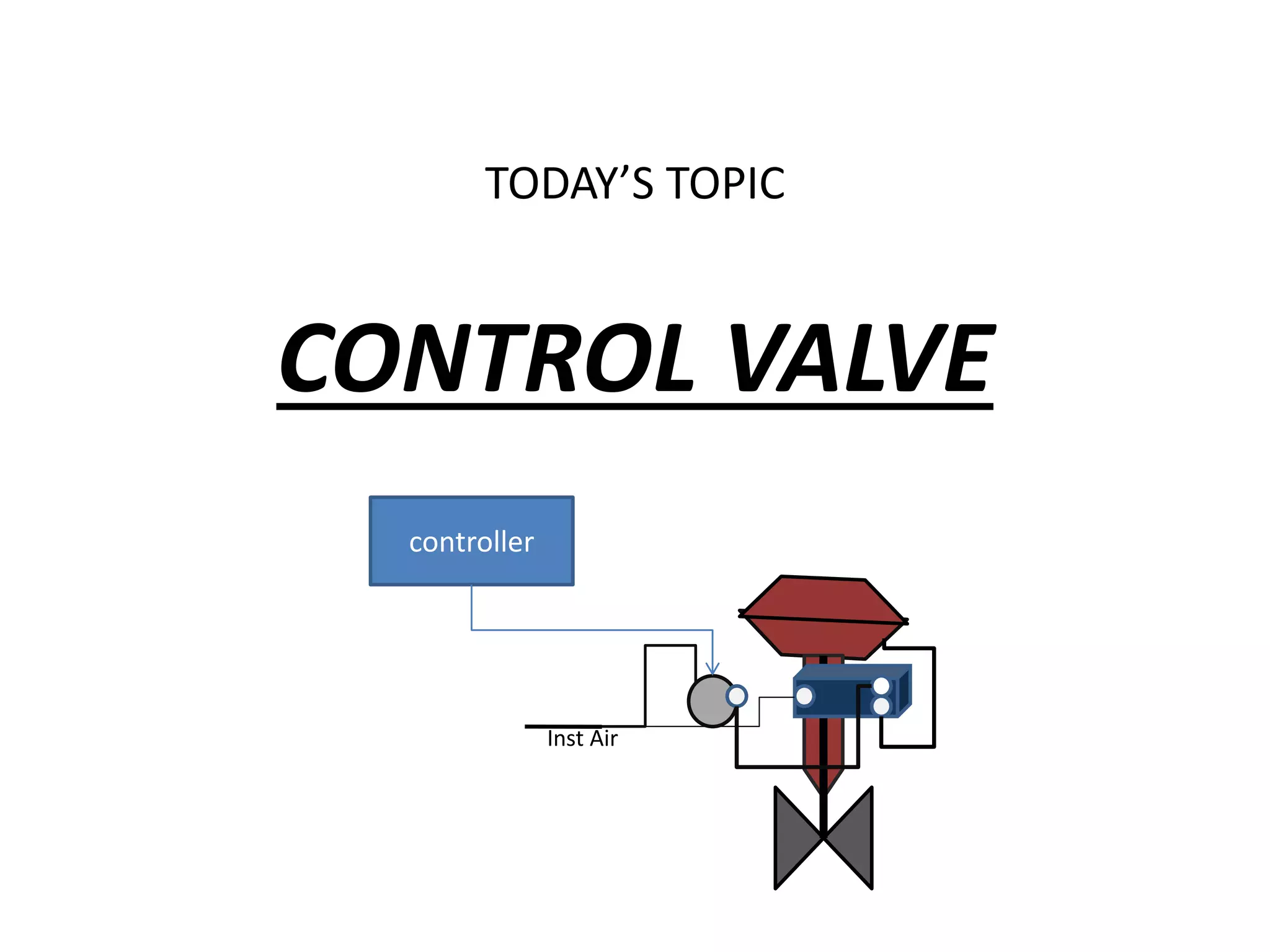

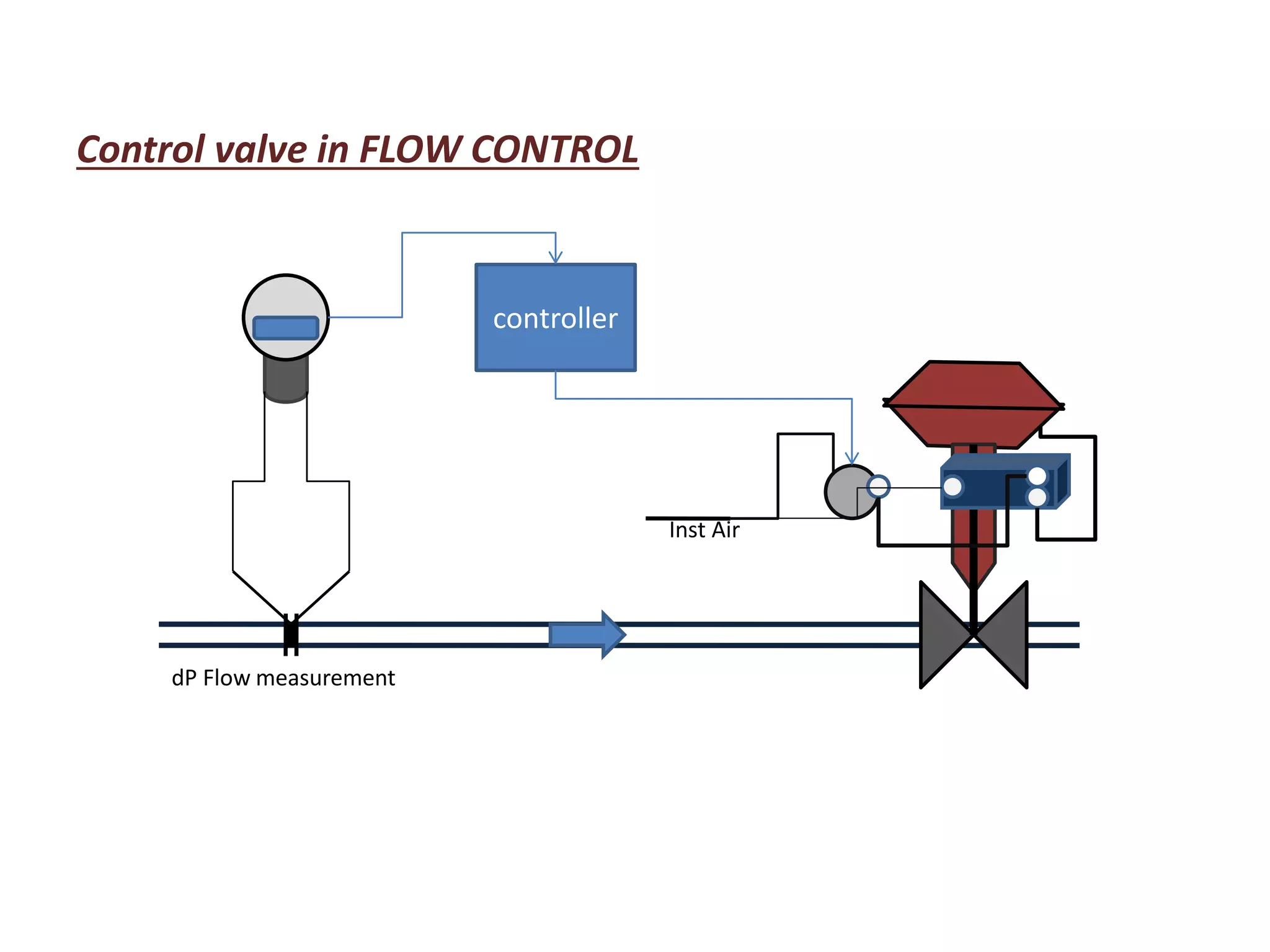

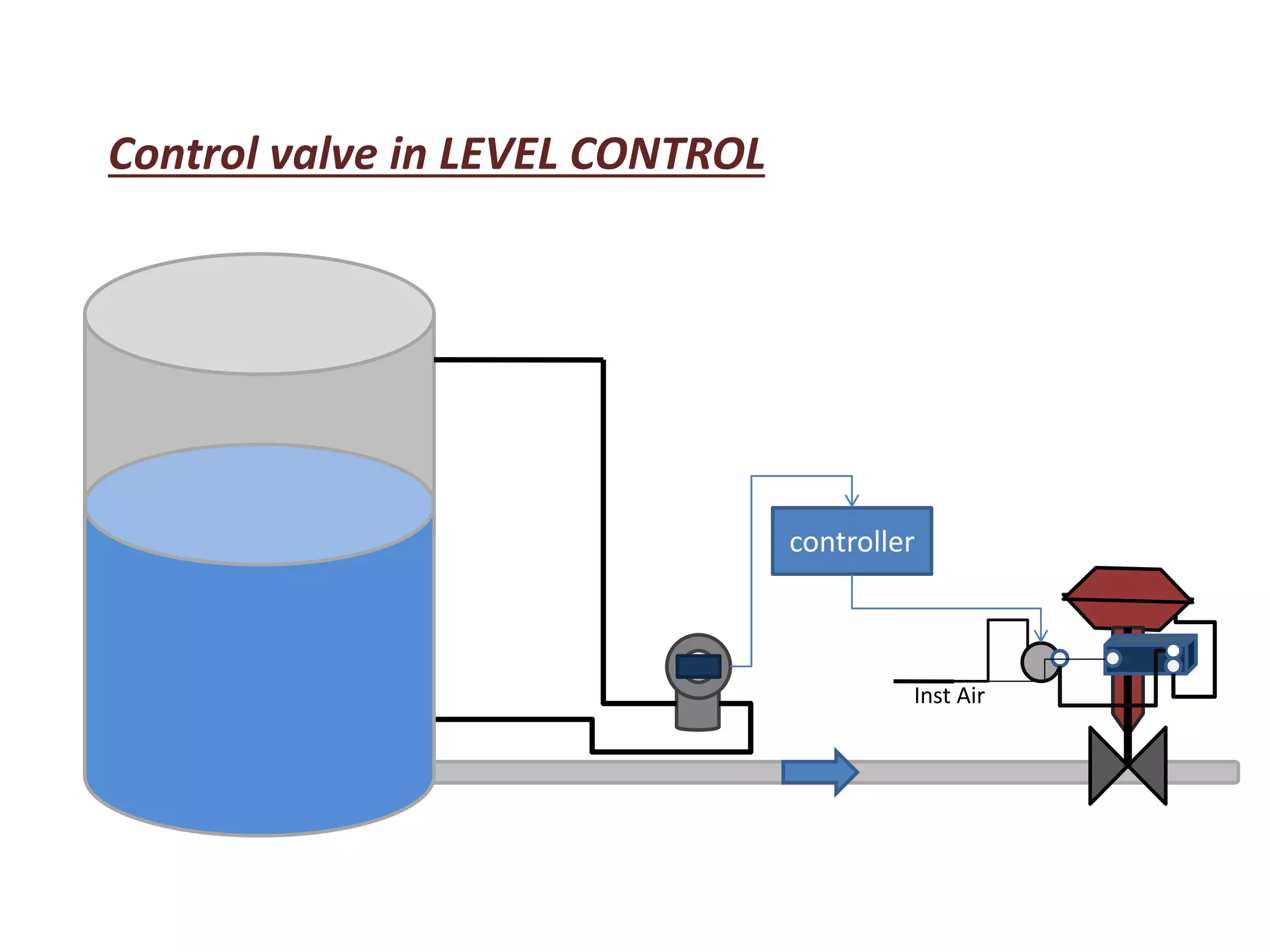

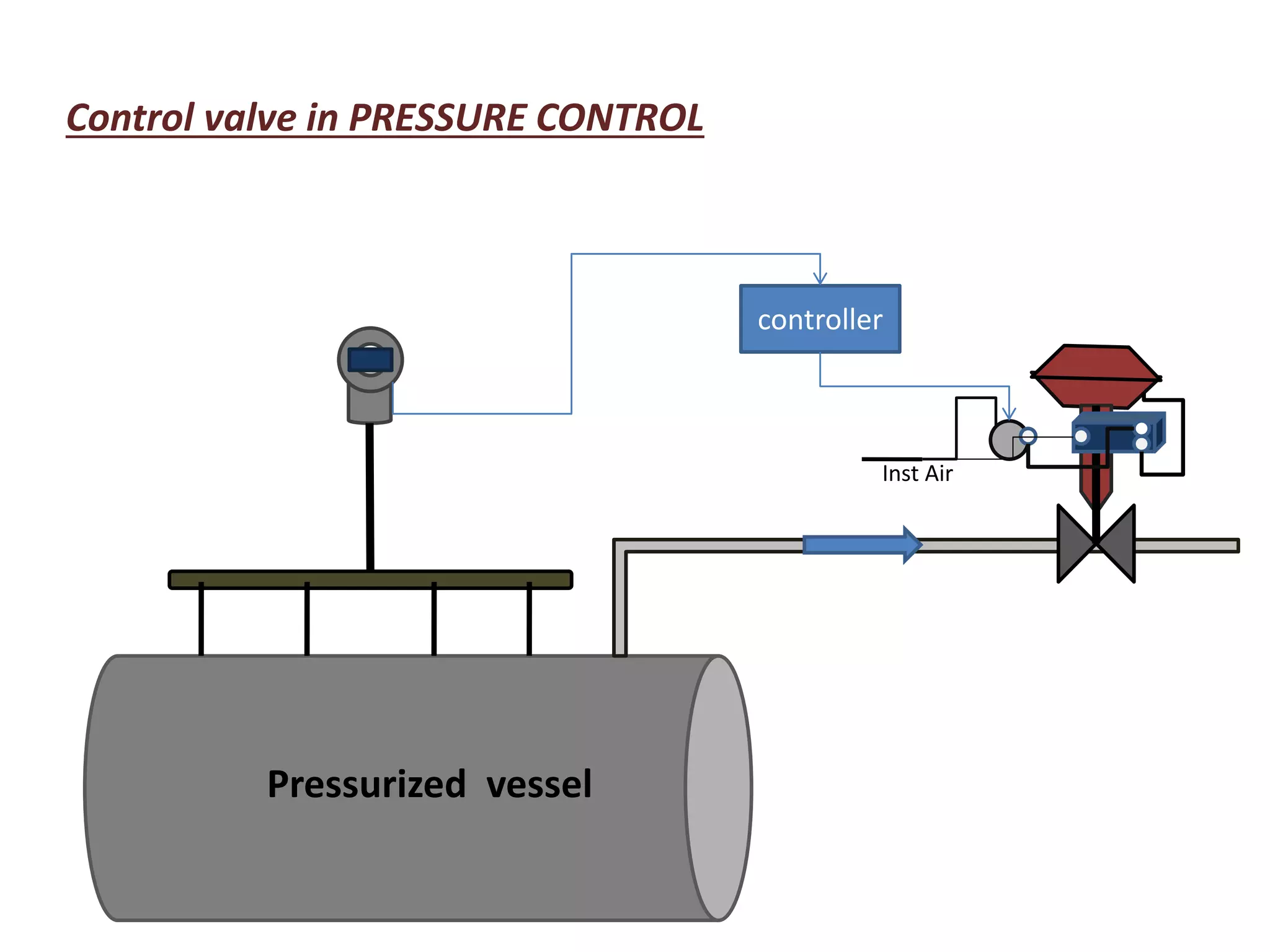

