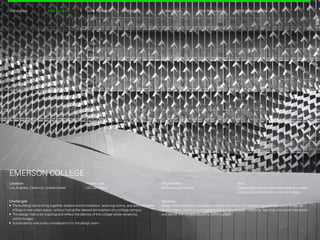

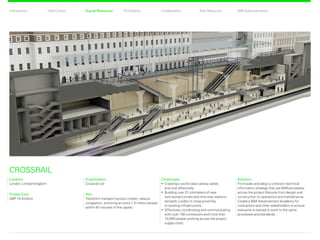

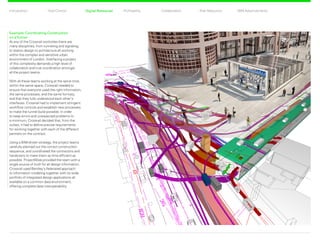

The document discusses the advancements in Building Information Modeling (BIM) within architecture, engineering, and construction, highlighting its role in improving collaboration, profitability, and risk reduction. It outlines three key pillars of BIM projects: people, processes, and technology, and emphasizes the importance of seamless collaboration through integrated models and shared data. By adopting BIM processes, projects like the Hollywood base for Emerson College and Crossrail can achieve better efficiency, reduced costs, and enhanced project outcomes.