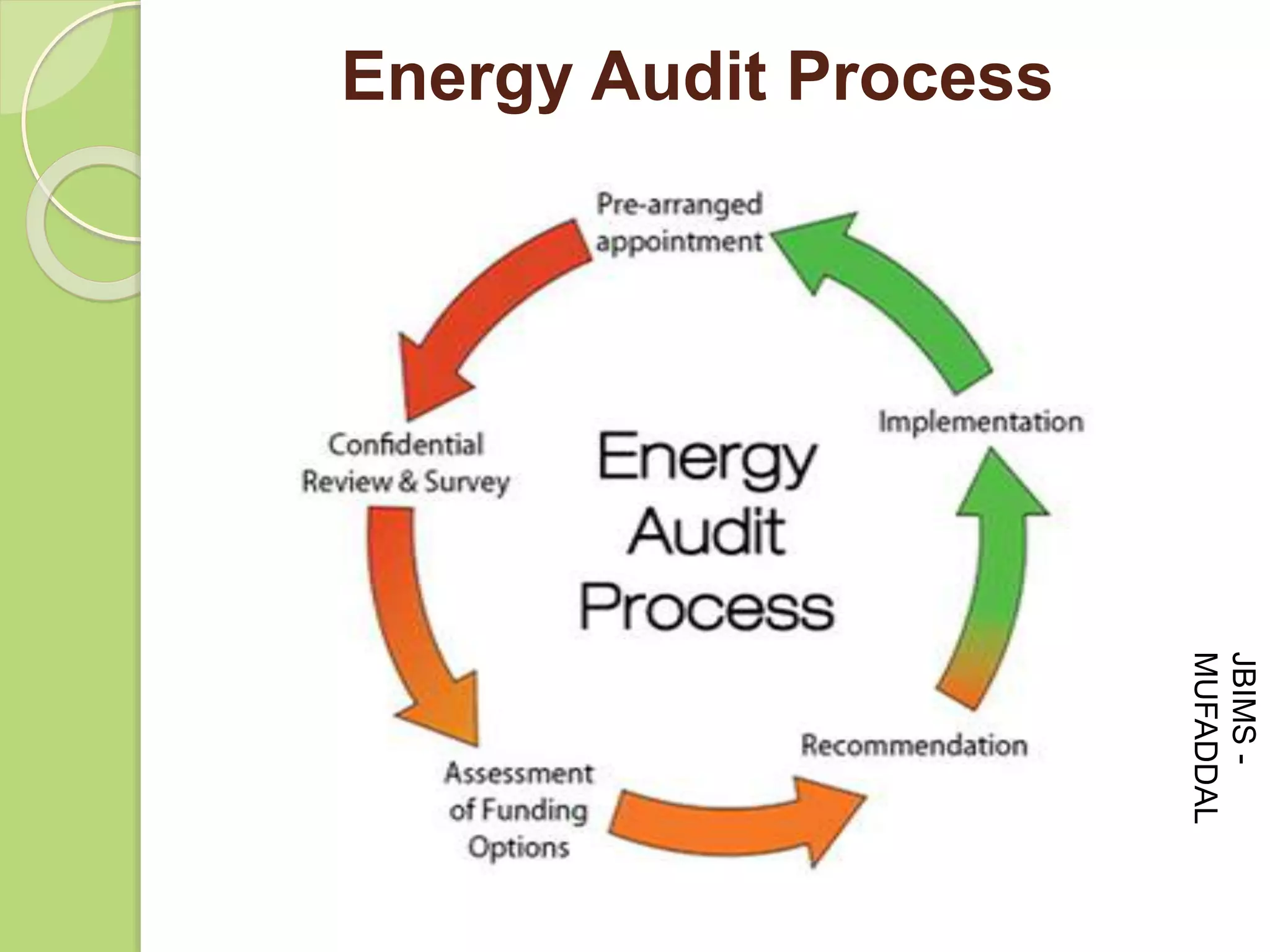

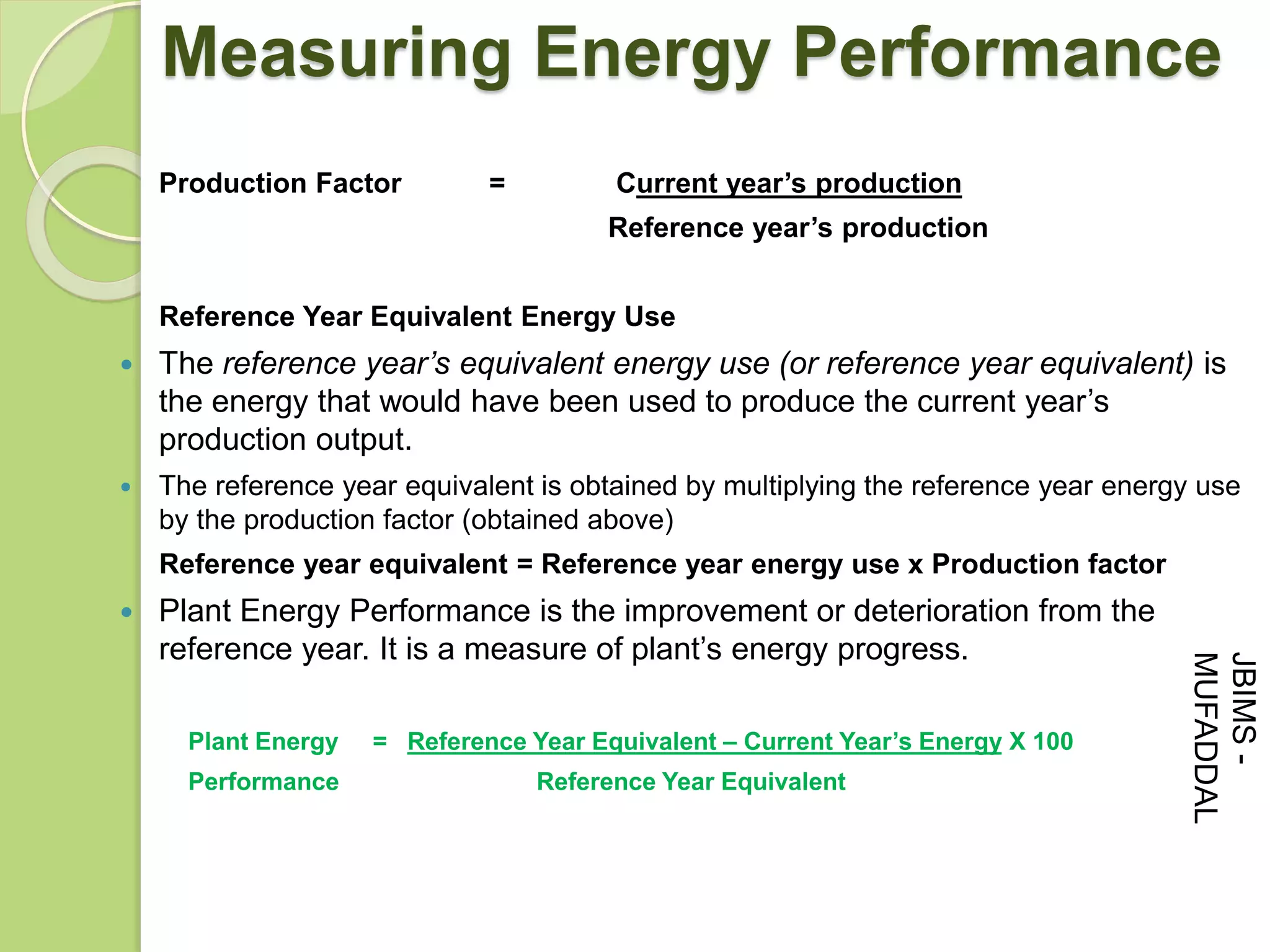

This document outlines the process and significance of energy audits, detailing various types such as preliminary, targeted, and detailed audits. It explains energy management concepts, energy types, benefits of conducting audits, and steps for implementation, alongside case studies demonstrating energy substitution for cost savings. Various methodologies for assessing and optimizing energy use are discussed to improve efficiency and reduce operational costs.