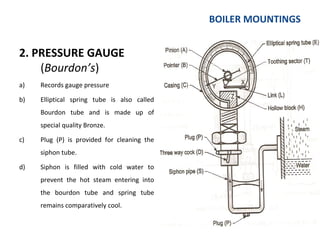

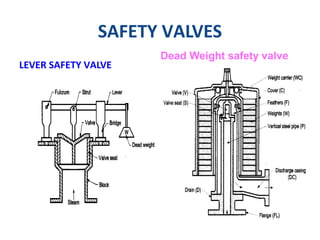

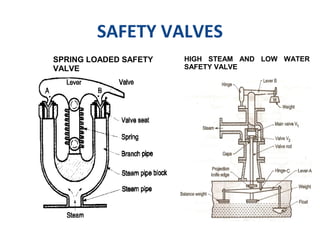

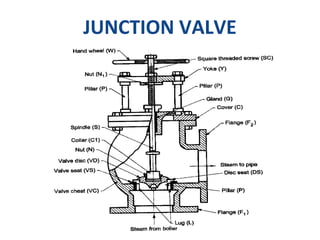

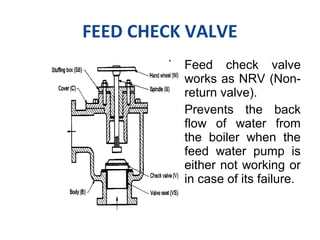

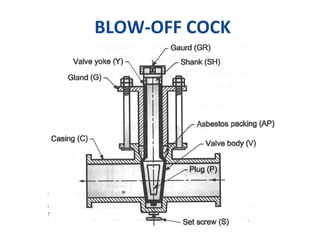

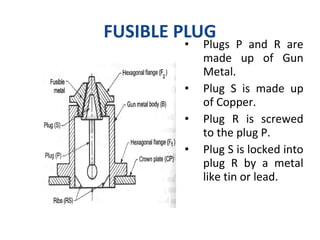

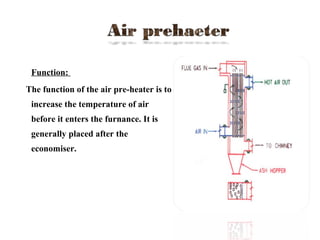

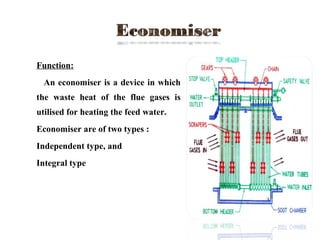

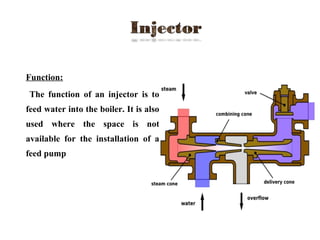

The document discusses different types of steam boilers, their classifications and components. It describes how boilers are classified based on the position of hot gases and water, method of firing, steam pressure, and water circulation method. It also discusses boiler mountings and accessories. Boiler mountings include safety devices like safety valves, pressure gauges, and fusible plugs. Boiler accessories that improve efficiency include water heating devices, superheaters, economizers, air preheaters, feed pumps and injectors.