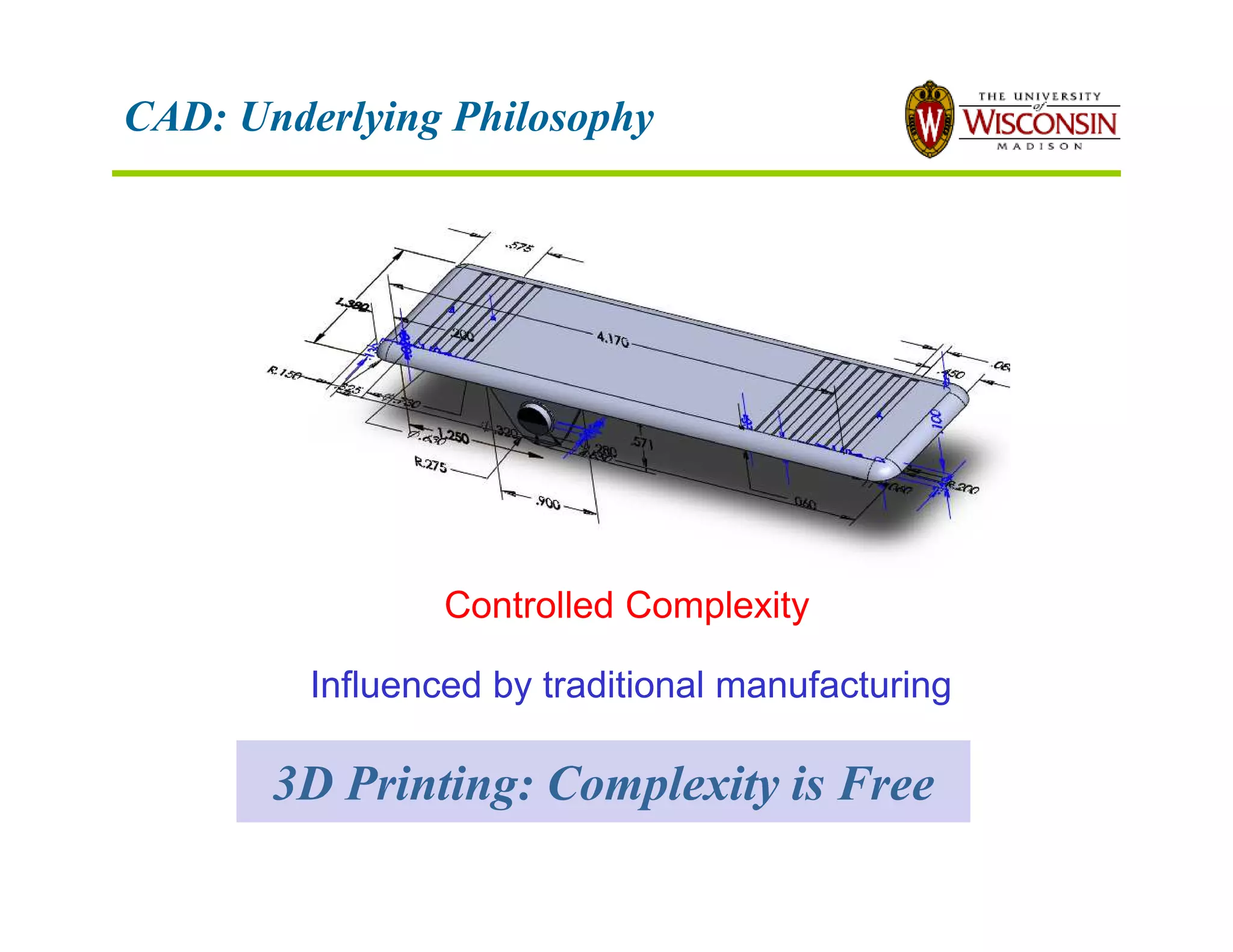

