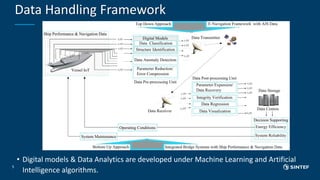

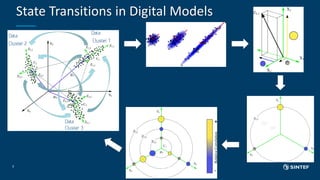

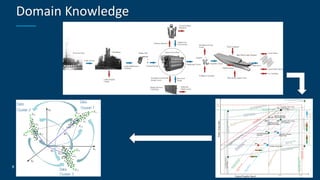

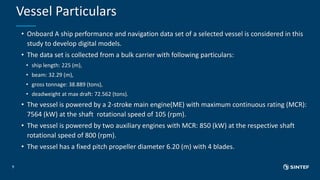

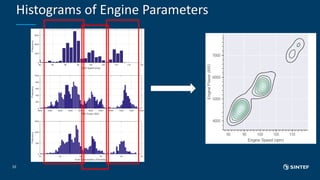

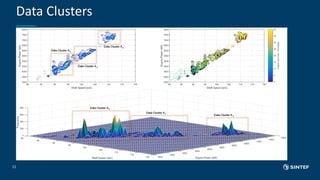

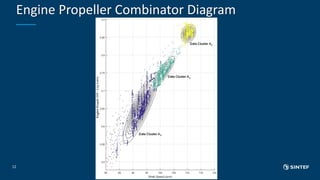

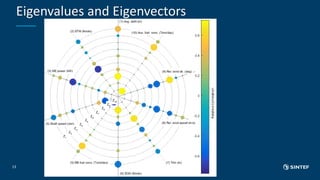

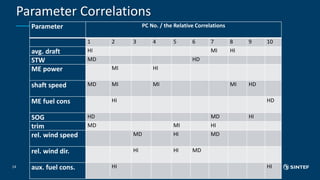

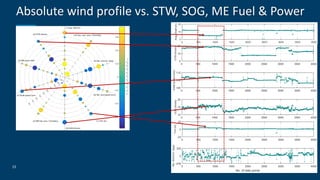

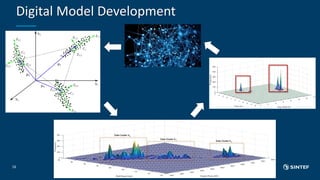

Digital models are being developed to handle large datasets collected from Internet of Things sensors on ships. These digital models can help overcome challenges in areas like model uncertainty, erroneous data, and high computational needs. The models are created using machine learning algorithms to identify clusters in ship performance and navigation parameters. They represent the relationships between factors like engine output, propeller characteristics, and vessel trim. Digital models have advantages like being self-learning, self-cleaning, and able to visualize vessel operations. They may help identify sensor faults, reduce data dimensions, and support efficient data handling frameworks.