This document provides information about TRUMPF's TruLaser fiber laser machines, including:

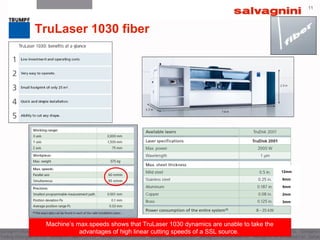

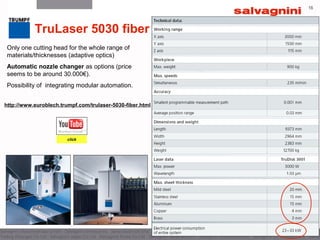

- The history of TRUMPF's fiber laser machines from 2008 to present, including models with 2kW, 3kW, 5kW, and 6kW power outputs.

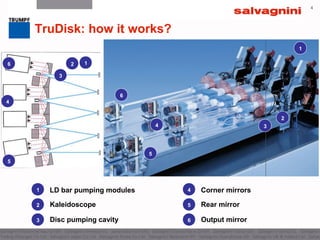

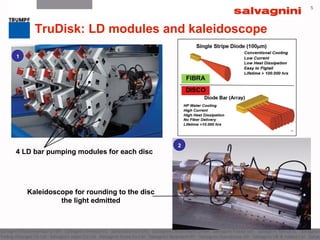

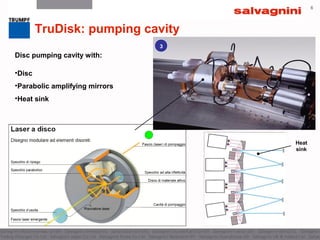

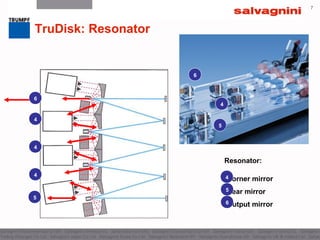

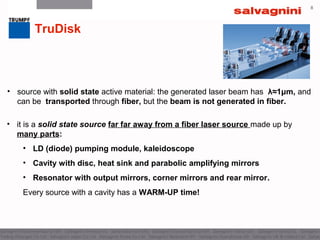

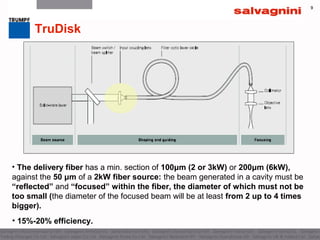

- Details on how TRUMPF's TruDisk solid state laser source works, including its laser diode pumping modules, kaleidoscope, pumping cavity, and resonator components.