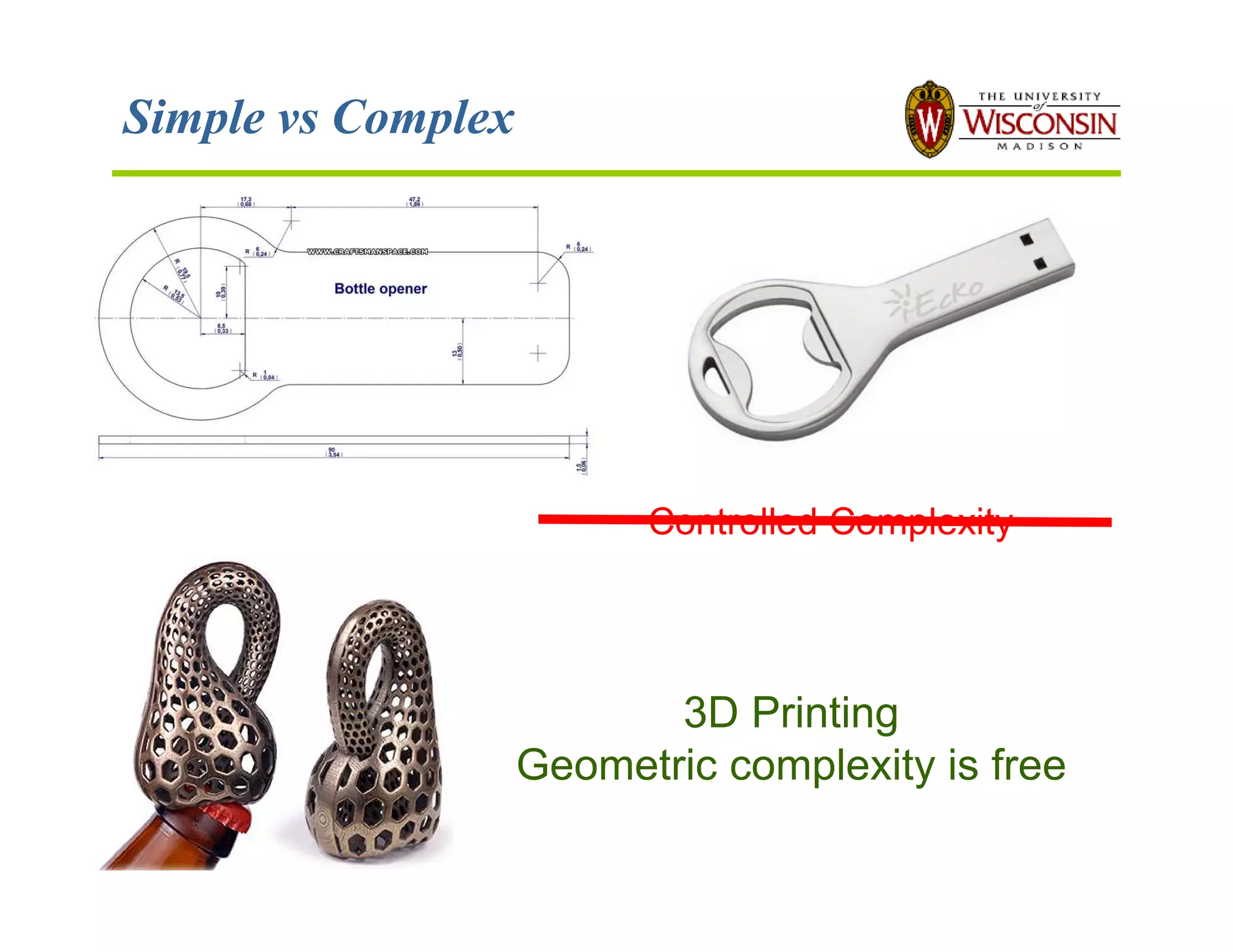

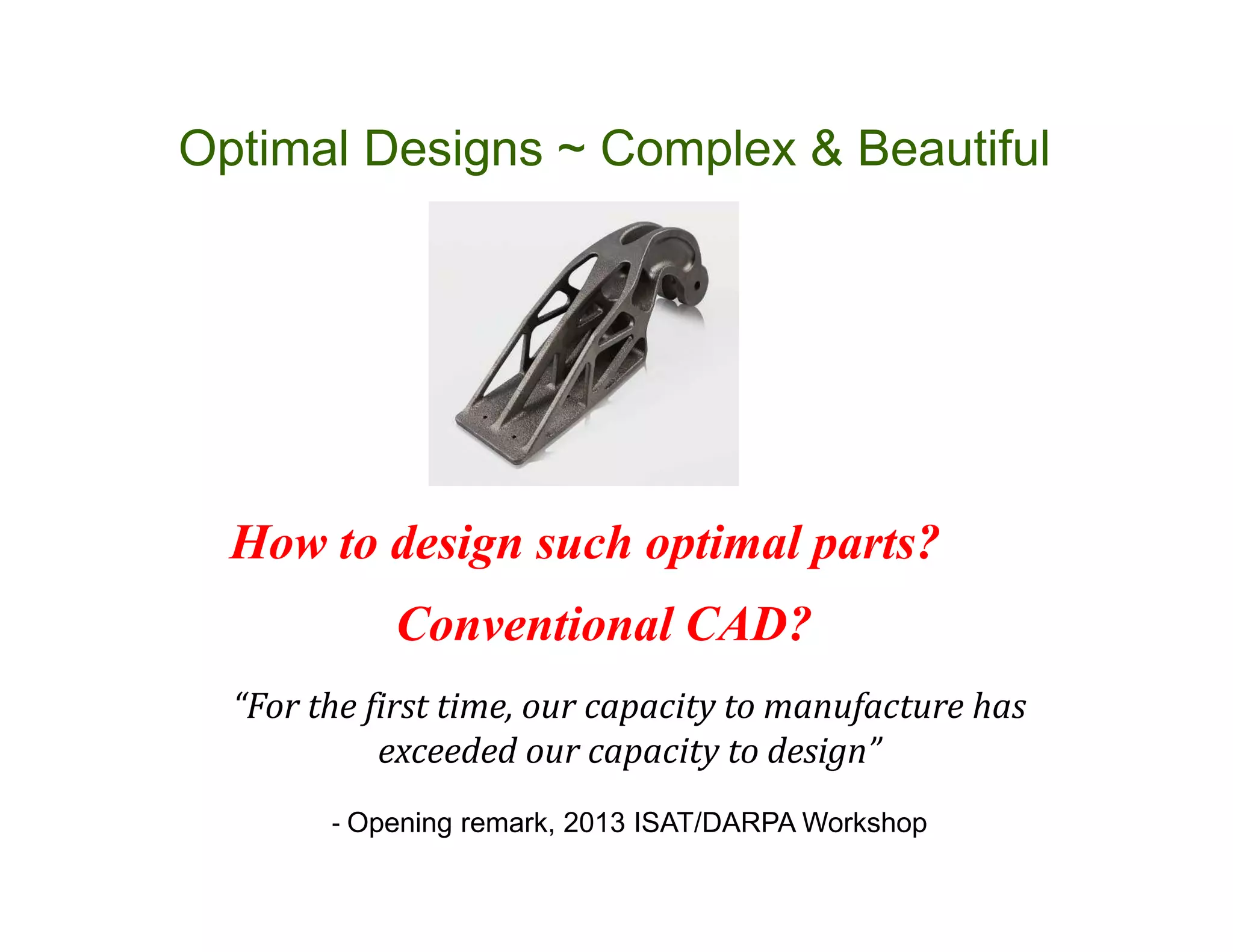

