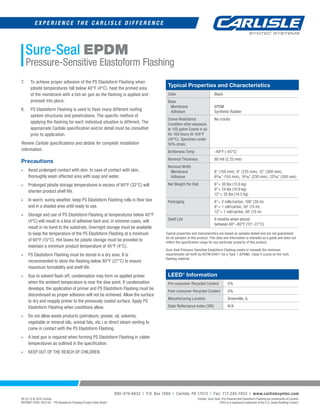

Carlisle's Sure-Seal EPDM Pressure-Sensitive Elastoform Flashing is a 60-mil-thick uncured EPDM membrane with a 30-mil-thick adhesive, available in various roll sizes and designed for easy application to irregular surfaces. The product is self-curing and ideal for flashing pipes and rooftop structures, requiring specific installation procedures to ensure proper adhesion and performance. Precautions for storage and use, including temperature regulations and handling protocols, are also provided to maximize the material's effectiveness and shelf life.