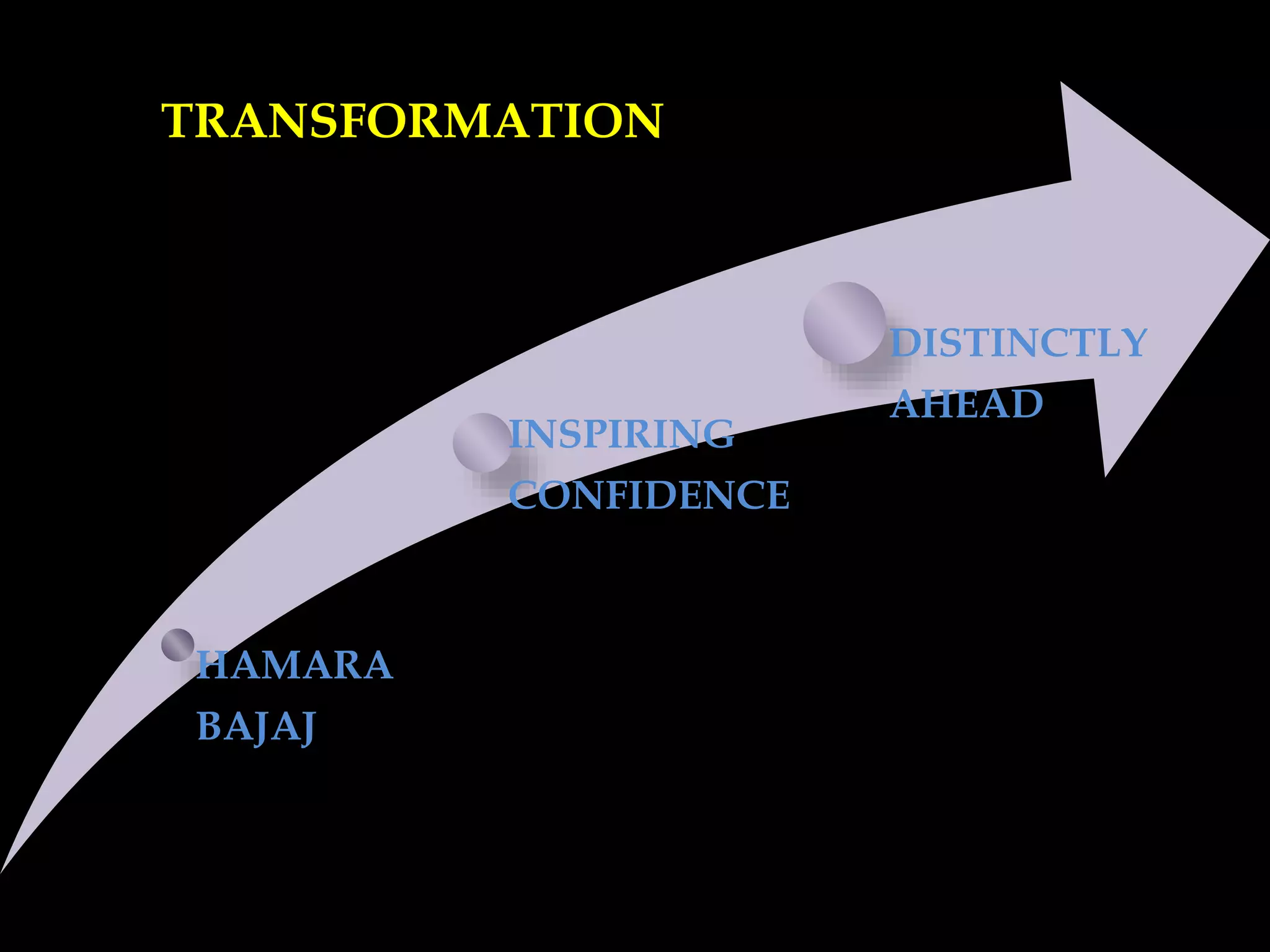

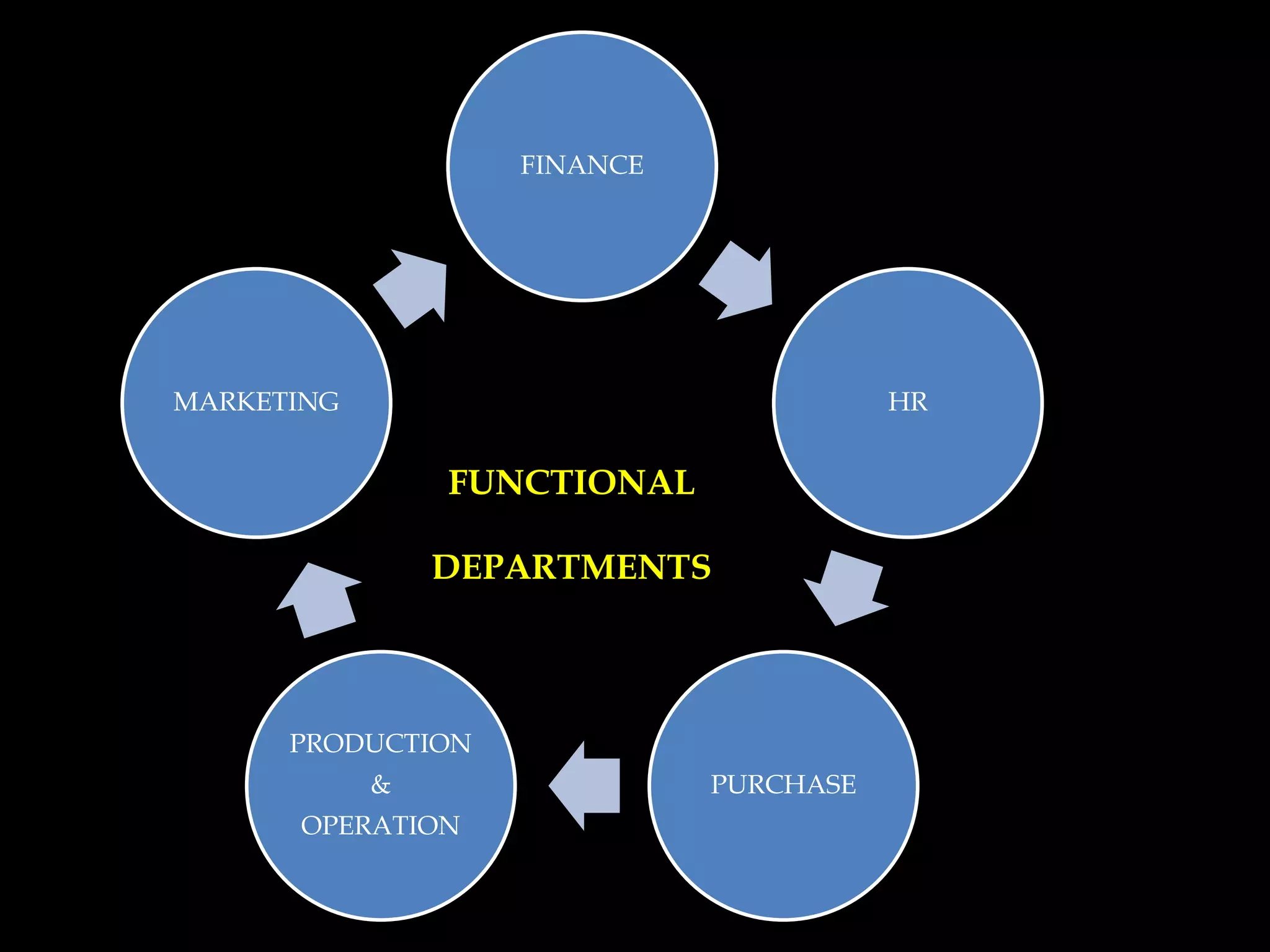

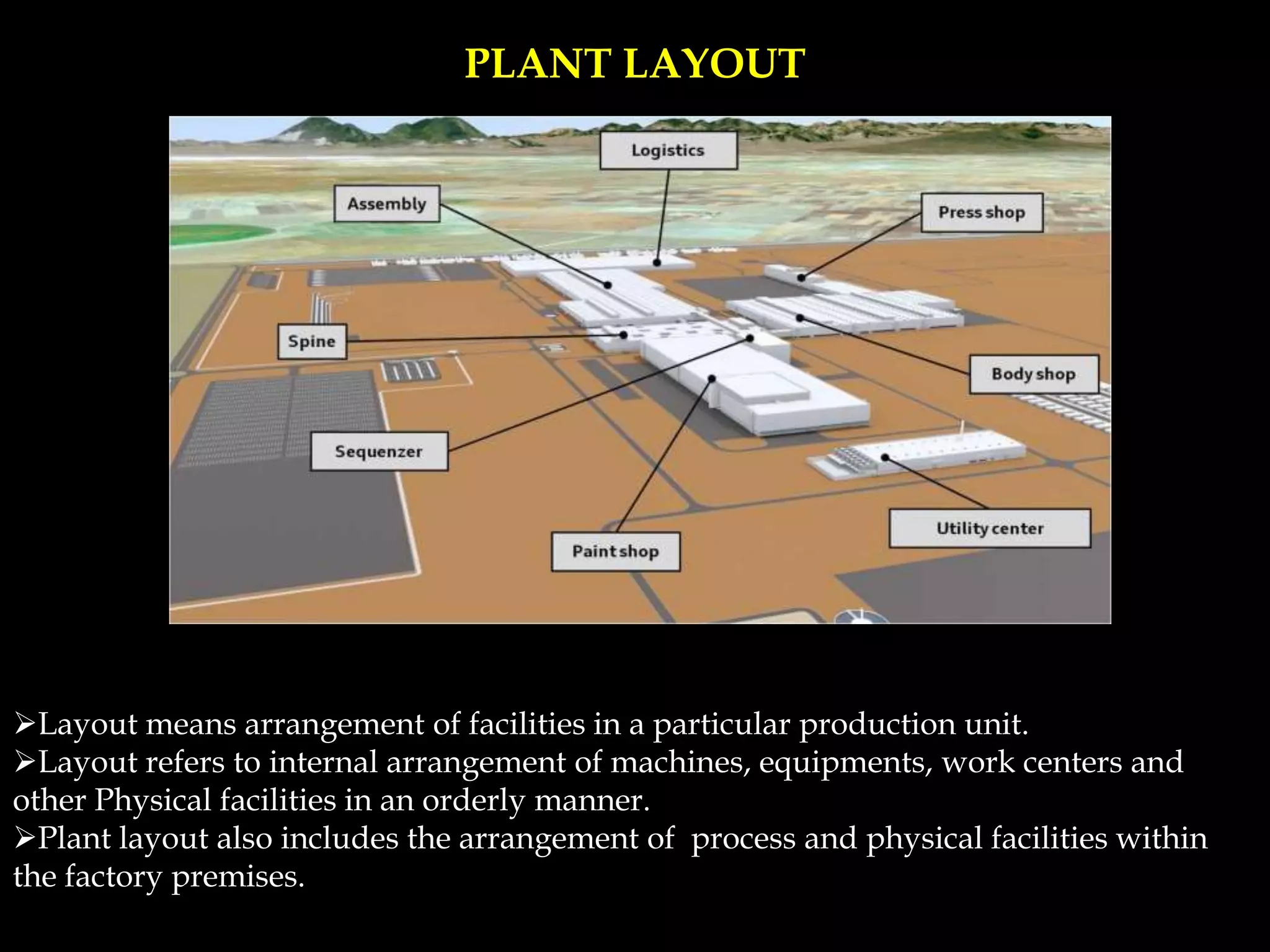

