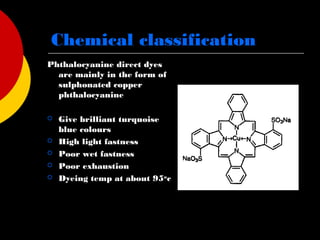

This document discusses direct dyes, which are anionic dyes used for cellulosic fibers. Most direct dyes have an azo or phthalocyanine structure and provide bright colors ranging from yellow to blue. The document describes the chemical classification and properties of various direct dyes, including their decomposition during dyeing and use in assessing cotton maturity. It also covers classifying dyes based on dyeing properties and treating dyed fabrics with metal salts or cationic fixing agents to improve wet fastness.