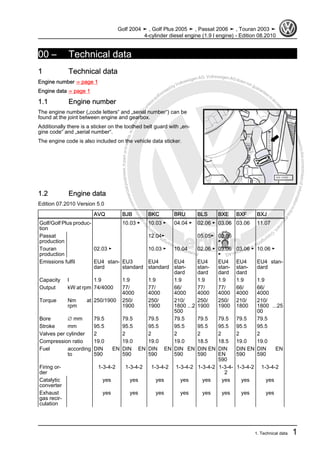

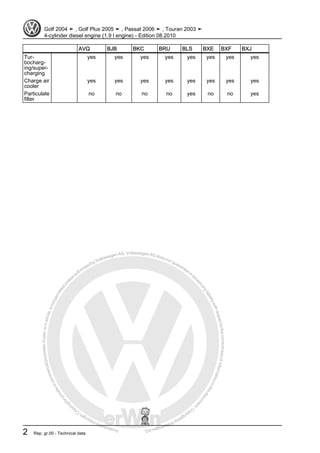

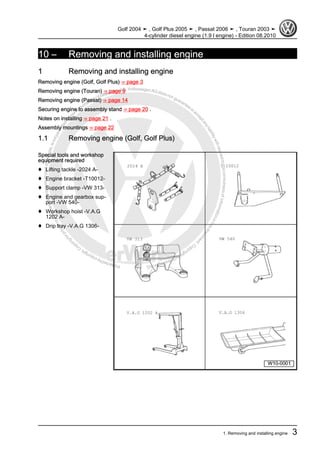

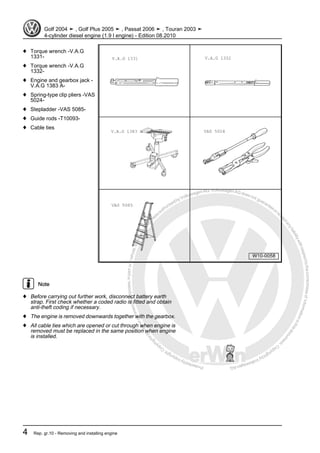

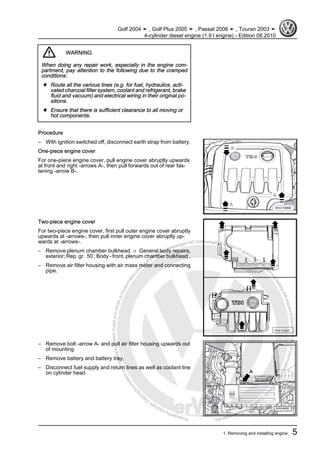

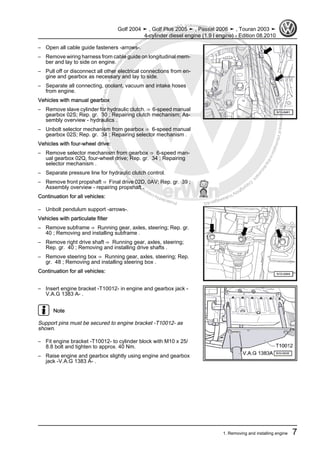

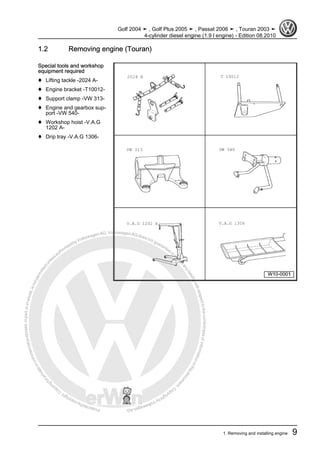

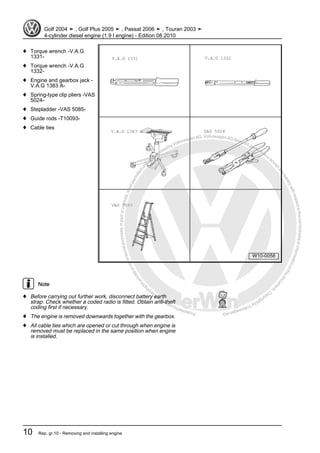

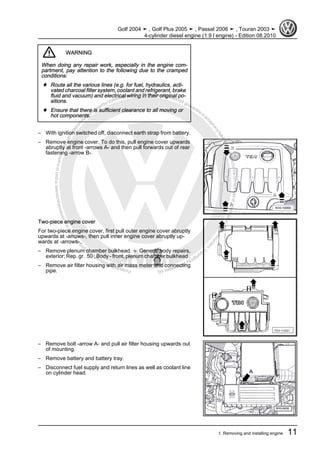

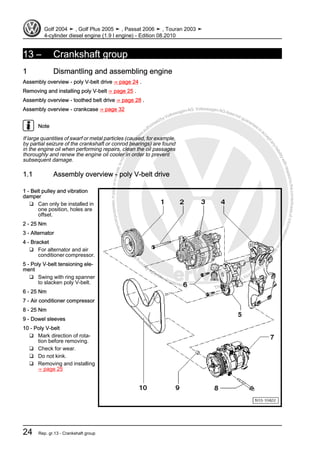

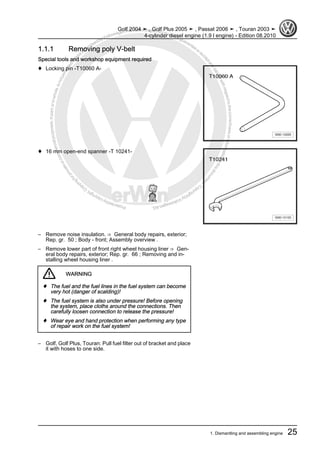

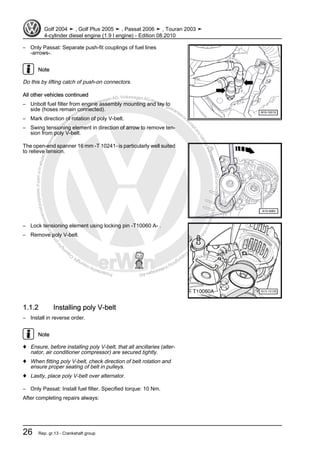

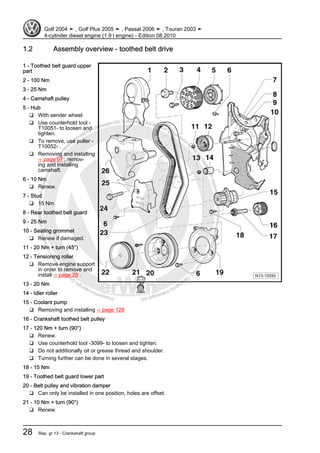

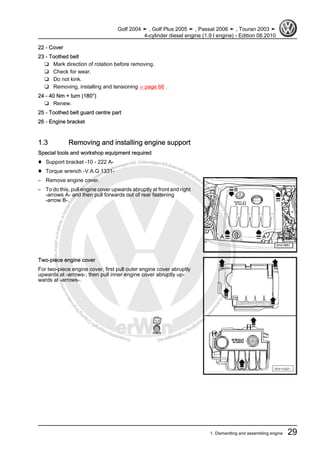

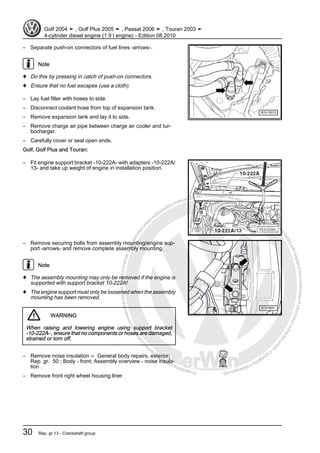

