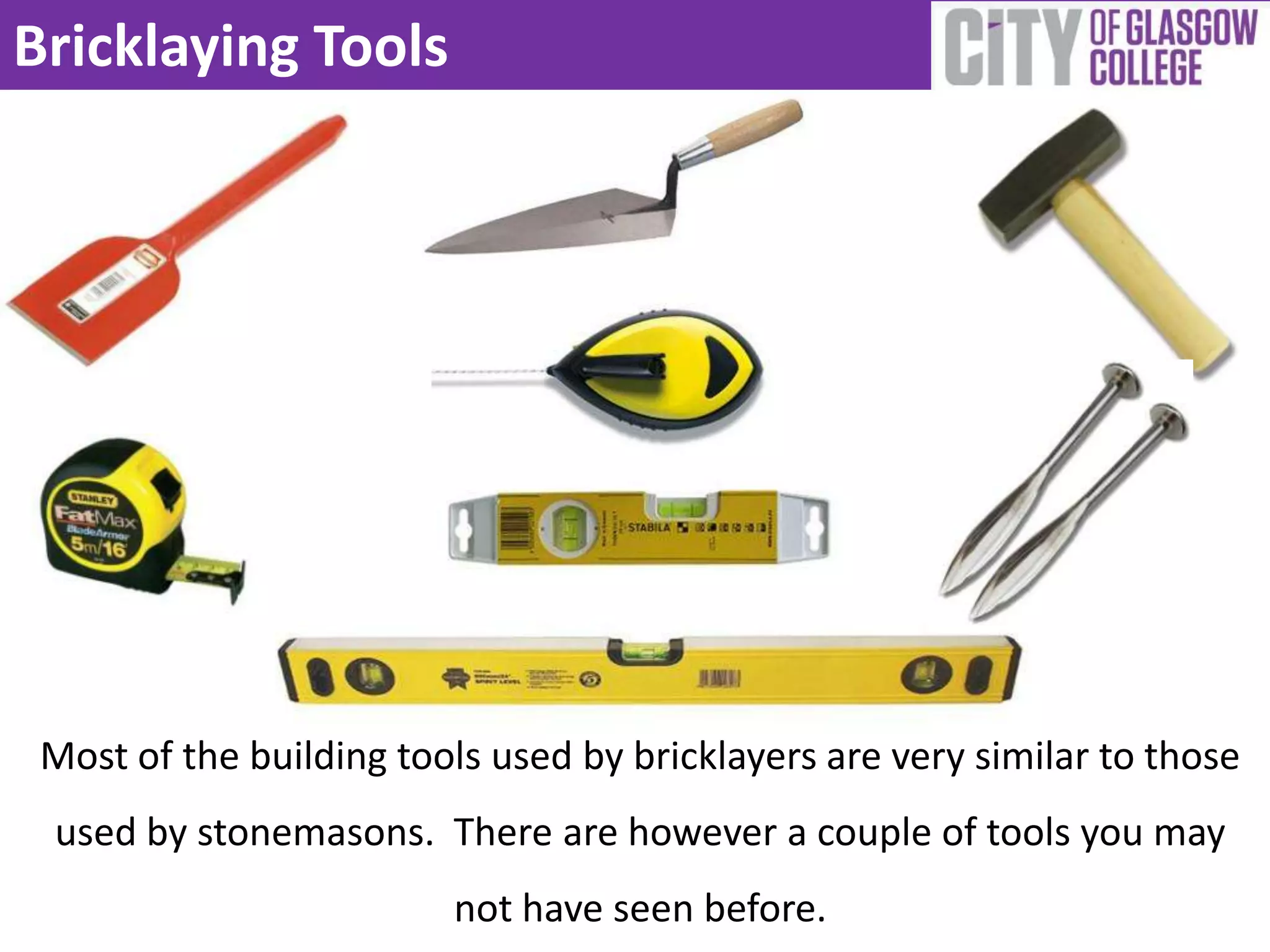

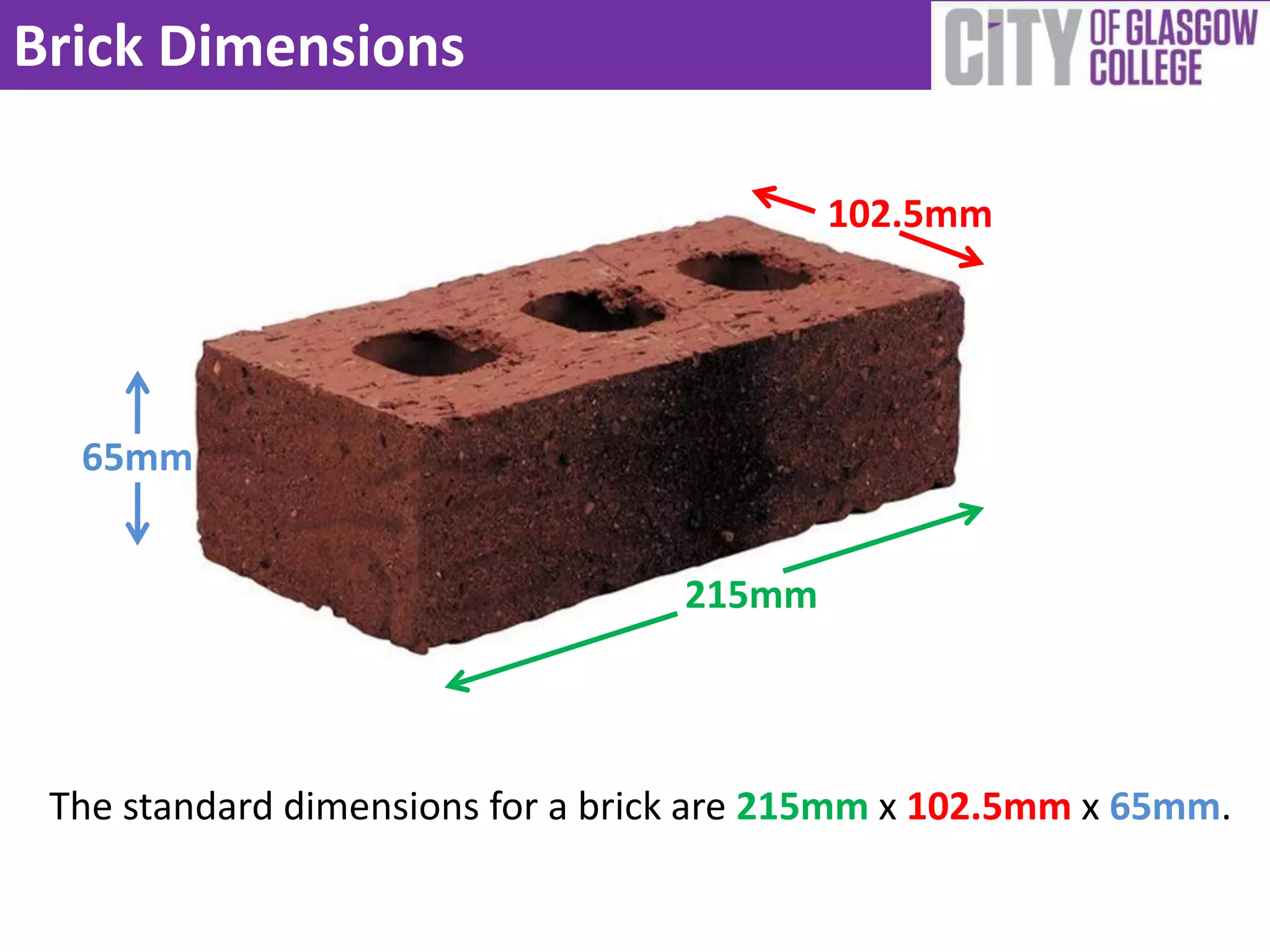

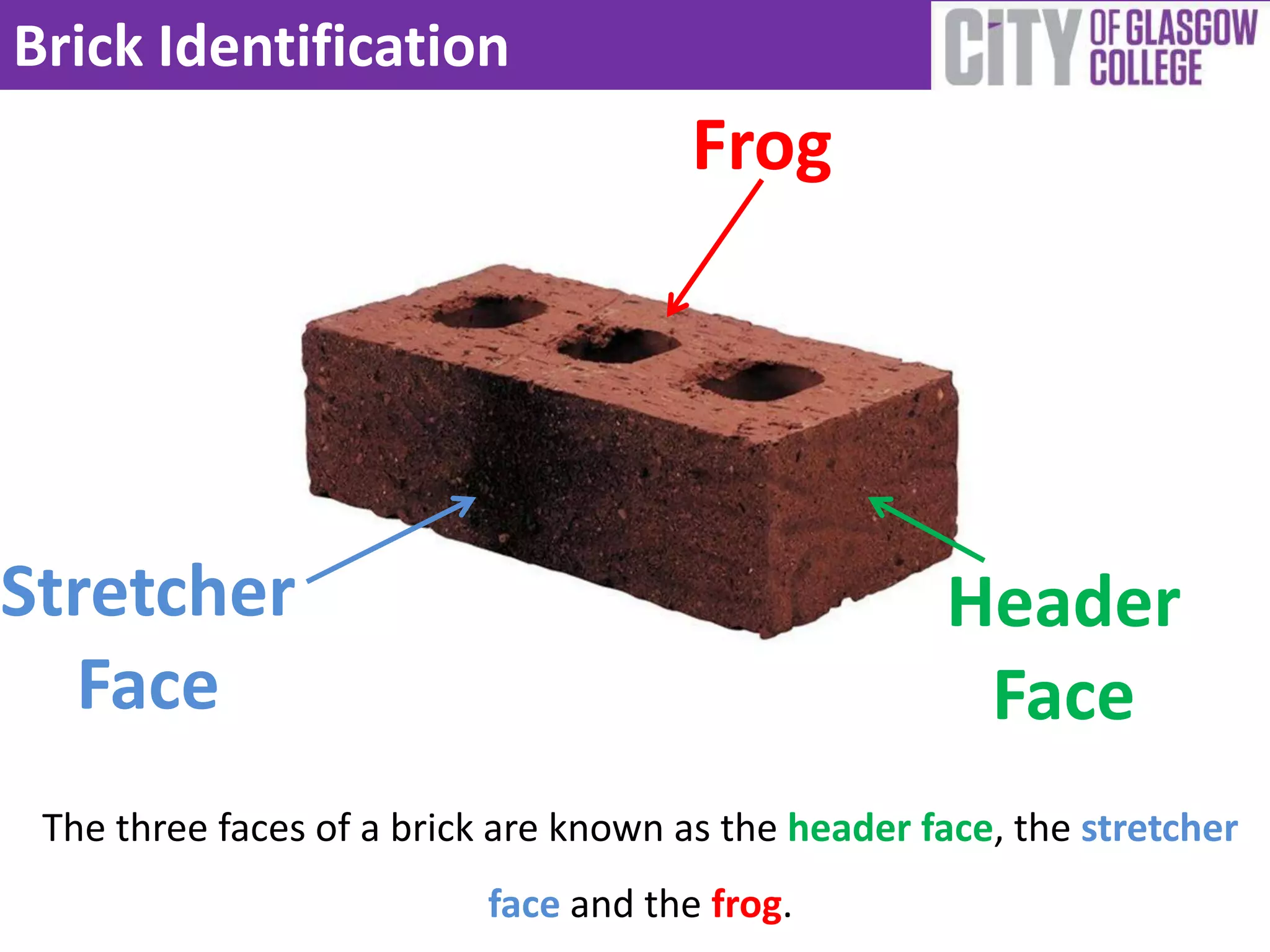

