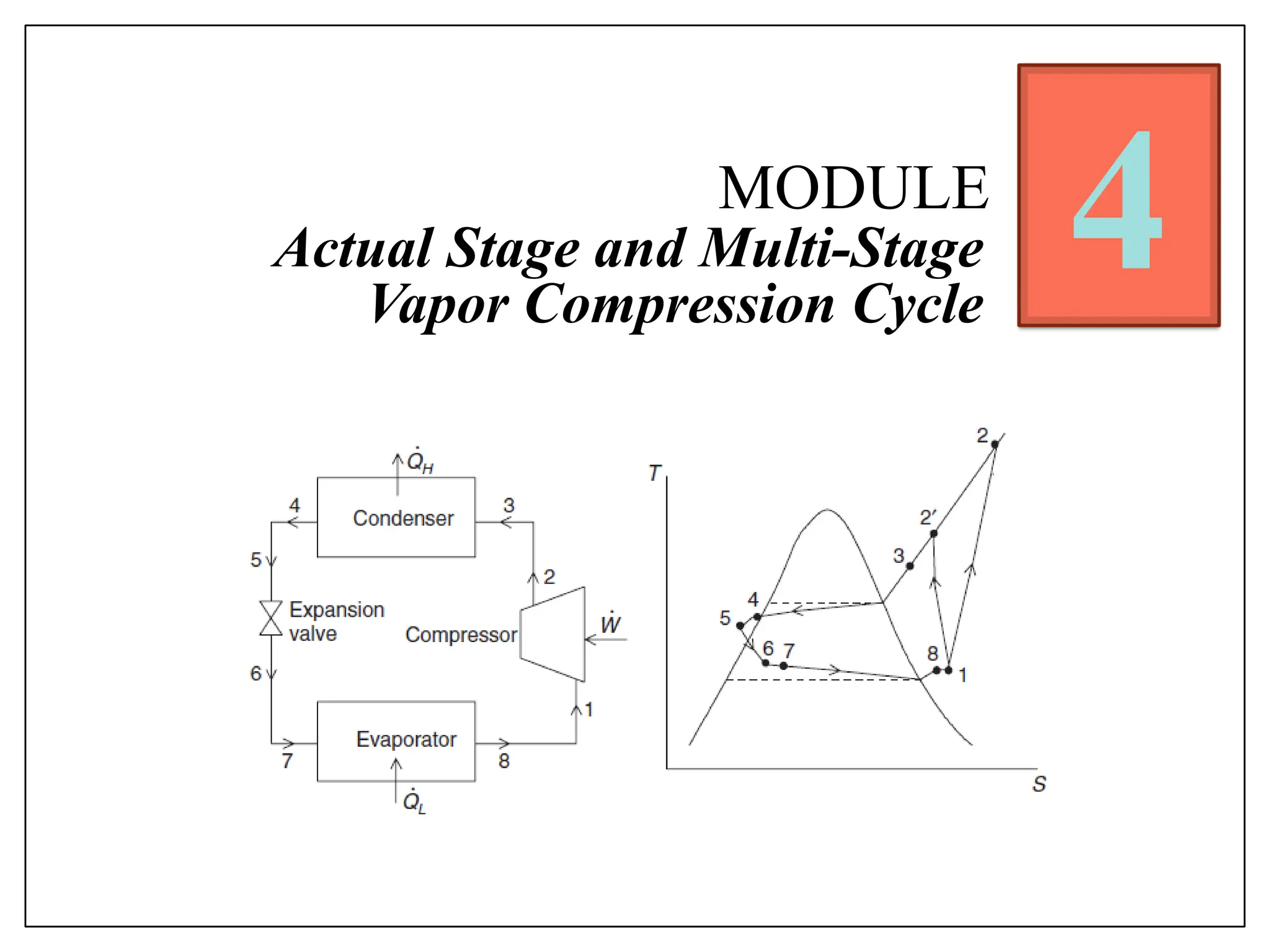

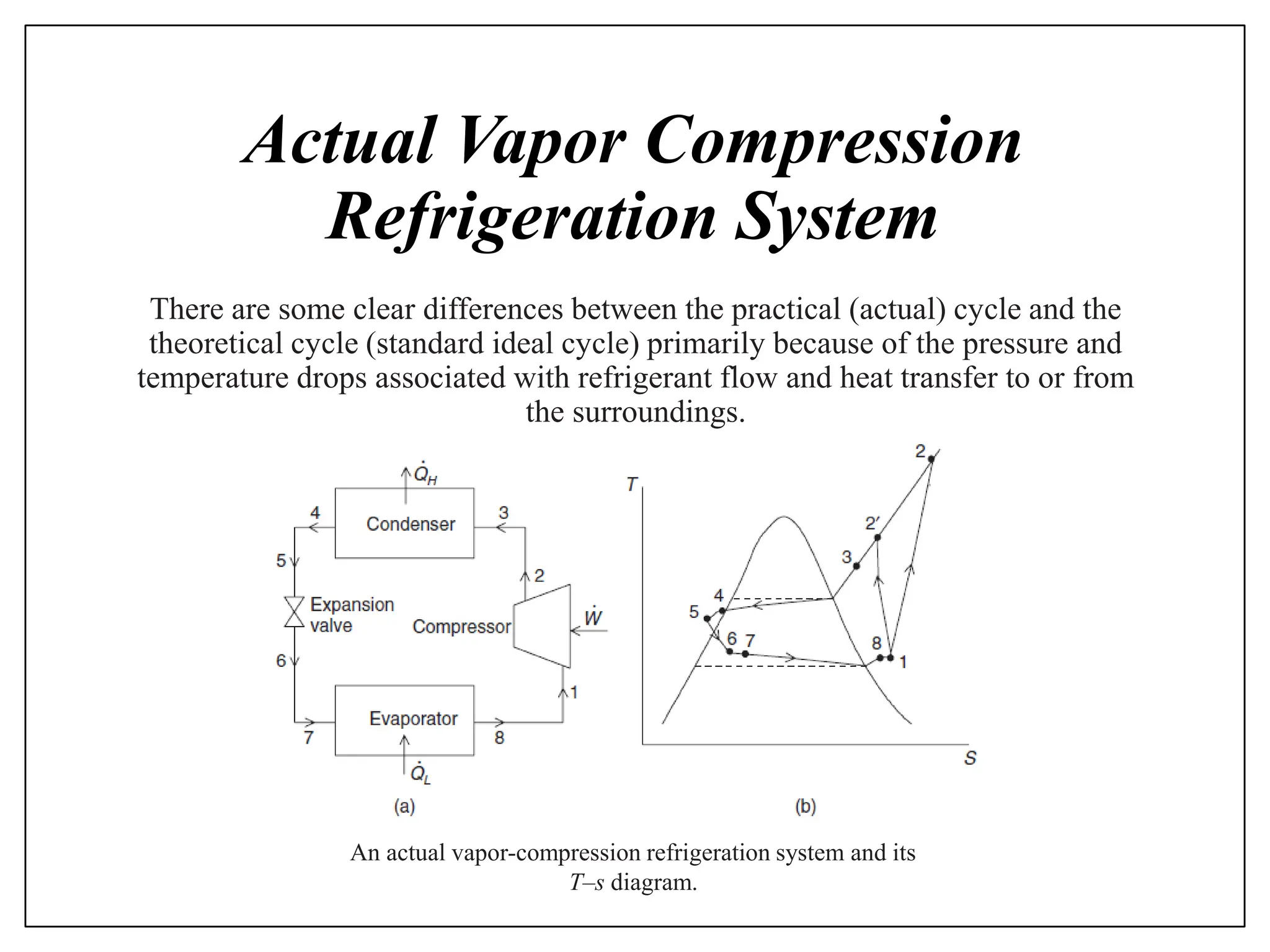

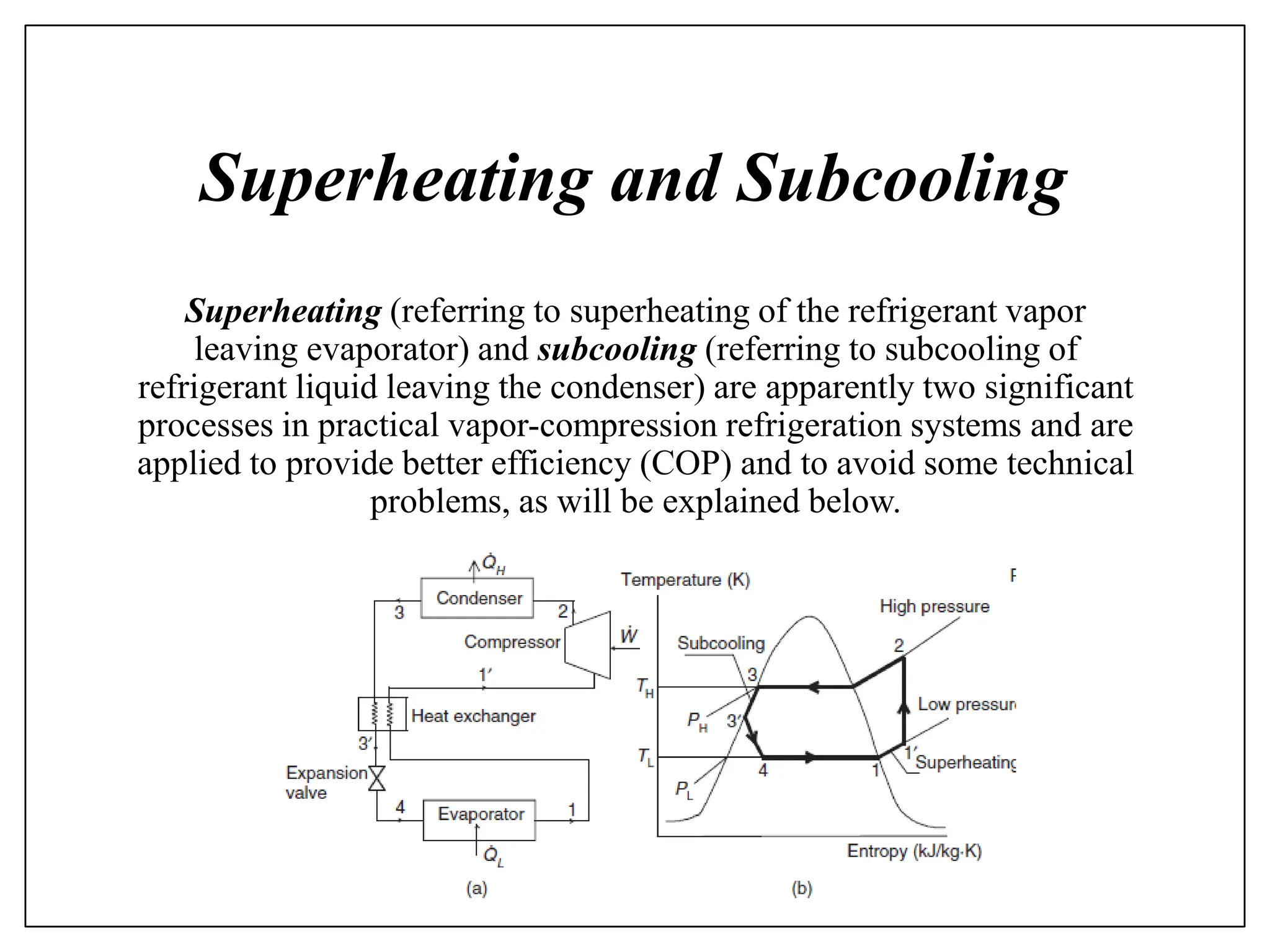

