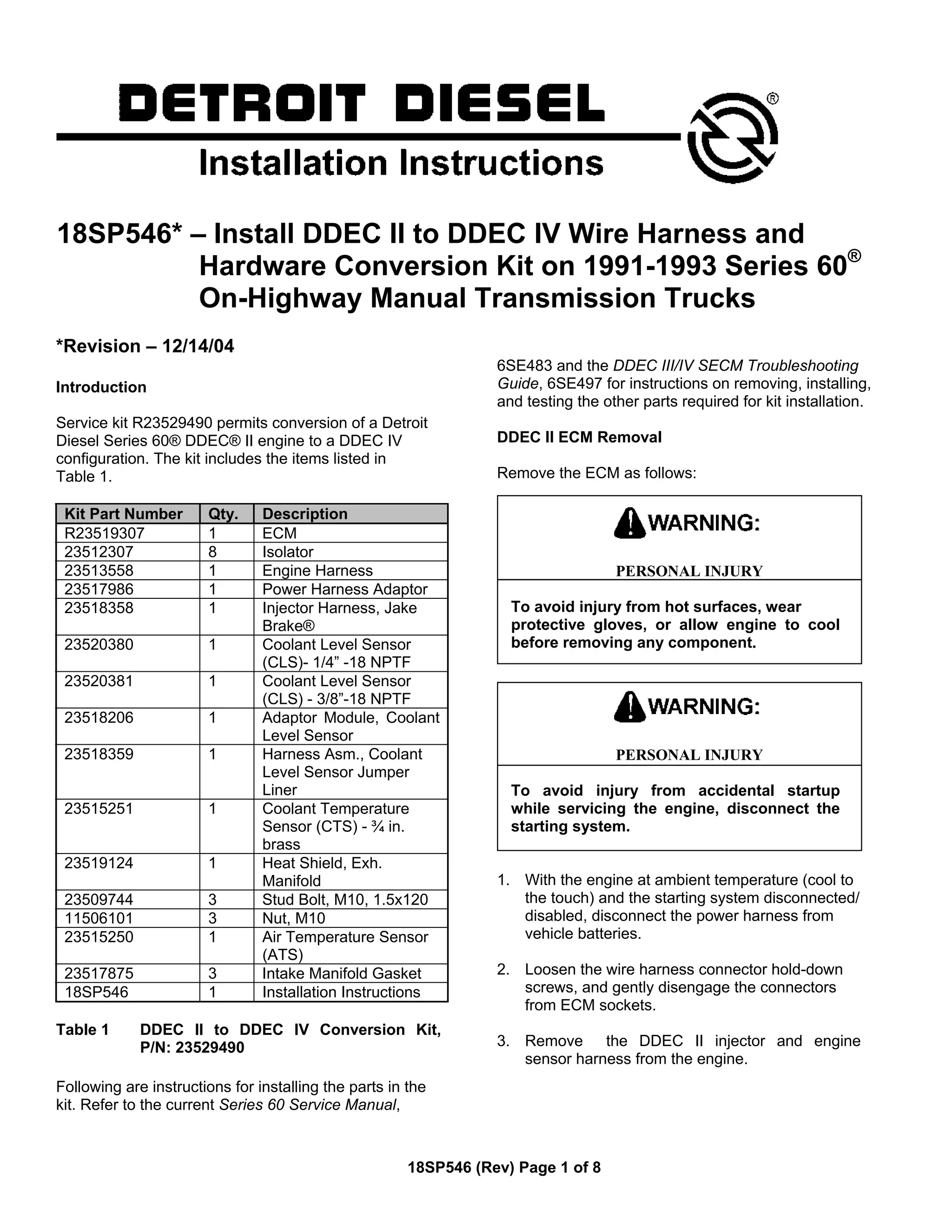

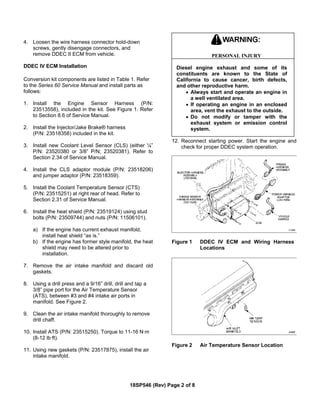

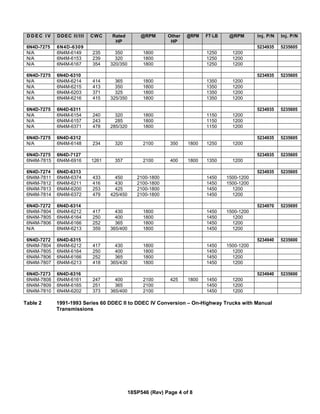

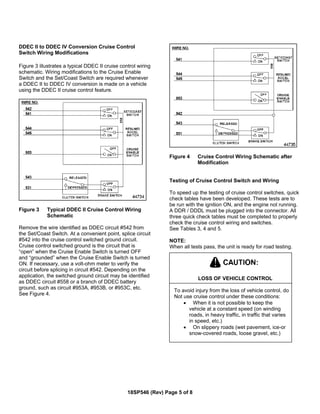

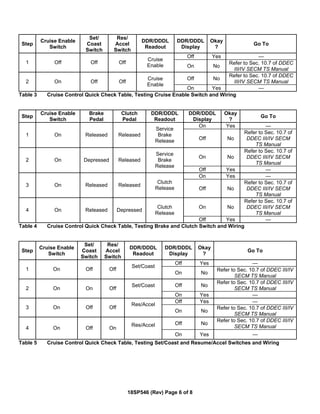

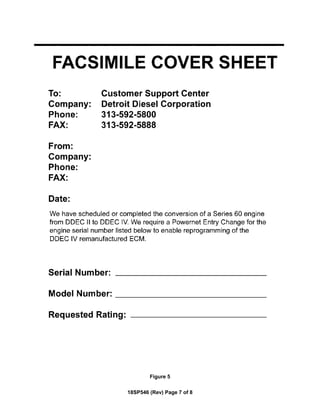

This document provides instructions for installing a conversion kit to update a 1991-1993 Series 60 diesel engine from DDEC II to DDEC IV controls. The kit includes a new ECM, harnesses, sensors and other hardware. The instructions describe removing the old components and installing the new ones, including wiring modifications for cruise control. Tables list the engine models, their original and new control ratings, and part numbers. Completing a fax form is described to update engine records after the conversion. Quick check tables are provided to test the new cruise control components.