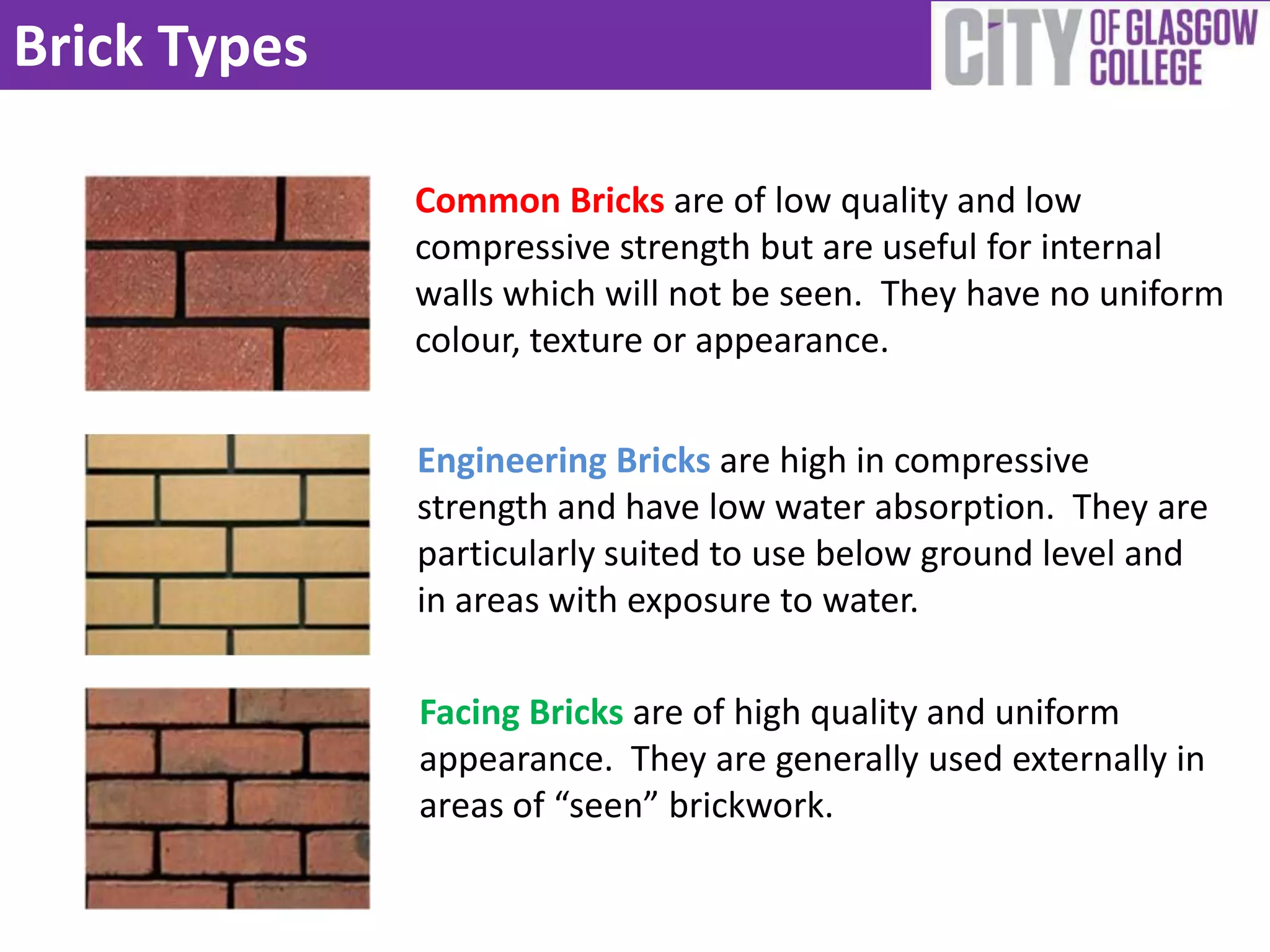

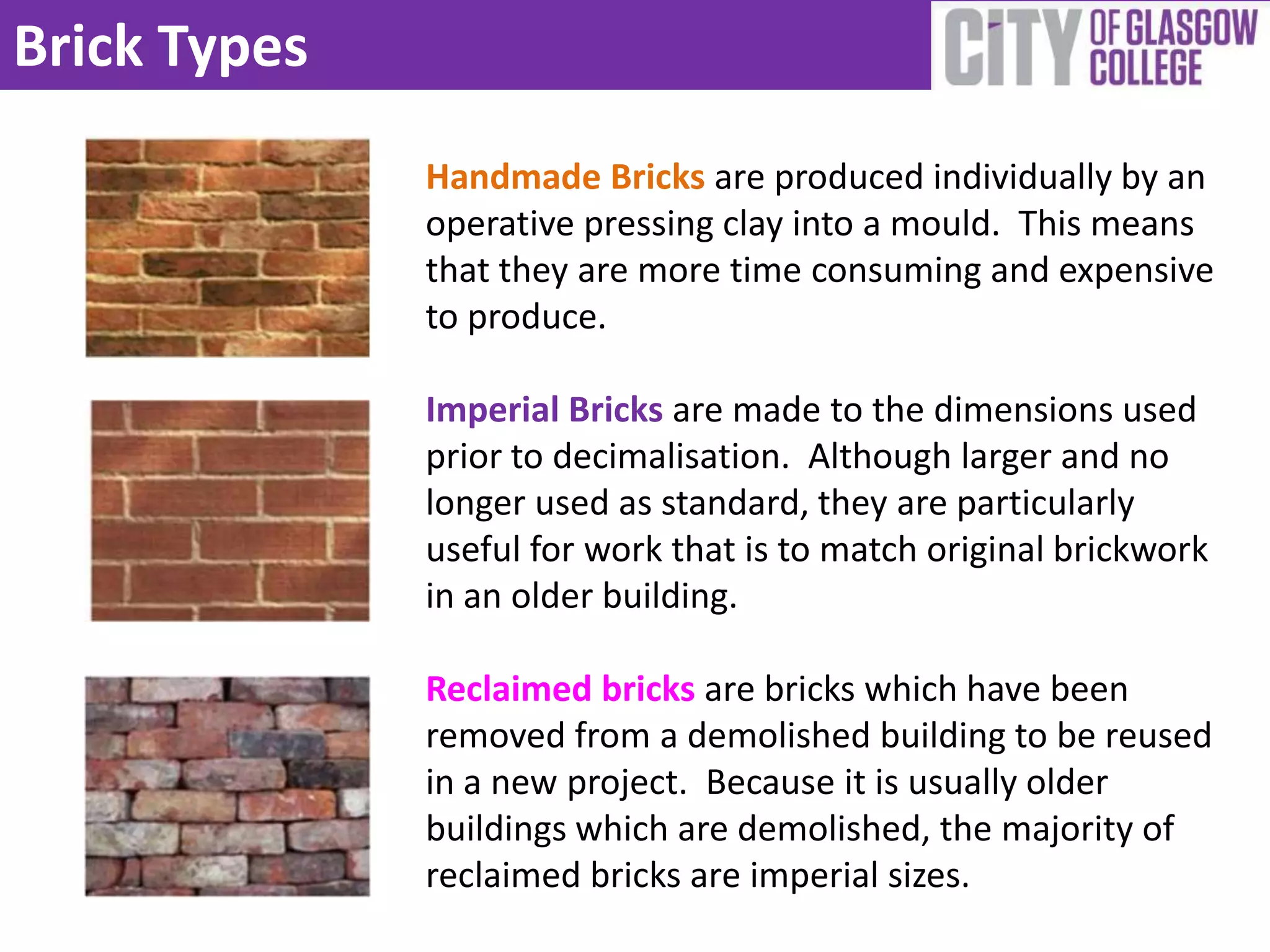

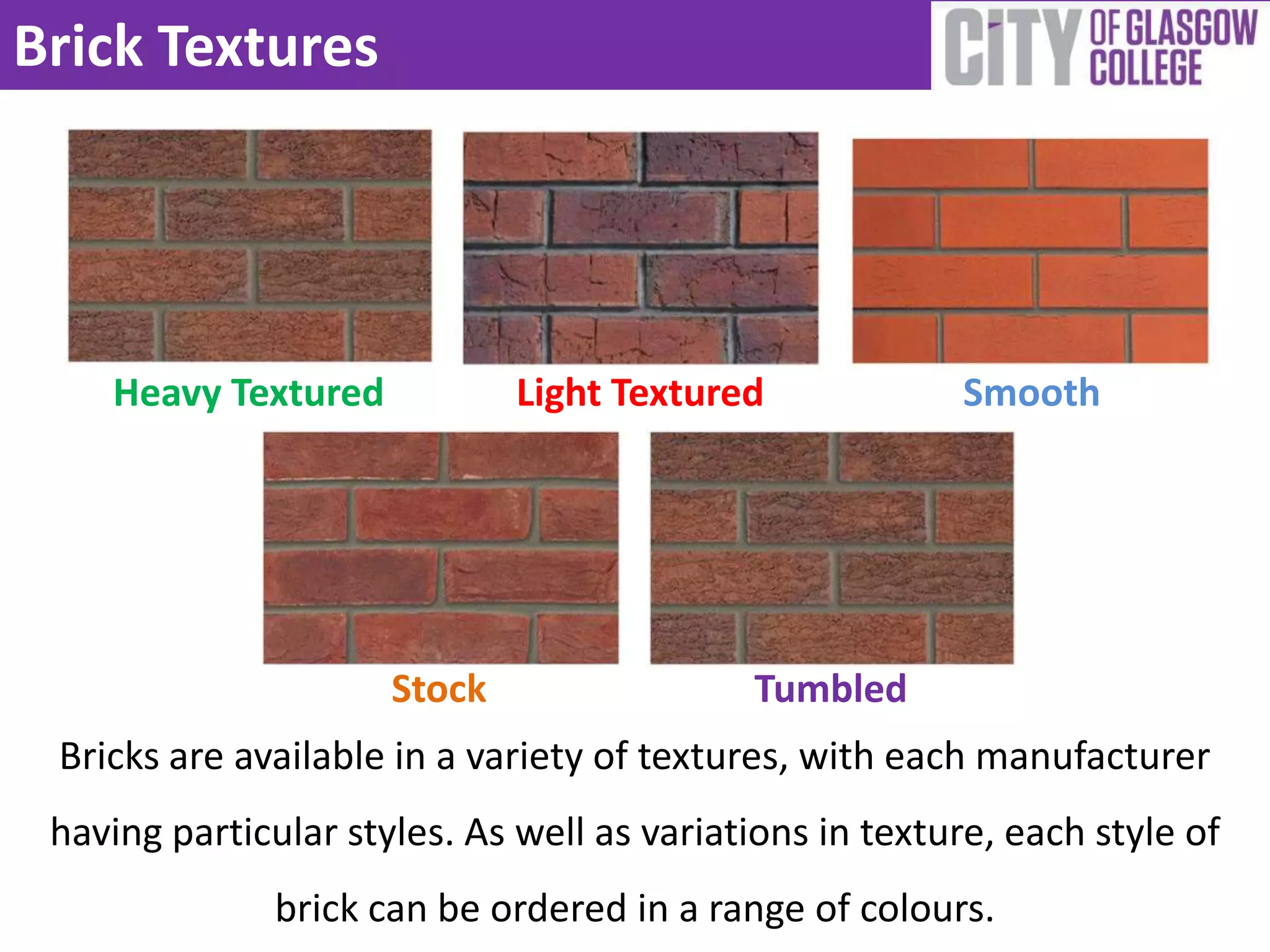

