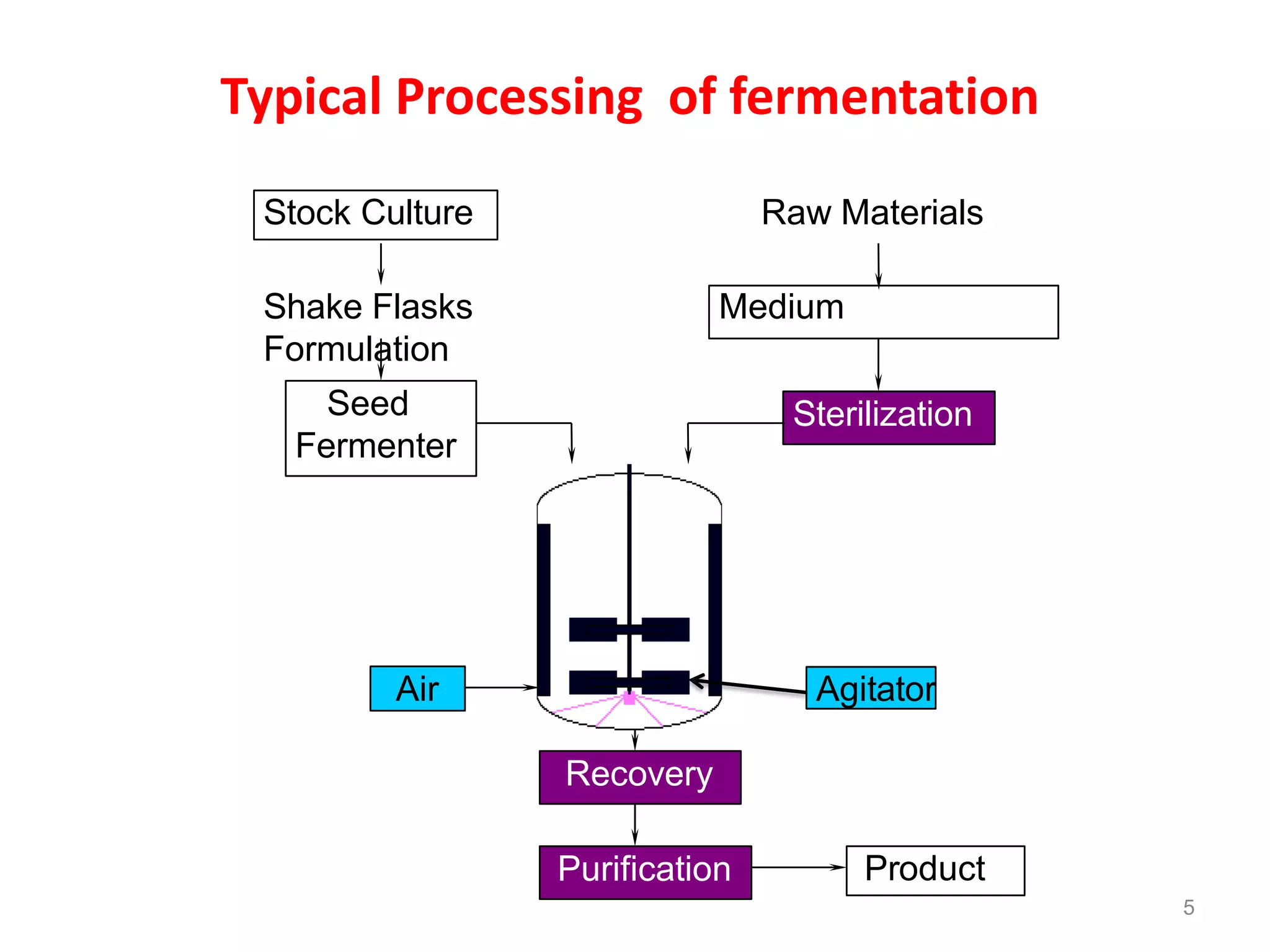

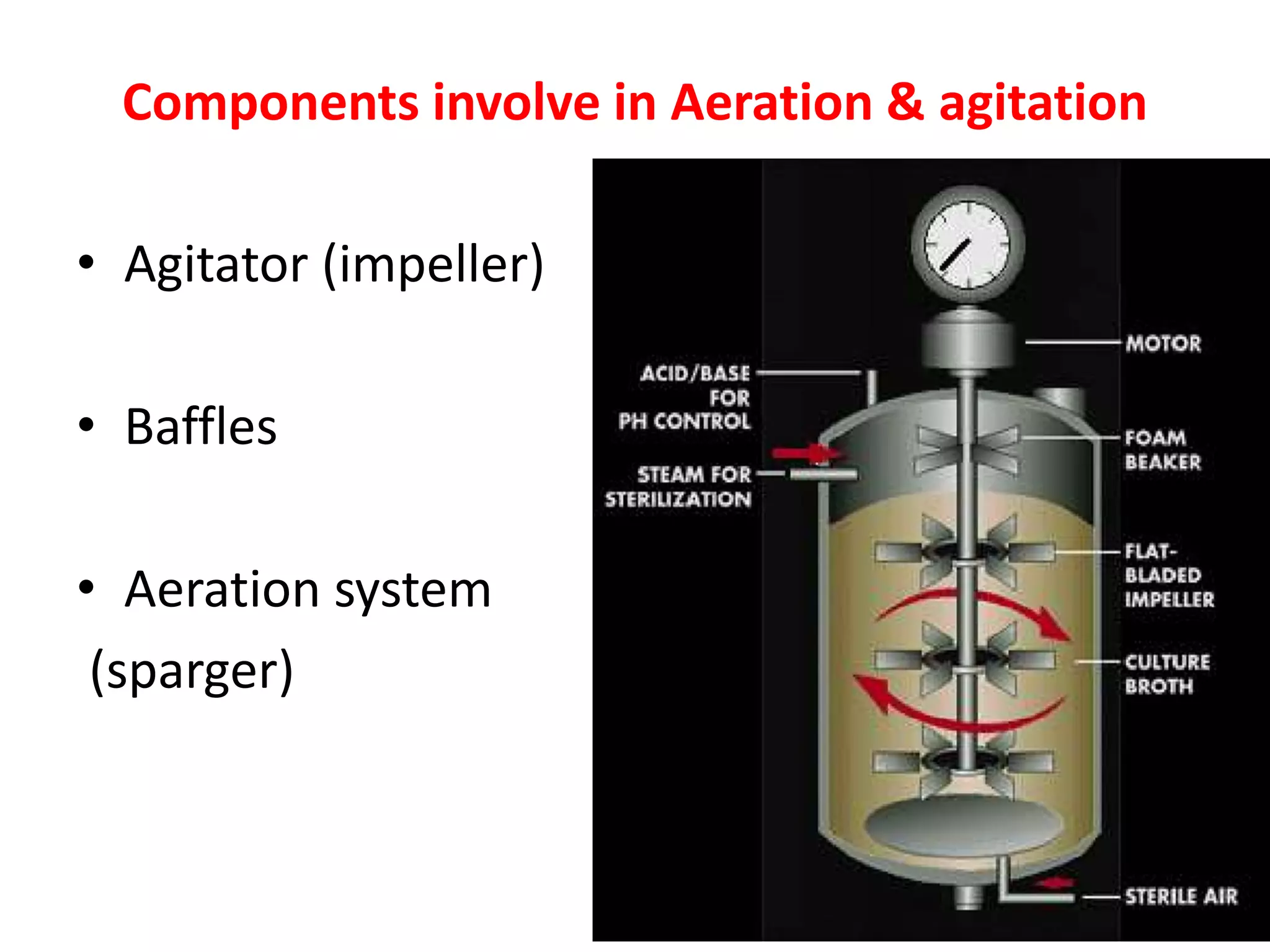

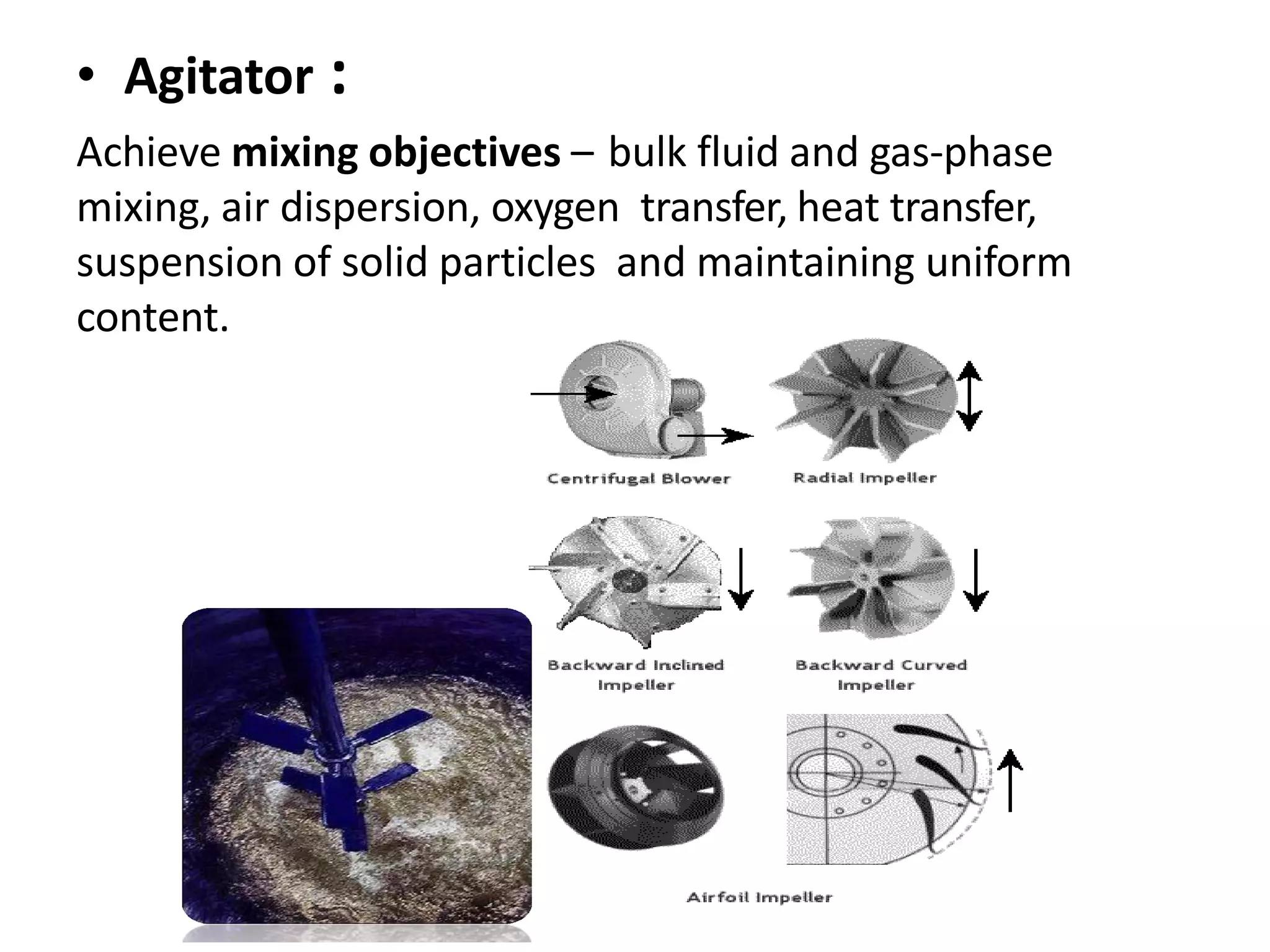

This document summarizes the aeration and stirring process used in fermentation. It discusses how oxygen is required for aerobic fermentation and is supplied through aeration and agitation of the fermentation broth. The key components that enable aeration and mixing are the agitator, baffles, and aeration system. Adequate aeration and mixing is important to disperse air bubbles, suspend cells, and enhance heat and mass transfer. Industrial fermentation processes use stirred tank fermenters to effectively oxygenate and mix large volumes of fermentation broth.