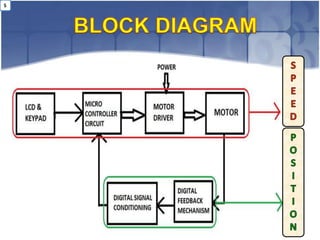

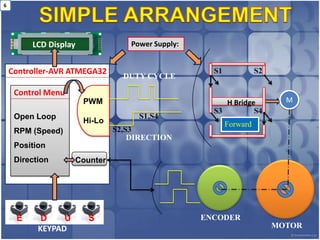

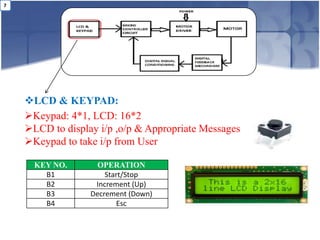

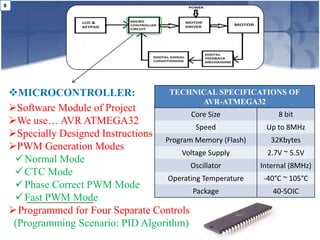

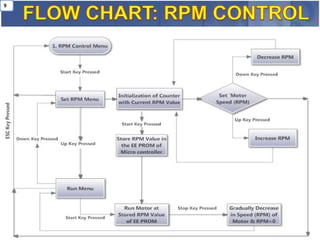

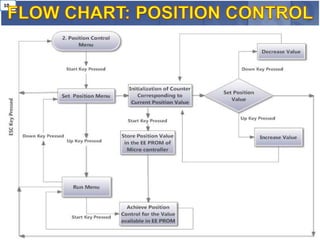

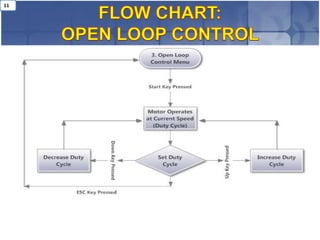

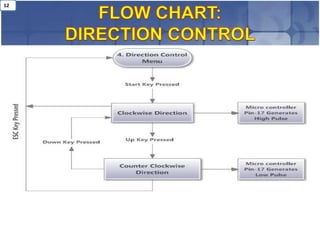

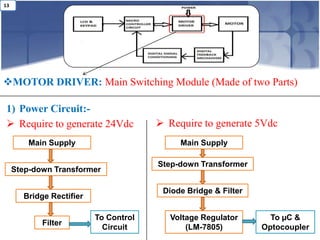

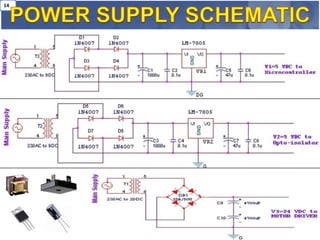

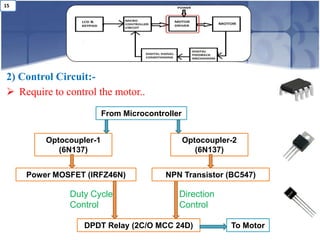

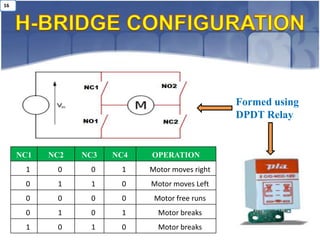

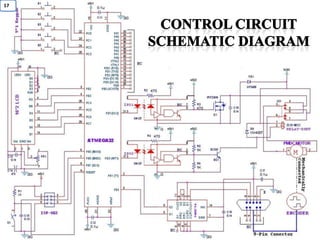

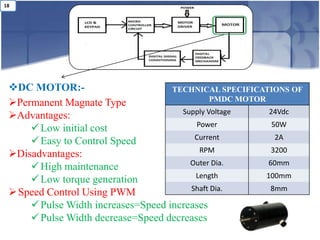

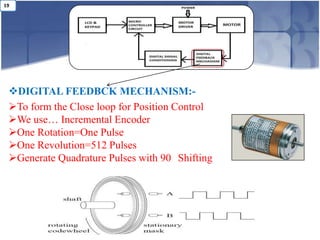

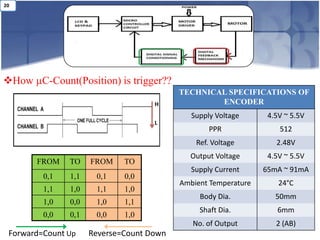

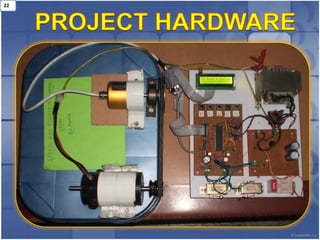

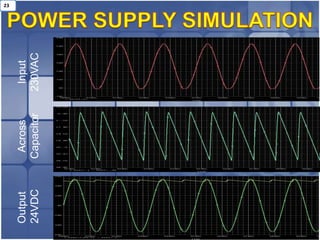

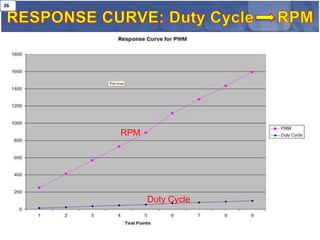

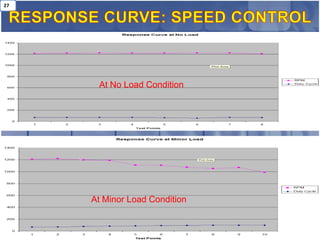

The document outlines the design of a control system for a DC motor using the AVR Atmega32 microcontroller, focusing on PID control and pulse width modulation to maintain constant speed under varying loads. It describes the technical specifications of the motor and microcontroller components, as well as the use of an incremental encoder for position feedback. The system is designed for flexibility in control through a user-friendly interface with an LCD display and keypad.