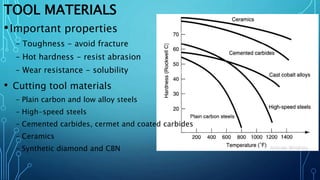

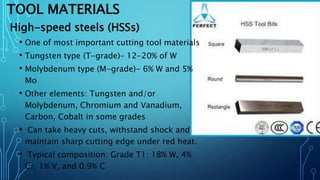

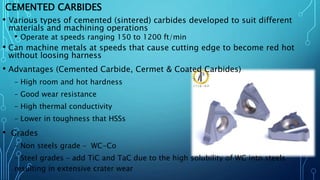

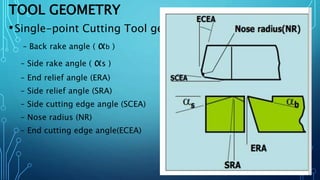

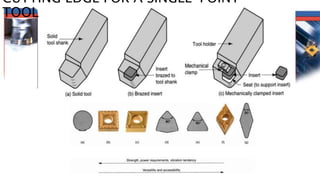

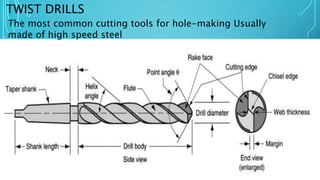

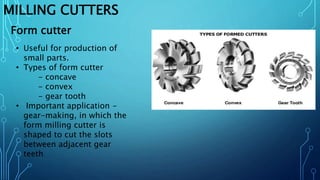

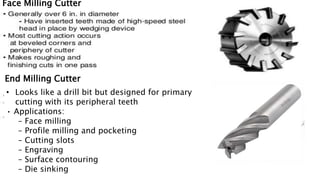

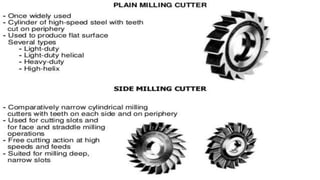

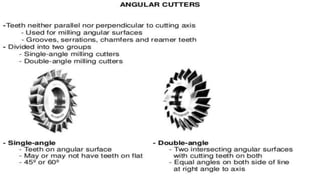

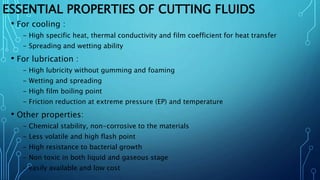

The document discusses the characteristics and types of cutting tools and cutting fluids essential for machining processes. It highlights the importance of selecting appropriate cutting tool materials based on properties such as hardness, wear resistance, and geometry to ensure efficient metal cutting. Additionally, it covers the roles of cutting fluids in reducing friction, cooling the workpiece, and extending tool life.