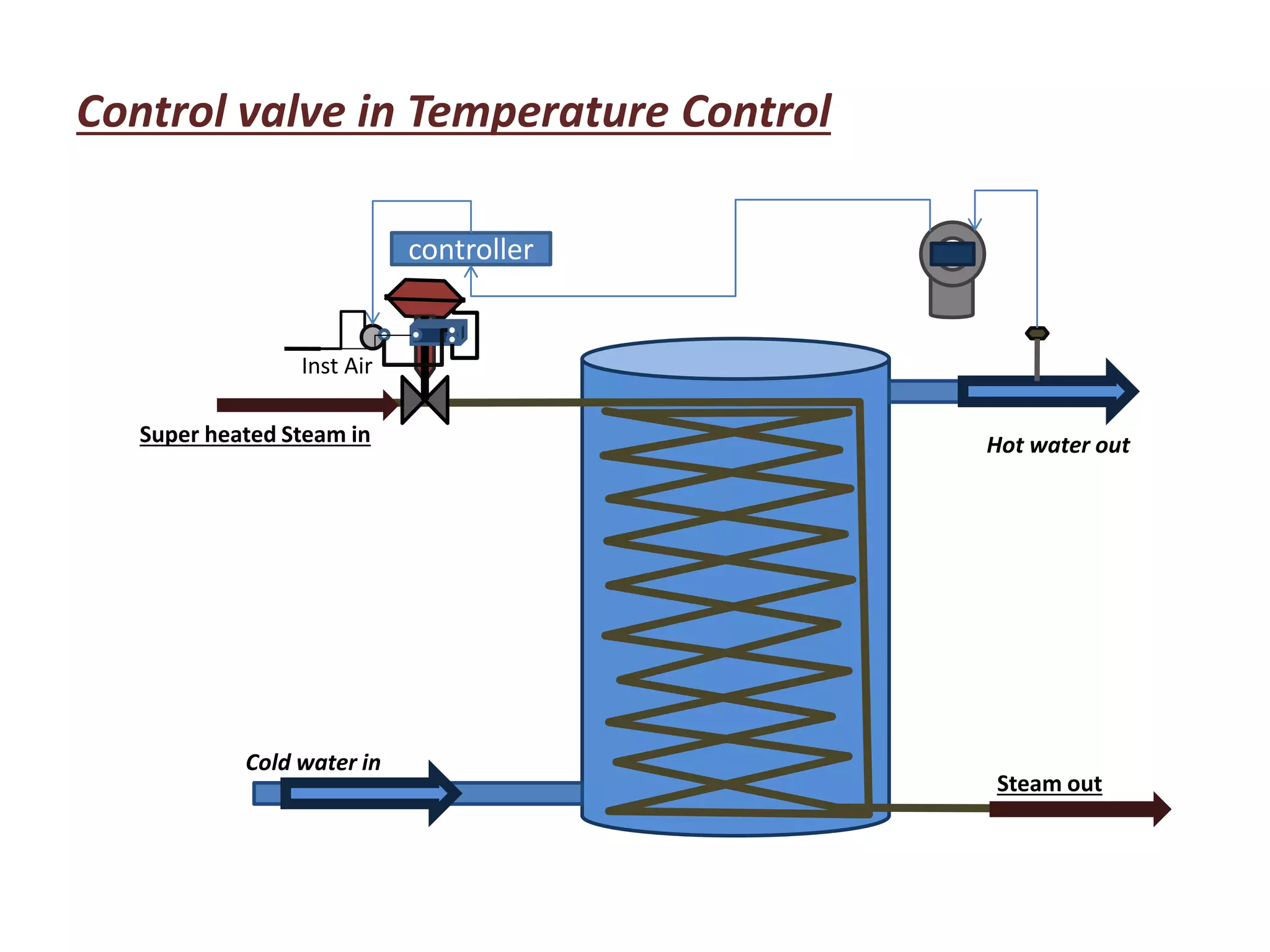

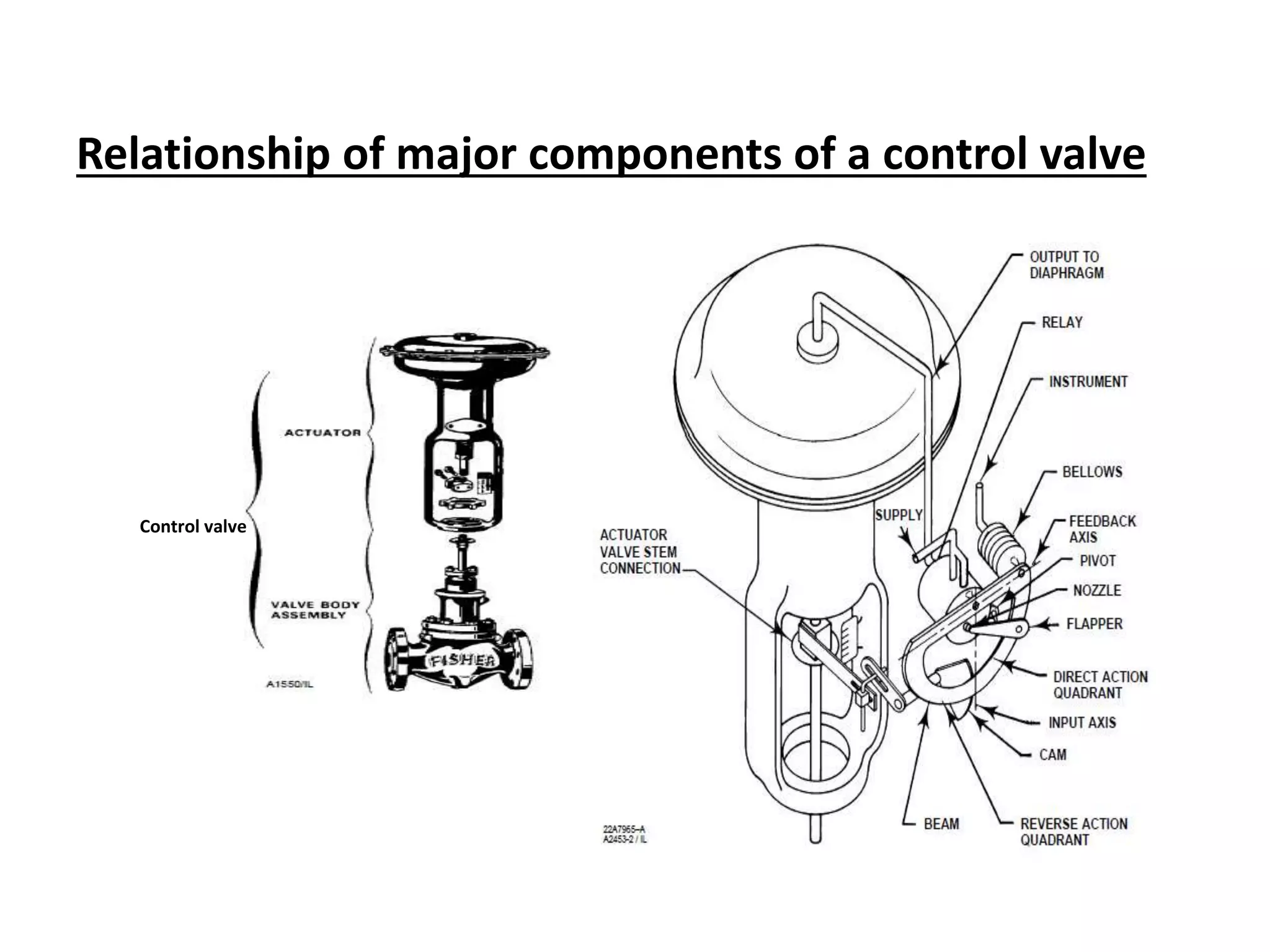

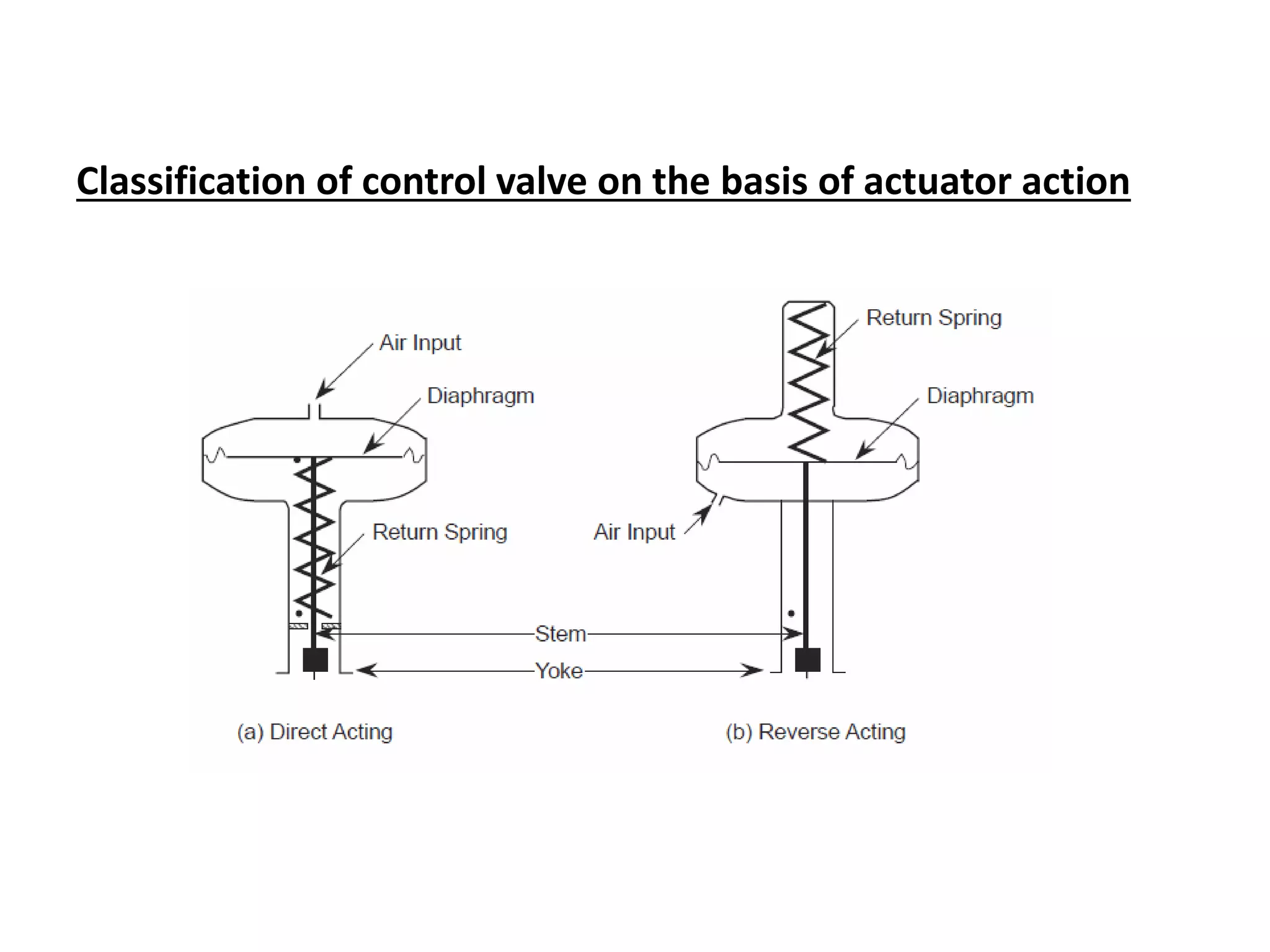

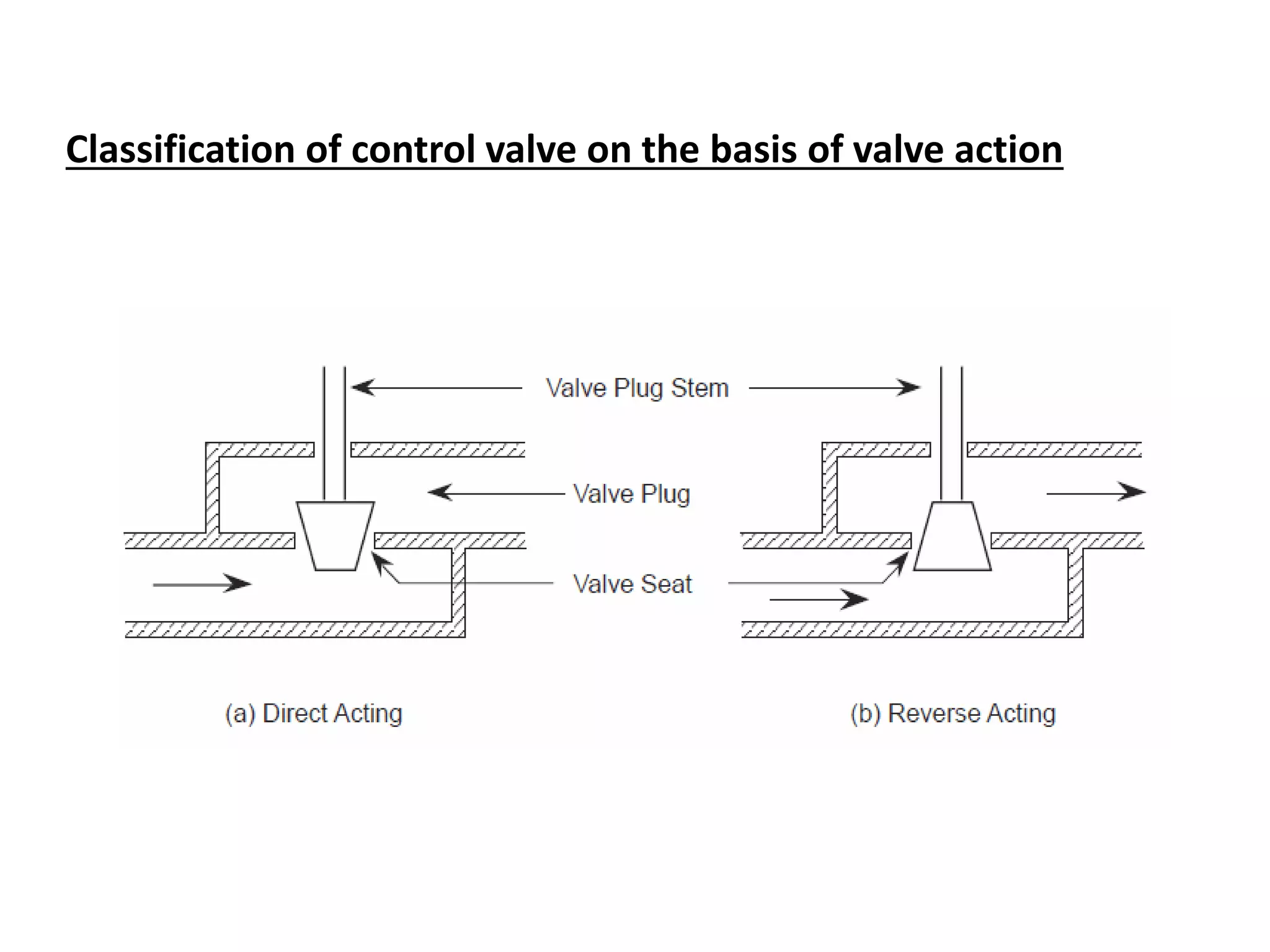

