The document discusses electron microscopy, detailing its principles, types, and specimen preparation methods. It explains two main types: Transmission Electron Microscope (TEM) and Scanning Electron Microscope (SEM), highlighting their working mechanisms, advantages, and disadvantages. The document emphasizes their applications in various scientific fields and outlines the required sample preparations, including dehydration and staining techniques.

![MICROSCOPY 1

ELECTRON MICROSCOPE

Electron beam is the source of illumination.

Image is produced by magnetic field.

Contrasting features between light microscope and electron microscope are

construction, working principle, specimen preparation, cost-expenses and designed

room (vacuum chamber).

ELECTRON

Electrons are sub-atomic particles around the nucleus with negative charge.

Electrons have high velocity and shorter wavelength about 0.05 A0 [105K times shorter

than wavelength of visible light- 5500 A0]

Shorter the wavelength, higher is the resolution.

Electrons are sensitive to magnetic field.

In 1924, BROGLIE proposed Dual nature of electrons (wave and particular)

PRINCIPLE OF ELECTRON MICROSCOPE

A vacuum chamber with heating metal filament such as tungsten [at about ~6000volts]

generates electron rays. Multiple electro-magnetic lenses i.e., the copper wires coiled

around hallow cylindrical tube induces electromagnetic field during current flow and

converts electron rays into electron beam. Electron beam is similar to light rays, but

have shorter wavelength. Electron beam on interaction with atoms of the biological

sample produces image and is displayed on fluorescent screen. Faster the electron

moves, shorter the wavelength and greater is the image quality.

TYPES OF ELECTRON MICROSCOPE

1. Transmission Electron Microscope [TEM]

2. Scanning Electron Microscope [SEM]

TRANSMISSION ELECTRON MICROSCOPE [TEM]

The Transmission Electron Microscope [TEM] was first type of Electron Microscope.

TEM was developed by MAX RUSKA in 1931 and was awarded Nobel Prize for Physics

in 1986.