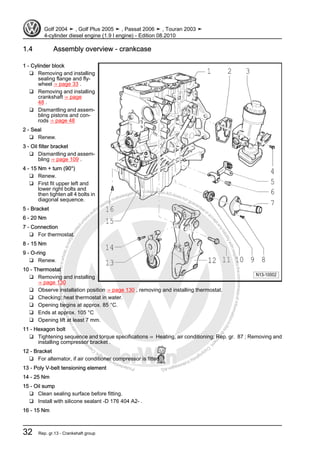

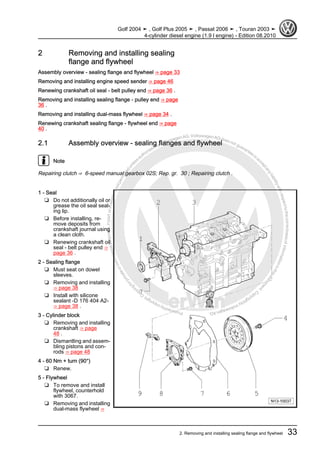

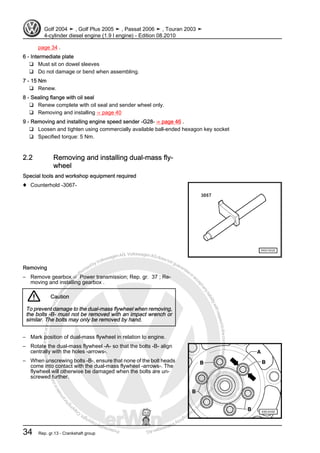

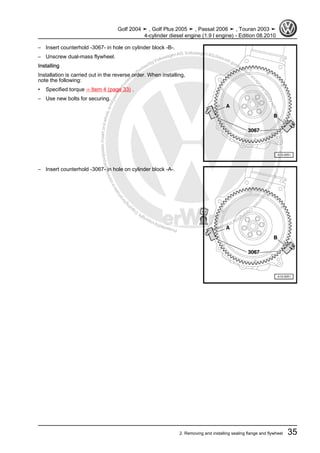

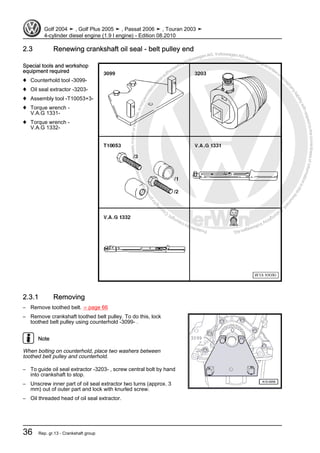

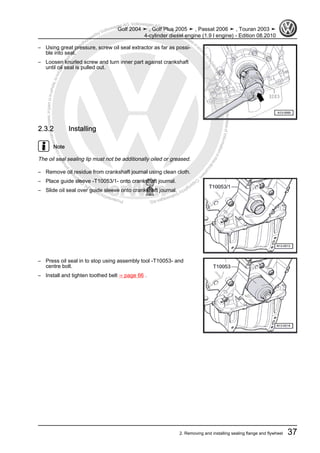

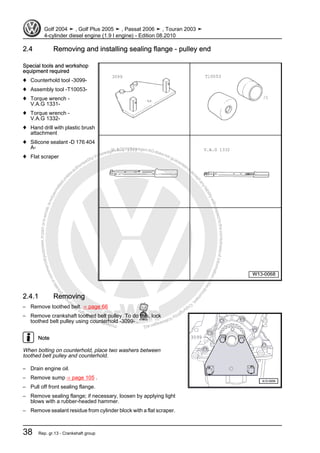

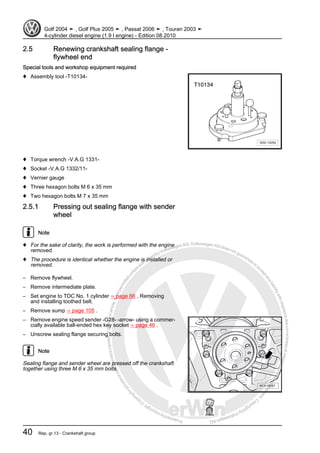

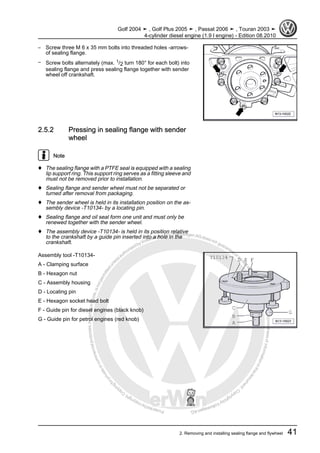

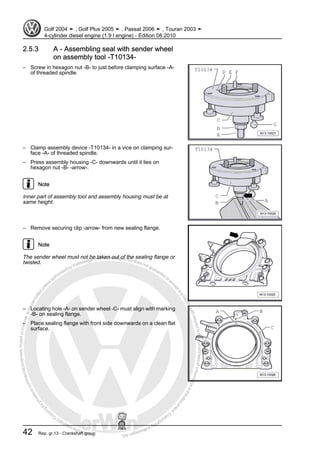

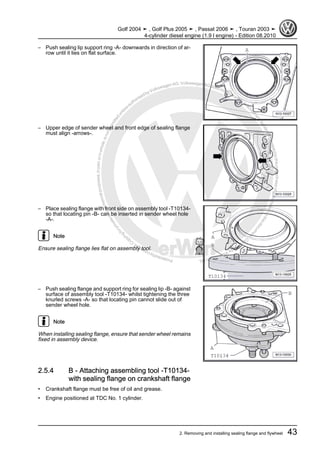

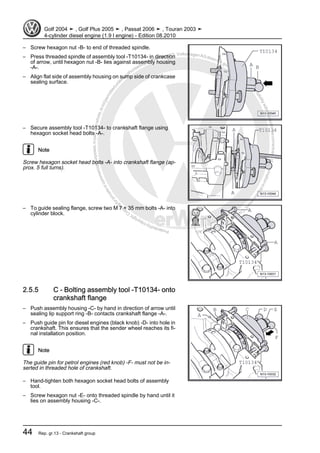

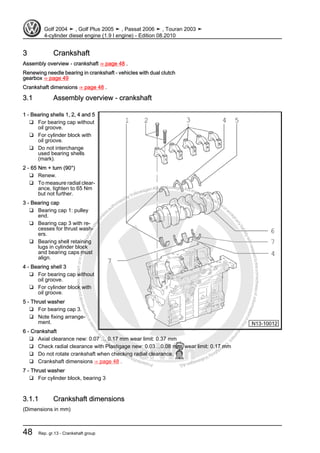

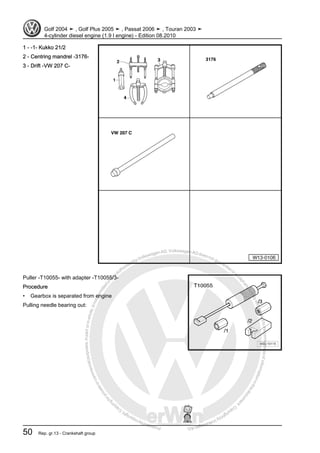

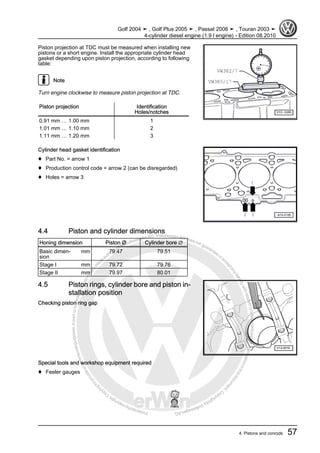

