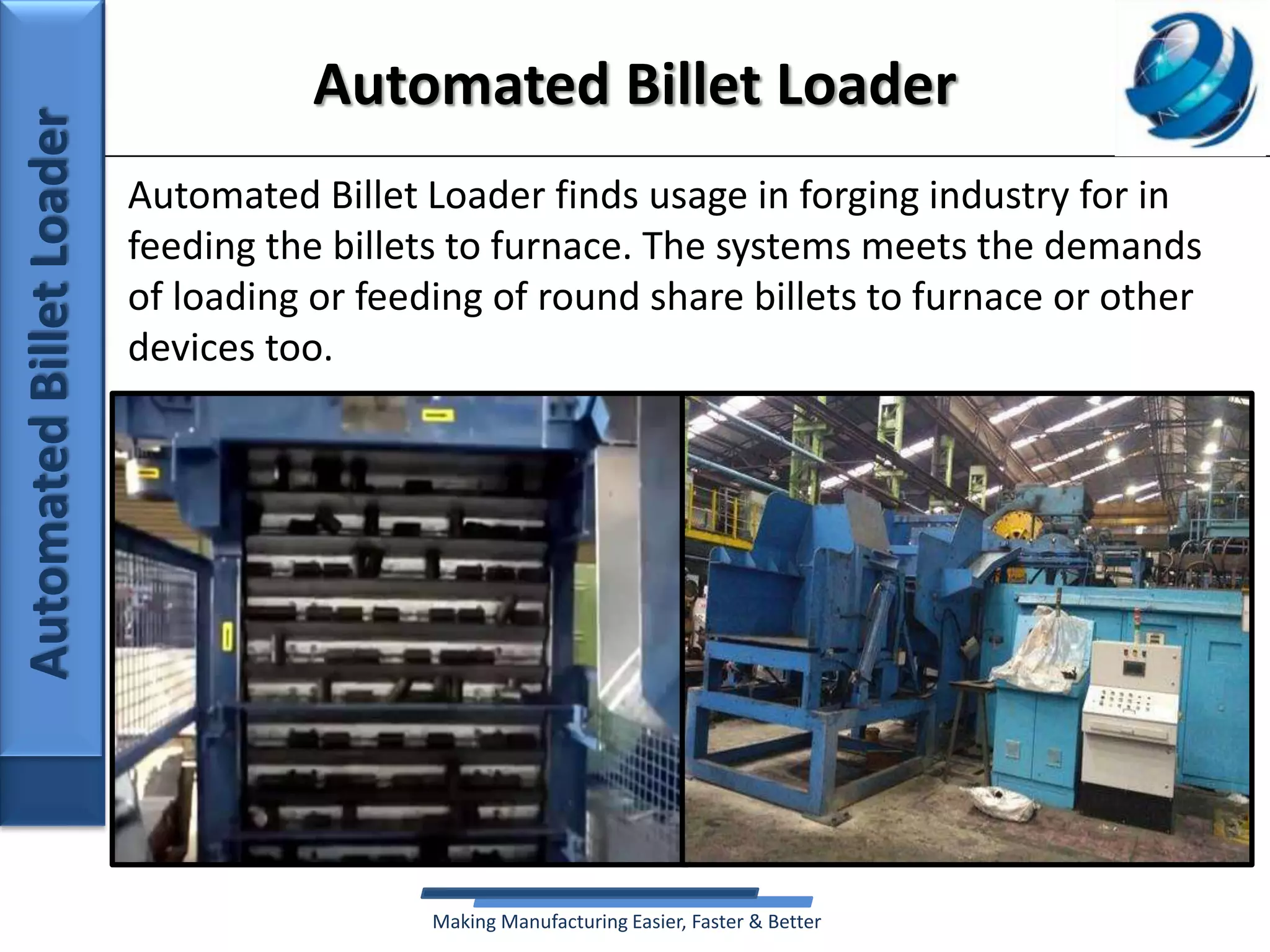

Ingenious provides an automated billet loading solution aimed at improving manufacturing efficiency in the forging industry. The system eliminates the disadvantages of manual loading processes by offering features such as hydraulic operations, automation, and reduced labor dependency. With a cycle time of 7-10 seconds and enhanced consistency in work, the automated system is designed to integrate seamlessly into existing setups.