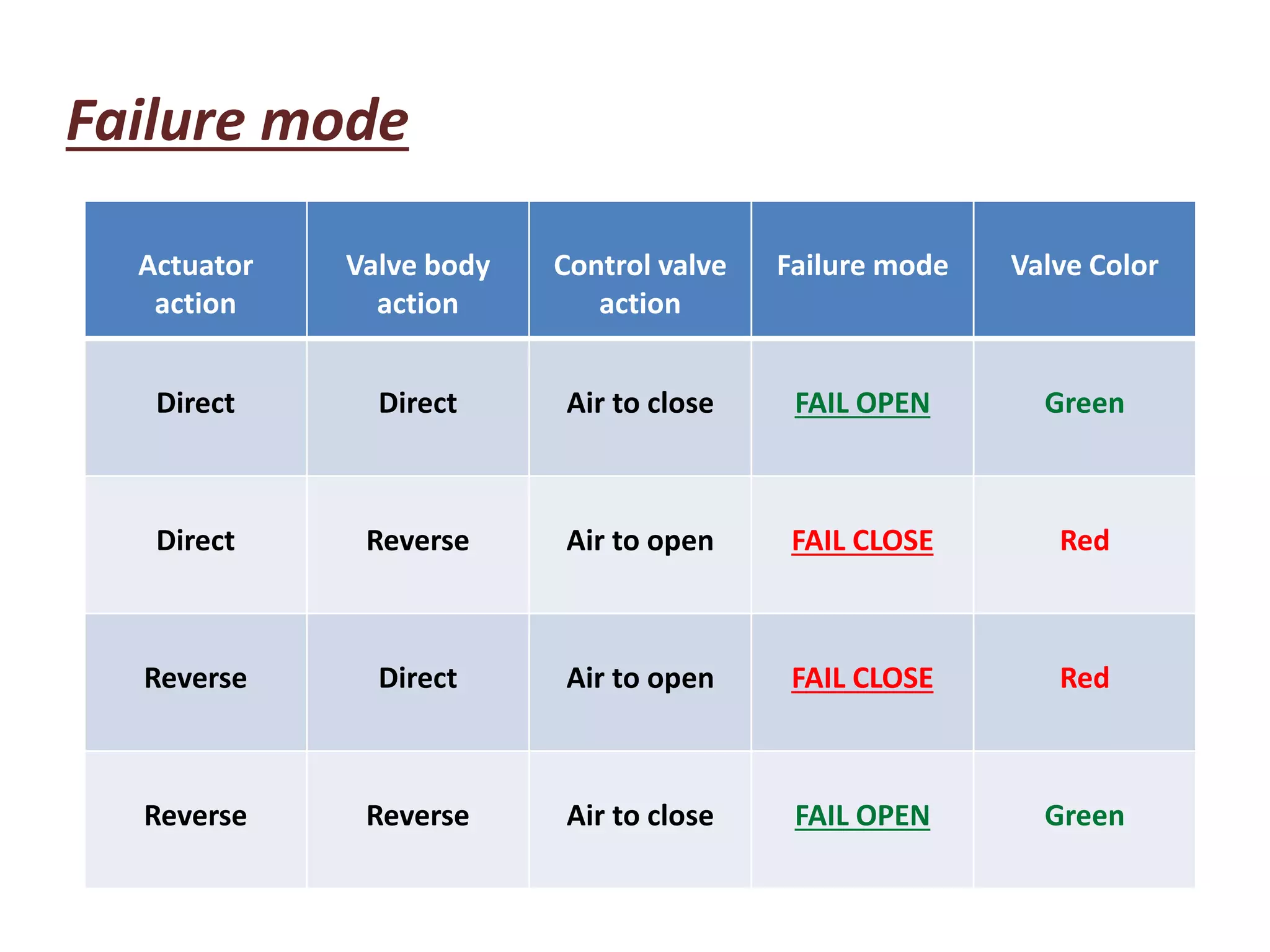

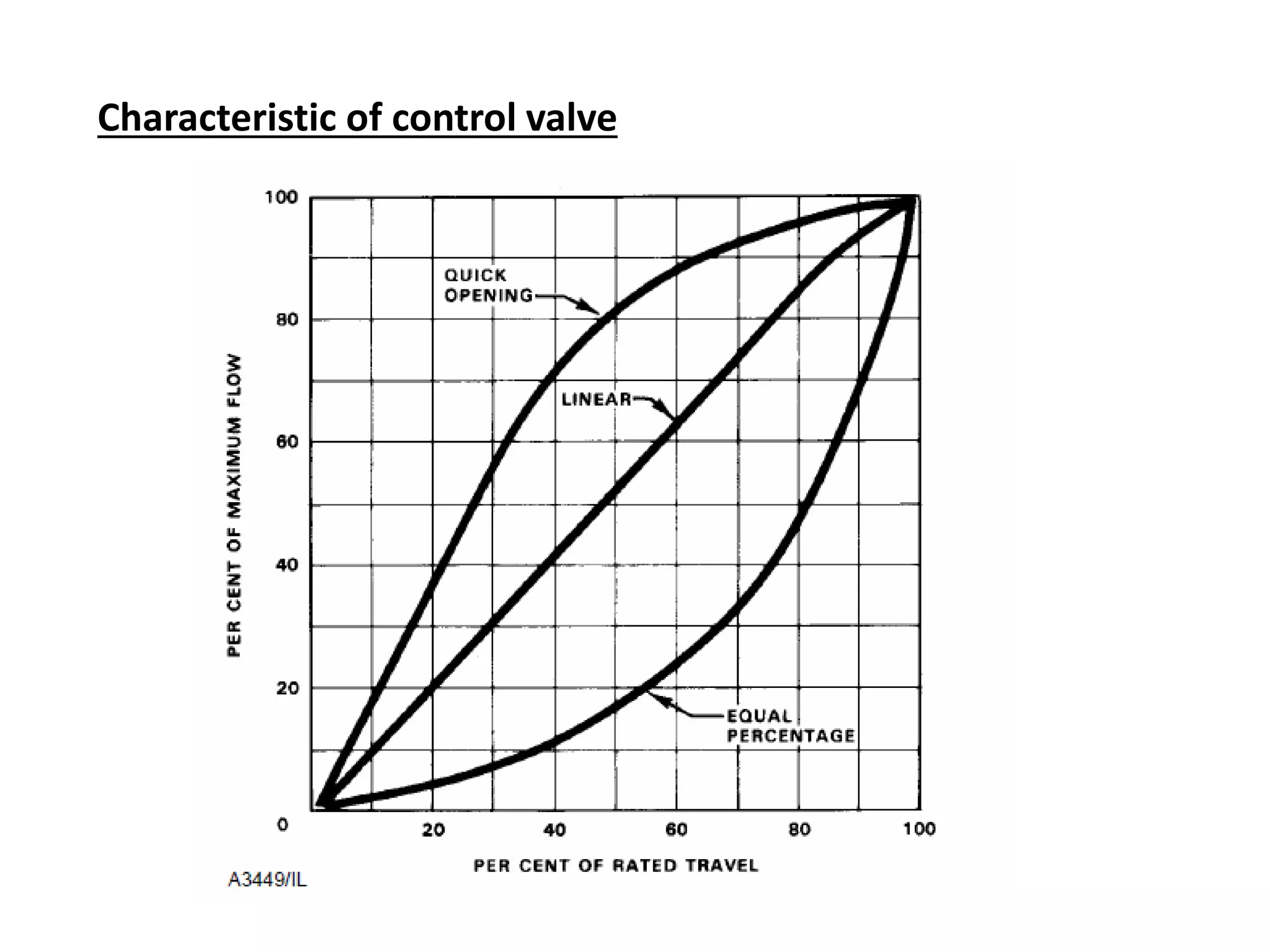

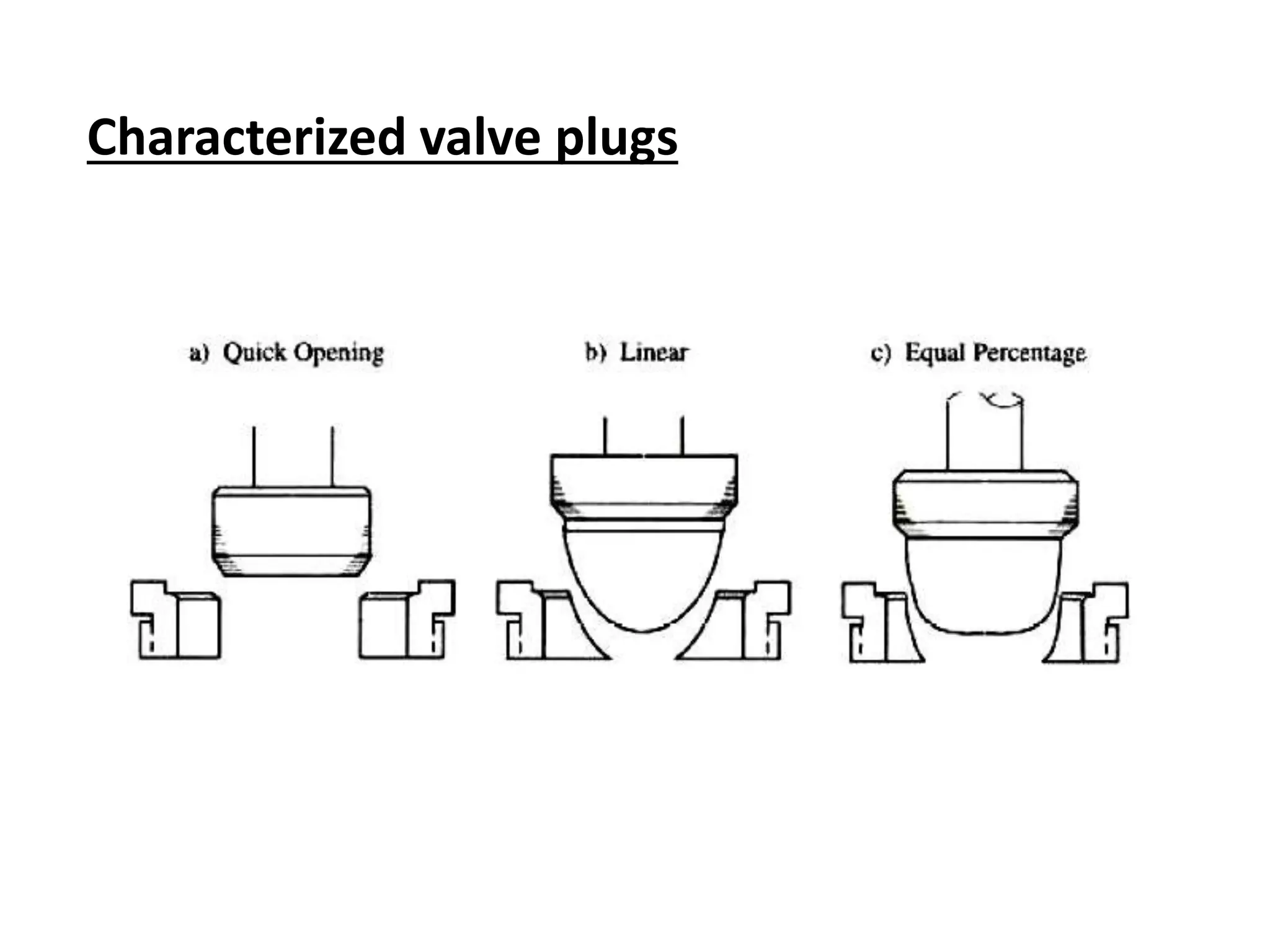

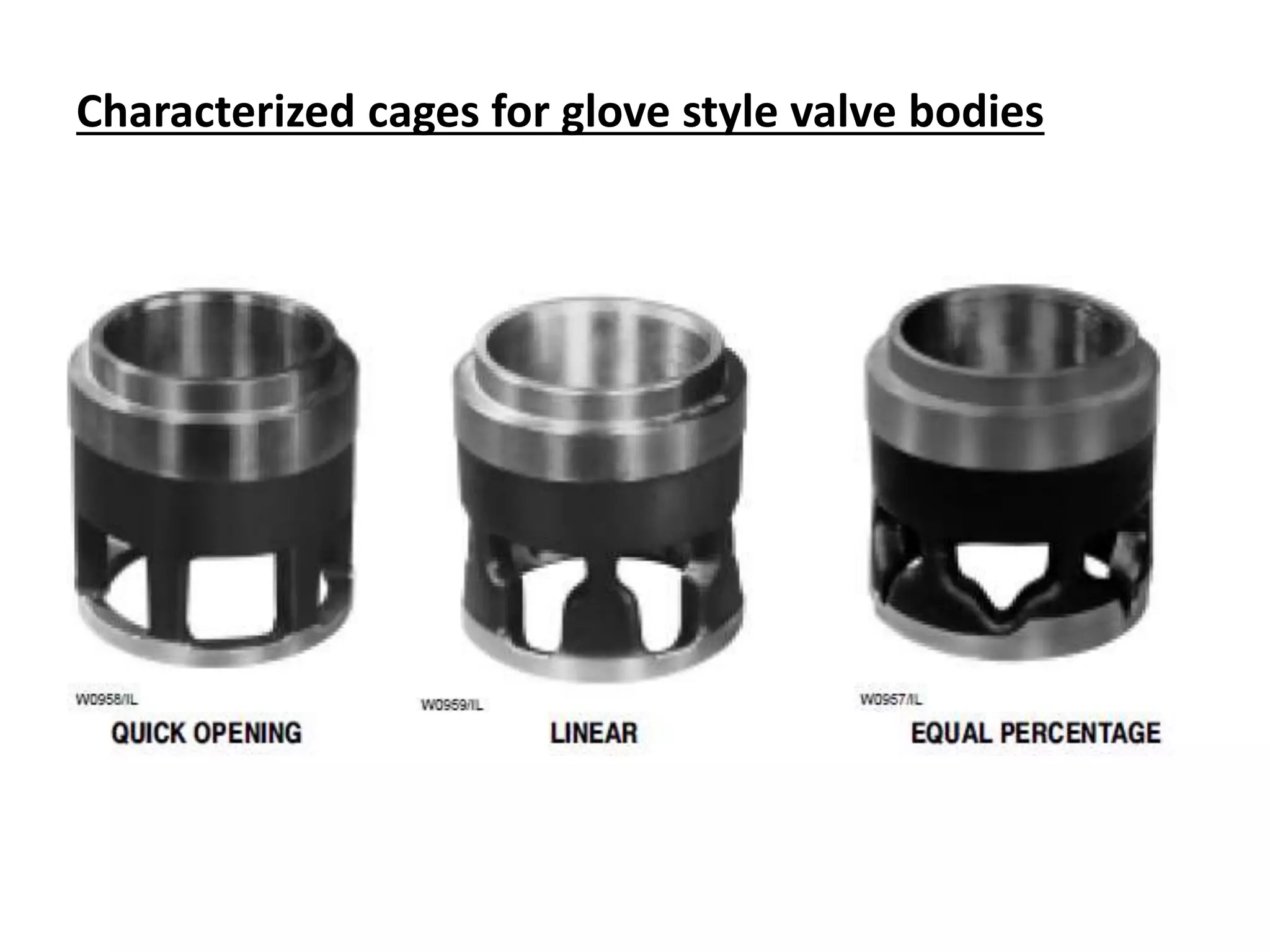

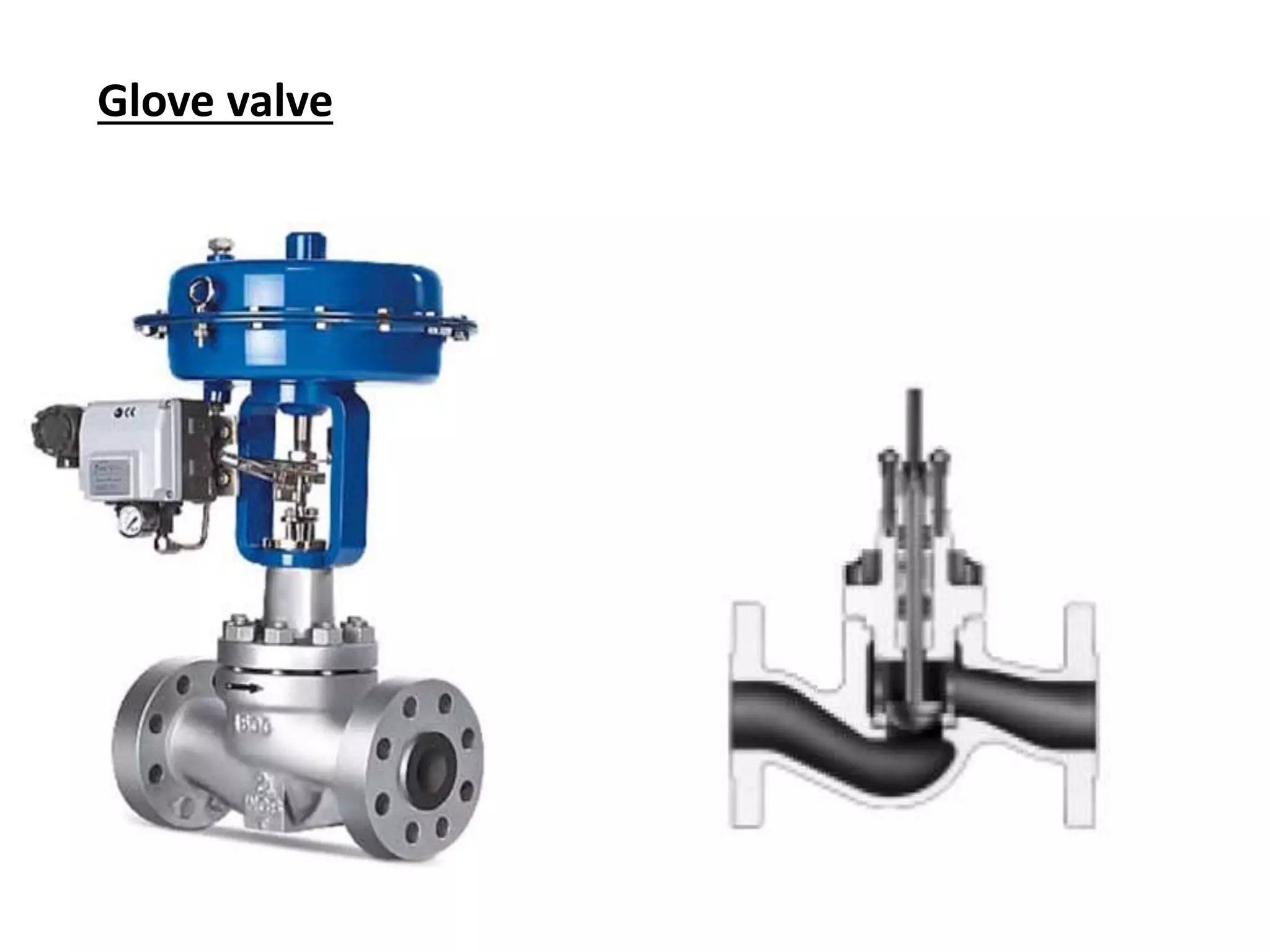