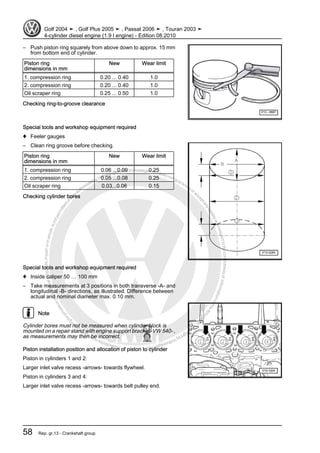

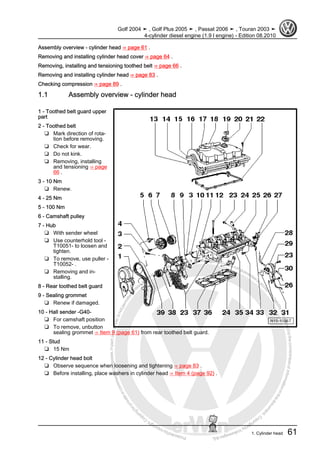

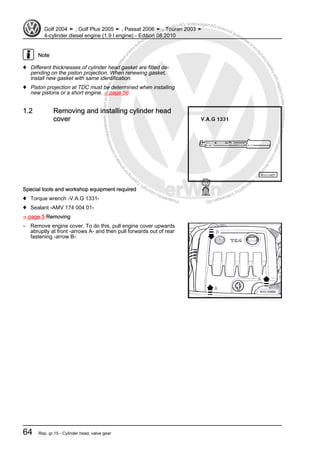

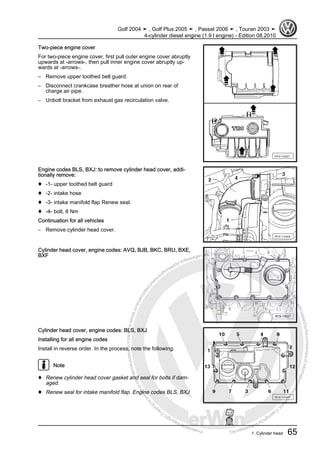

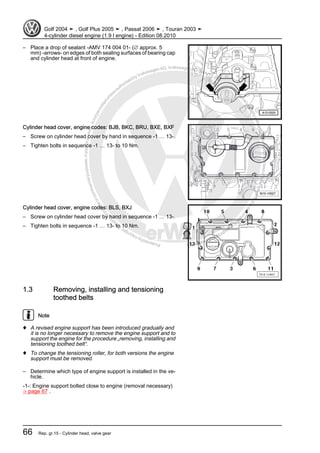

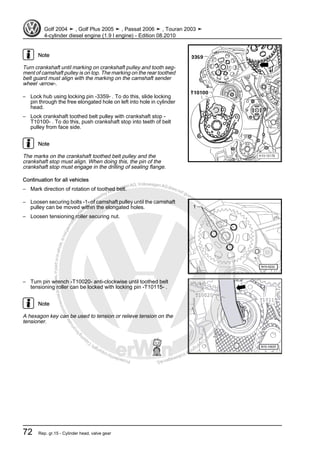

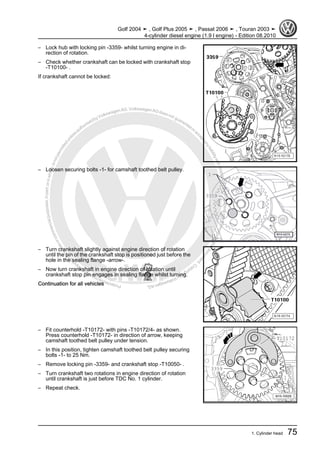

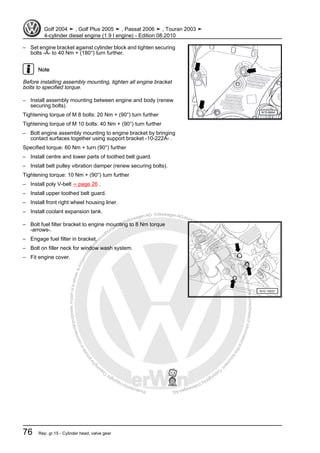

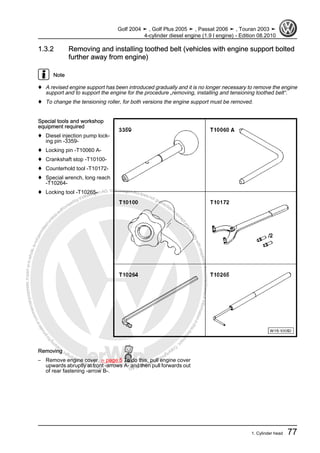

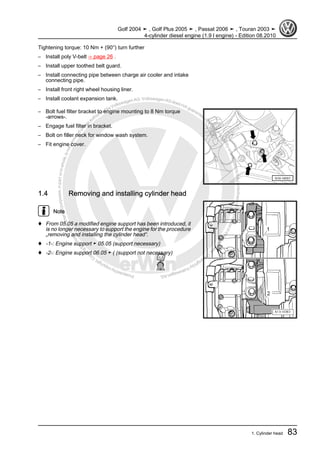

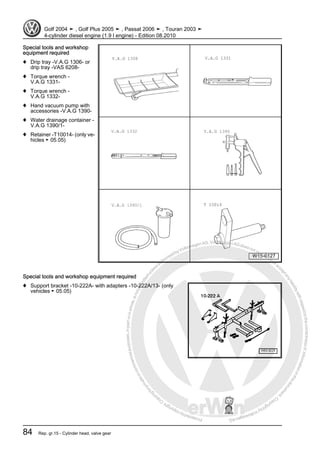

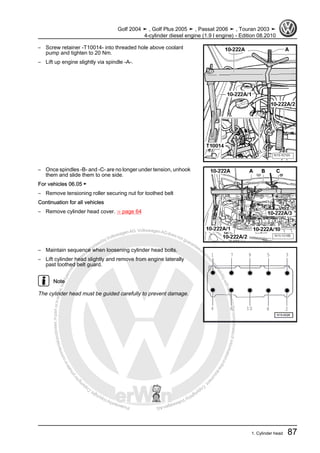

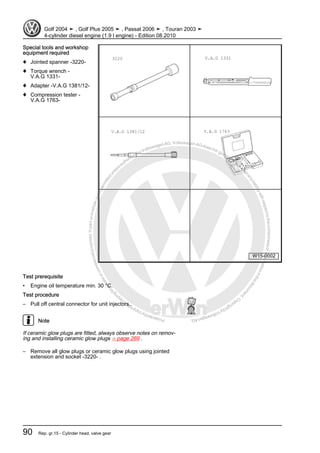

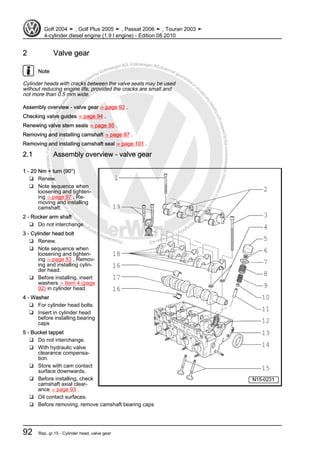

