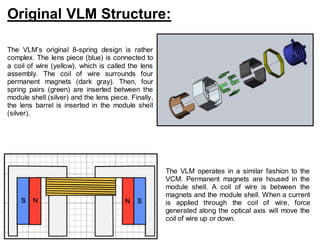

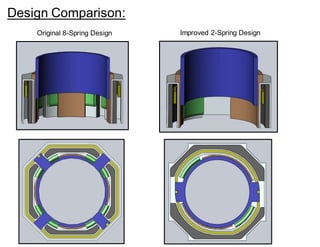

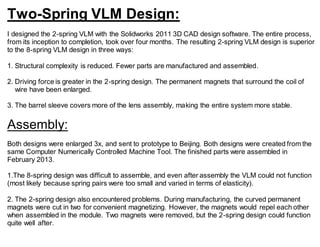

The document describes the design and testing of a two-spring vibrating linear motor (VLM) intended to improve upon an original eight-spring design. The original design was difficult to manufacture and assemble due to its complexity. The author designed a simpler two-spring VLM using CAD software and had prototypes manufactured. During testing, the eight-spring VLM could not be assembled or function properly, while the two-spring design worked reliably though with some minor modifications during assembly. The document concludes the two-spring design is superior due to lower manufacturing costs and improved reliability.