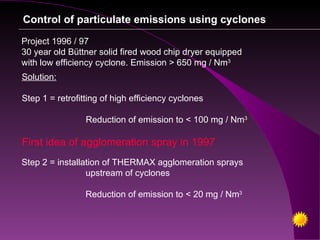

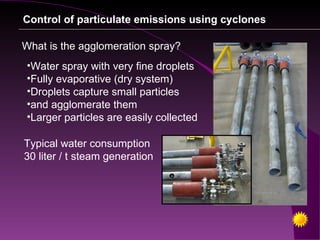

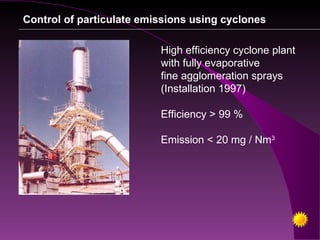

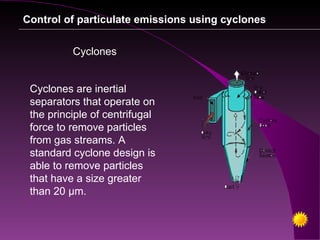

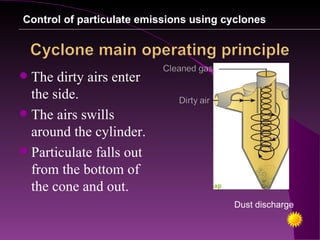

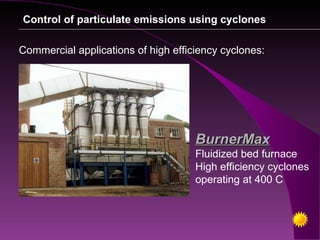

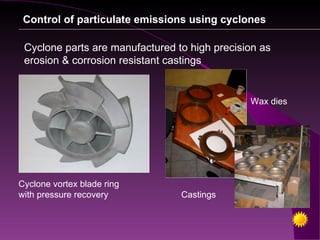

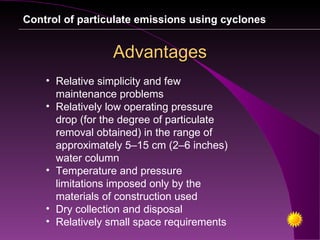

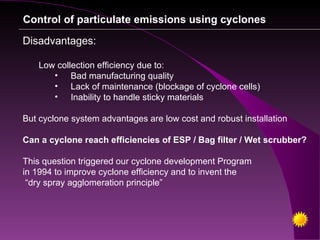

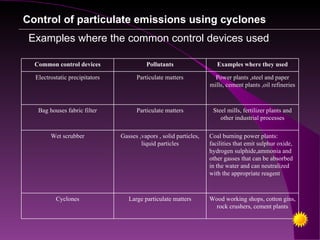

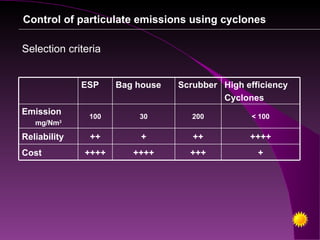

The document discusses controlling particulate emissions using cyclones. It begins with an introduction to the topic and then poses questions to be addressed. It goes on to define particulate emissions and discuss their sources and effects on humans, plants, and animals. It also describes common particulate control systems like electrostatic precipitators, baghouses, and wet scrubbers. The document then focuses on cyclones, covering their history, the use of agglomeration sprays, applications, working principle, advantages, and limitations.