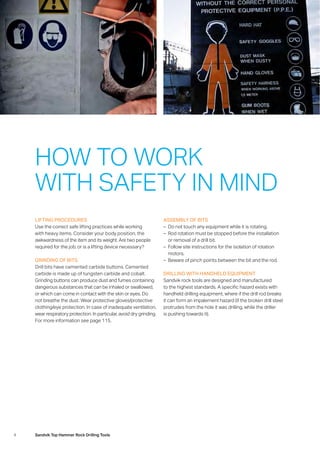

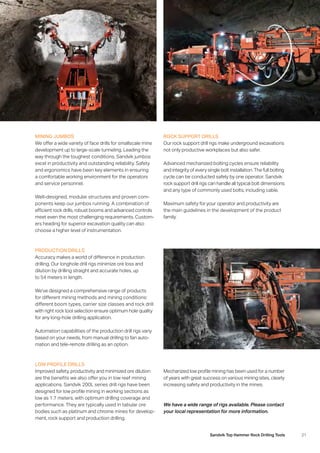

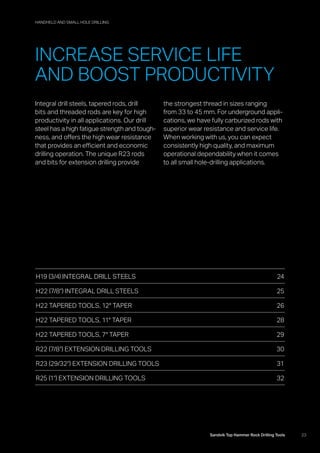

This document provides safety information and guidelines for the use of Sandvik top hammer rock drilling tools. It discusses the importance of safety, proper personal protective equipment, risk assessment, safe operating procedures, and hazard identification. The document recommends specific safety practices for different operations like grinding bits, drilling, lifting, cleaning rods, and dealing with worn parts. Overall, the document emphasizes putting safety first when using Sandvik rock drilling tools and equipment.