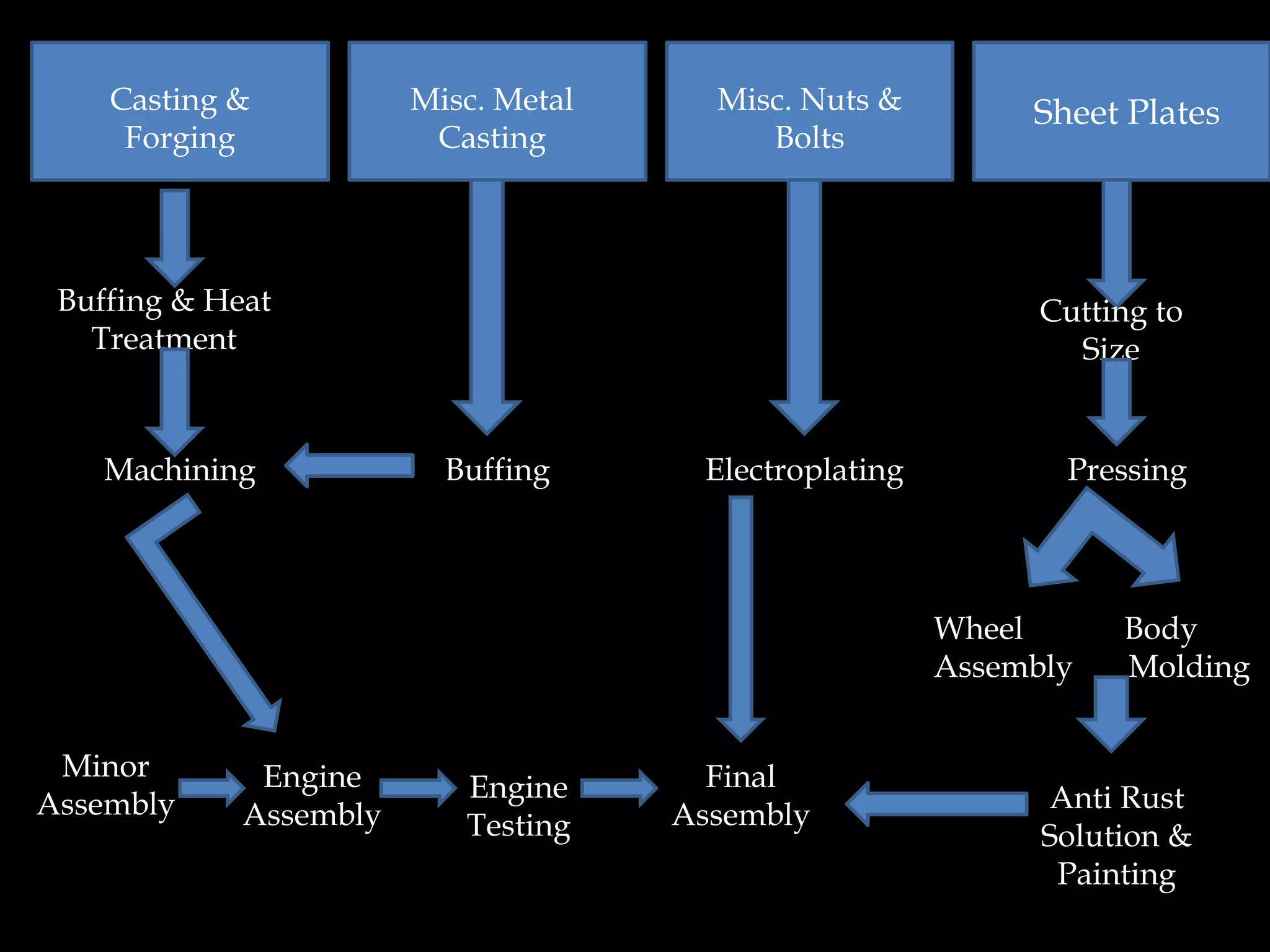

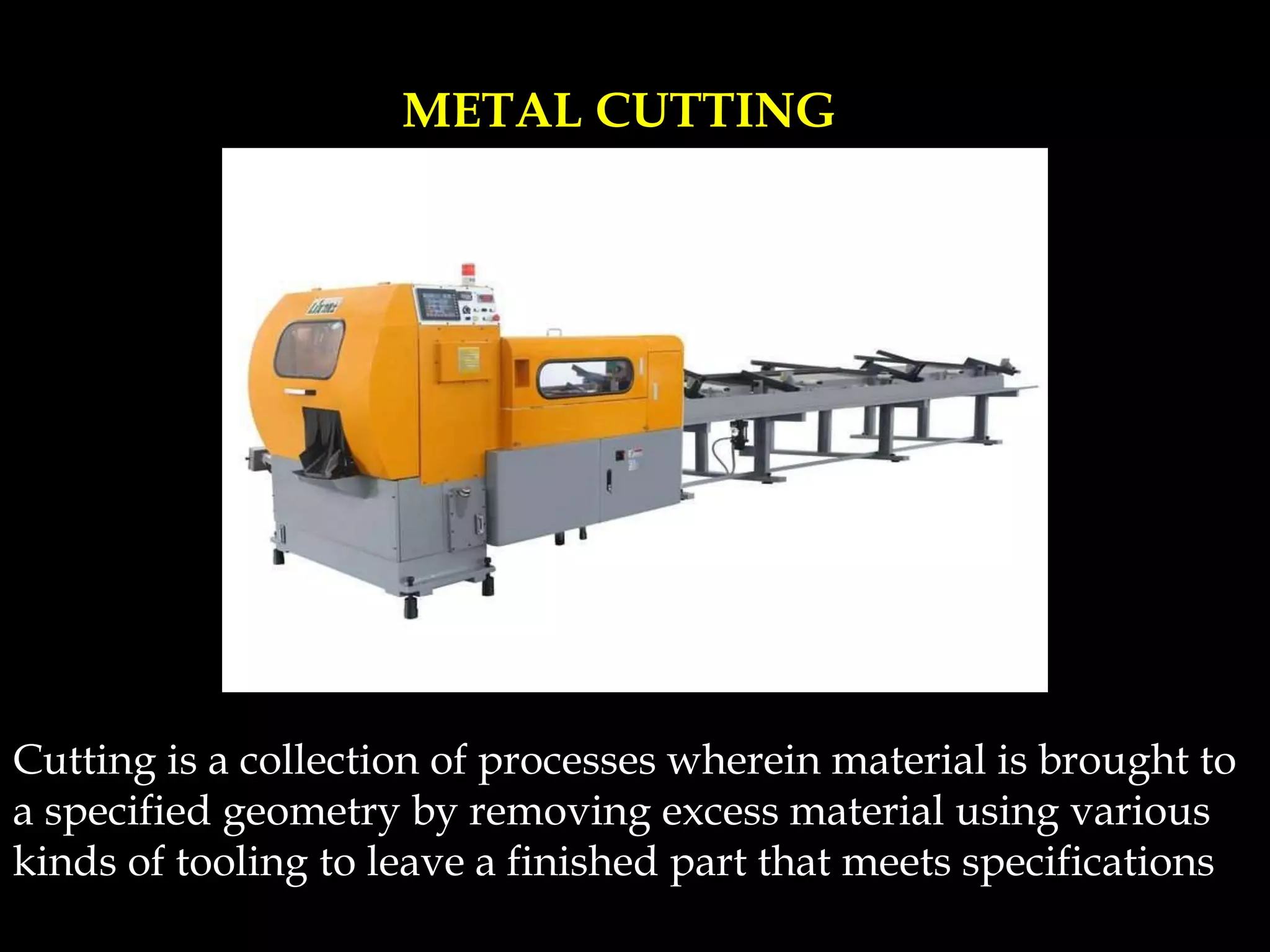