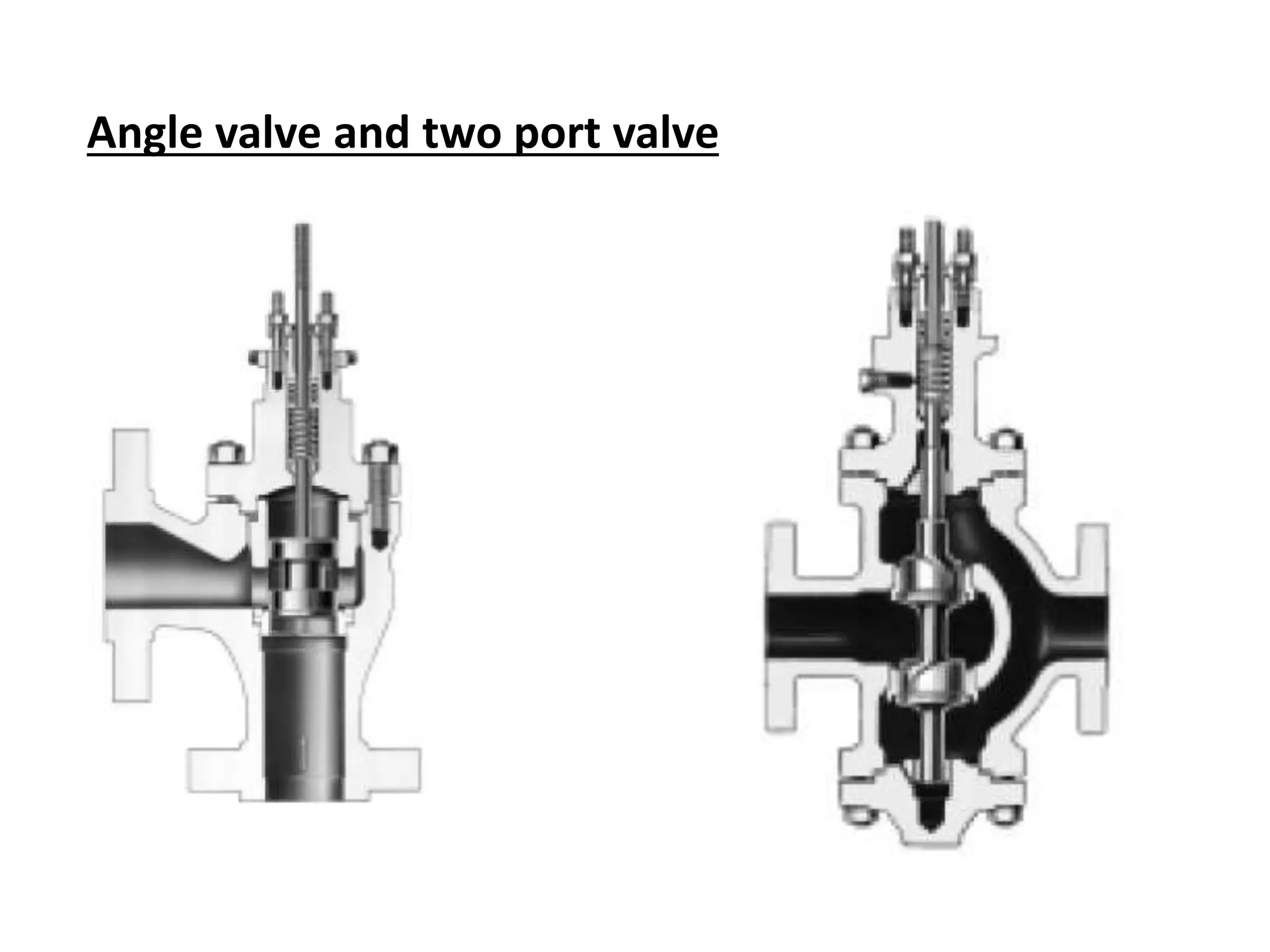

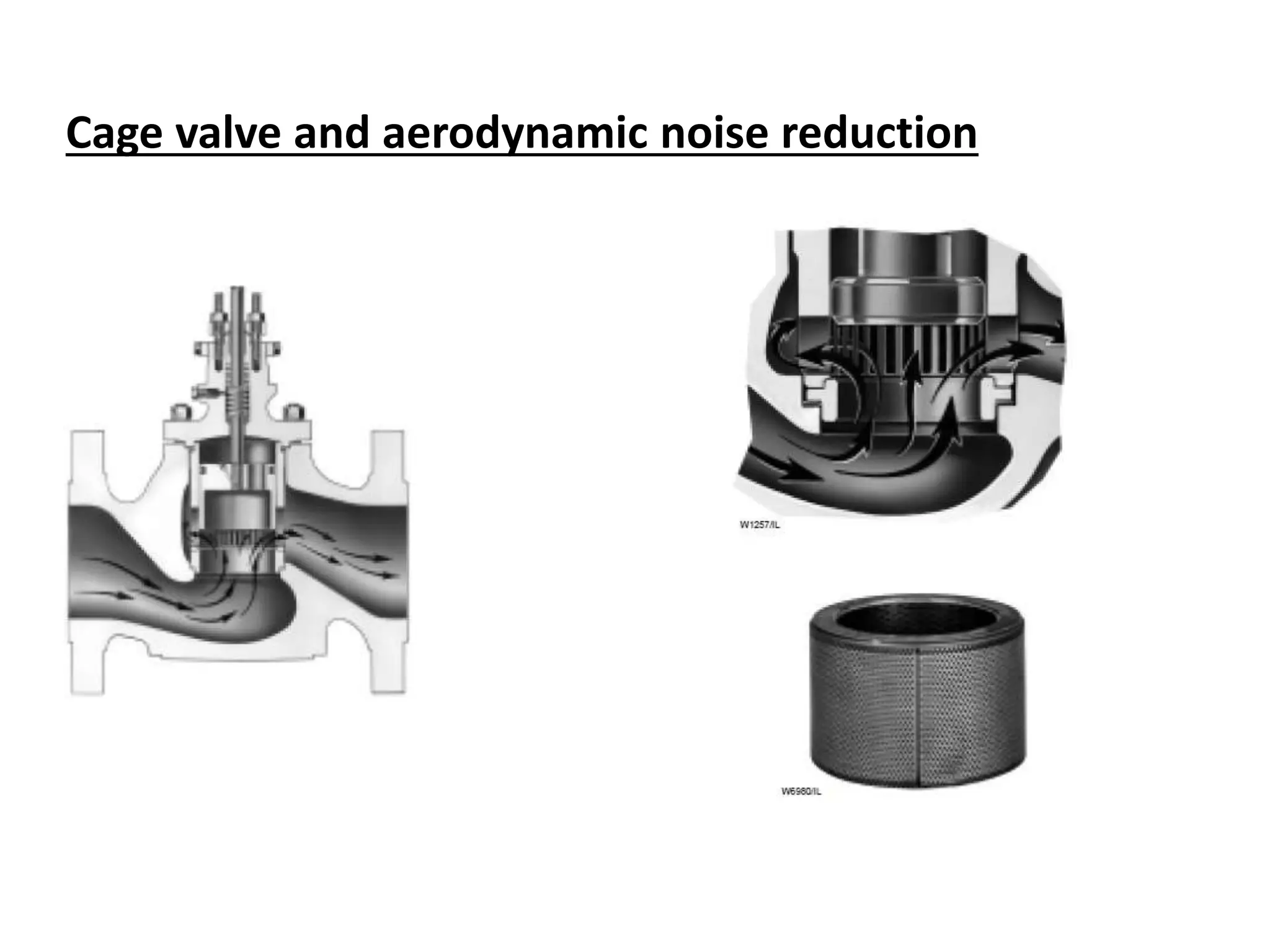

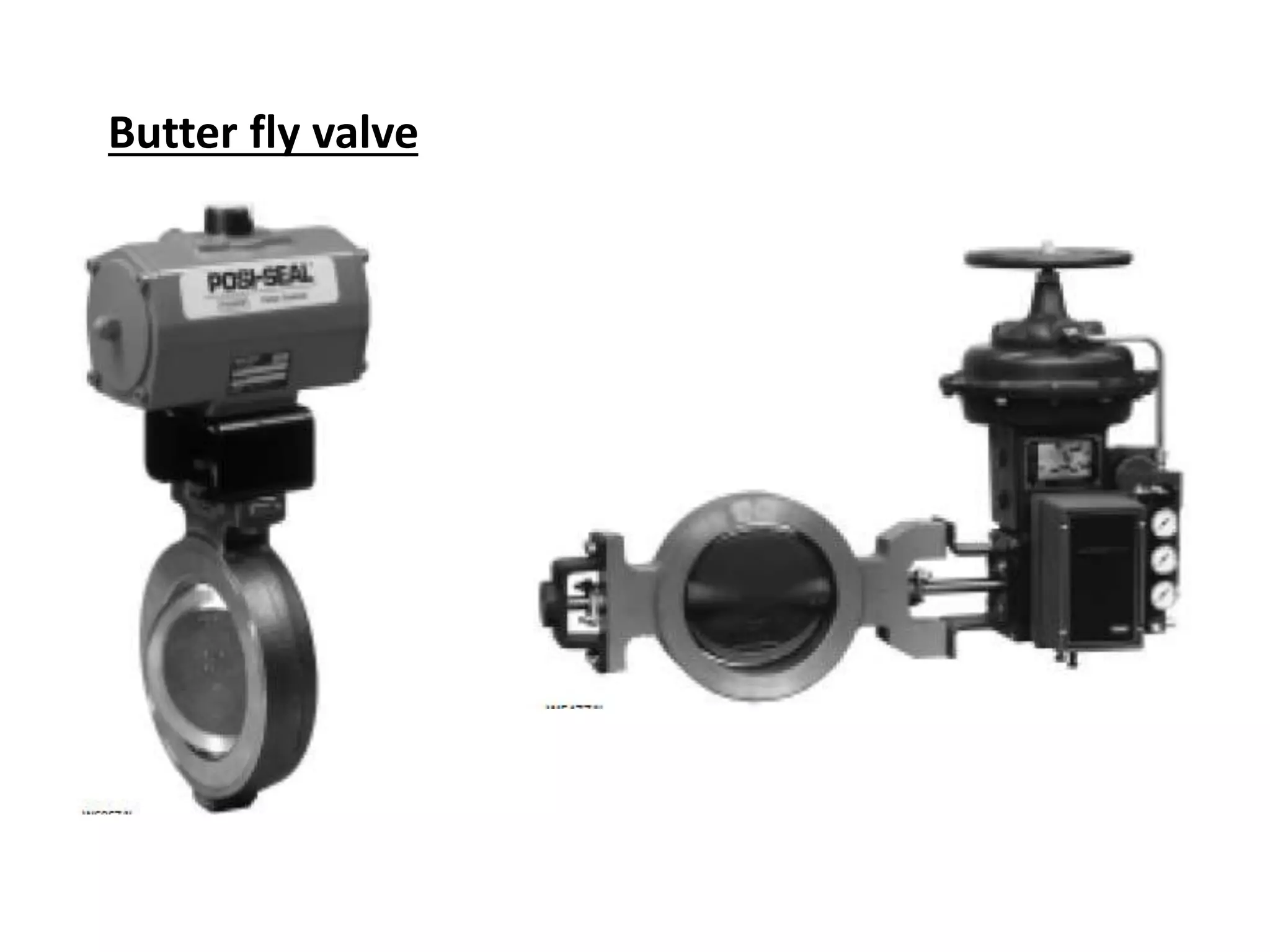

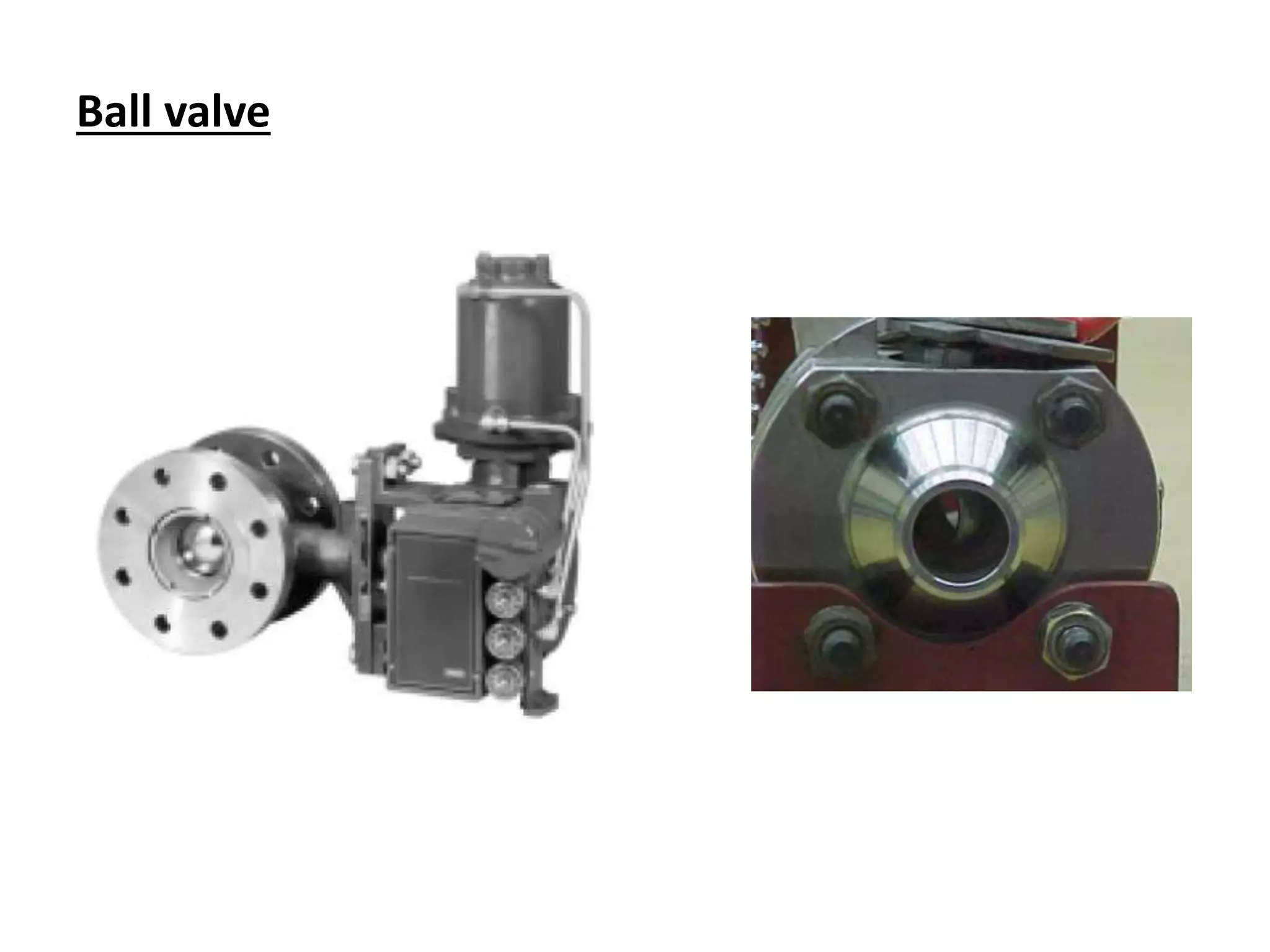