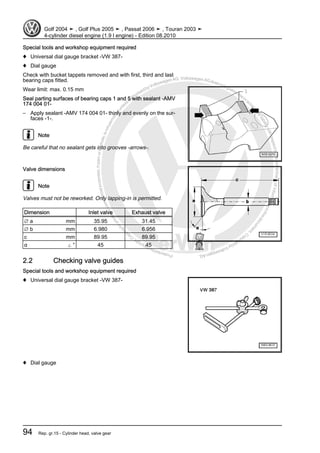

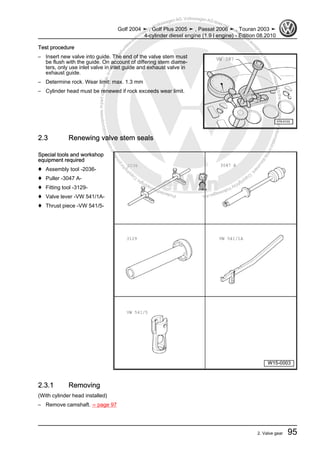

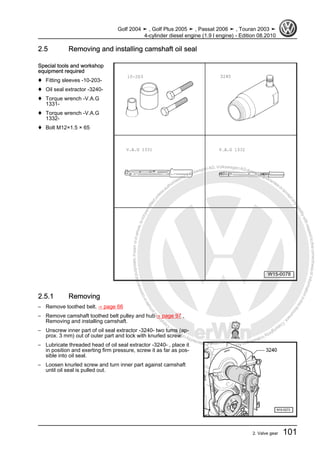

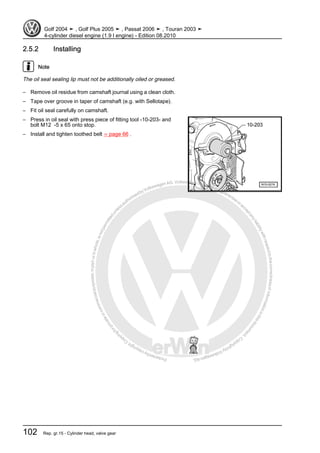

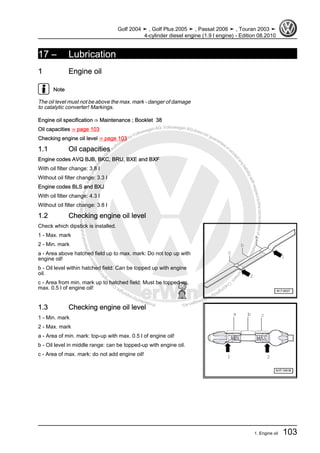

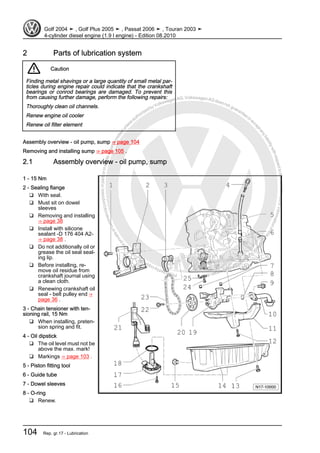

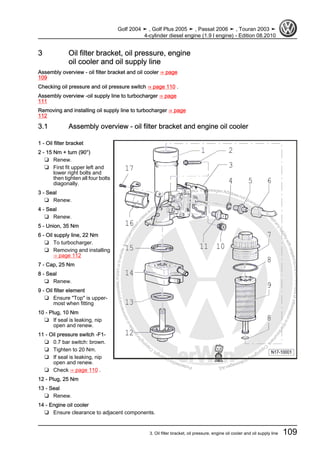

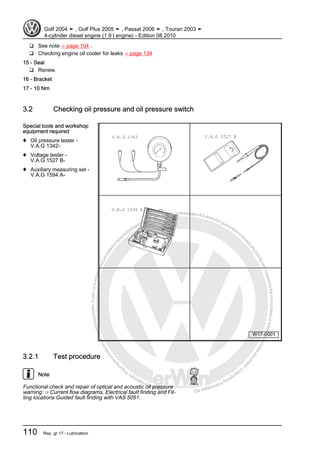

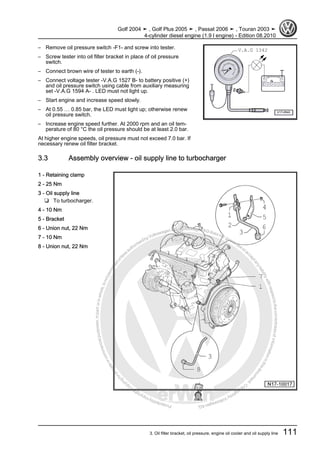

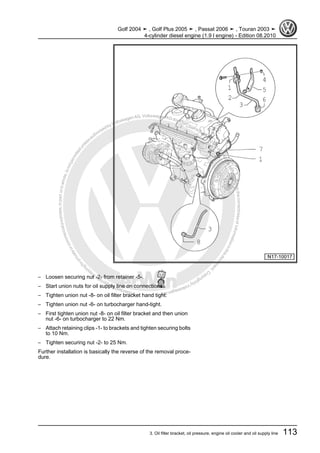

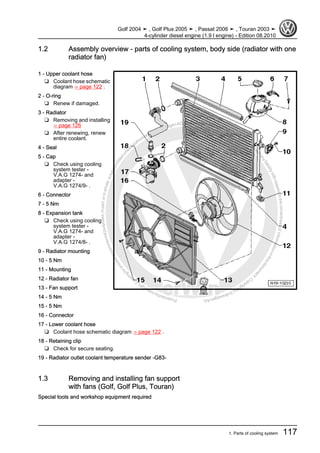

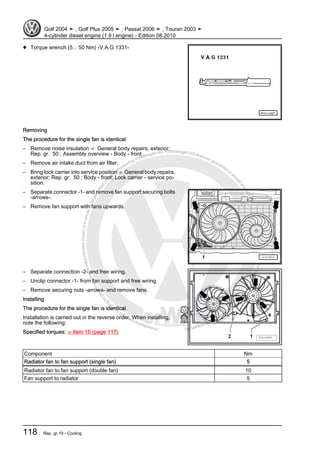

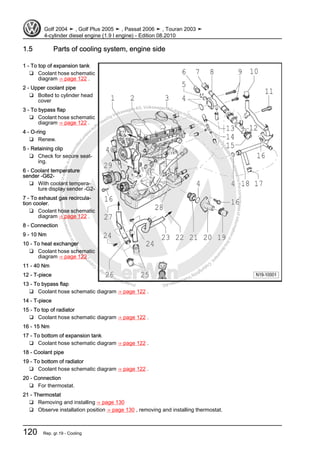

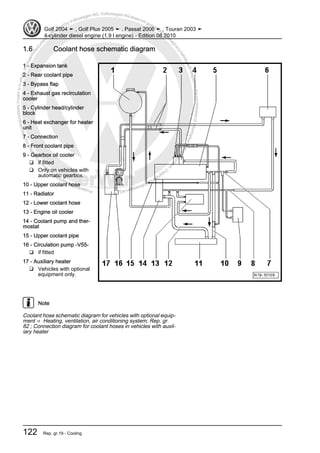

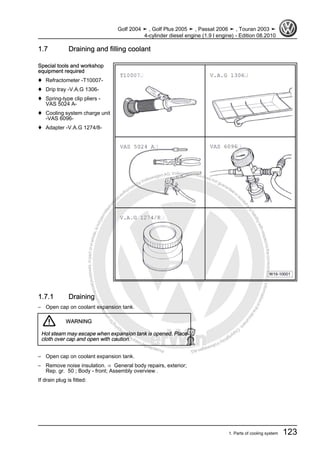