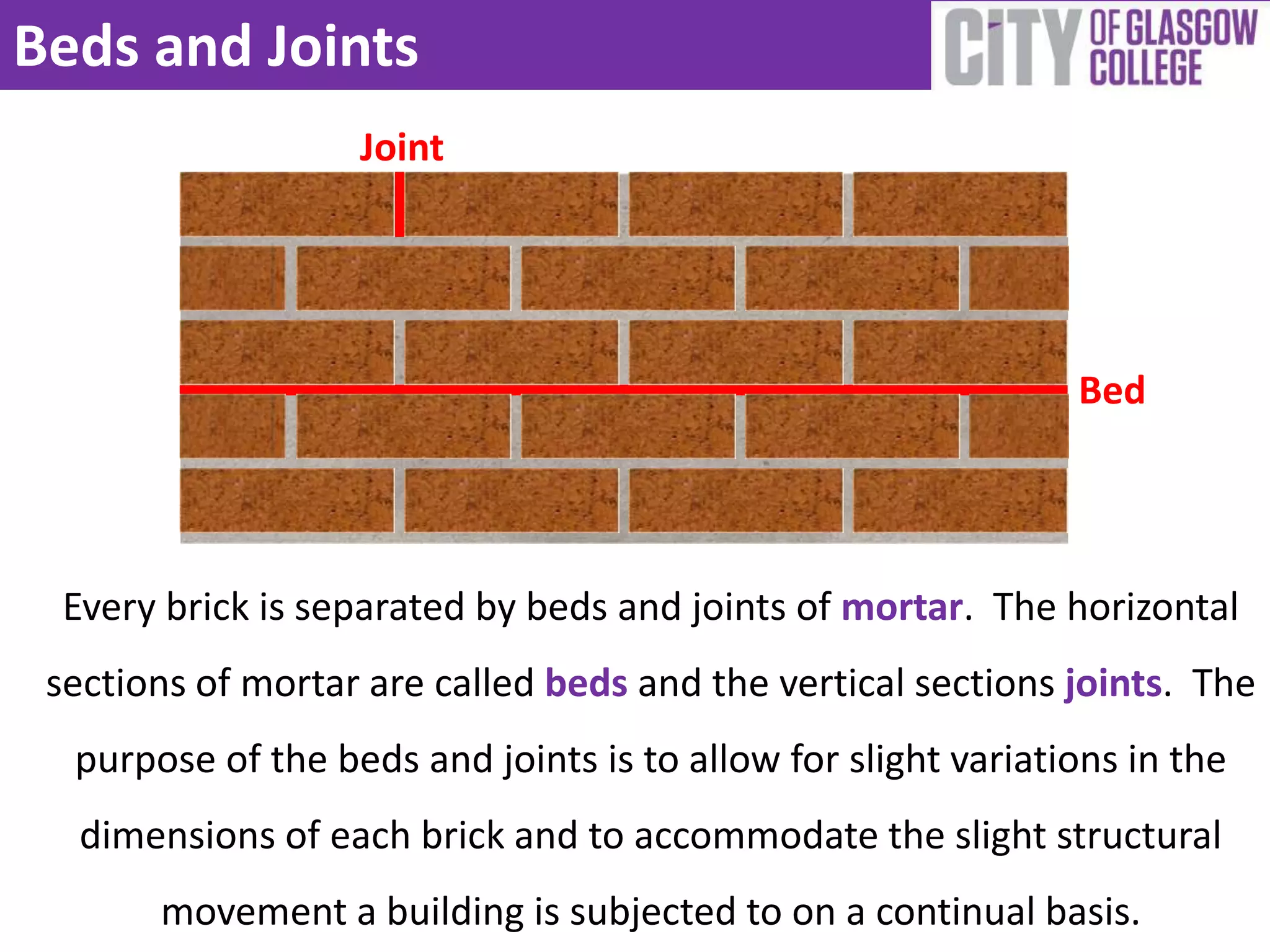

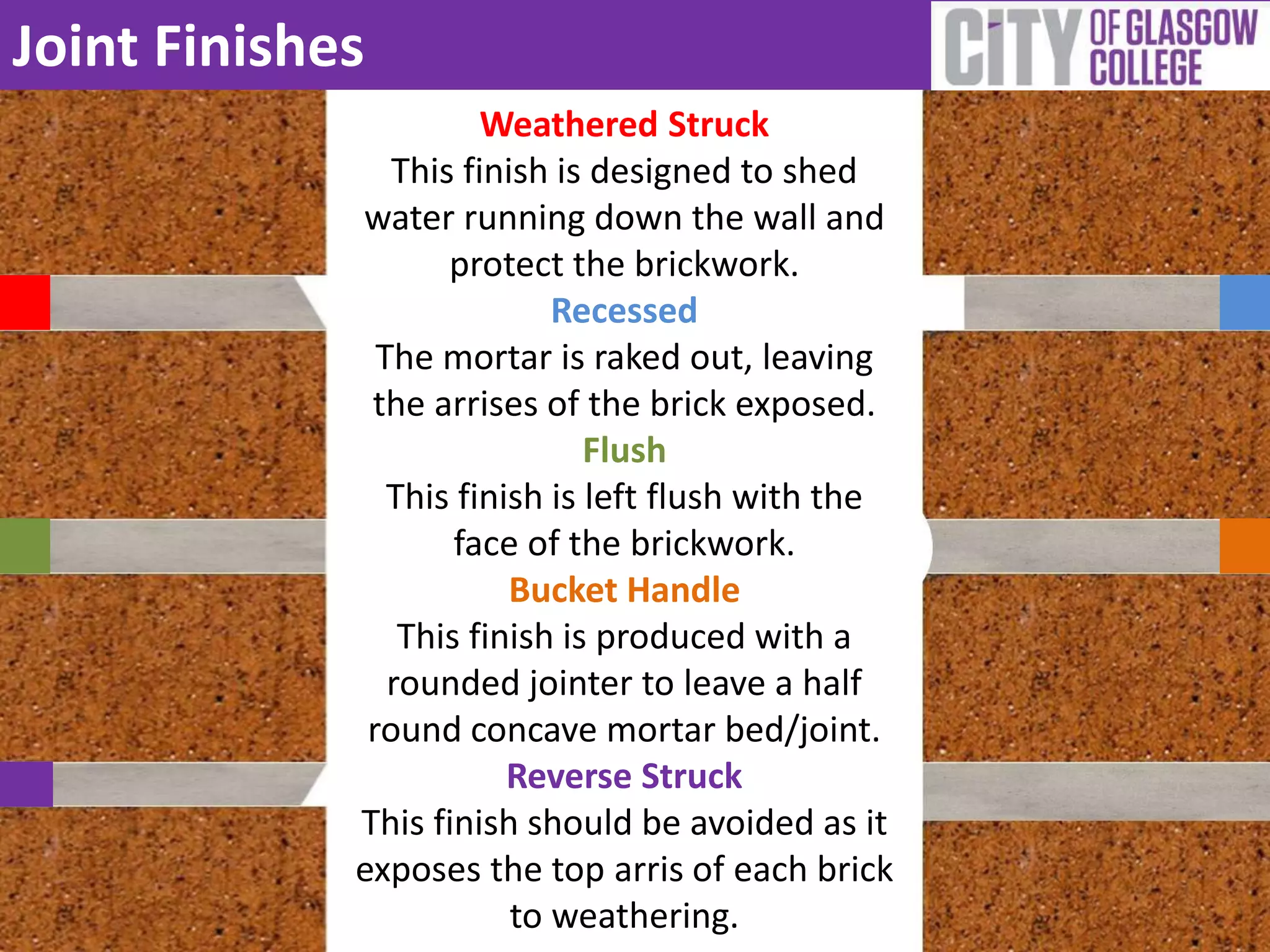

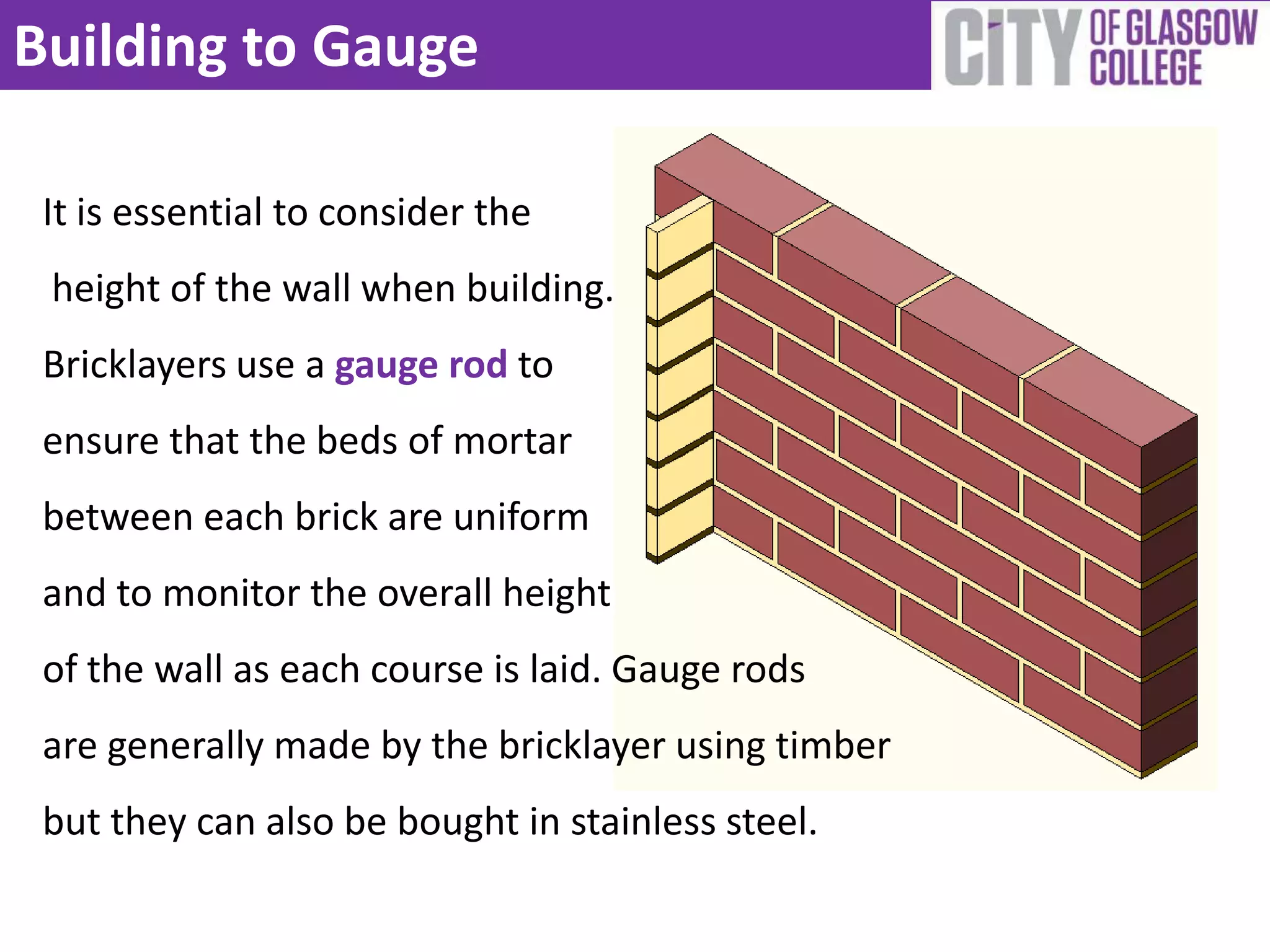

