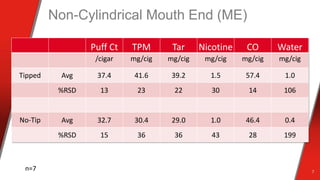

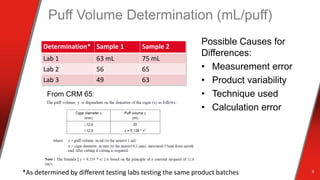

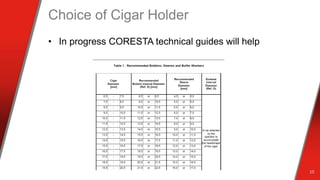

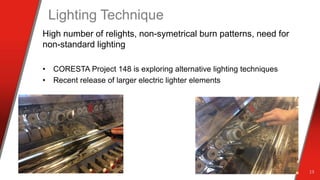

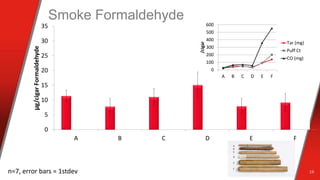

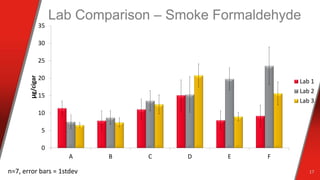

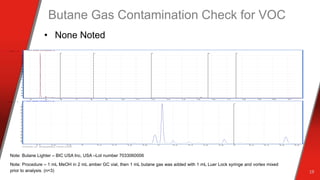

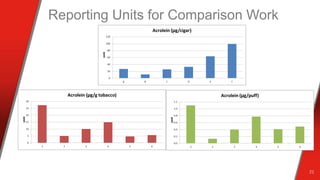

The document discusses the challenges and considerations in developing methods for testing cigar products, particularly regarding smoke constituents. Key topics include sample storage, preparation for smoking, data analysis, and the variability introduced by flavored products and non-standard design elements. Conclusions highlight the need for standardized methods and controls due to the diverse nature of cigar smoking experiences and product variations.