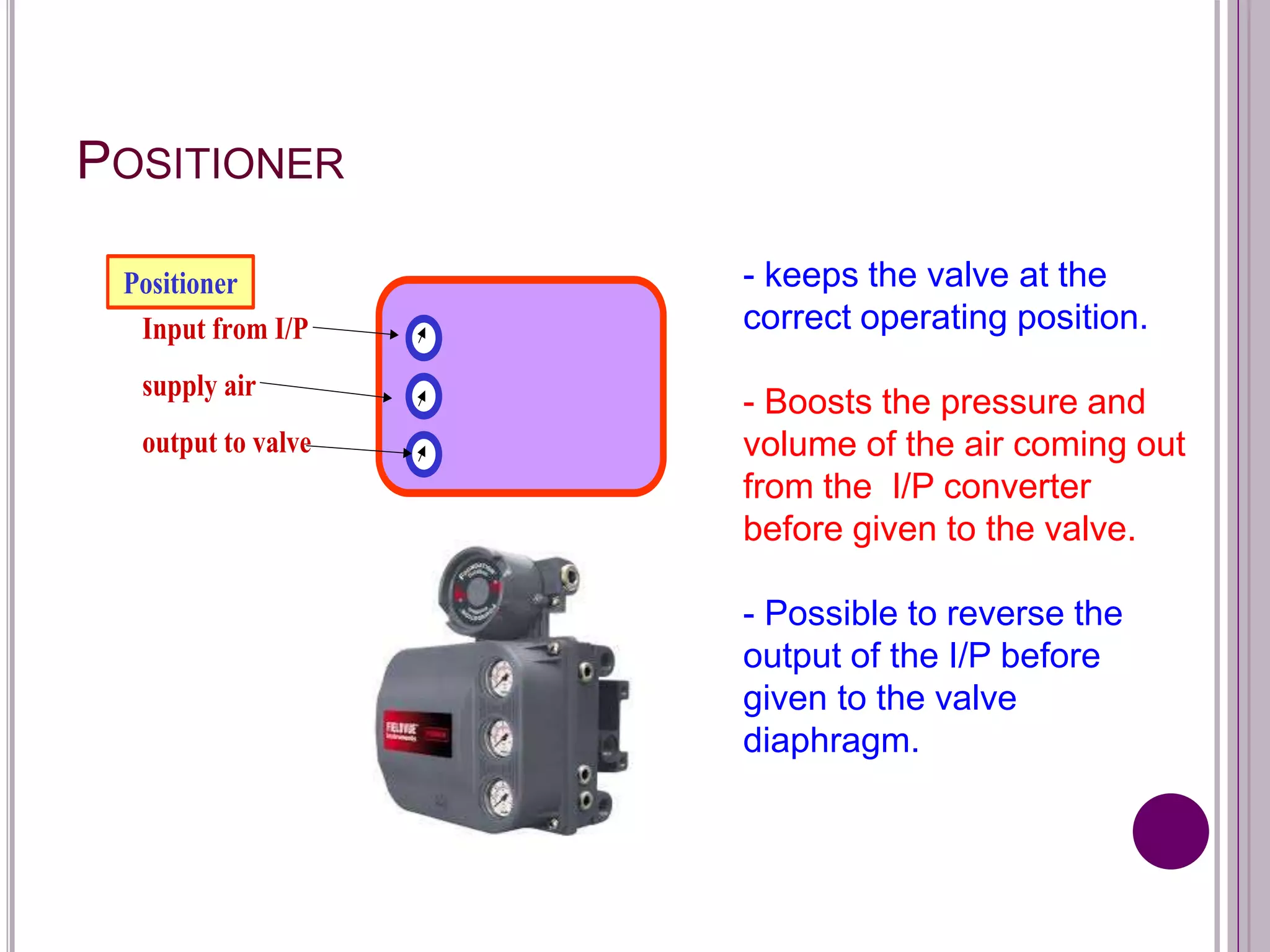

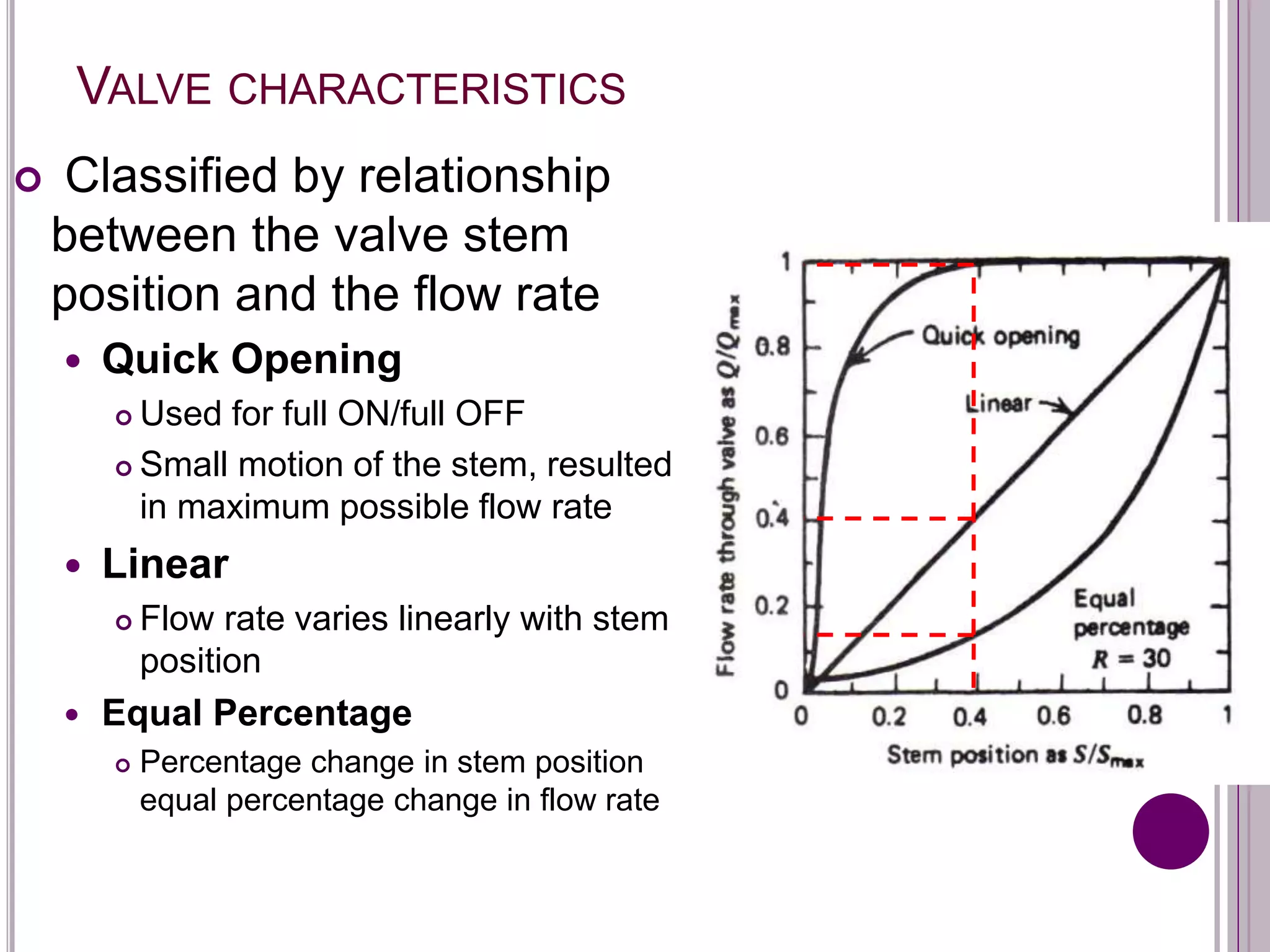

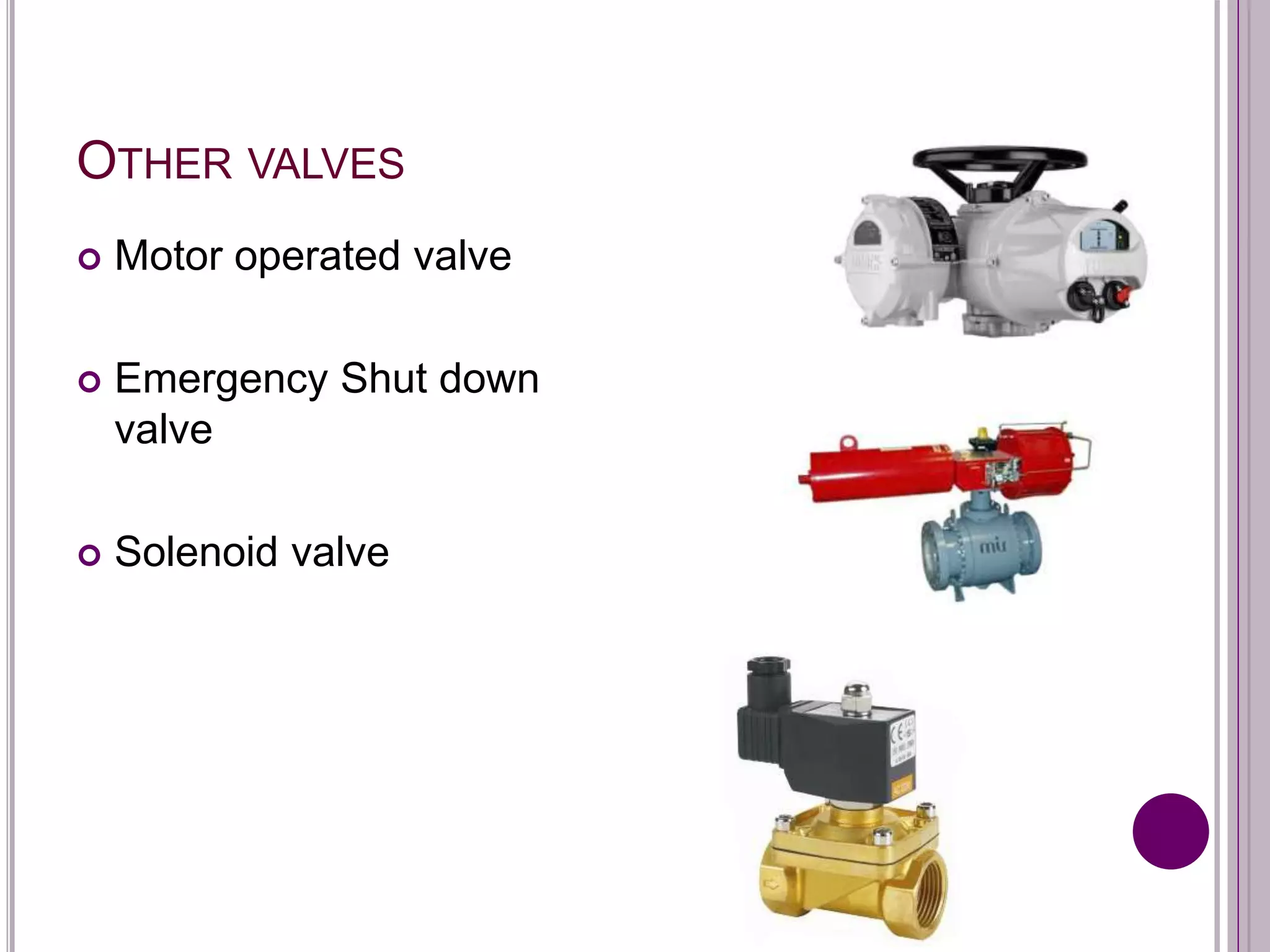

Final control elements are devices like valves and pumps that adjust the manipulated variable to control process parameters. Common parameters include pressure, flow, level, and temperature. Control valves have components like actuators, bodies, and trim. Actuators provide the force and include pneumatic, hydraulic, and electric types. Valves types are ball, butterfly, gate, and globe valves. Positioners maintain the correct valve position. Control valves can experience issues like leaks, sticking, or nonlinear flow. Troubleshooting addresses problems like deadband, overshoot, sizing errors, and nonlinear characteristics.