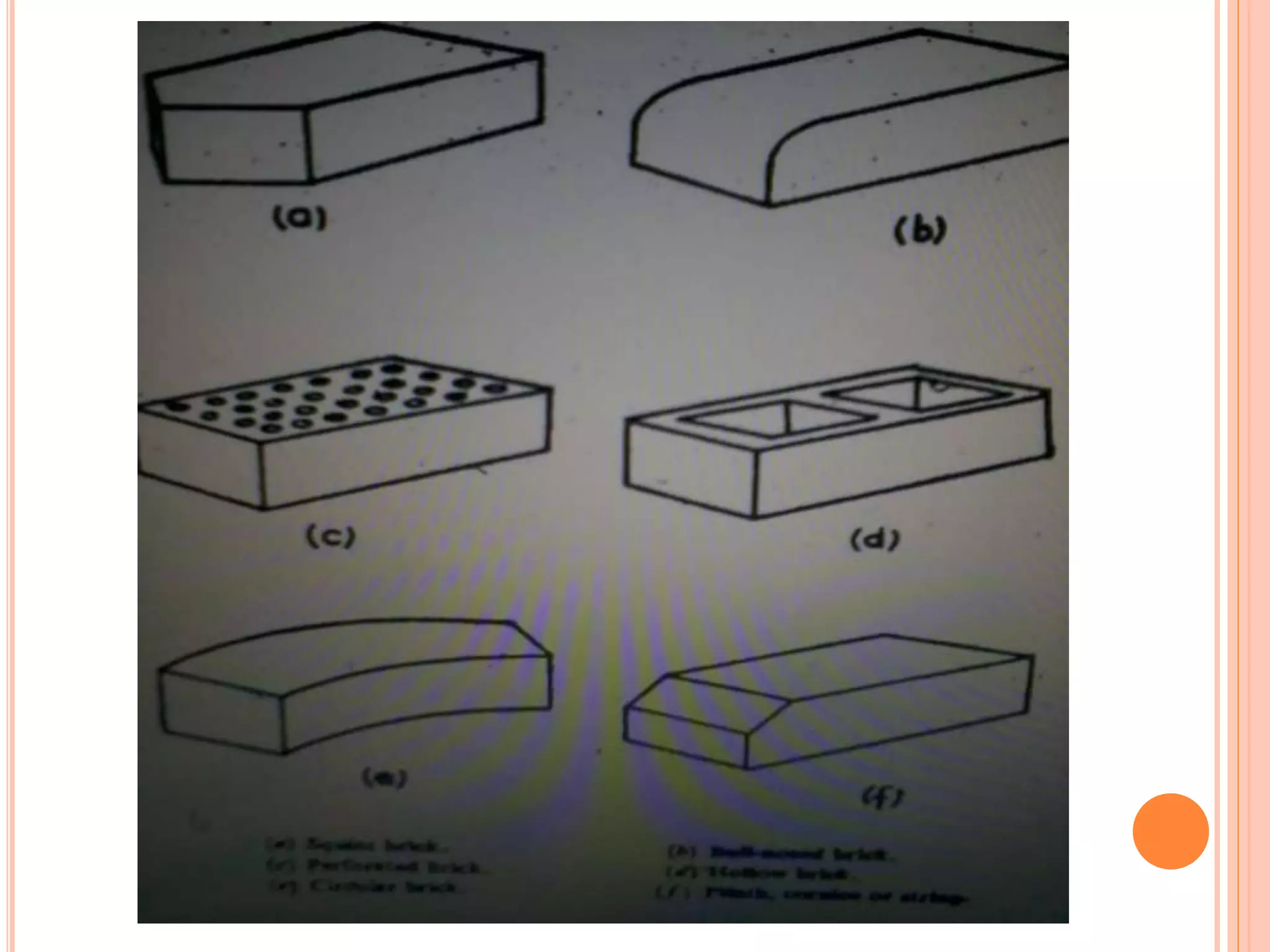

The document provides a comprehensive overview of bricks, detailing their composition, manufacturing processes, and classifications. It emphasizes the essential elements that contribute to the quality and durability of bricks, as well as their various types and uses in construction. Key factors, such as the chemical components, molding methods, and testing standards for bricks, are also highlighted.