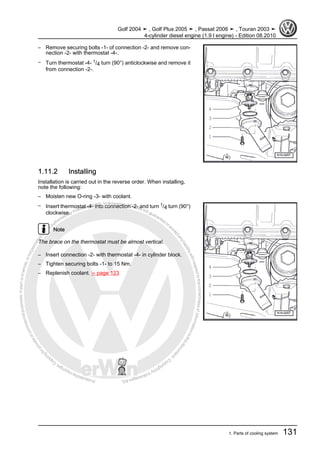

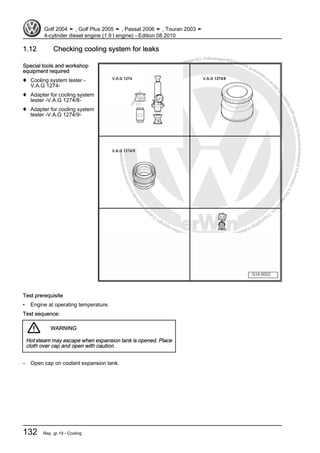

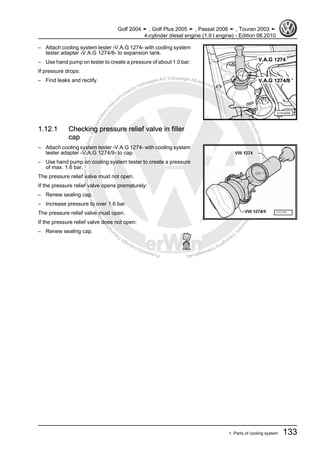

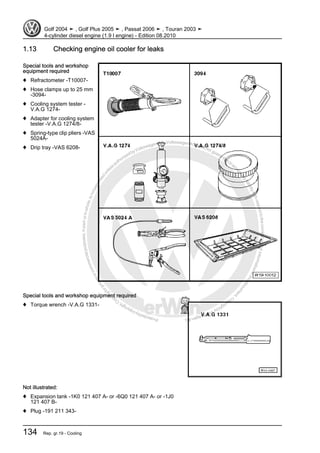

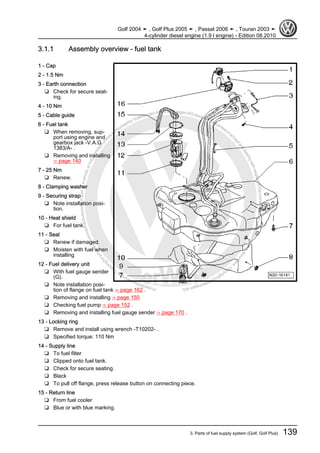

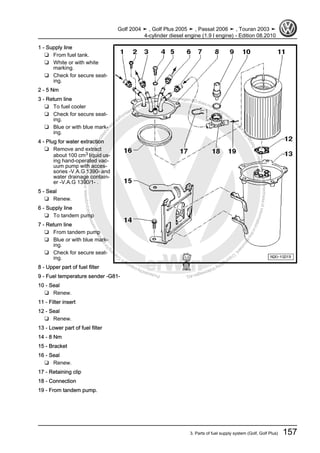

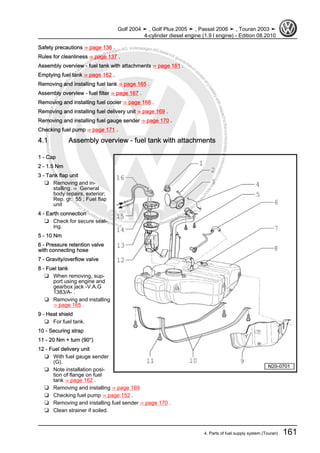

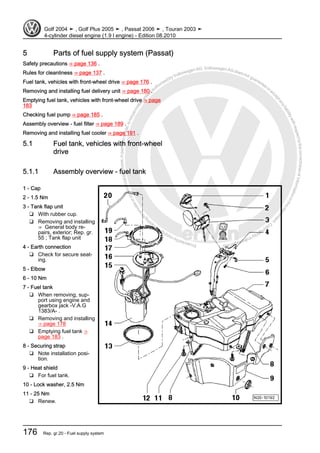

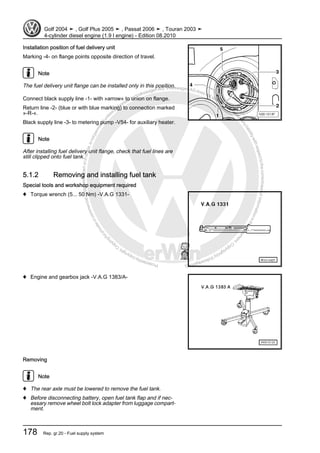

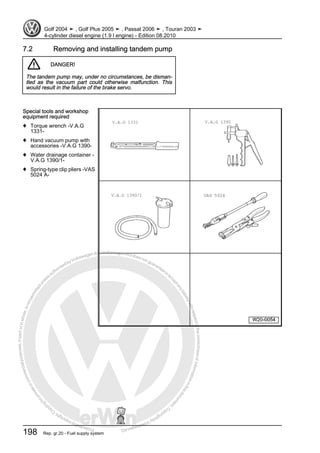

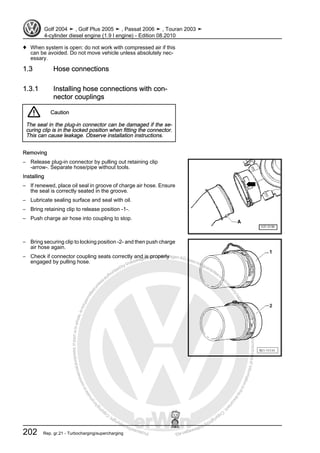

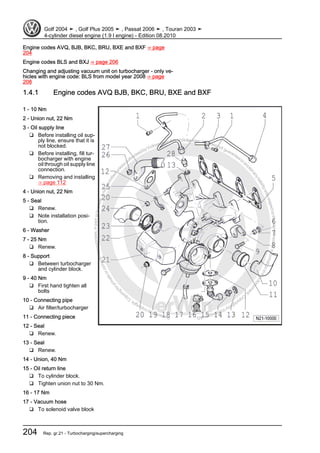

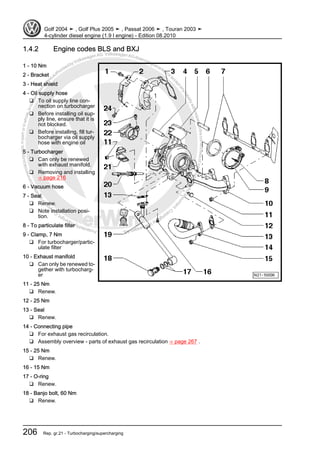

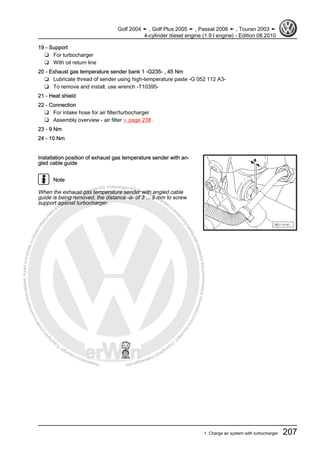

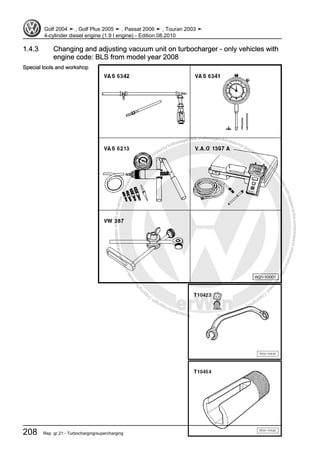