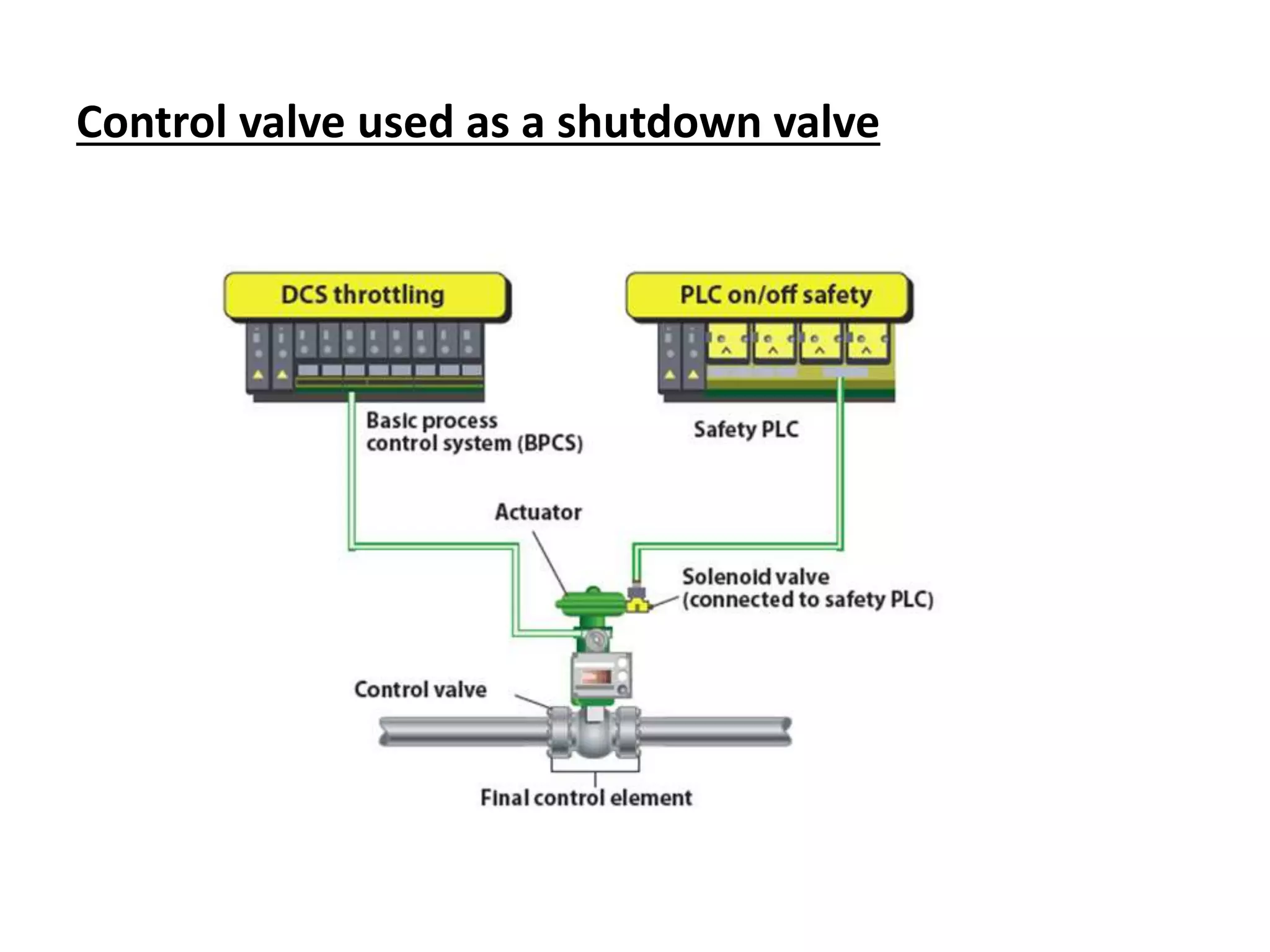

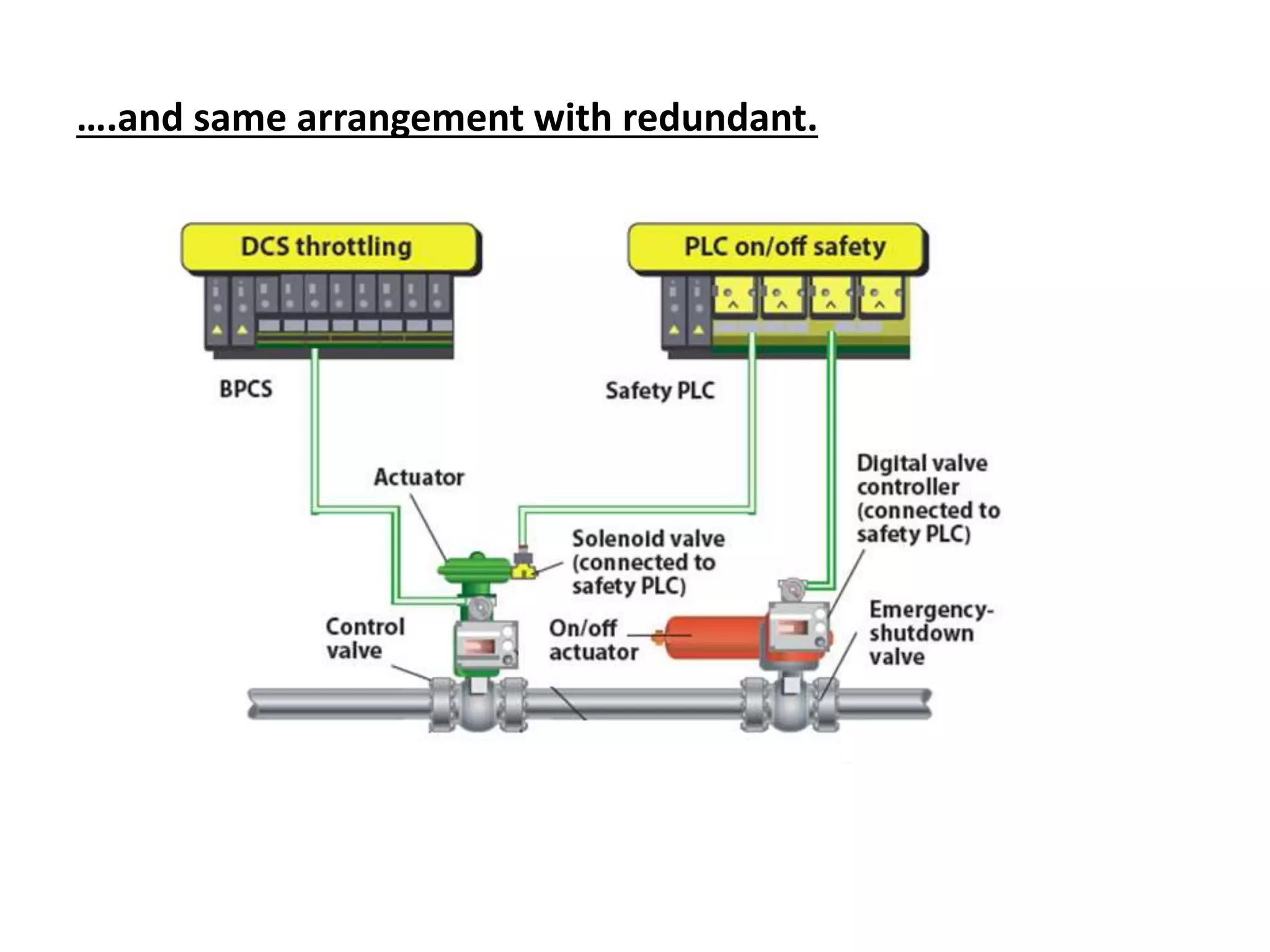

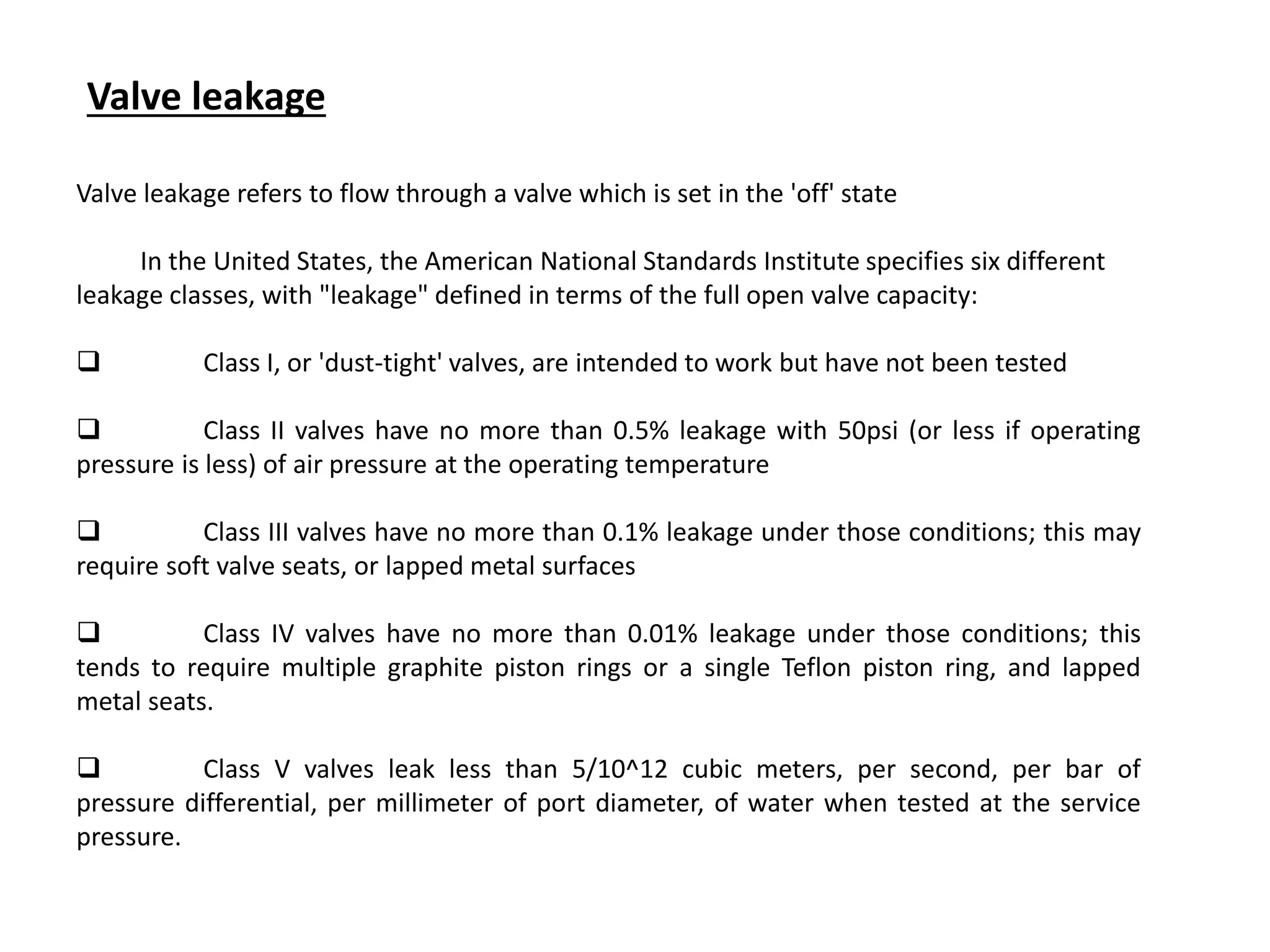

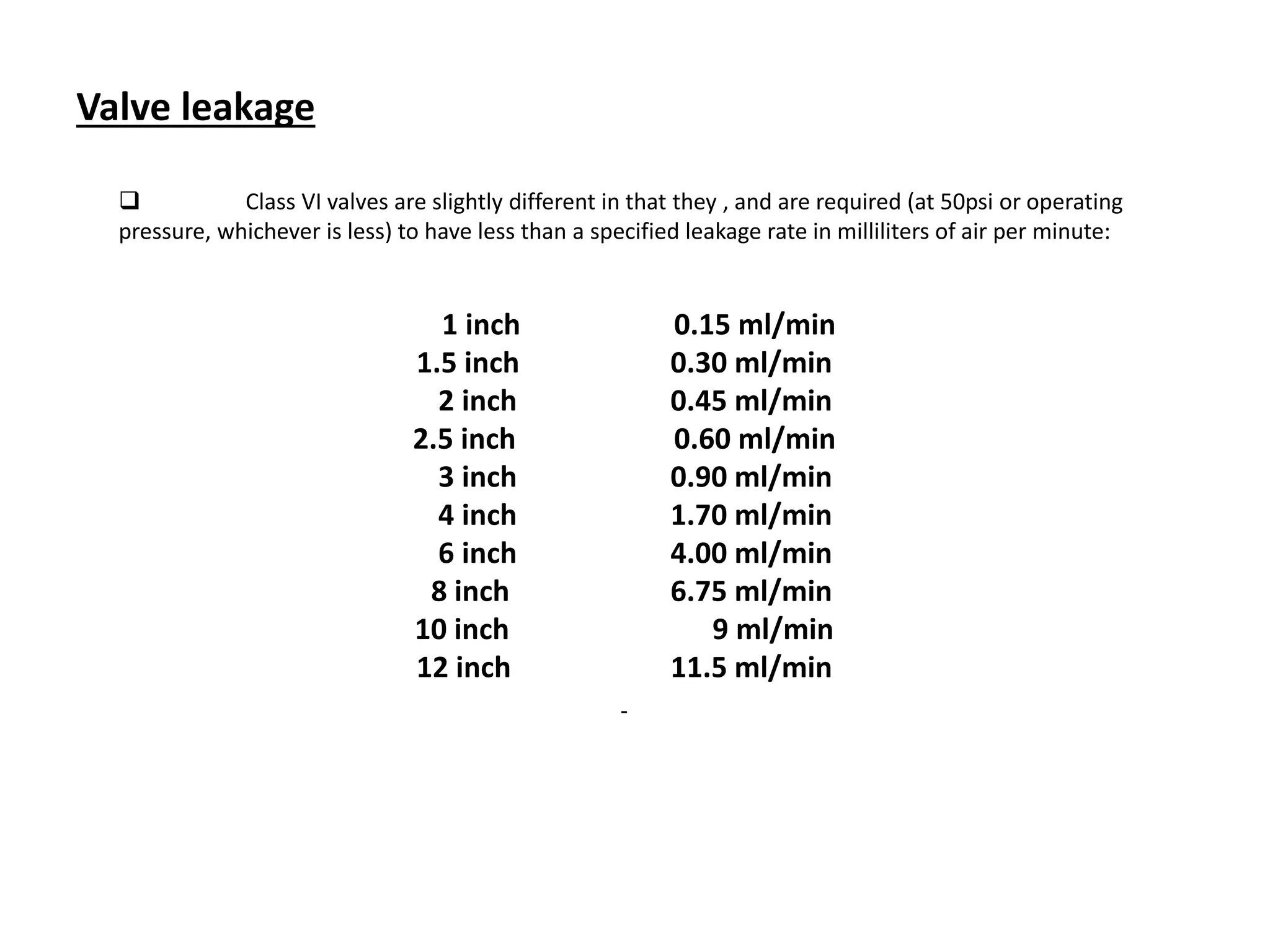

This document discusses control valves, including their applications in flow, level, pressure, and temperature control. It defines control valves as valves that are remotely controlled to maintain parameters like flow rate, level, pressure, and temperature. The document then covers classifications of control valves based on actuator and valve action. It also discusses components like the valve body and actuator. Characteristics, plugs, cages, and typical valve types are described. Failure modes and valve leakage classes are defined.