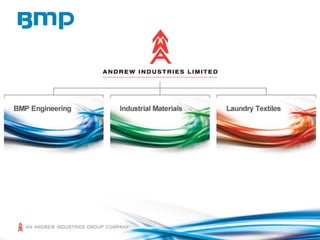

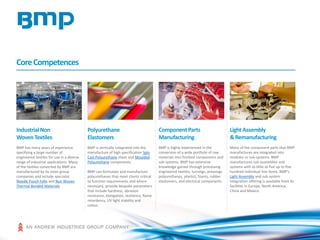

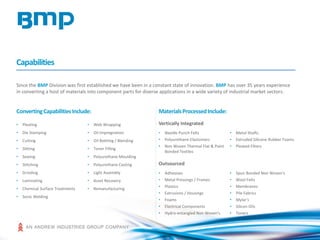

BMP is a global company specializing in the manufacture of nonwoven textiles, polyurethane elastomers, and mechanical components for various industrial applications. The company also offers services in remanufacturing and asset recovery, with a strong focus on innovation and meeting customer requirements in sectors such as automotive, printing, and appliances. With over 35 years of experience, BMP emphasizes product performance, cost reduction, and sustainability in its operations across different regions including Europe, North America, and Asia.