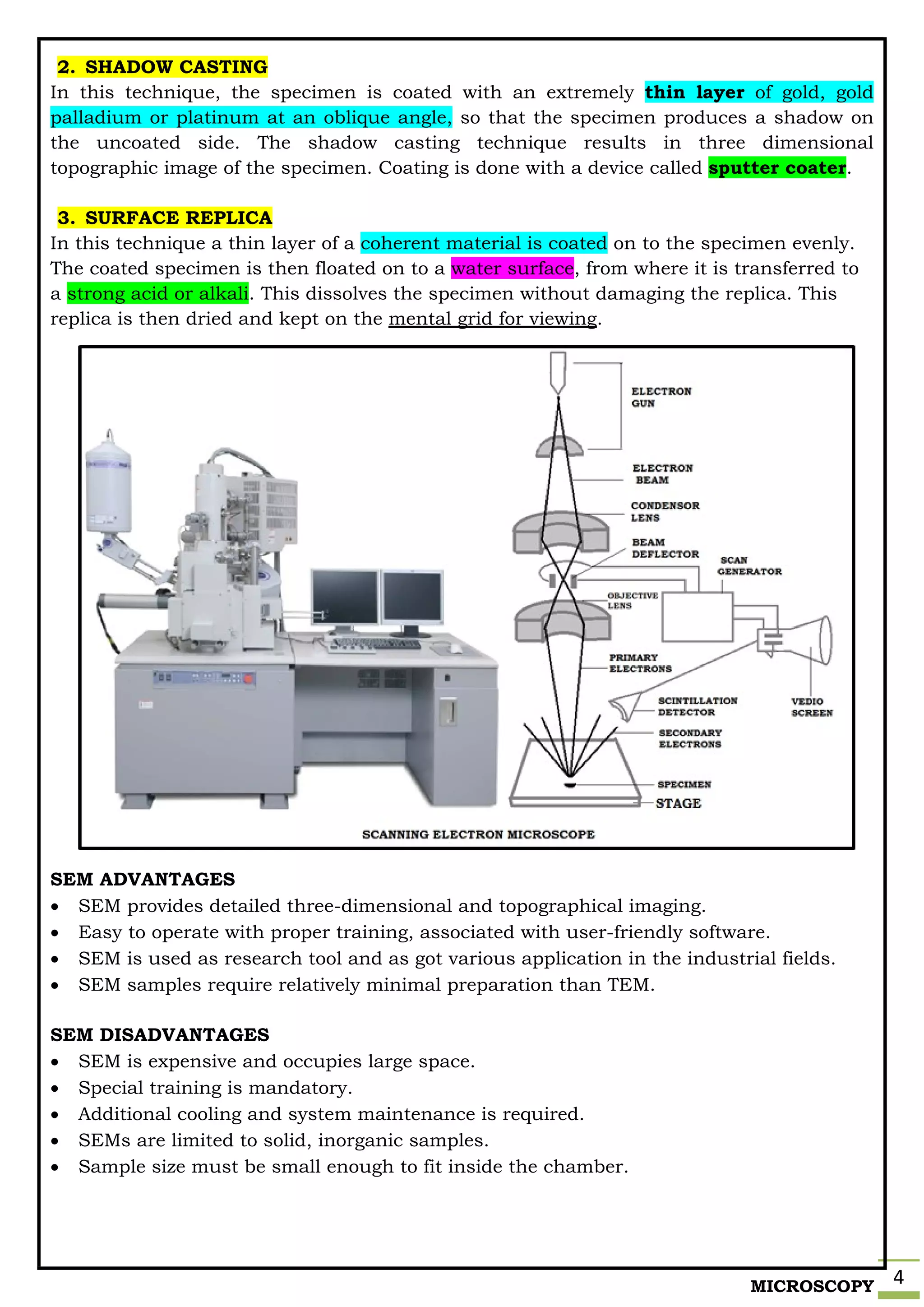

WORKING PRINCIPLE

Electron generator is the source of illumination with a tungsten filament. When heated

by electric current, it emits a stream of electrons. The stream of electrons is directed

through anode aperture into a condenser lens system. The condenser lens system (1st

electromagnetic coils) adjusts the beam and guides the beam towards the specimen. As

the electron beam passes through the specimen placed below the condenser, electron

beam is scattered depending on the varying refractive index of the specimen. From the

specimen, the beam of electrons passes through objective/intermediary lens (2ndset of

electromagnetic coils) forming an intermediary image. The projection lens(3rdset of

electromagnetic coils) produces final image and is projected on a fluorescent screen/

photographic plate.](https://image.slidesharecdn.com/5-210528083125/75/5-Microsocope-ELECTRON-MICROSCOPE-TEM-SEM-Basics-1-2048.jpg)

![MICROSCOPY 3

TEM ADVANTAGES

TEM provides most powerful magnification.

TEM offers detailed and high quality image.

They are easy to operate with proper training.

TEM is ideal for a number of different fields such as life-sciences, nanotechnology,

medical, biological and material research, forensic analysis, gemology and metallurgy.

TEM provides topographical, morphological, compositional and crystalline information.

TEM DISADVANTAGES

TEMs are large and very expensive.

Dehydration may alter morphological features dealing to mis-interpretation.

Requires large, special housing and maintenance.

They are expensive and as laborious sample preparation

Images are black and white.

Operation and analysis requires special training.

SCANNING ELECTRON MICROSCOPE [SEM]

Scanning Electron Microscope [SEM] was developed by DENNIS MC MULLAN (PhD

student - England) and CHARLES OUTLAY (Engineer) in 1948.

SEM generates an image by scanning the specimens with a beam of electrons and

enables topographical study of the specimen surface.

NOTE: The path of the electron beam within SEM differs from that of the TEM.

