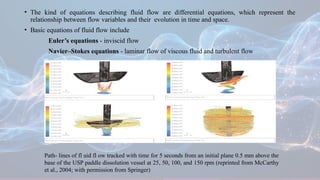

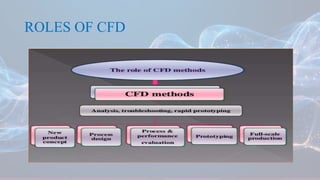

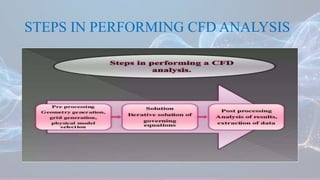

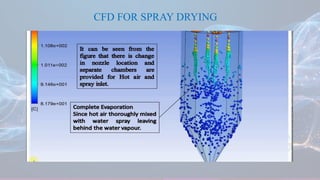

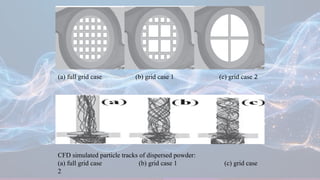

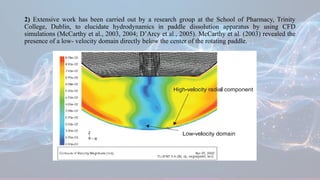

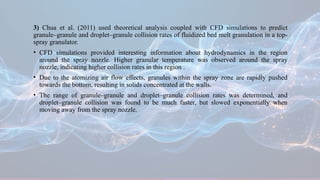

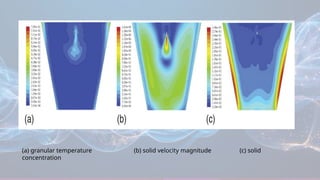

The document discusses Computational Fluid Dynamics (CFD), detailing its principles, advantages, disadvantages, roles, and applications, particularly in the pharmaceutical industry. CFD is highlighted as a powerful tool for simulating fluid flow, offering significant time and cost savings while enabling analysis of complex systems under various conditions. It also reviews previous research using CFD in pharmaceutical applications and lists several popular CFD software programs.