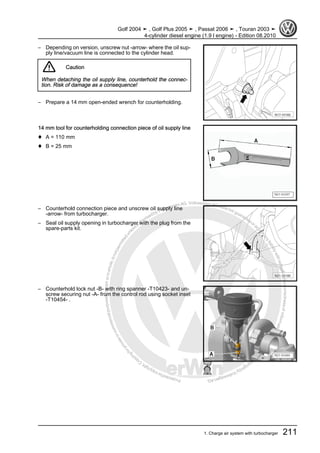

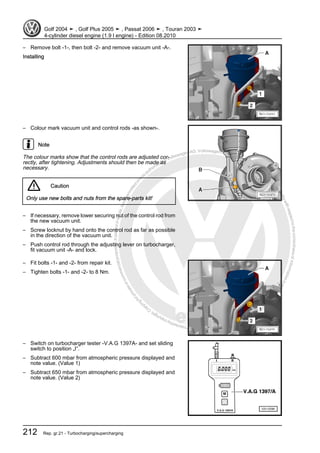

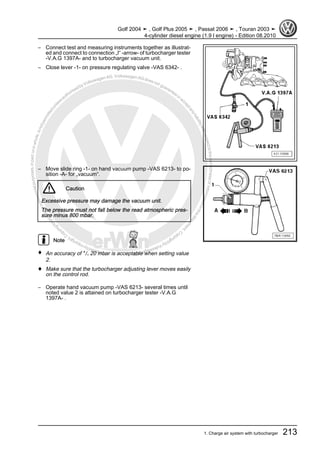

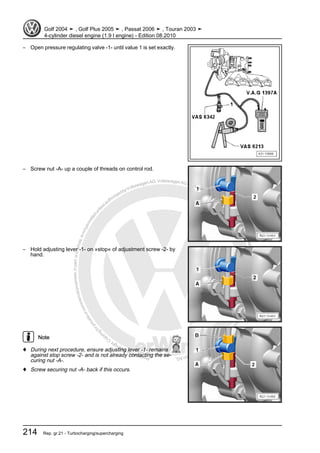

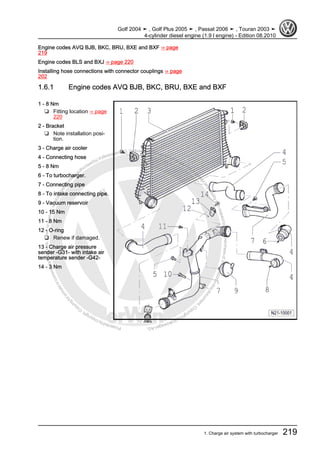

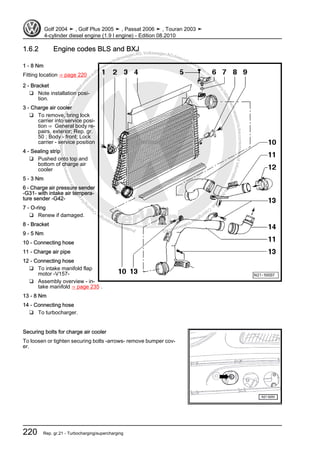

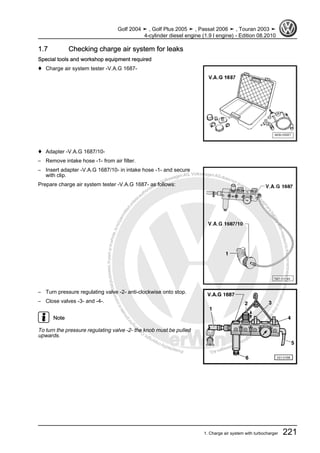

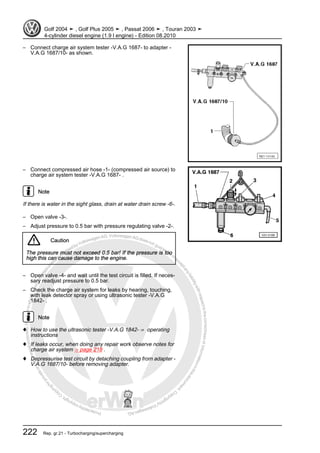

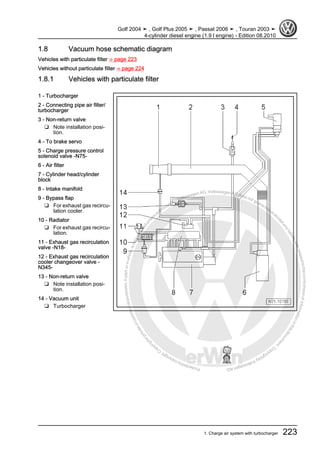

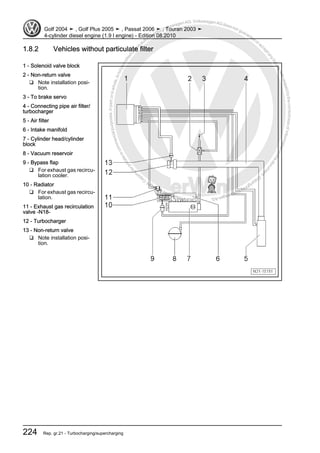

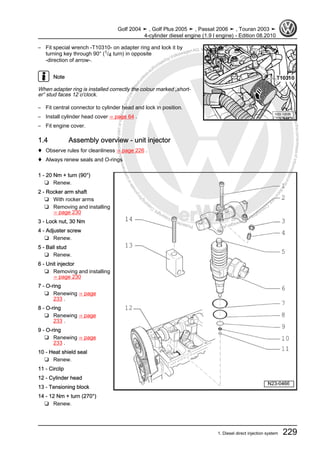

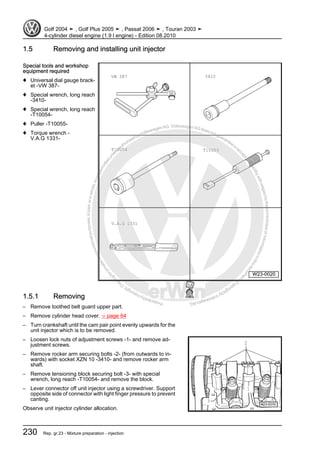

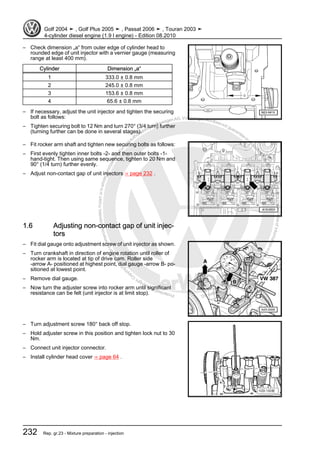

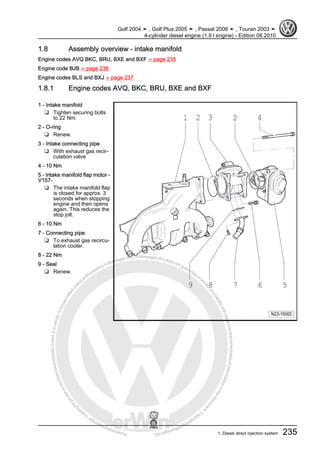

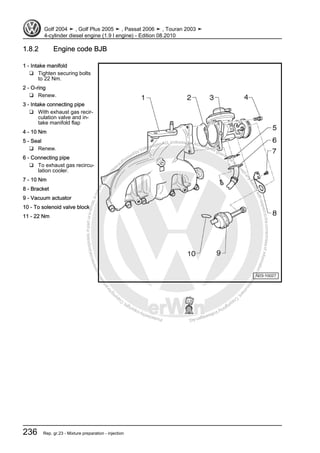