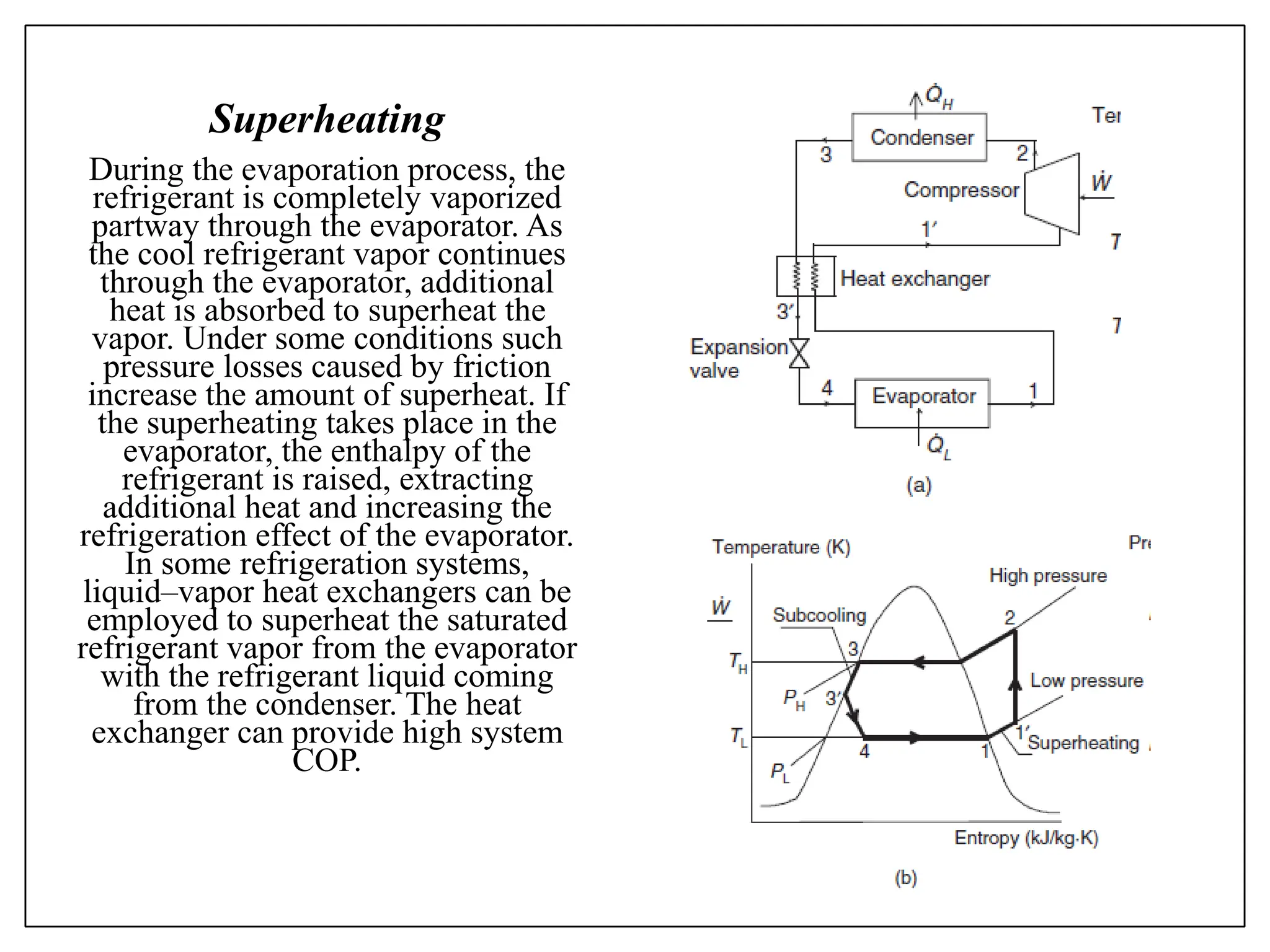

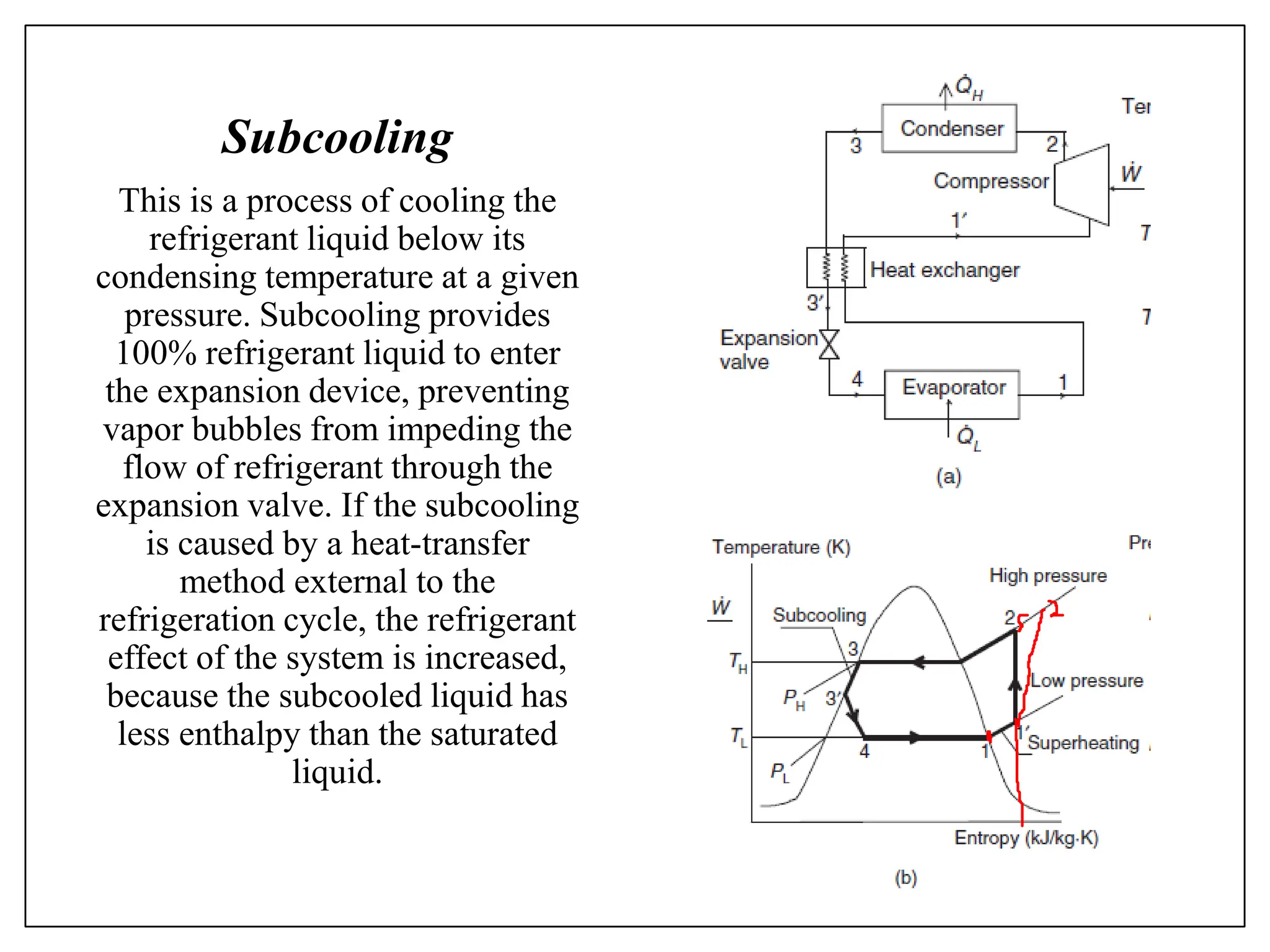

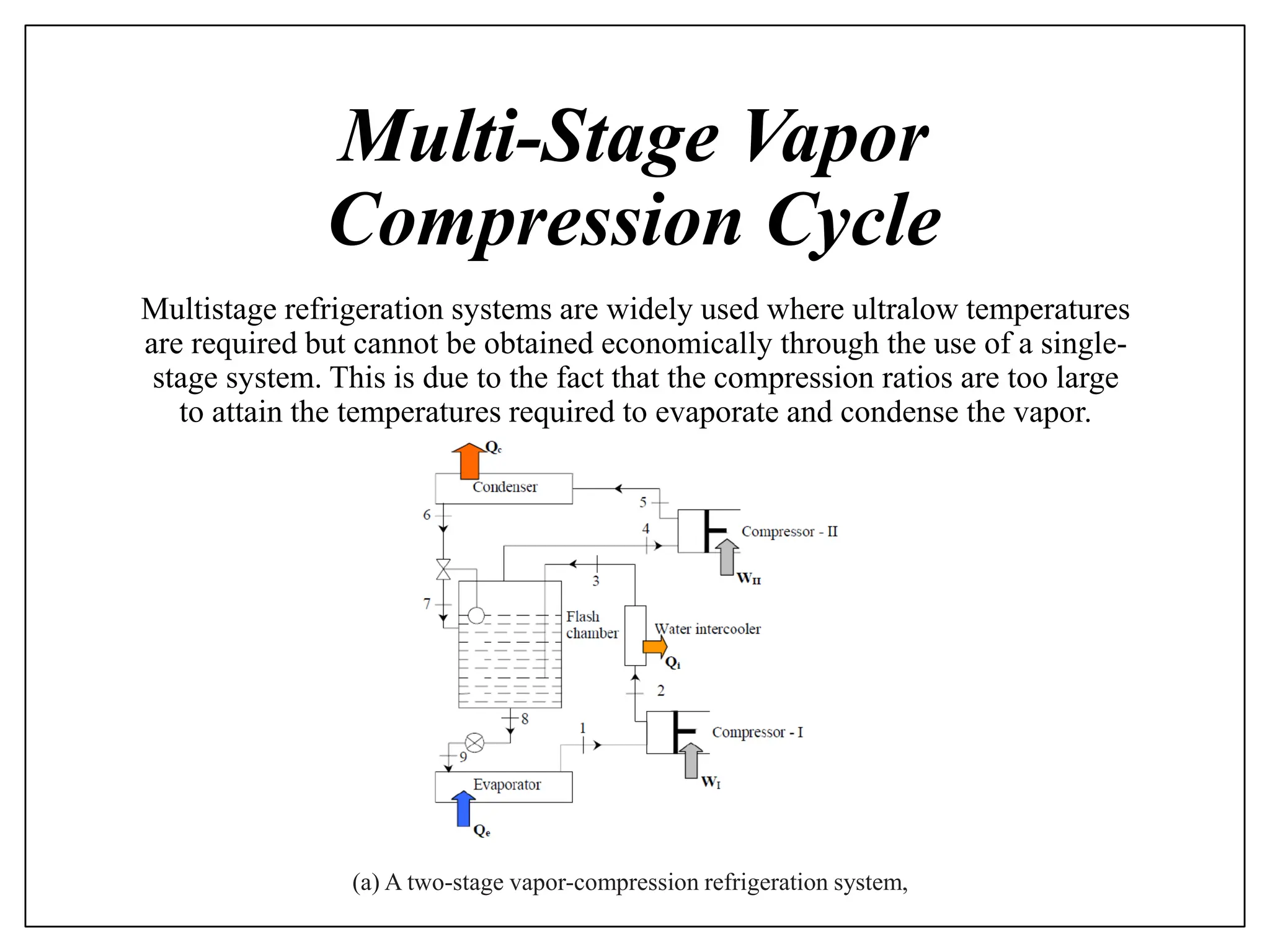

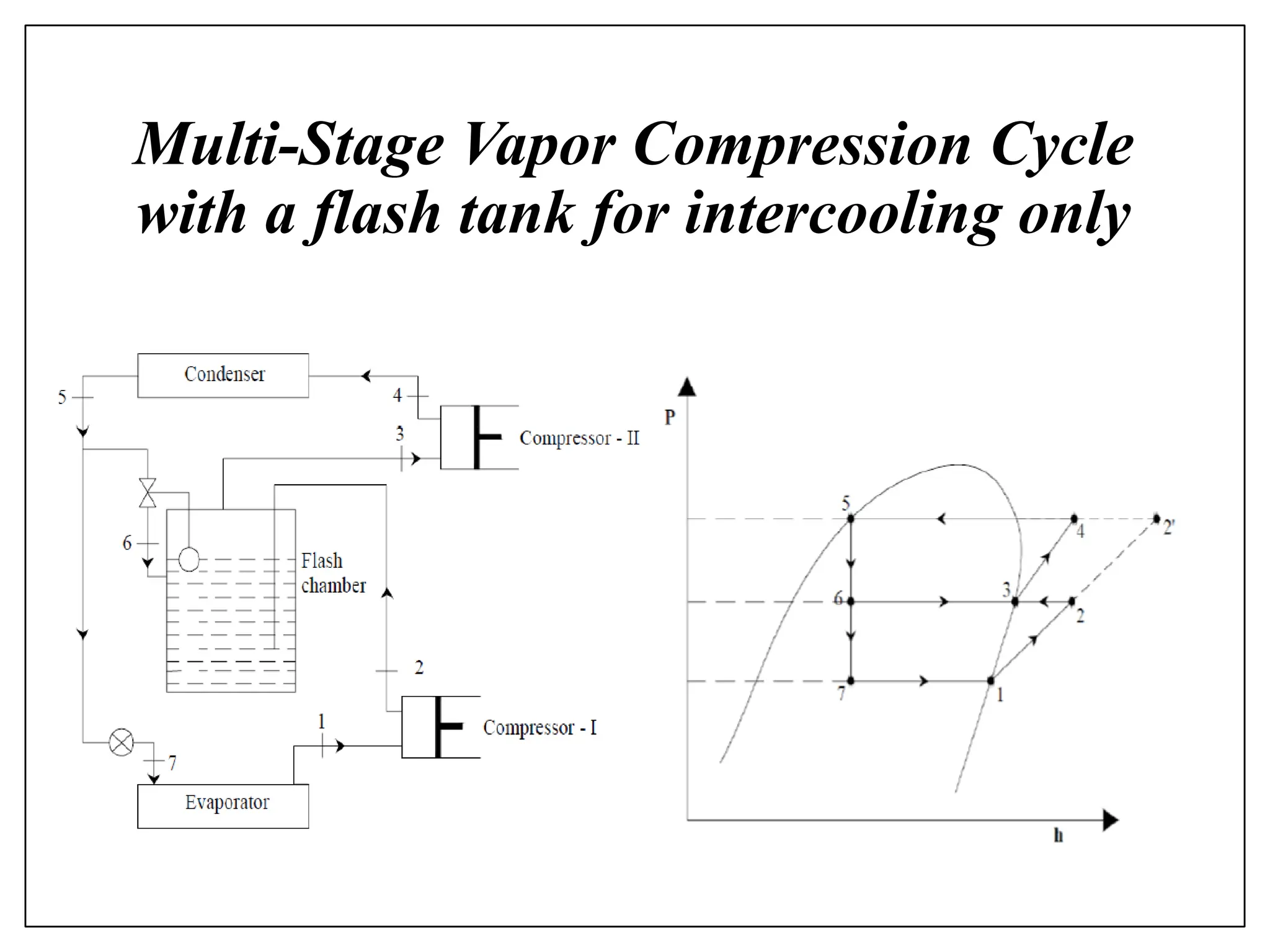