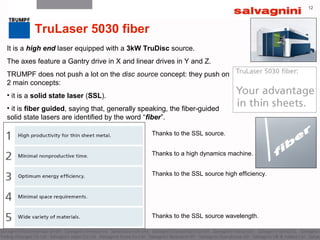

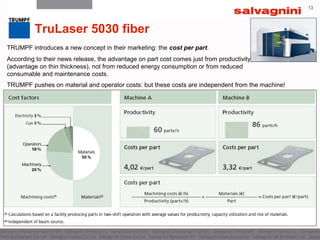

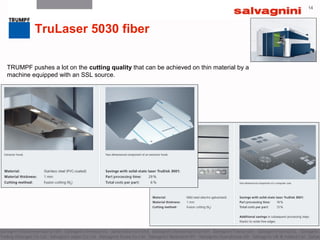

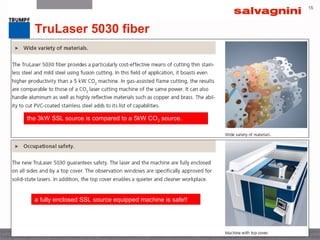

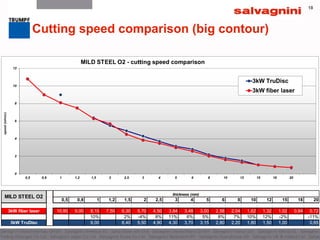

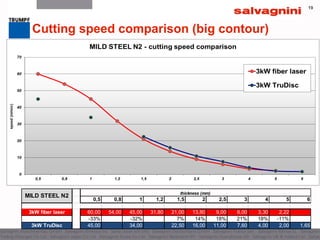

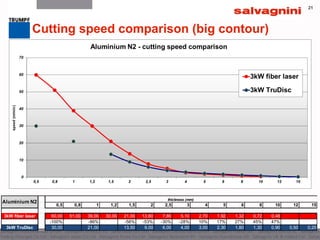

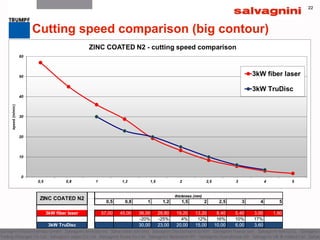

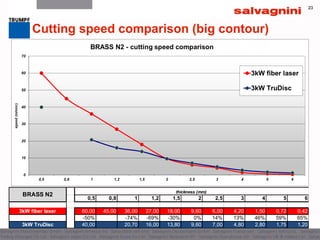

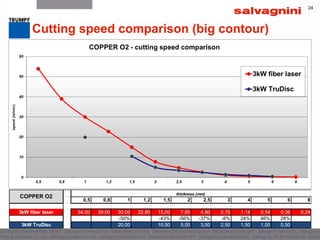

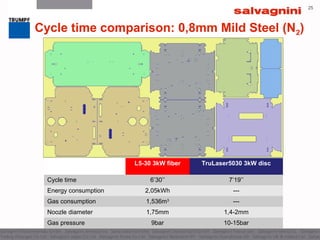

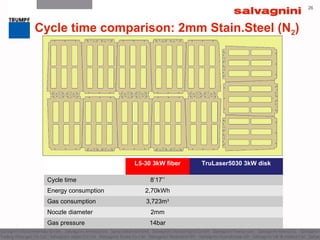

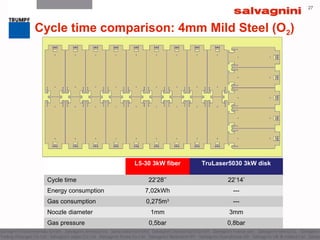

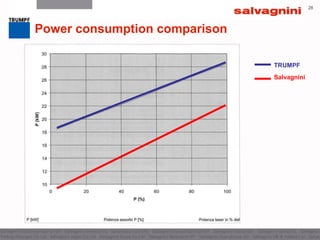

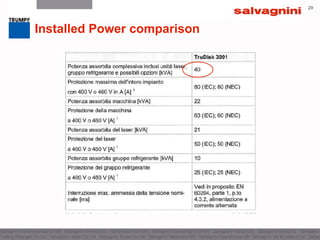

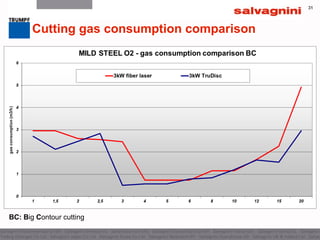

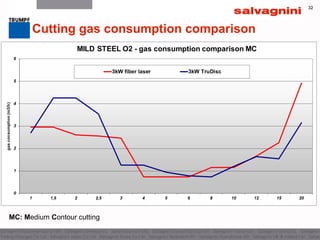

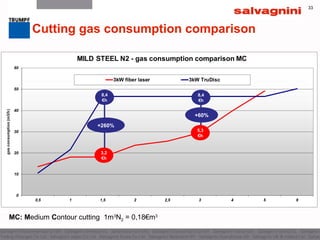

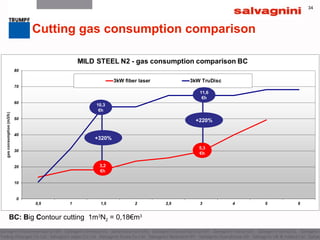

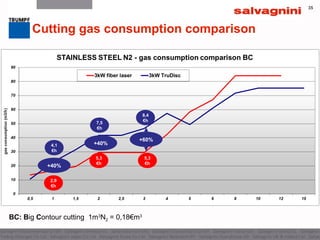

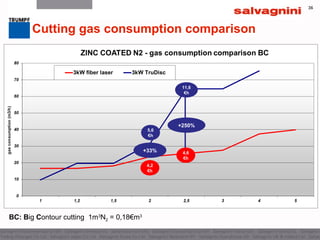

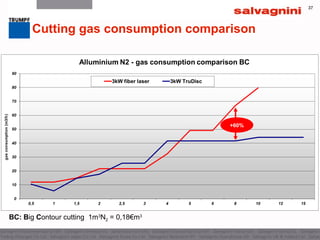

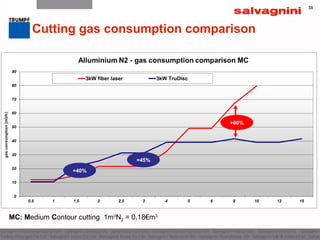

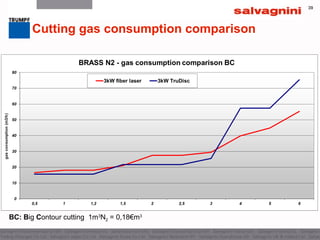

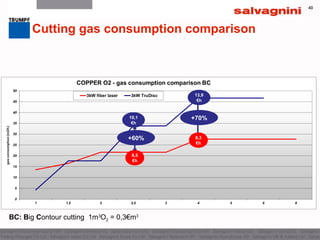

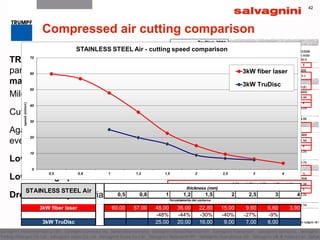

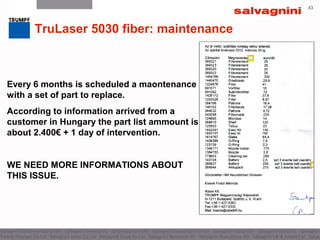

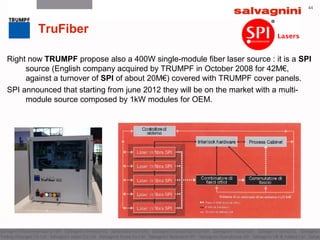

- Comparisons of cutting speeds, cycle times, power consumption, and gas consumption between TRUMPF's 3kW fiber laser and 3kW TruDisk laser source. The fiber laser provides higher speeds for