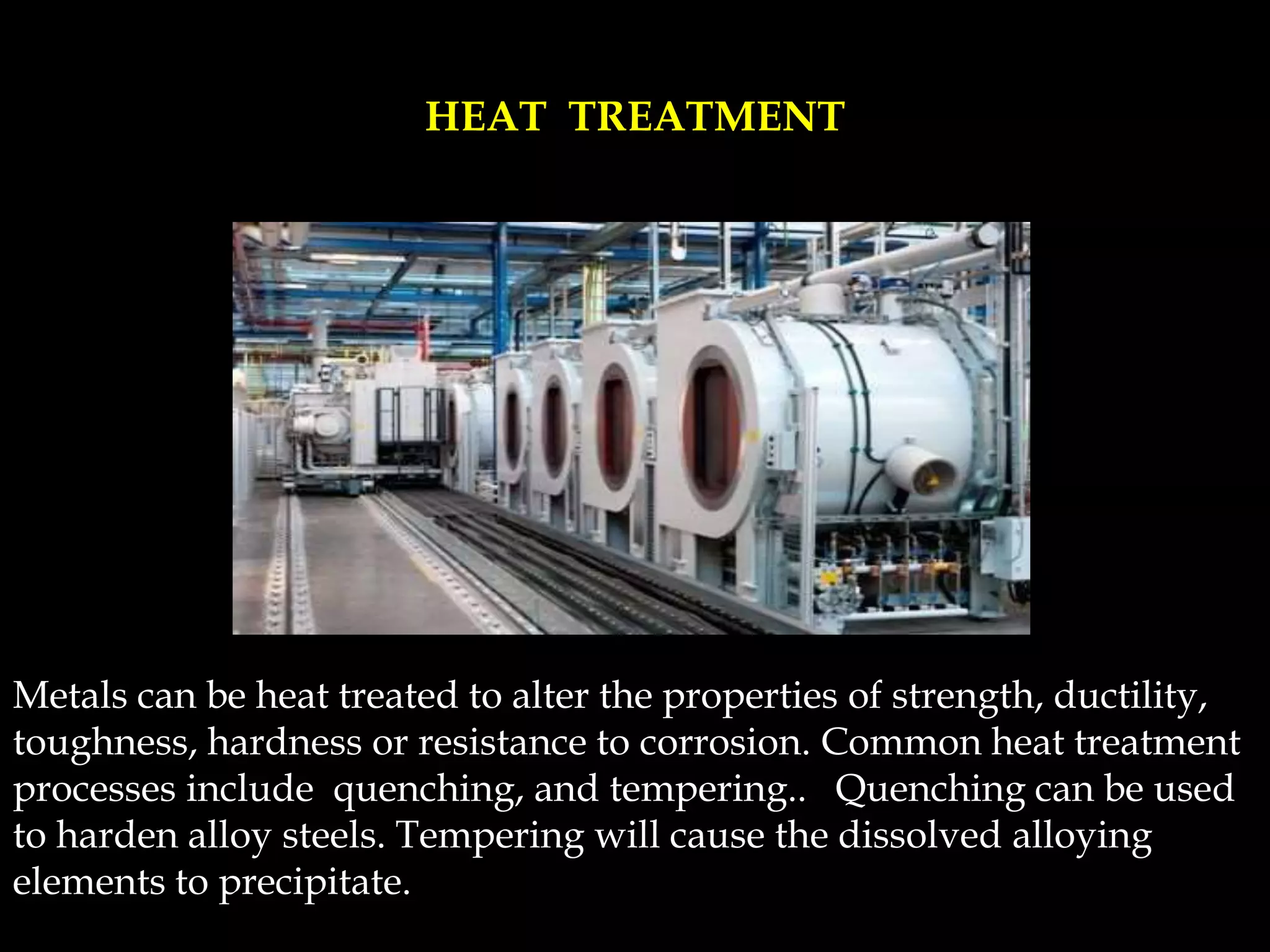

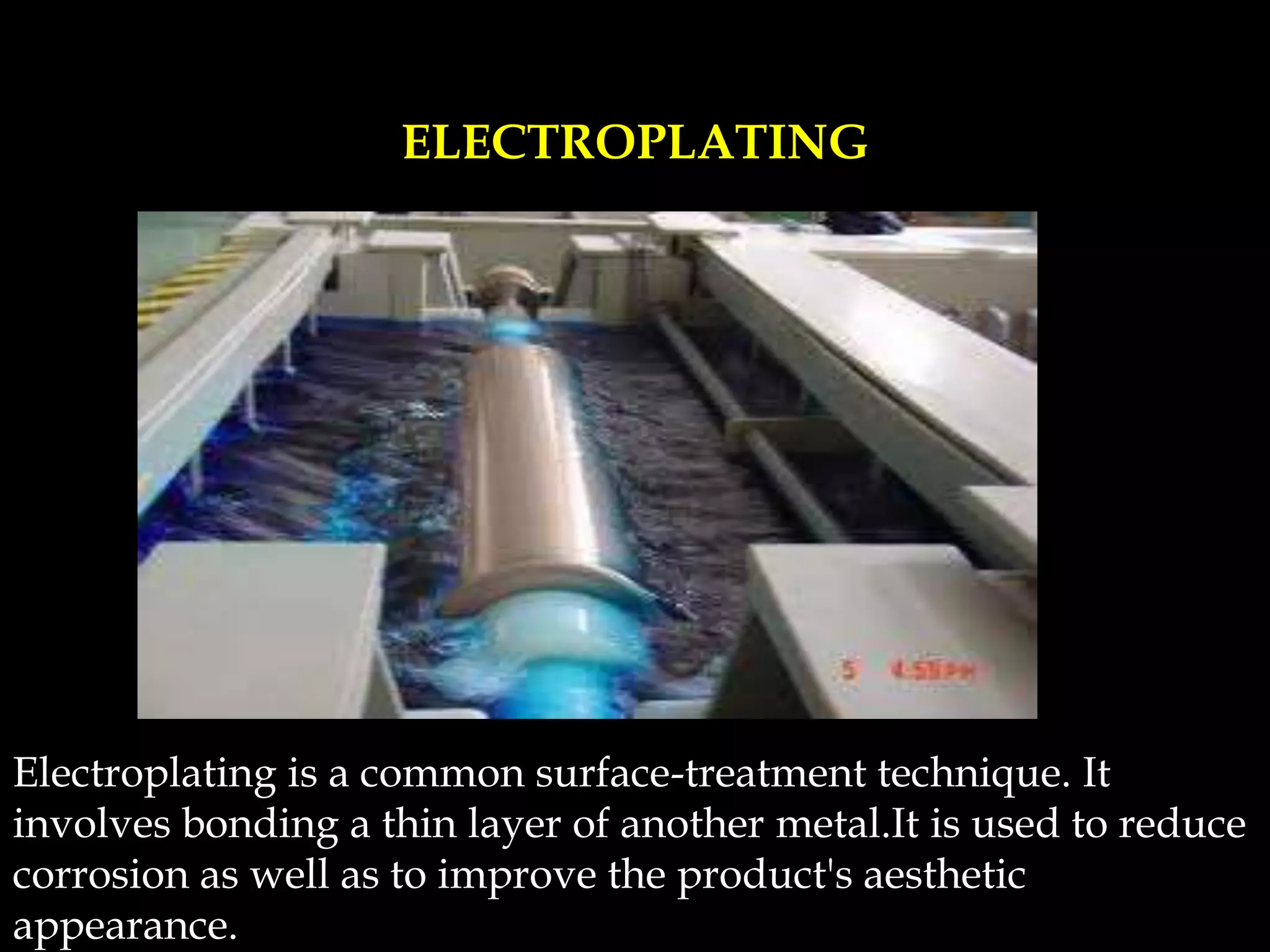

Bajaj Auto was founded in 1926 in India by Jamnalal Bajaj. It focuses on value-based manufacturing of motorcycles, scooters, and auto rickshaws. The company aims to be the largest automobile manufacturer in India through focusing on quality, continuous improvement, and pollution-free production. Bajaj Auto's manufacturing process involves metal cutting, forming, heat treatment, painting, and electroplating to produce vehicles and parts at its plant spread over 906 acres in Waluj, Maharashtra.