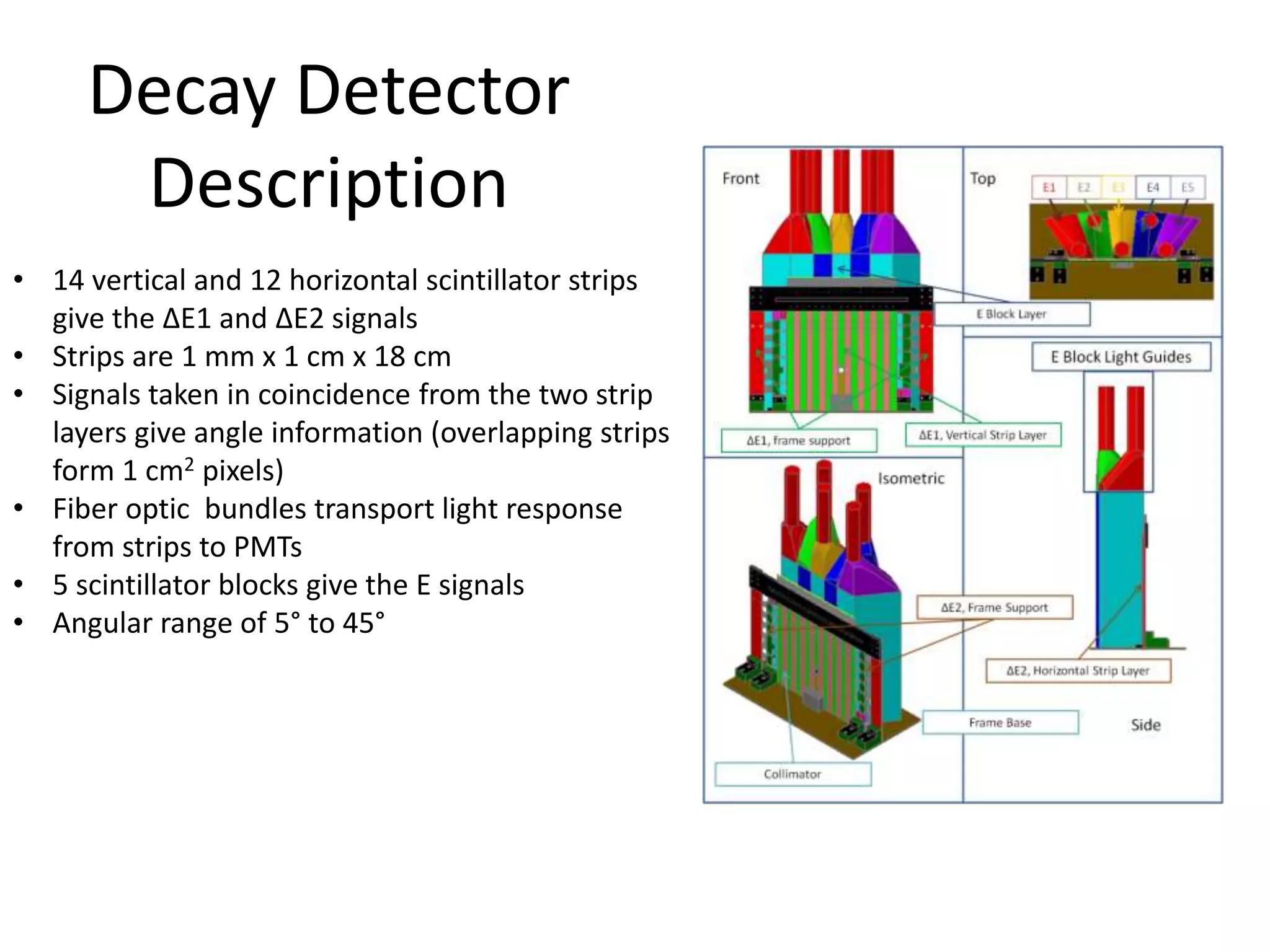

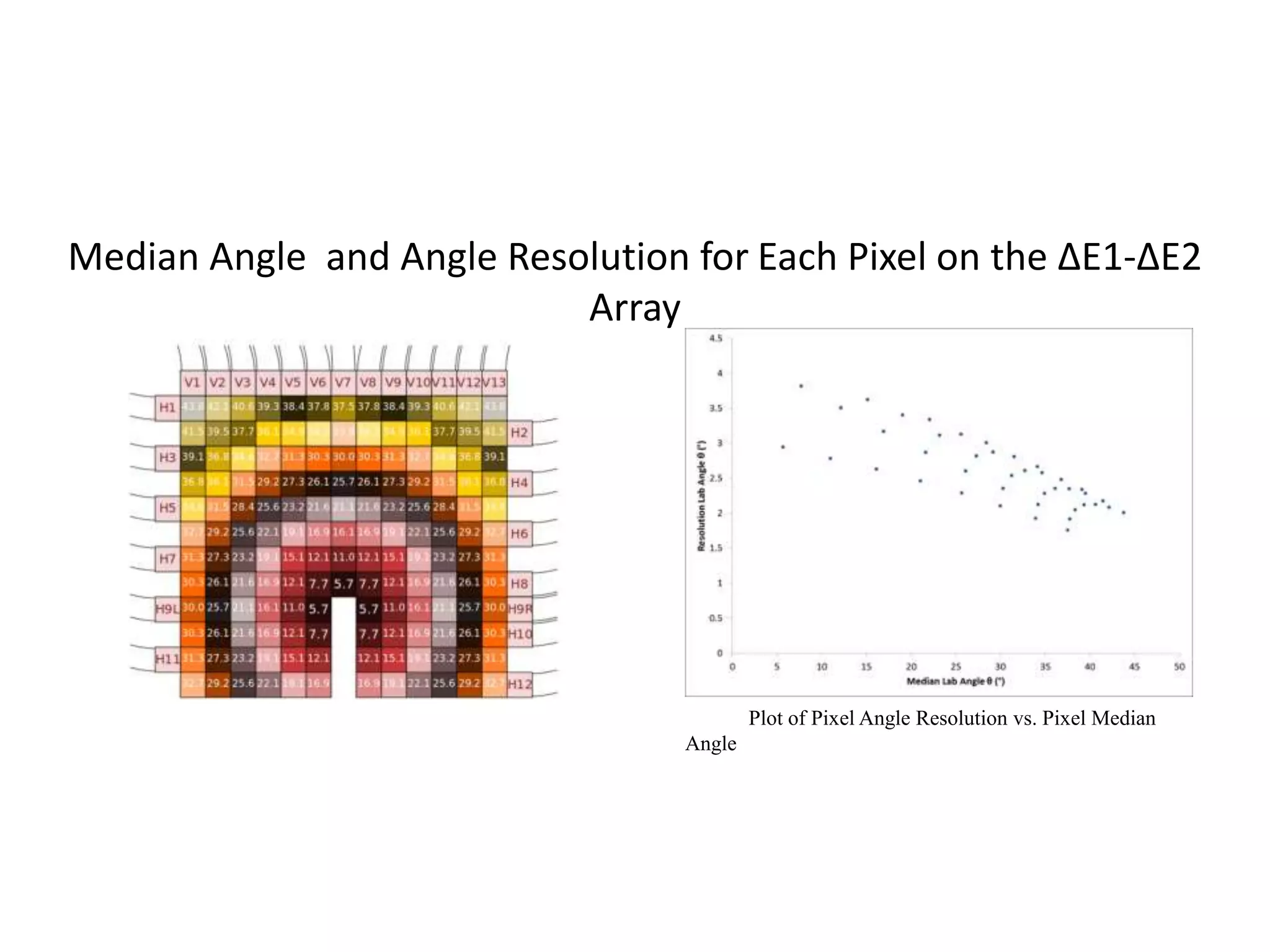

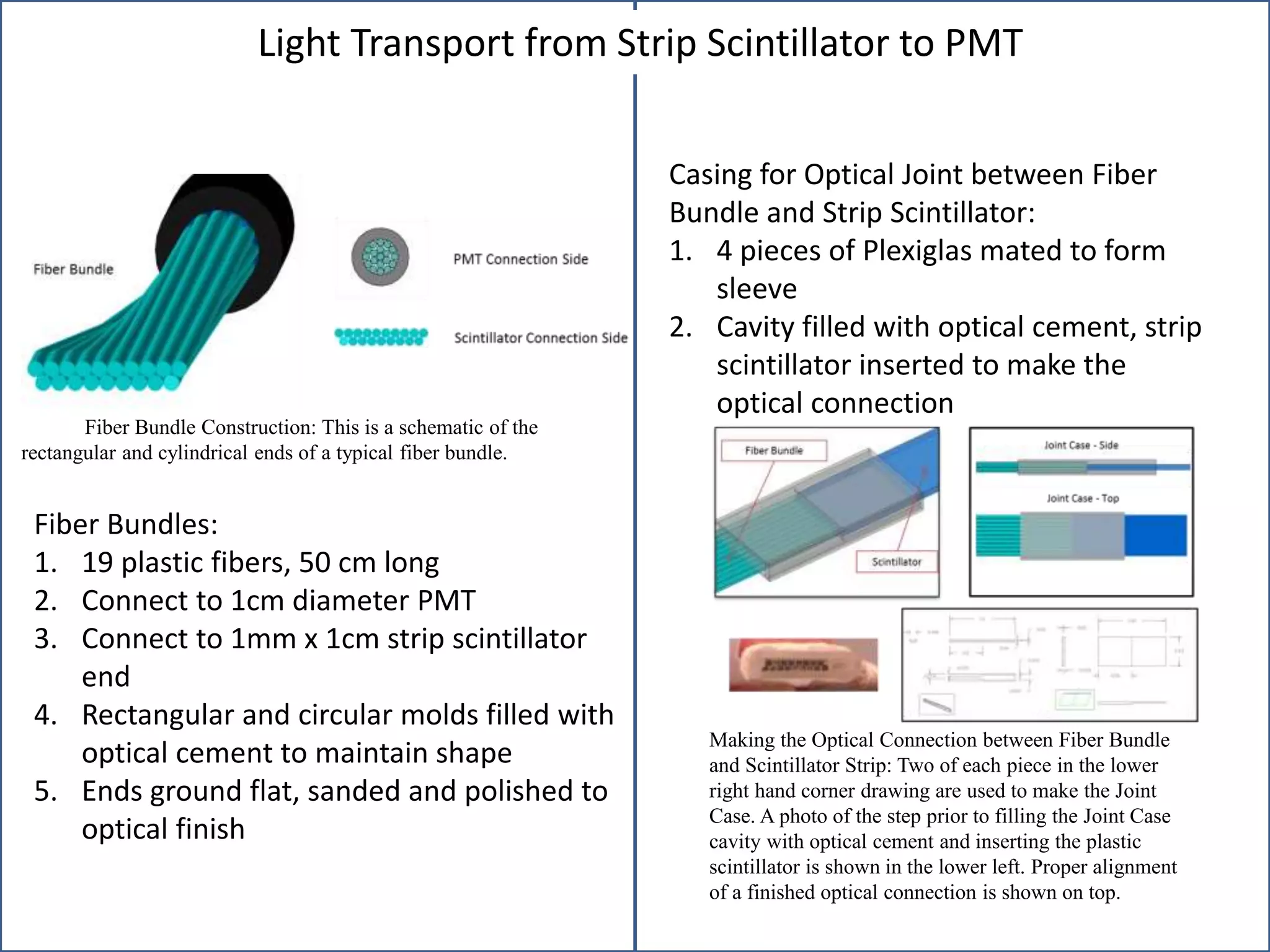

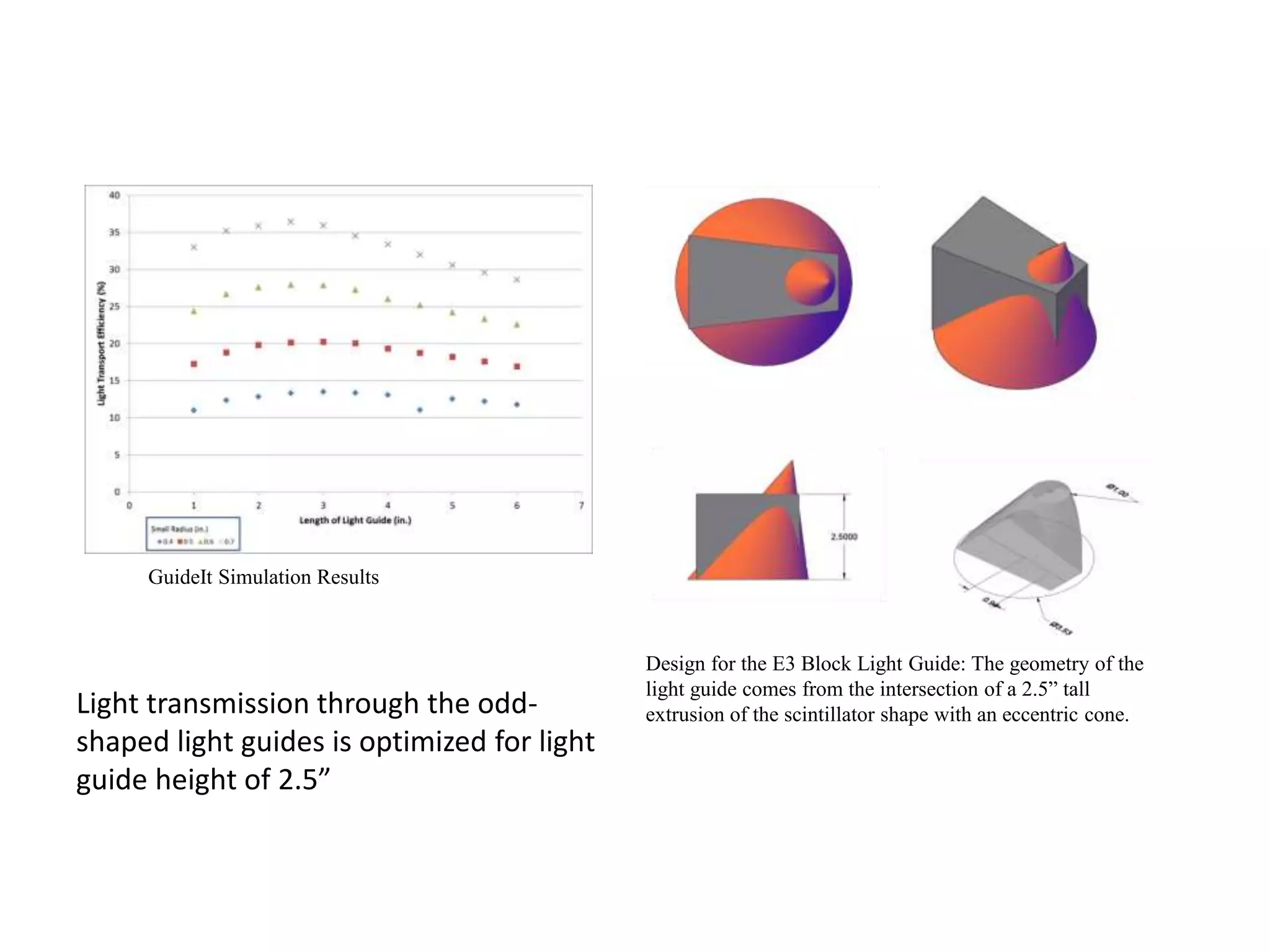

