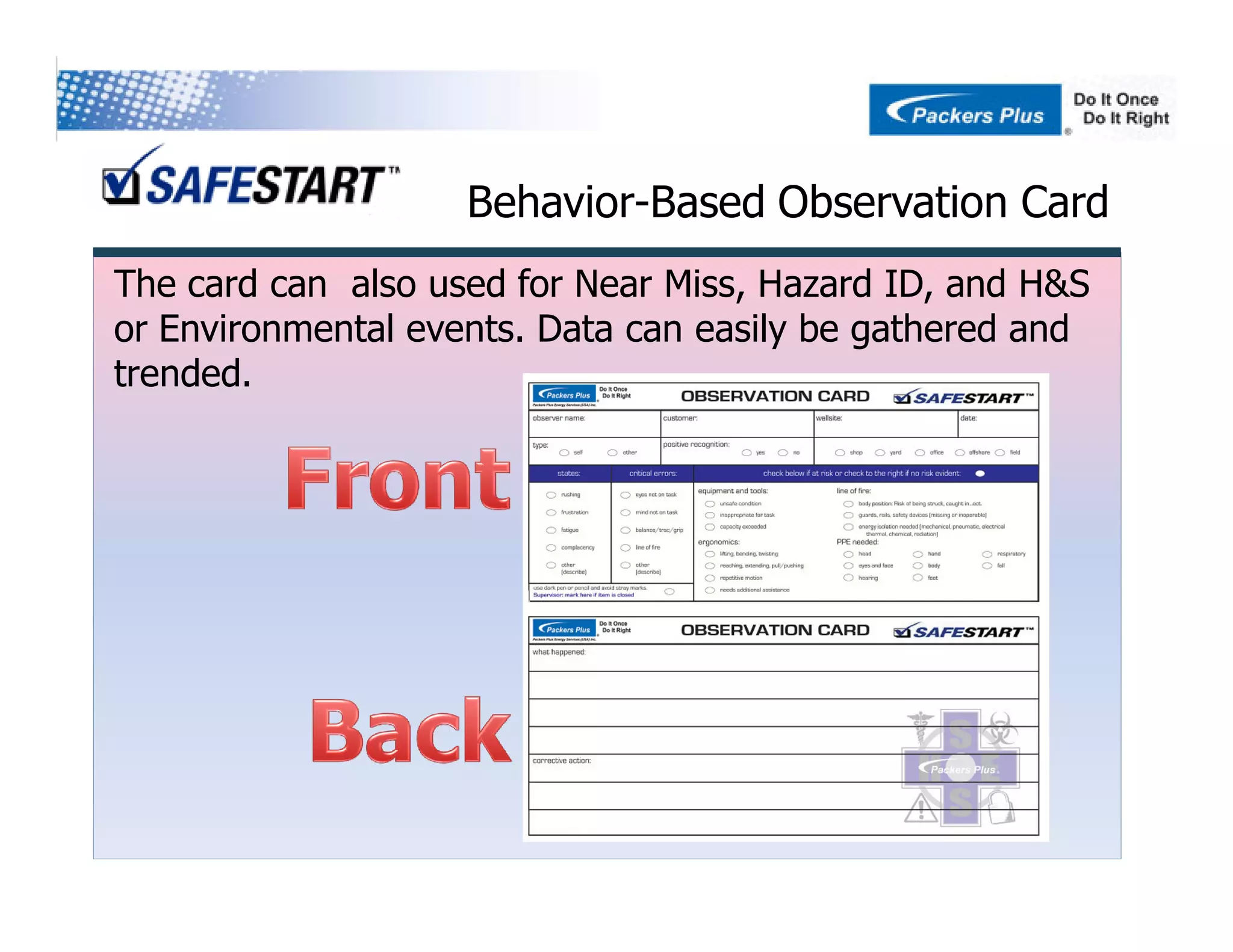

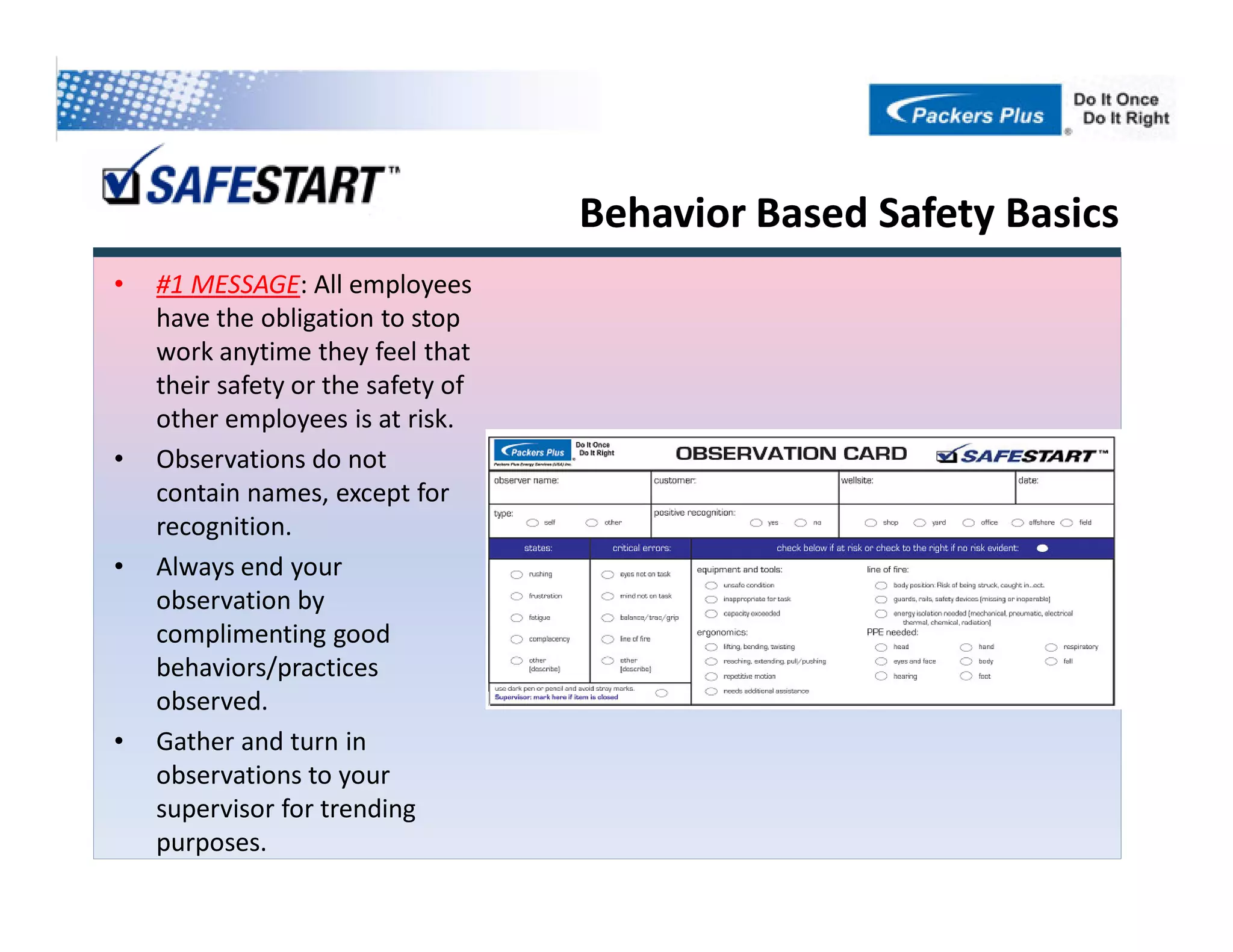

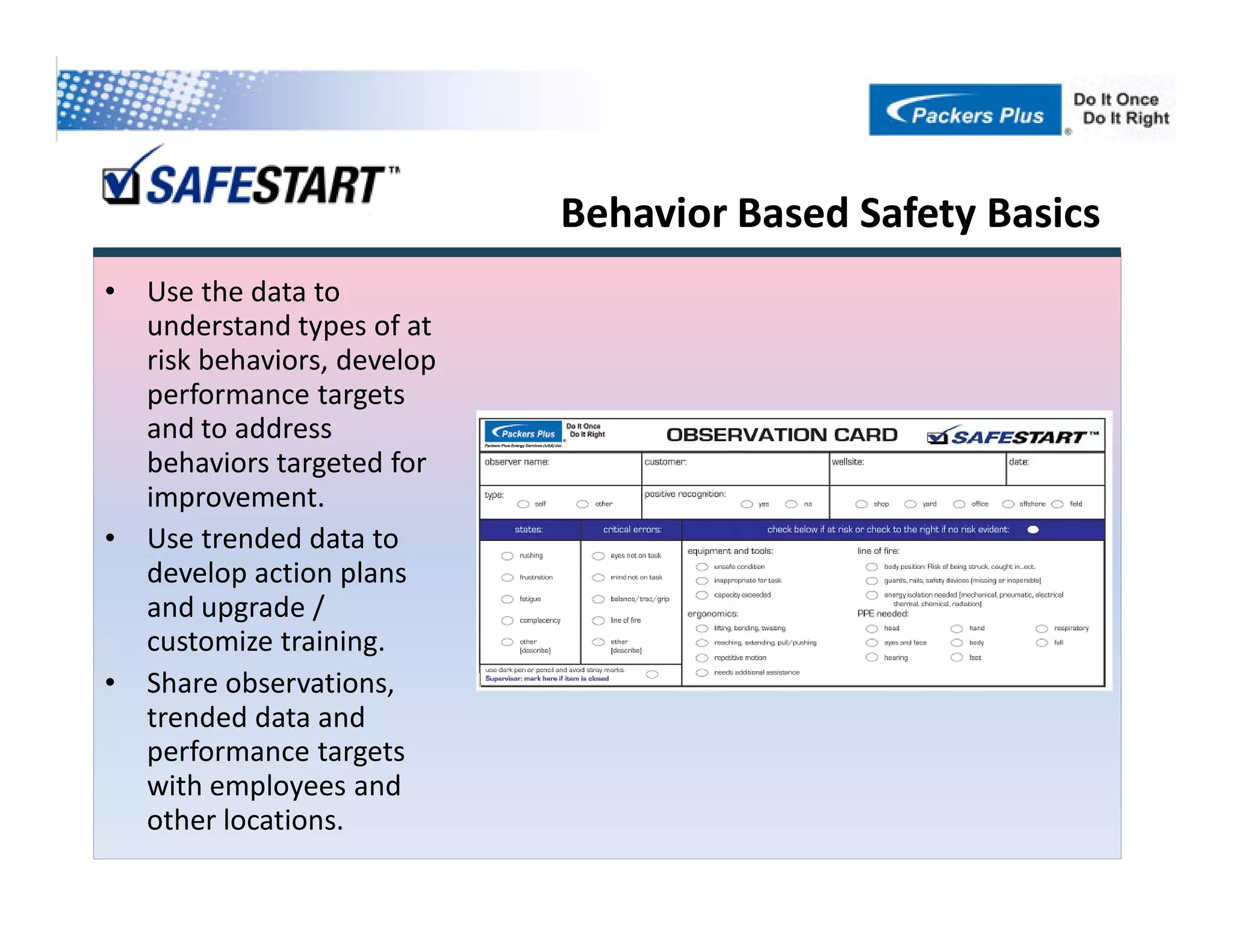

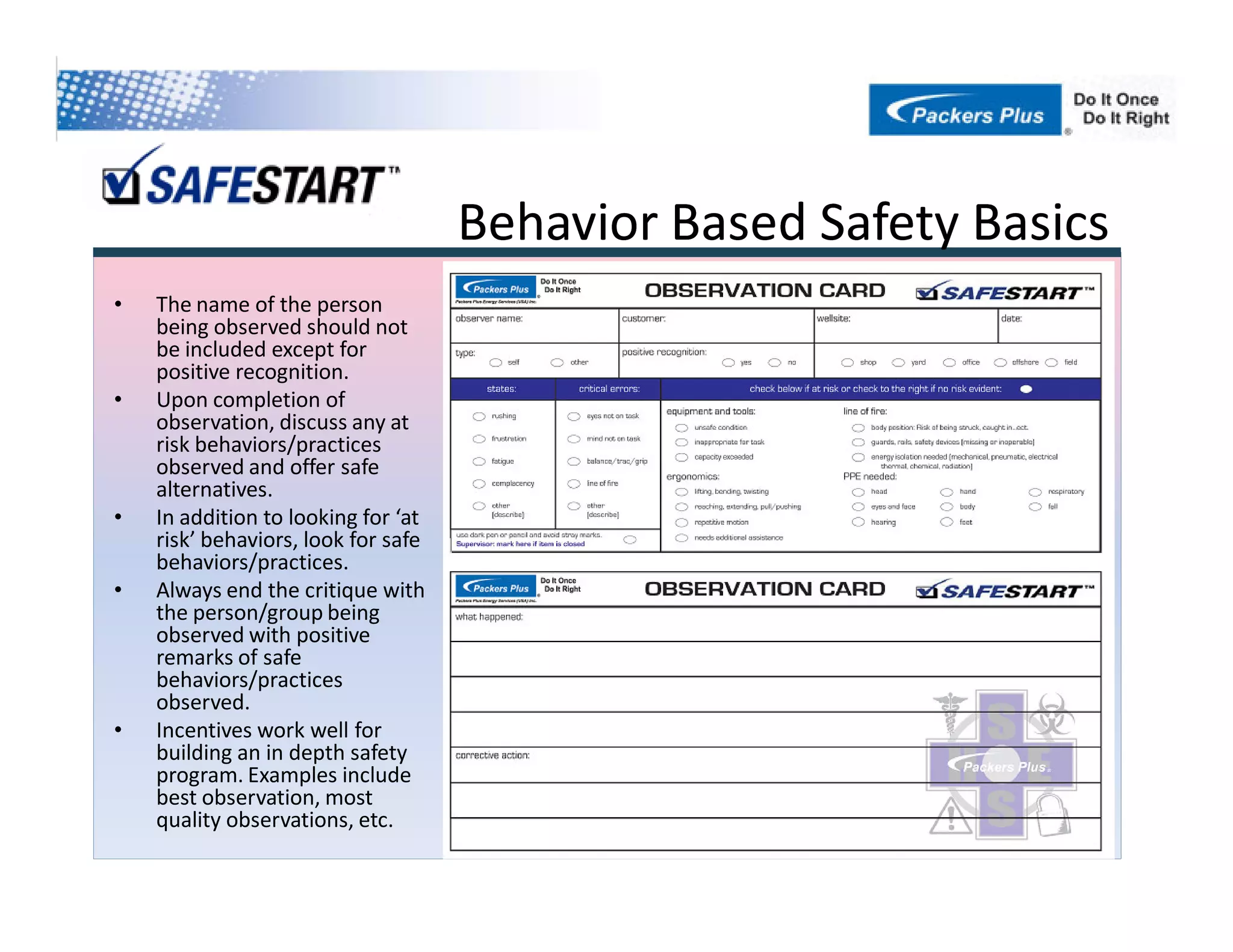

