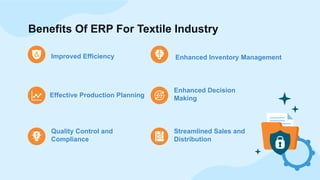

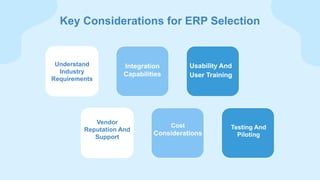

The document outlines the importance of ERP systems for the textile industry, which enhance efficiency, inventory management, production planning, and decision-making. Key considerations for ERP selection include understanding industry requirements, integration capabilities, usability, vendor reputation, and cost. Ultimately, ERP implementation enables textile companies to streamline operations, ensure compliance, and achieve sustainable growth.