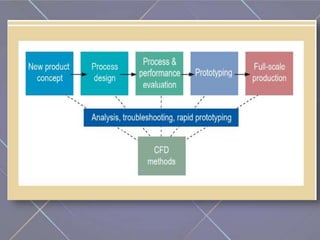

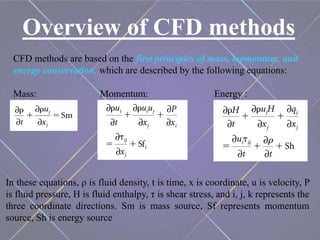

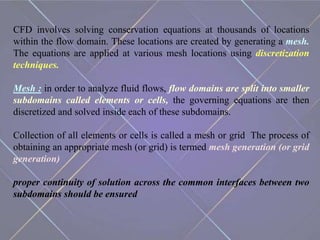

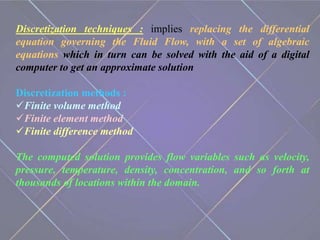

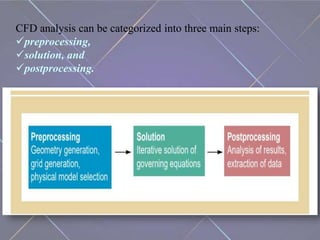

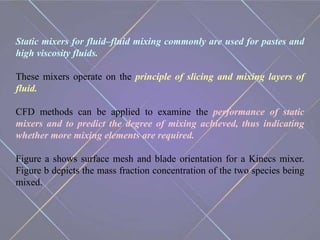

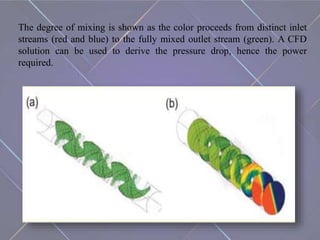

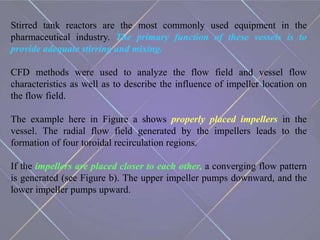

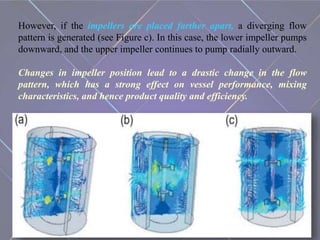

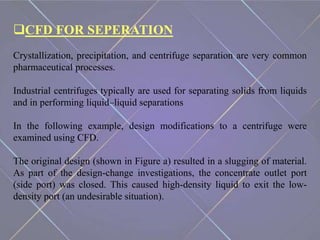

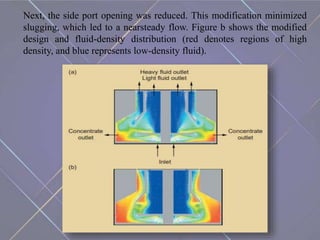

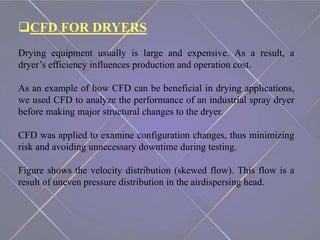

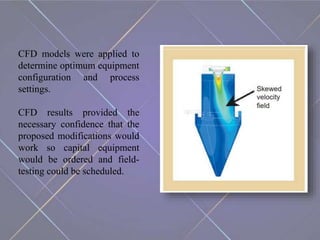

Computational Fluid Dynamics (CFD) is a numerical method used to analyze fluid flow, with applications in various fields, including the pharmaceutical industry. It involves modeling flow regions, applying physical principles, and solving governing equations using discretization techniques to obtain data on flow variables. CFD can optimize processes, predict performance, and reduce costs, although its accuracy depends on physical models, numerical errors, and boundary conditions.