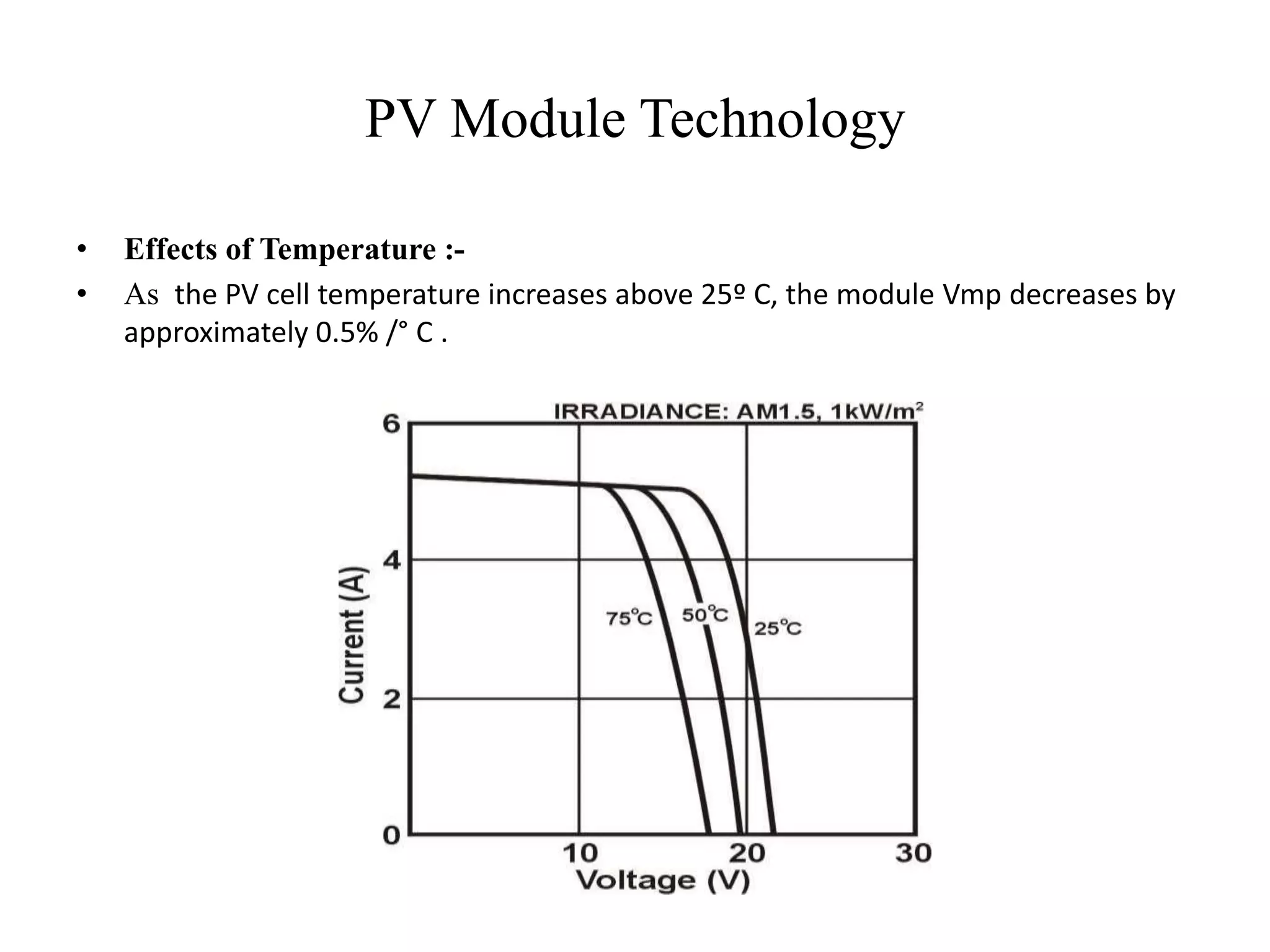

The document discusses the advantages and potential of solar energy as a renewable resource, emphasizing India's ample solar energy availability. It explains the workings of photovoltaic (PV) cells, the different types of solar technologies, their efficiencies, and materials used, including mono and polycrystalline silicon. Additionally, it highlights various applications of solar PV systems across different settings, from residential to commercial uses.