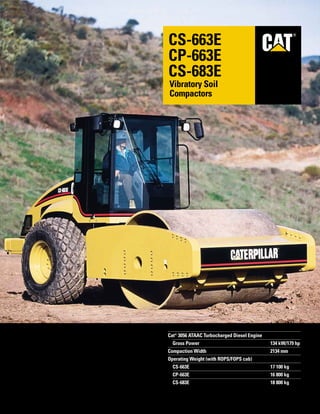

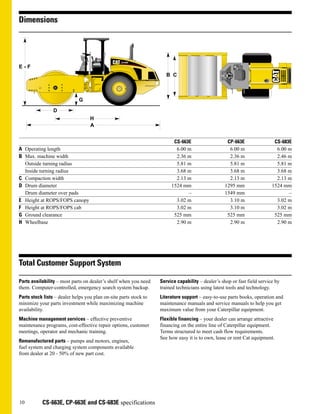

1. The document provides specifications for three soil compactor models (CS-663E, CP-663E, CS-683E) manufactured by Caterpillar, including their engine, propulsion system, vibratory system, operator station, and serviceability features.

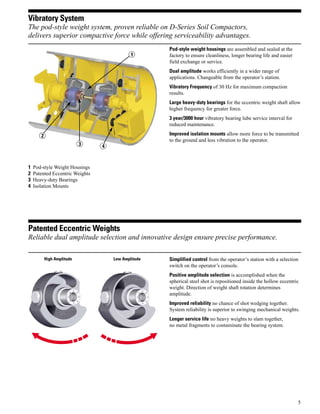

2. Key features highlighted are the Cat 3056 engine, dual propel pump system, pod-style vibratory weight system, ergonomic operator station with optional cab, and one-piece hood providing excellent visibility and service access.

3. The models are designed for reliability, serviceability, and operator comfort, with enhancements to production capabilities.