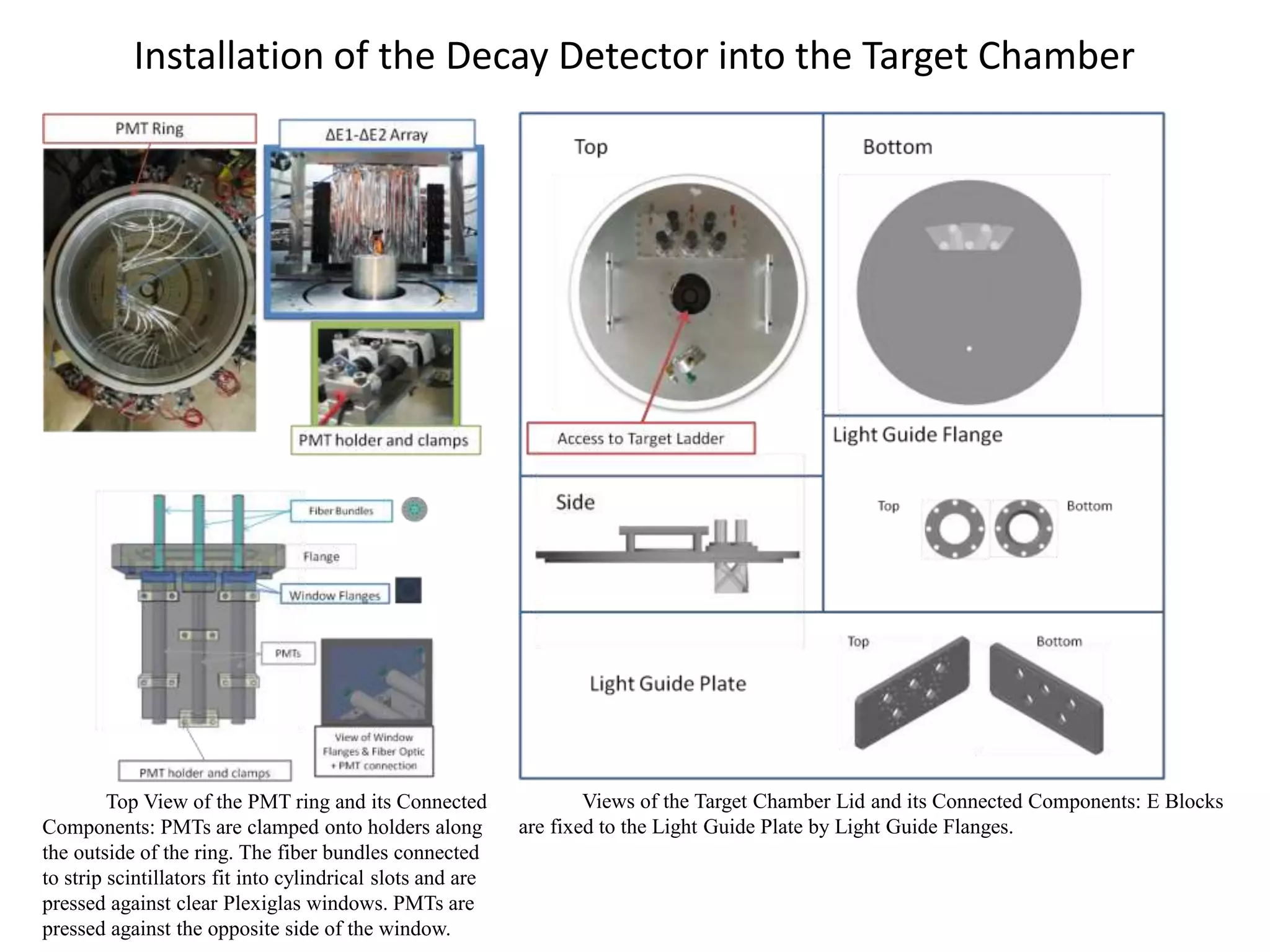

The decay detector consists of vertical and horizontal scintillator strips that produce ΔE1 and ΔE2 signals when particles pass through. Signals from overlapping strips form 1 cm2 pixels and provide angular information. Five scintillator blocks give E signals. Fiber optic bundles transport light from the strips to PMTs. The angular range covered is 5° to 45°. Proper construction of the fiber bundles and their connection to the scintillator strips is important for light transport efficiency. The detector components are assembled into a ring structure that is installed into the target chamber lid.