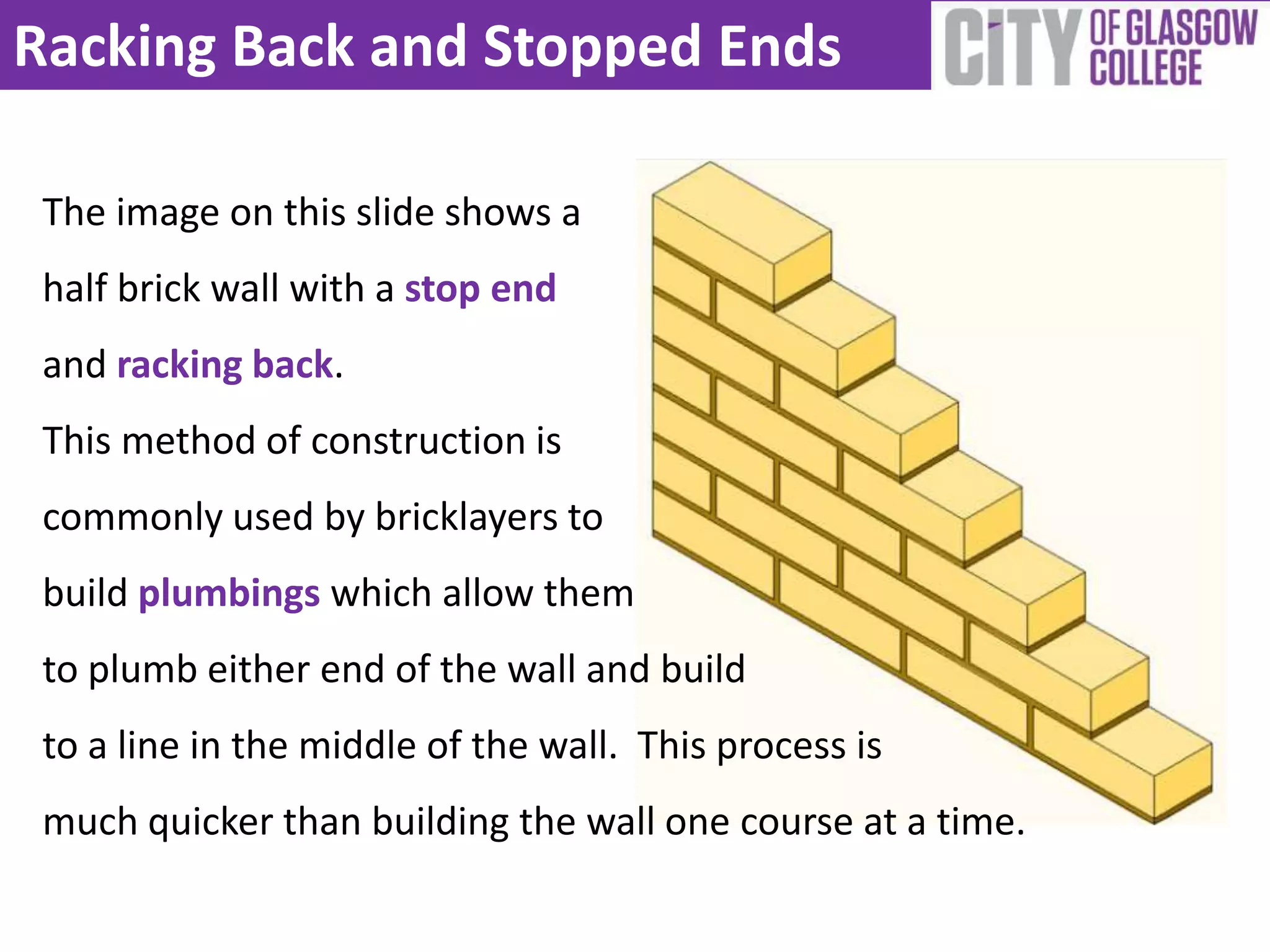

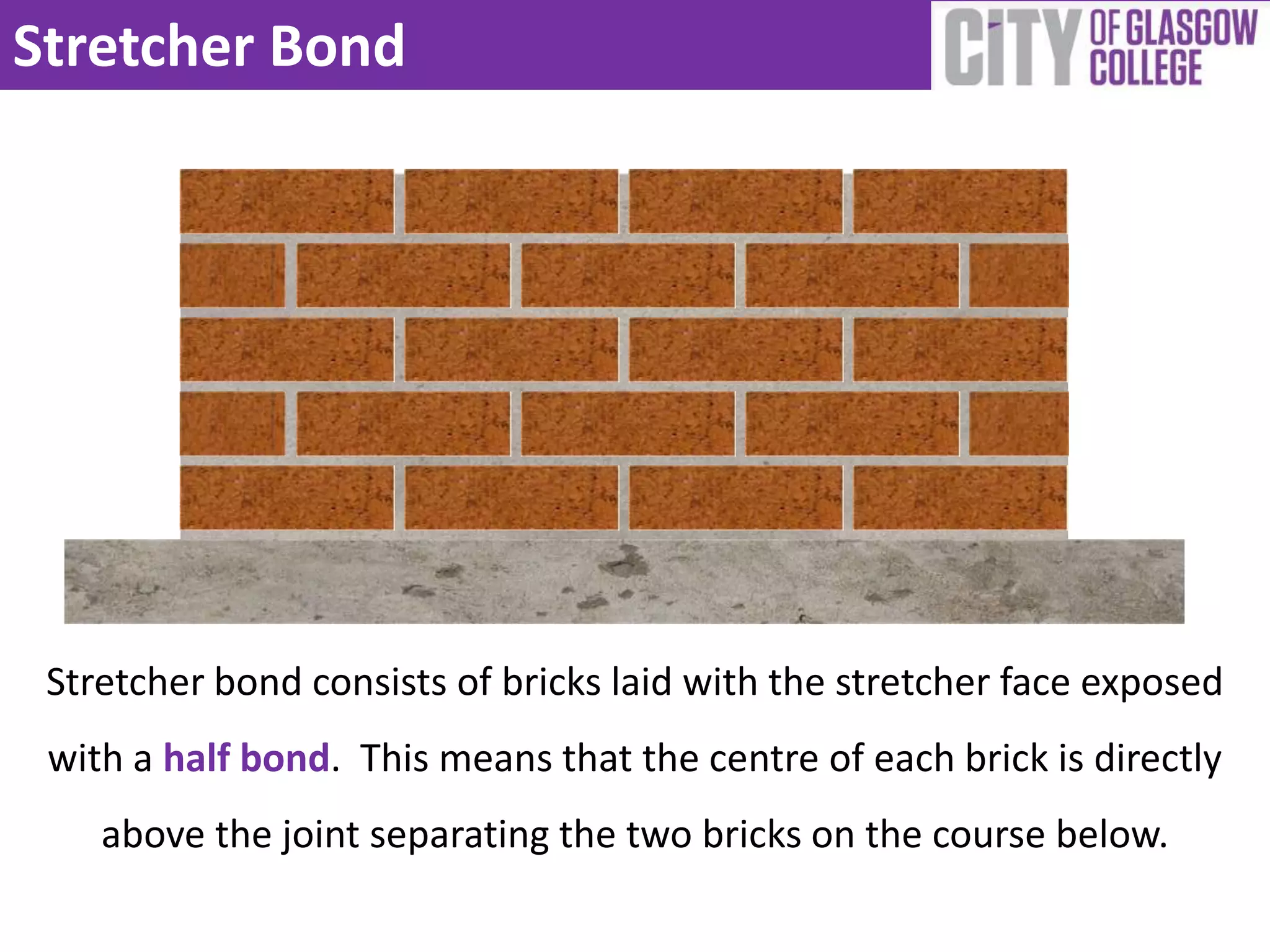

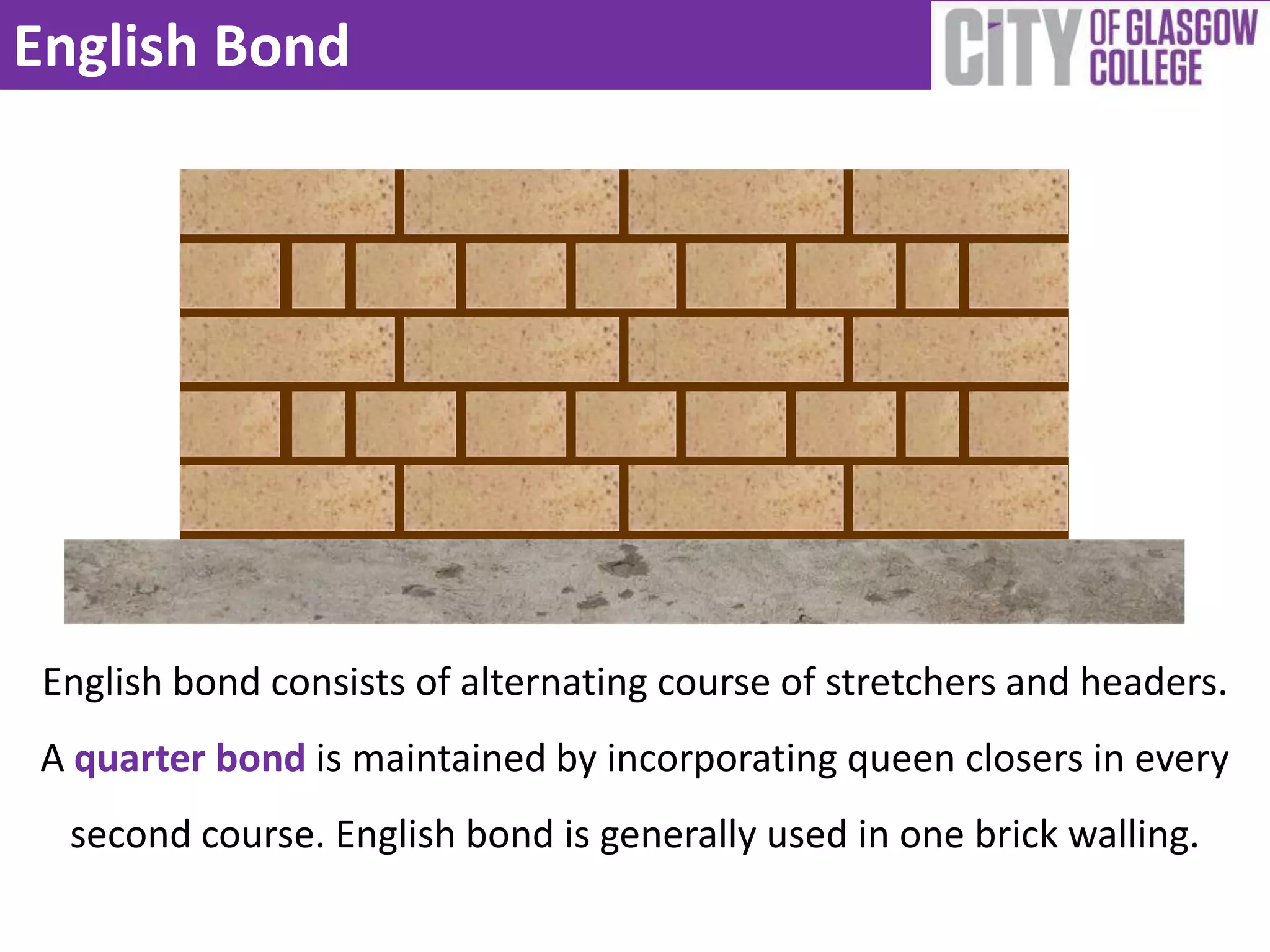