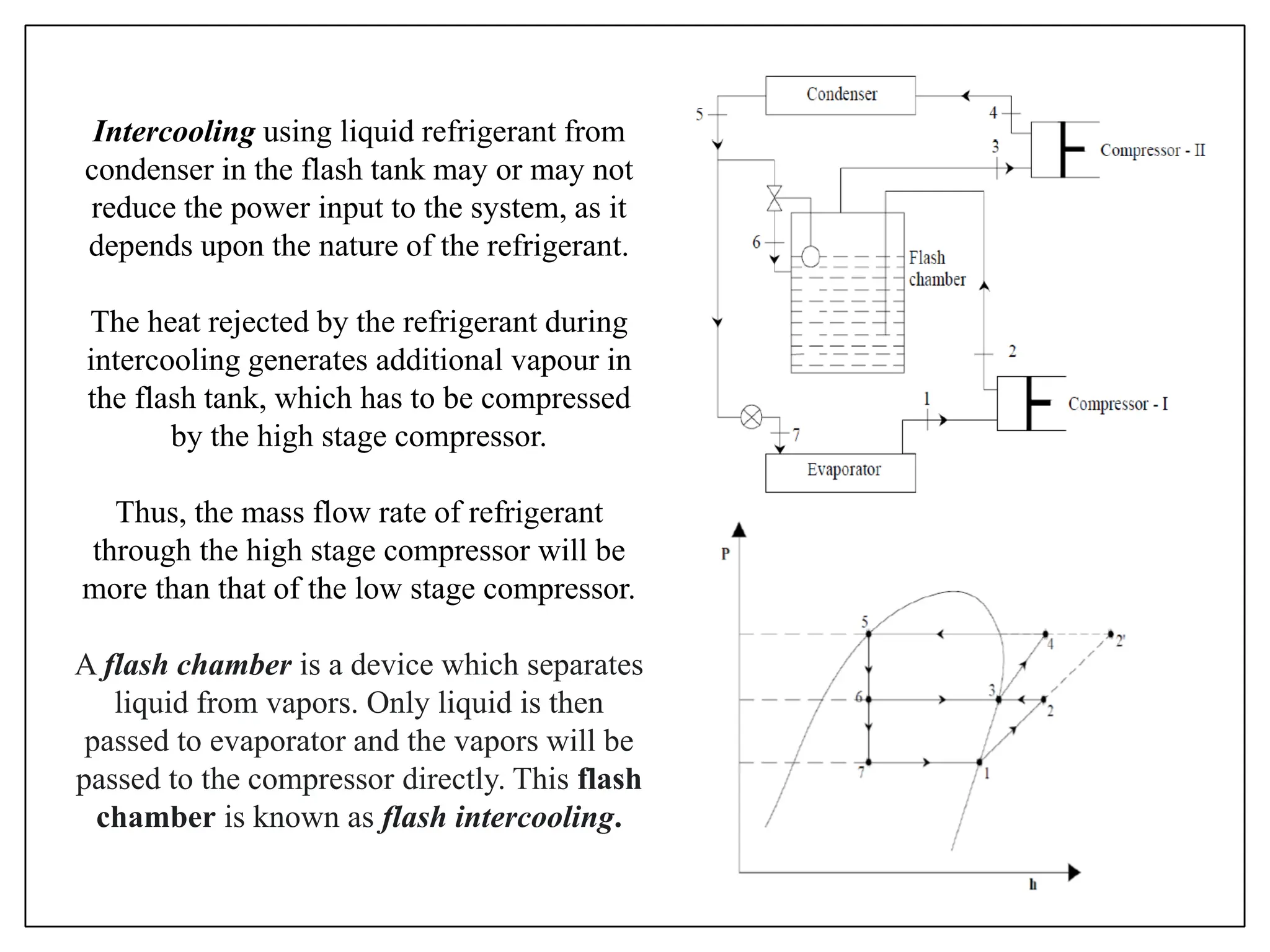

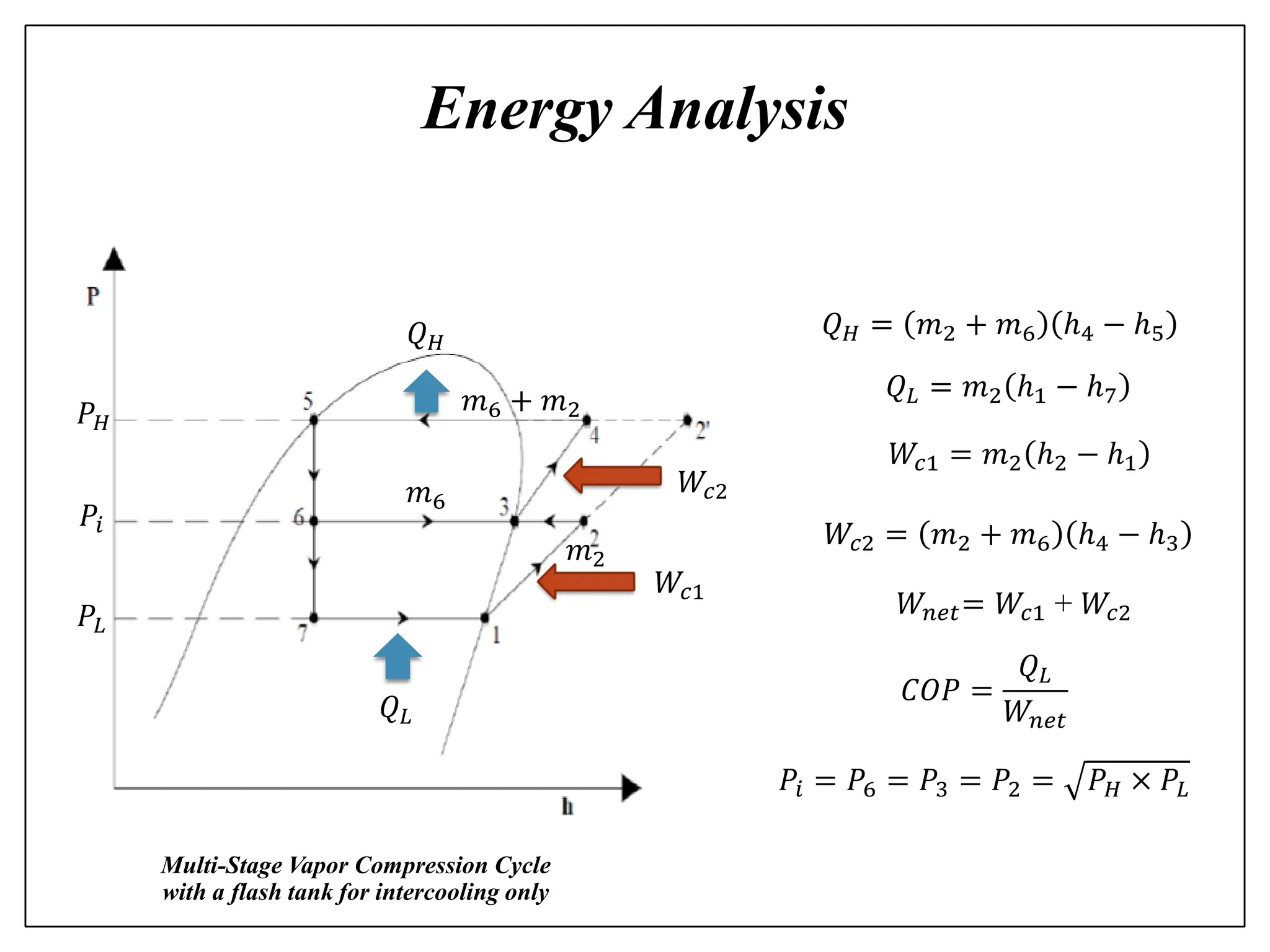

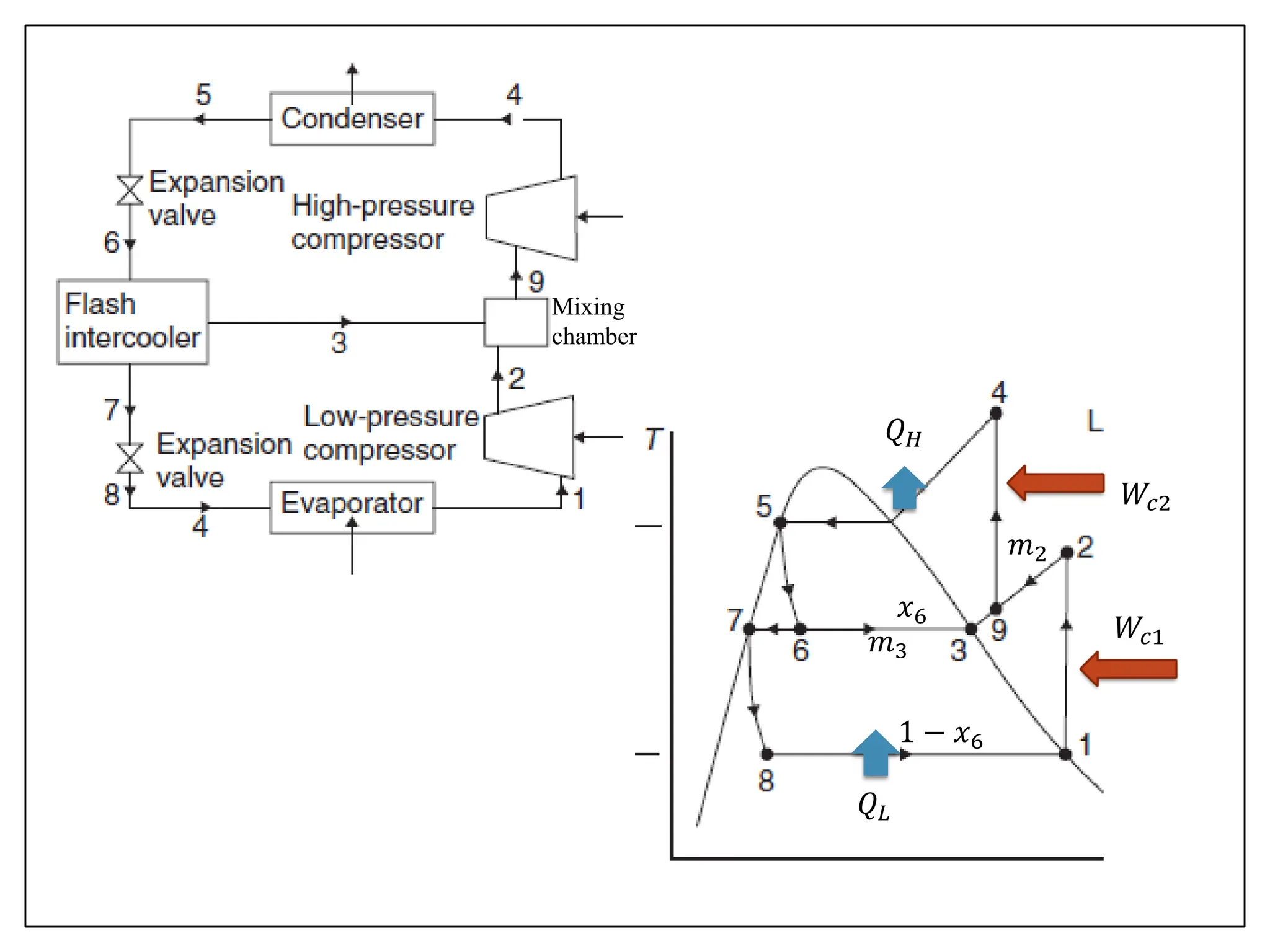

