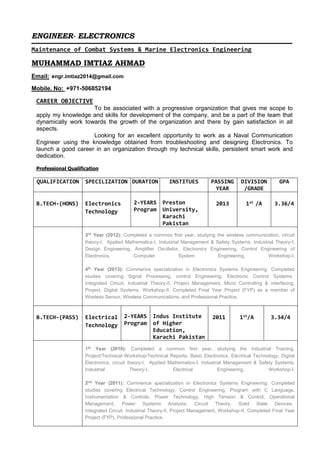

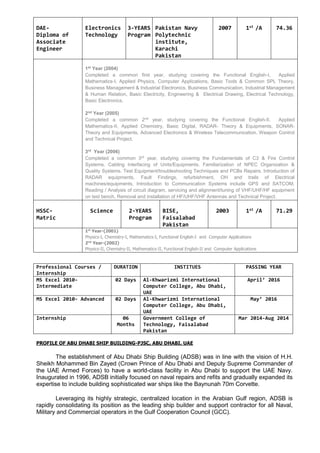

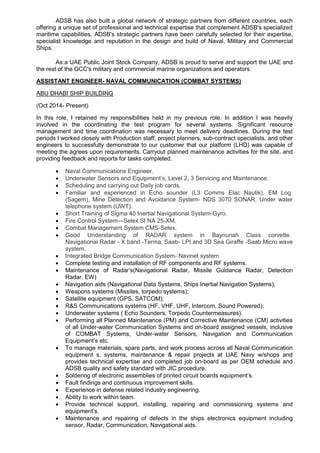

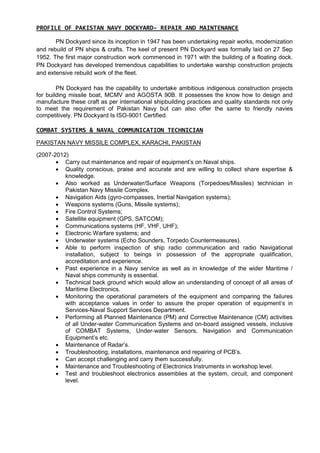

Muhammad Imtiaz Ahmad is seeking a position as a Naval Communication Engineer where he can utilize his experience in maintaining and repairing combat systems and marine electronics. He has over 10 years of experience working with the Pakistan Navy and in marine engineering services in Saudi Arabia and Abu Dhabi. His experience includes maintaining equipment such as radar systems, sonar, satellite communications systems, fire control systems, and more. He is proficient in troubleshooting electronics issues and has experience coordinating maintenance activities and meeting deadlines.