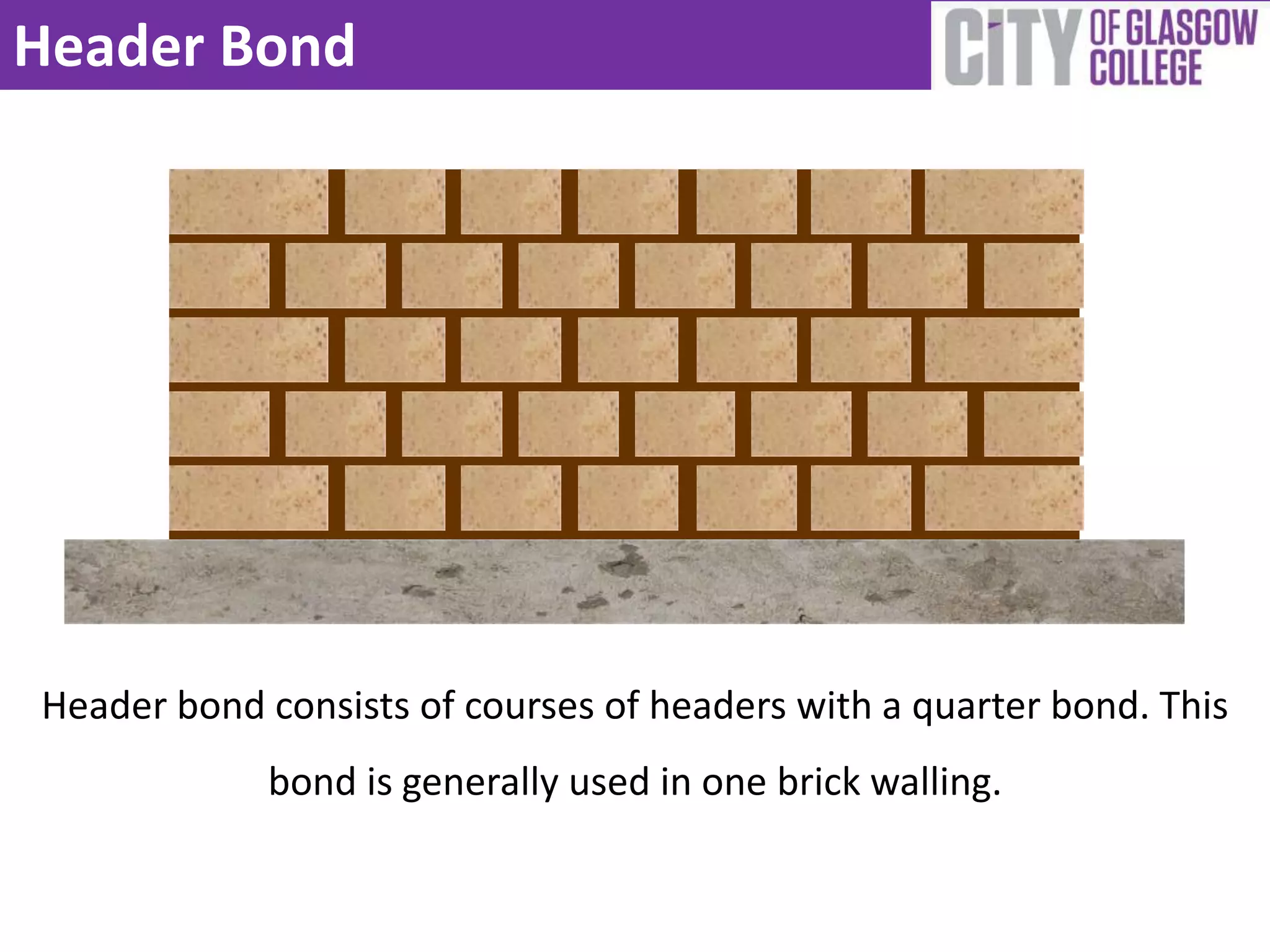

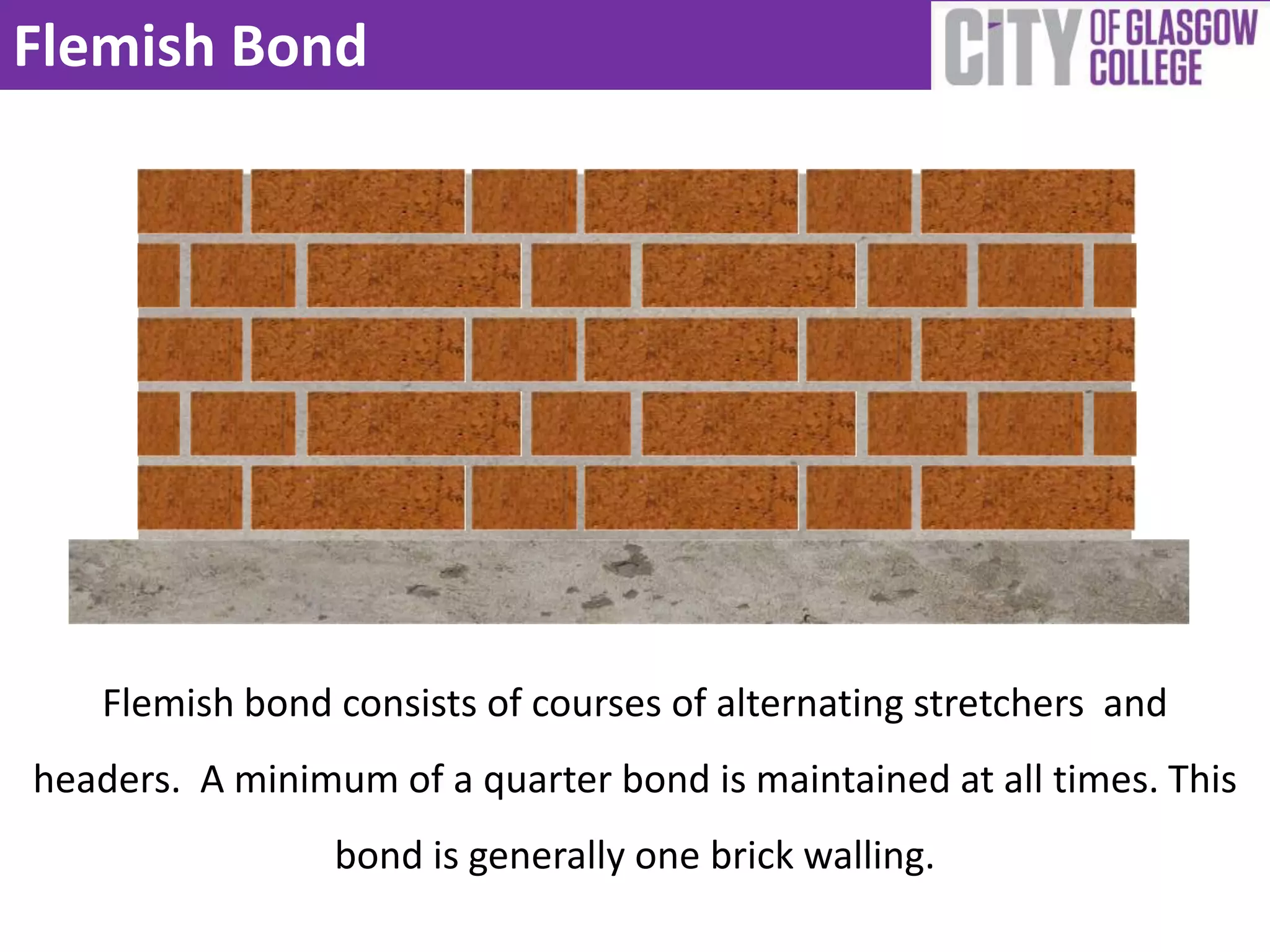

This document provides an introduction to brick walling for stonemasons. It describes common bricklaying tools such as hammers and jointers. It also details brick dimensions, identification of faces, common types of bricks, mortar beds and joints, bonding patterns such as stretcher and English bond, and basic bricklaying techniques like building to gauge. References are provided for images used from external sources.