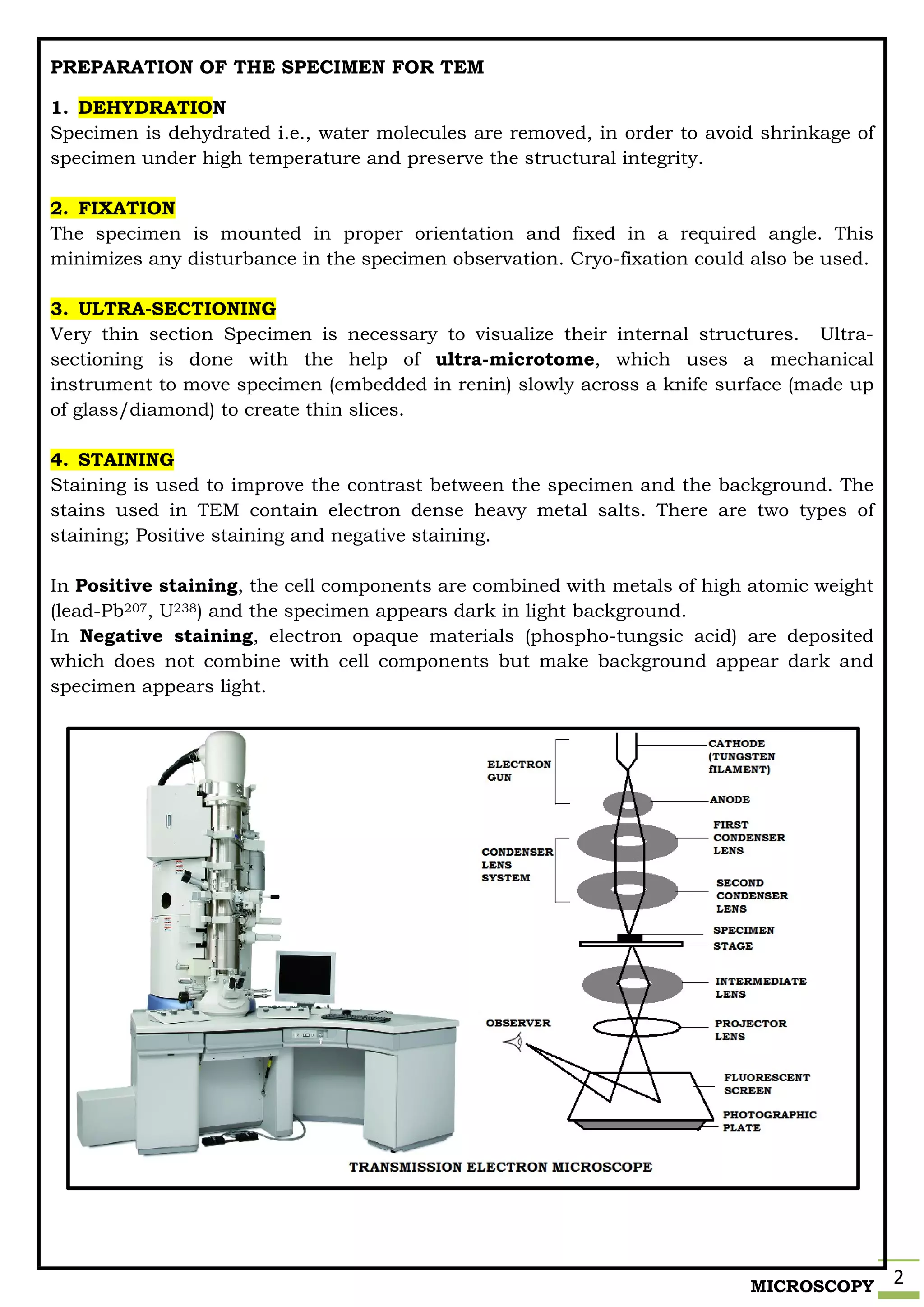

WORKING PRINCIPLE

Electron gun is the source of illumination in a vacuum chamber that produces a stream

of electrons and is directed into a condenser lens, thus generating the narrow electron

beam. Rapidly moving electron beam passes through the beam deflector, enters the

objective lens and primary electron beam is created. The primary electron beam strikes

the specimen, the surface atoms discharge shower of second electrons and are called as

Secondary electrons. The secondary electrons are collected by a Scintillator detector

(composed of scintillator and photomultiplier) which generates an electronic signal.

These signals help in the formation of the final image on a CRT/Video screen. The

secondary electrons emitted from each point on the specimen are characteristic of the

surface. The image on the screen thus reflects the composition and topography of the

specimen surface. This image gives a three-dimensional appearance.

PREPARATION OF THE SPECIMEN FOR SEM

1. DEHYDRATION

SEM allows observing the surface topography. So, dehydration is achieved by critical

point drying which minimizes artifact formation (disturbance in surface configuration).

In critical point drying, at a particular temperature and pressure the liquid changes to

gas without any surface tension damage to the specimen. The specimen is first immersed

in ethanol or acetone to remove water and then in pressurized liquid of CO2.

Simultaneously, rising the temperature above 320C (the critical point of CO2). At this

temperature, the liquid vaporizes without surface tension leaving the specimen perfectly

dry.](https://image.slidesharecdn.com/5-210528083125/75/5-Microsocope-ELECTRON-MICROSCOPE-TEM-SEM-Basics-3-2048.jpg)