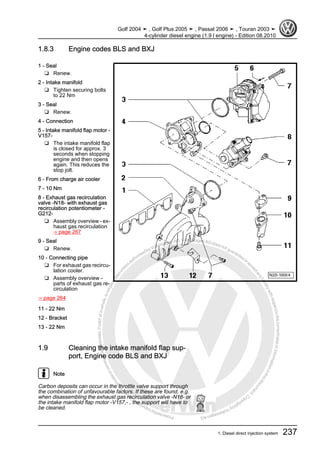

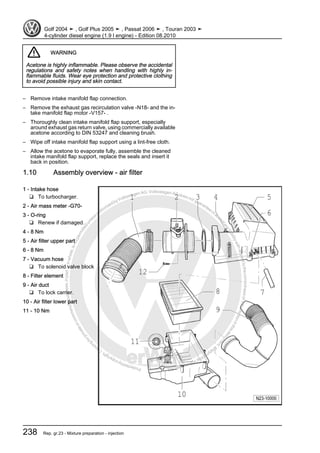

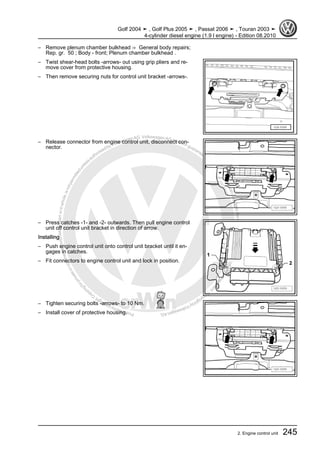

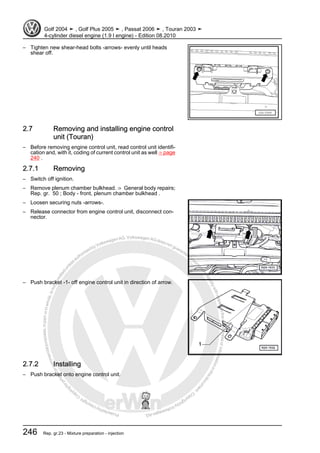

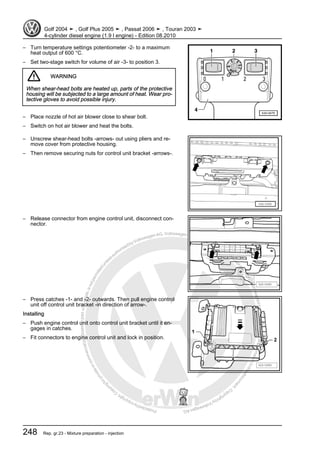

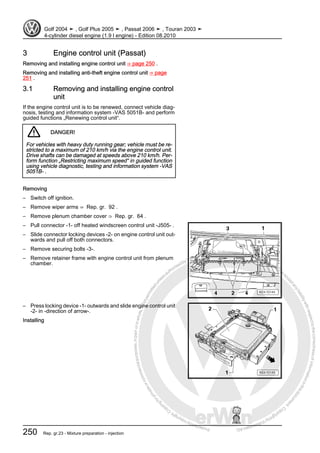

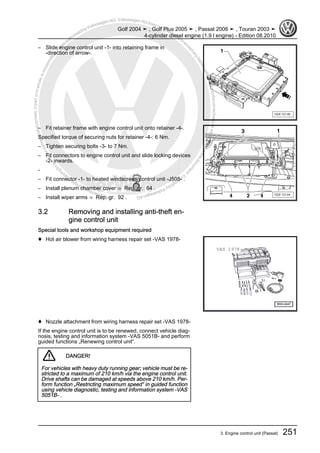

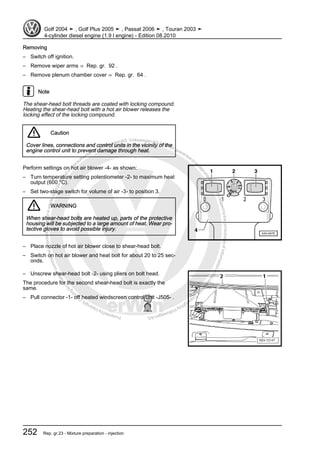

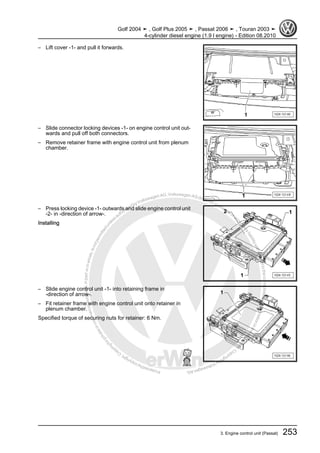

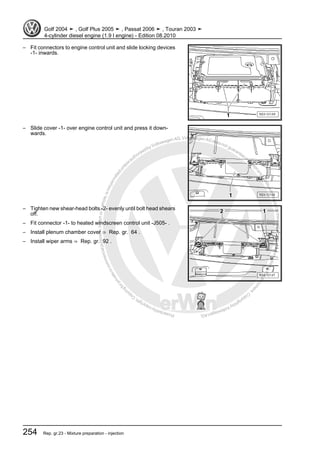

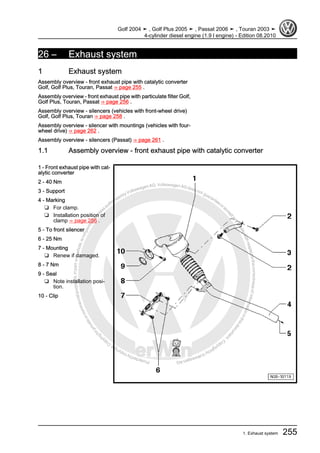

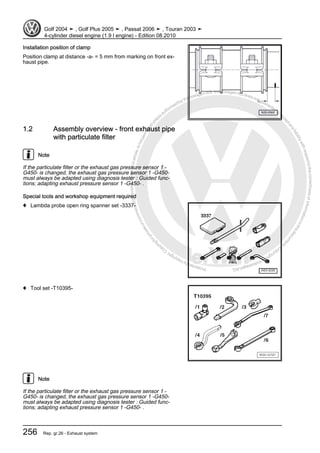

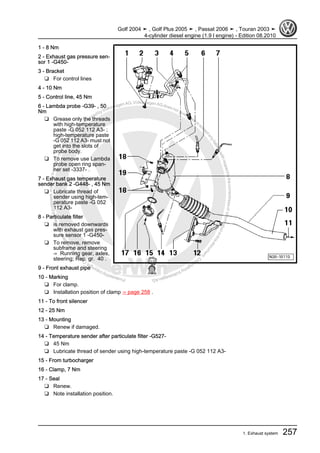

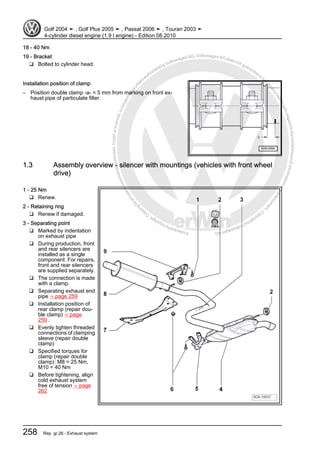

