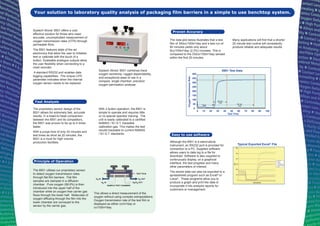

The document summarizes an oxygen permeation analyzer called the 8501. It features advanced digital electronics, automated test routines, data logging capabilities, and accuracy traceable to standards. The 8501 offers a cost-effective solution for measuring oxygen transmission rates through permeable films. It features easy operation, with tests taking as short as 20 minutes. The analyzer is compact, precise, and rugged for high volume production facilities.