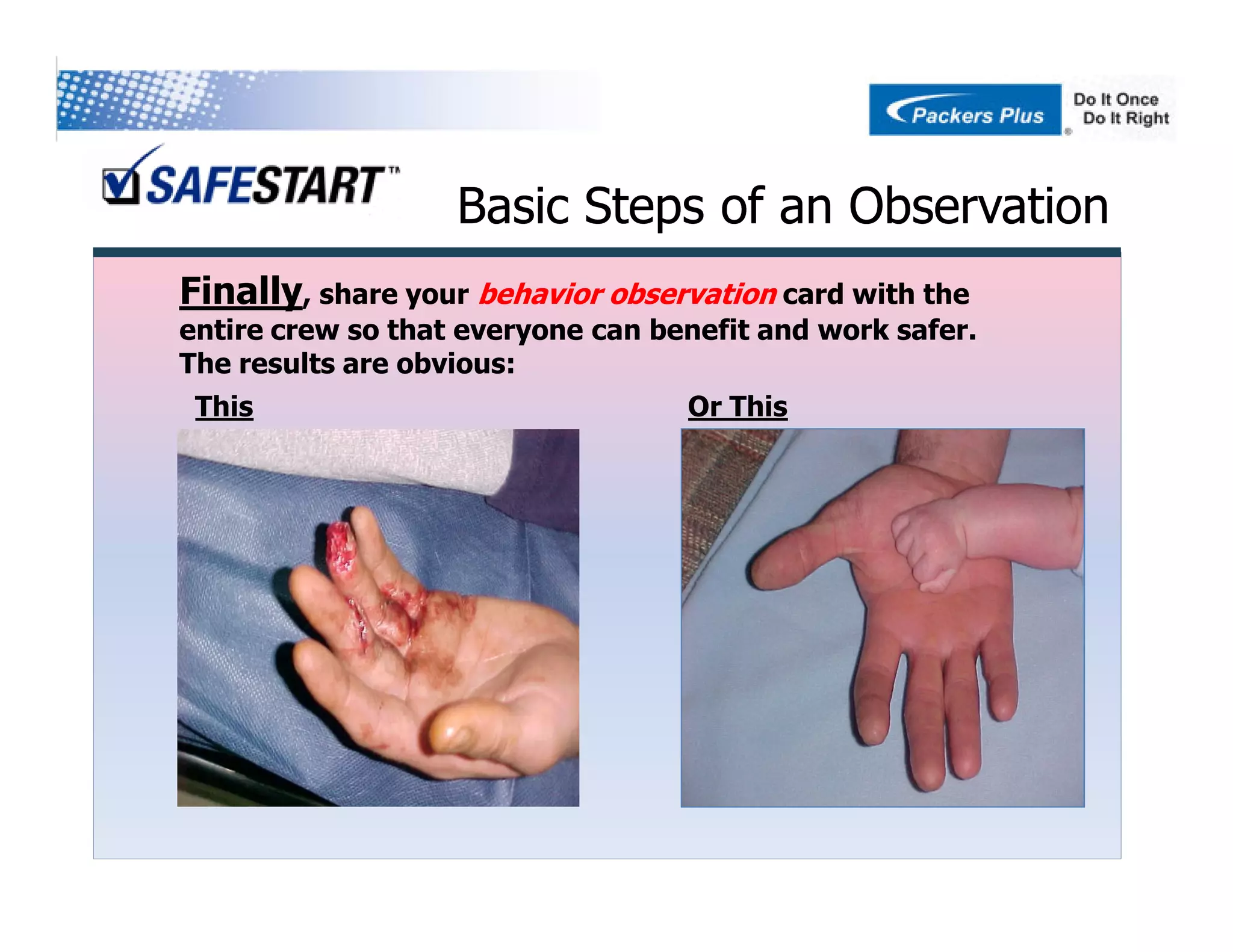

This document provides an overview of a behavioral-based safety observation program. It describes the basics of such a program, which involves employees recording safety observations of each other, with a focus on stopping unsafe work. The core aspects of the program are outlined, including observing behaviors, analyzing for safe and unsafe acts, providing feedback, and reporting observations. A seven-step process for conducting observations is also detailed, covering approaching employees, discussing hazards, agreeing on safer work methods, and documenting the interaction. The goals of the program are to increase hazard awareness and develop safer practices among employees.