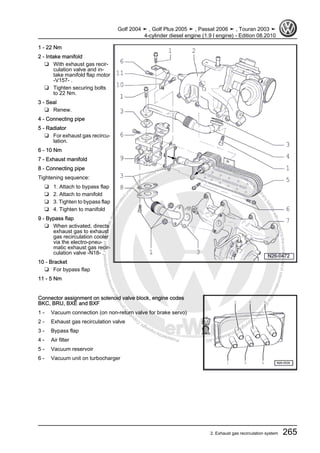

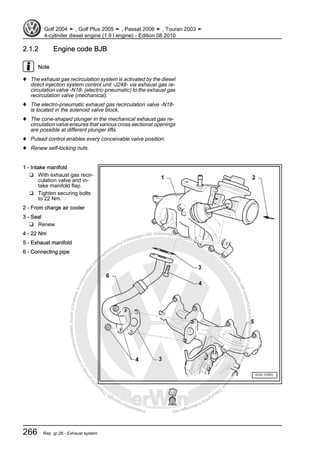

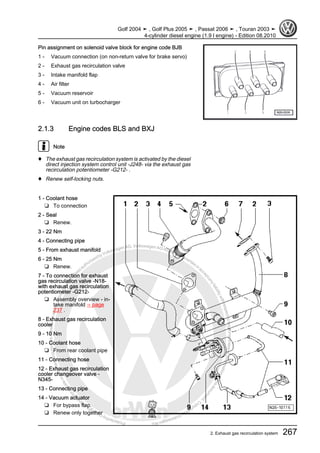

This document provides technical information for Volkswagen workshop manuals regarding 4-cylinder diesel engines. It contains instructions for removing and installing engine components, testing procedures, and specifications. Copyright protections are outlined at the beginning and end of the document. Repair groups covered include the crankshaft, cylinder head, valve gear, lubrication system, and other engine systems. Adherence to the technical instructions is important for vehicle safety and roadworthiness.