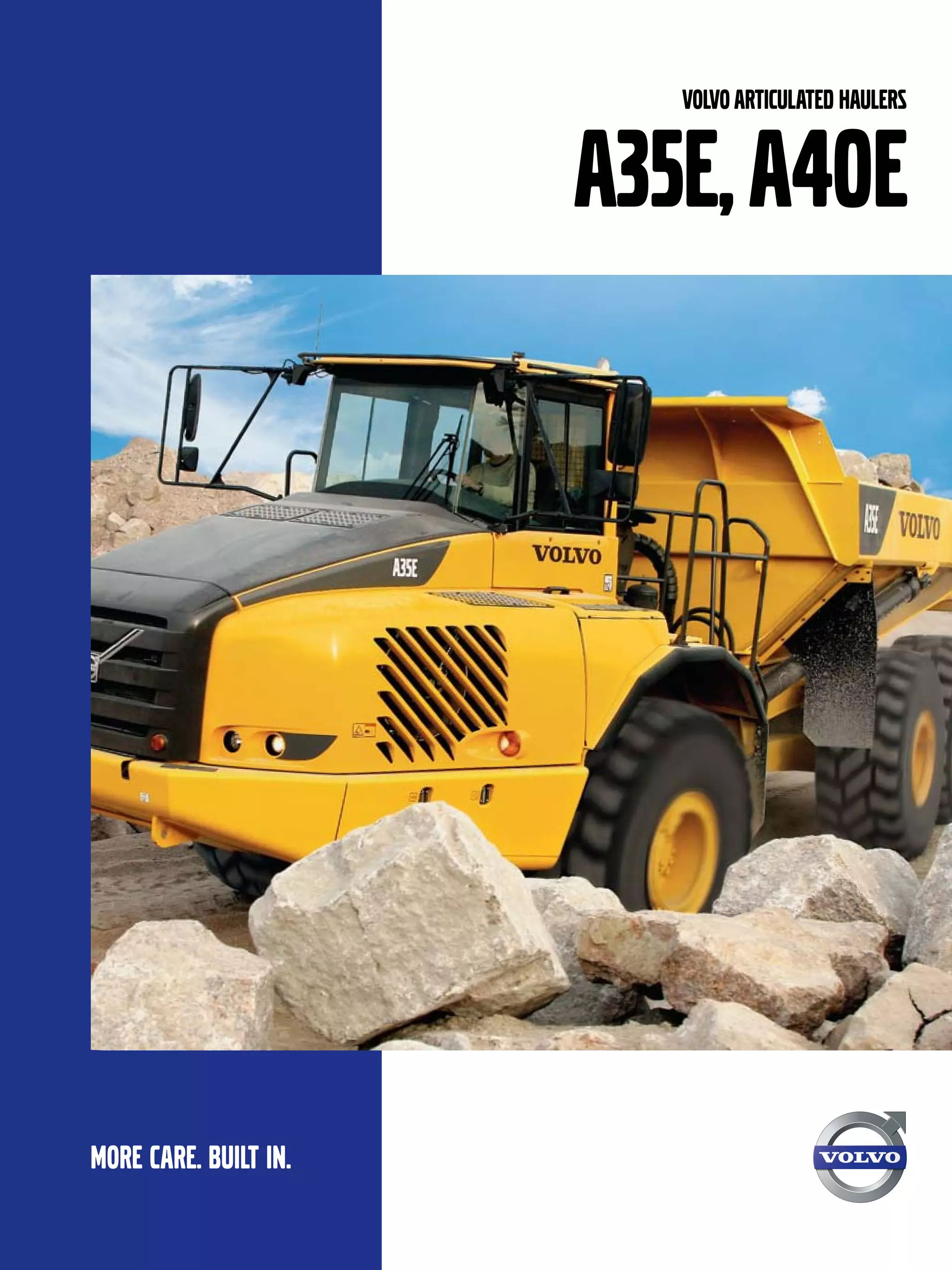

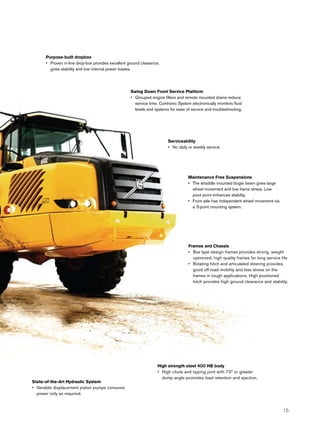

Volvo manufactures the A35E and A40E articulated haulers. As the world's leading manufacturer of articulated haulers since developing the concept in the 1960s, Volvo reinforces its position with the E-series. The A35E and A40E are reliable, productive, and cost-effective machines for hauling various loads in demanding conditions. Volvo's telematics and monitoring systems help operators maximize uptime and efficiency.