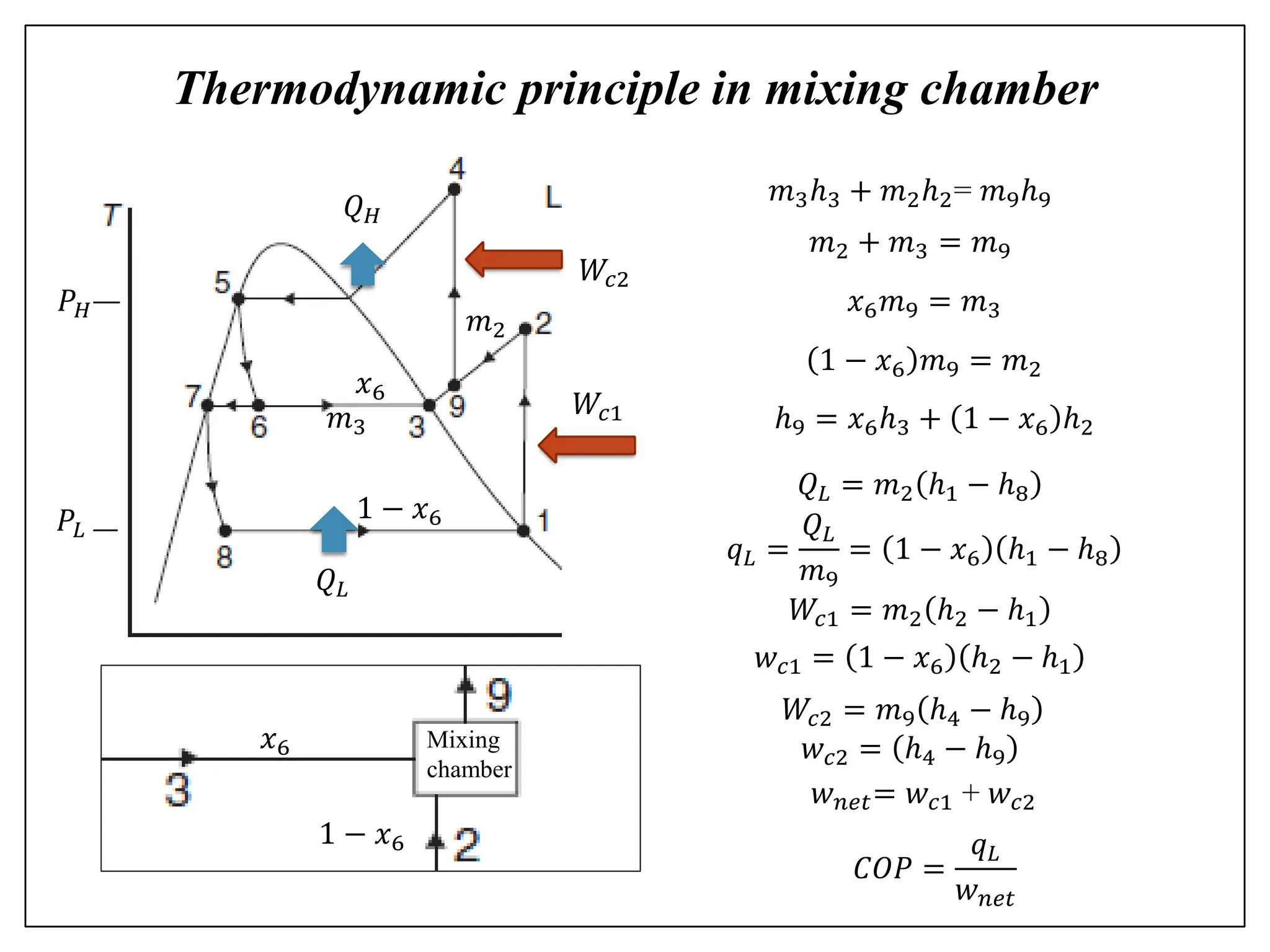

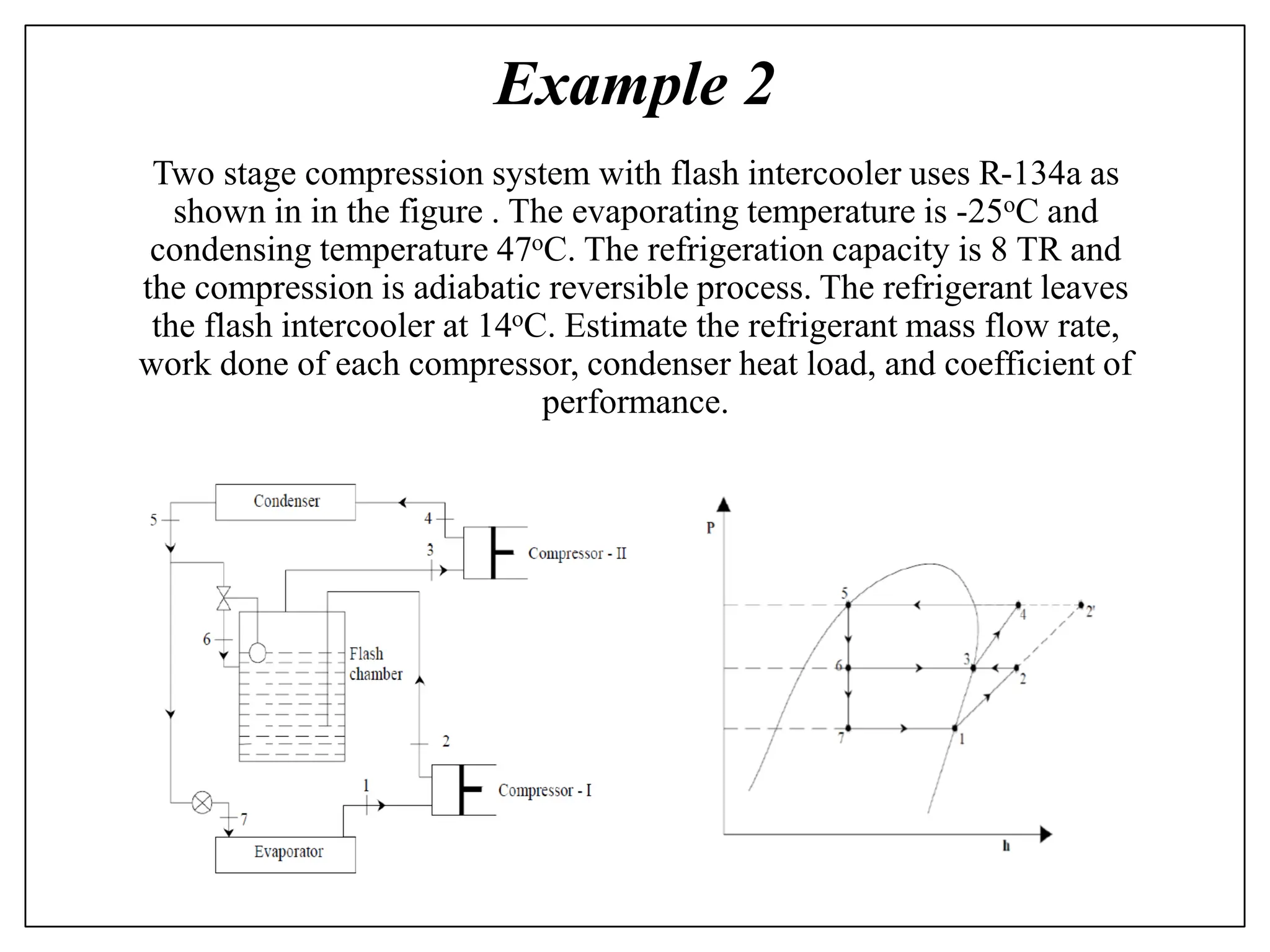

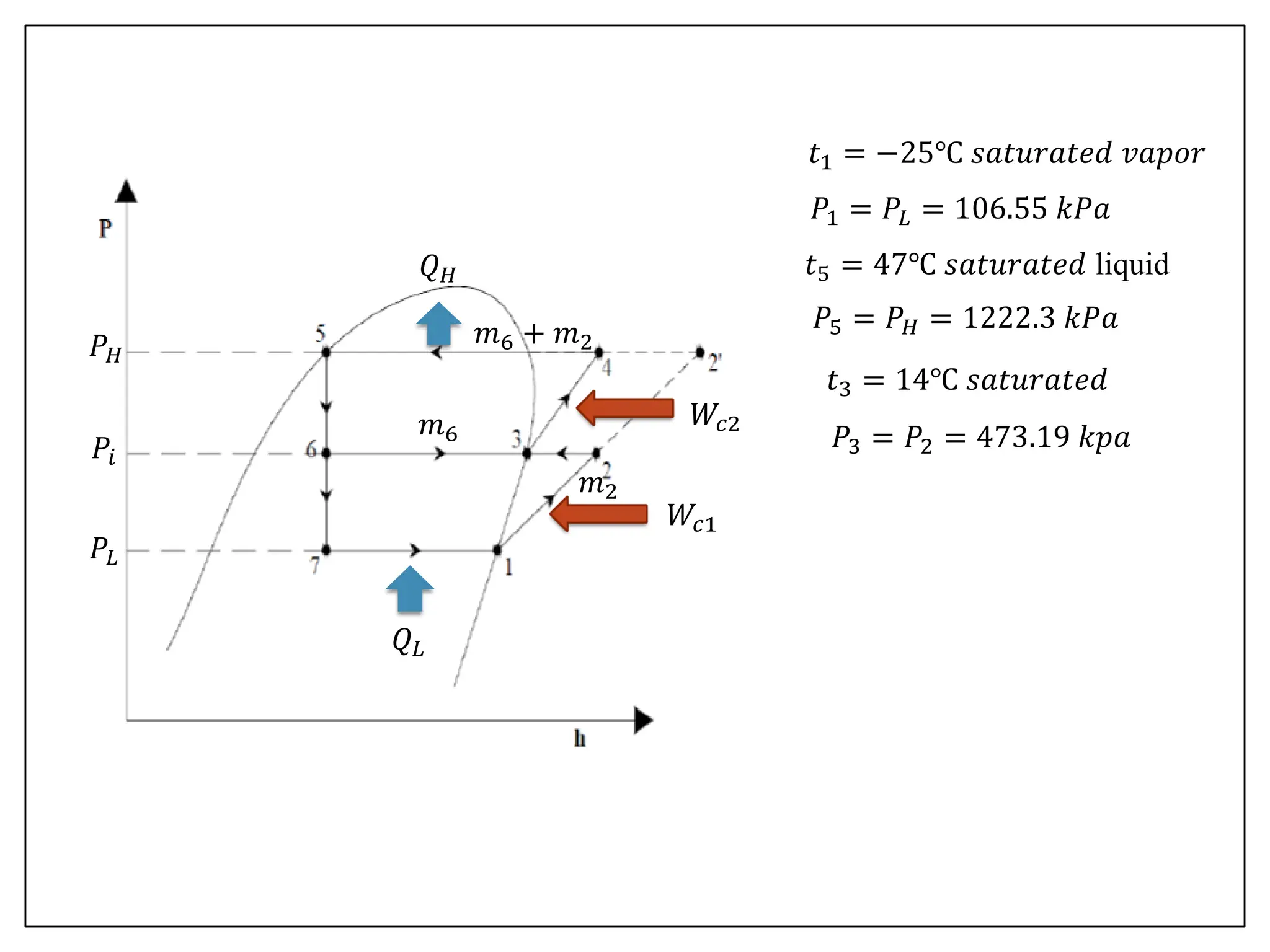

The document outlines the functioning and analysis of vapor compression refrigeration cycles, focusing on actual versus theoretical cycles, superheating, and subcooling processes. It explains the differences between single-stage and multi-stage systems, emphasizing their applications in achieving ultra-low temperatures and improving efficiency. Additionally, the document provides exercises and examples for calculating various performance parameters such as heat absorption, work input, and coefficient of performance (C.O.P.) in refrigeration systems.