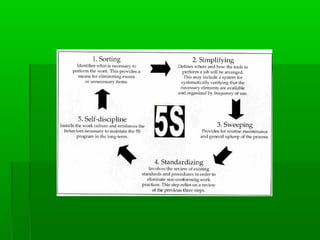

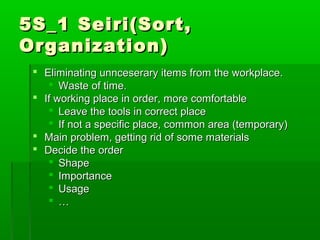

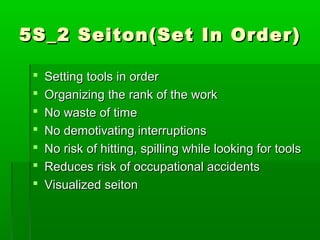

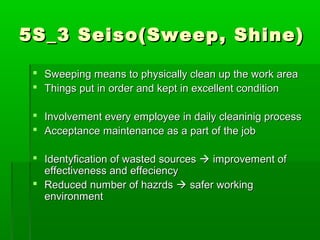

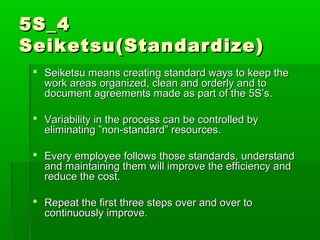

The document discusses the 5S methodology for organizing and standardizing the workplace. It describes the 5S steps of seiri (sort), seiton (set in order), seiso (sweep), seiketsu (standardize), and shitsuke (sustain). Implementing 5S creates a clean, organized workplace that improves efficiency, safety, and employee ownership. Proper communication, training, and management support are needed to successfully adopt the 5S system in an organization.