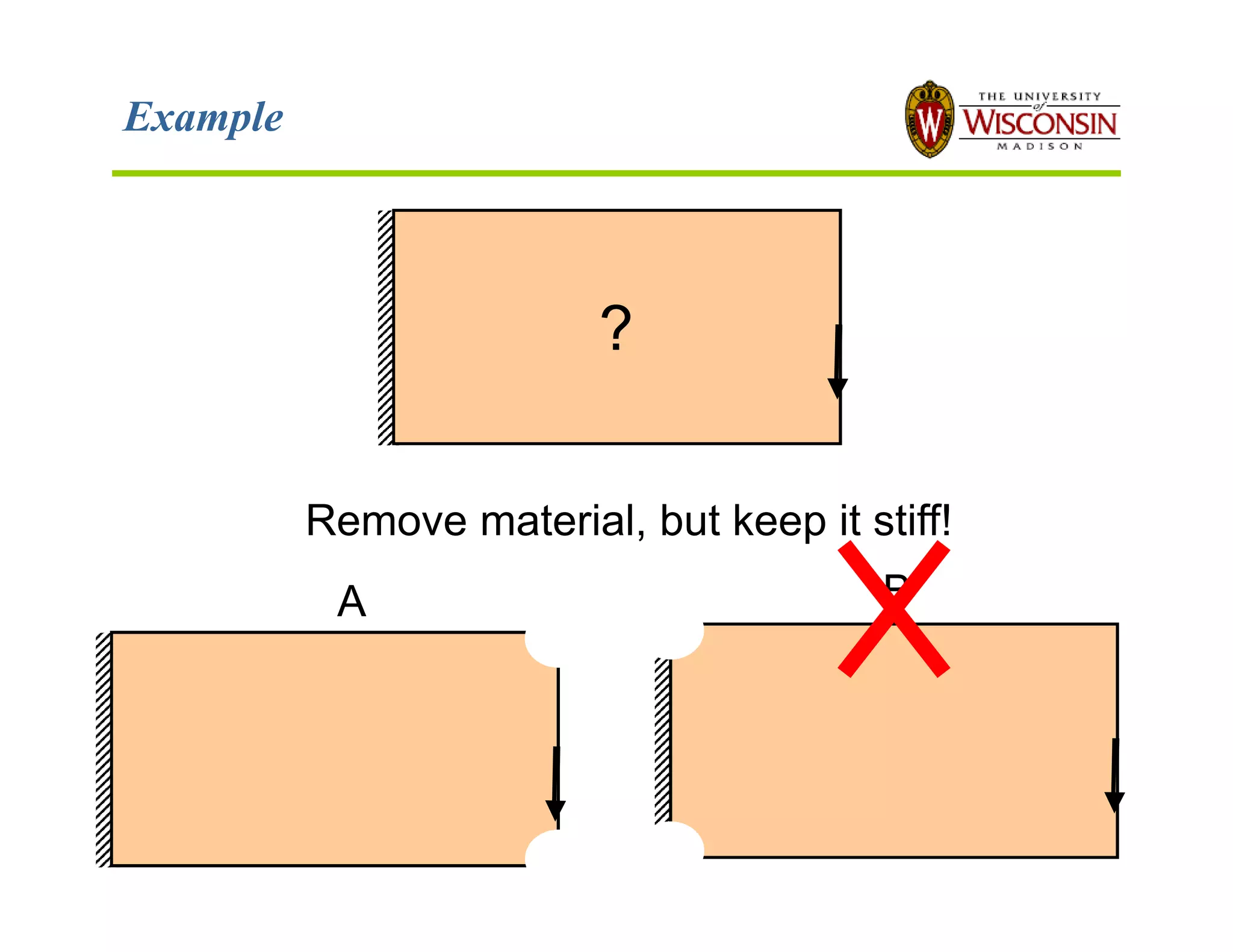

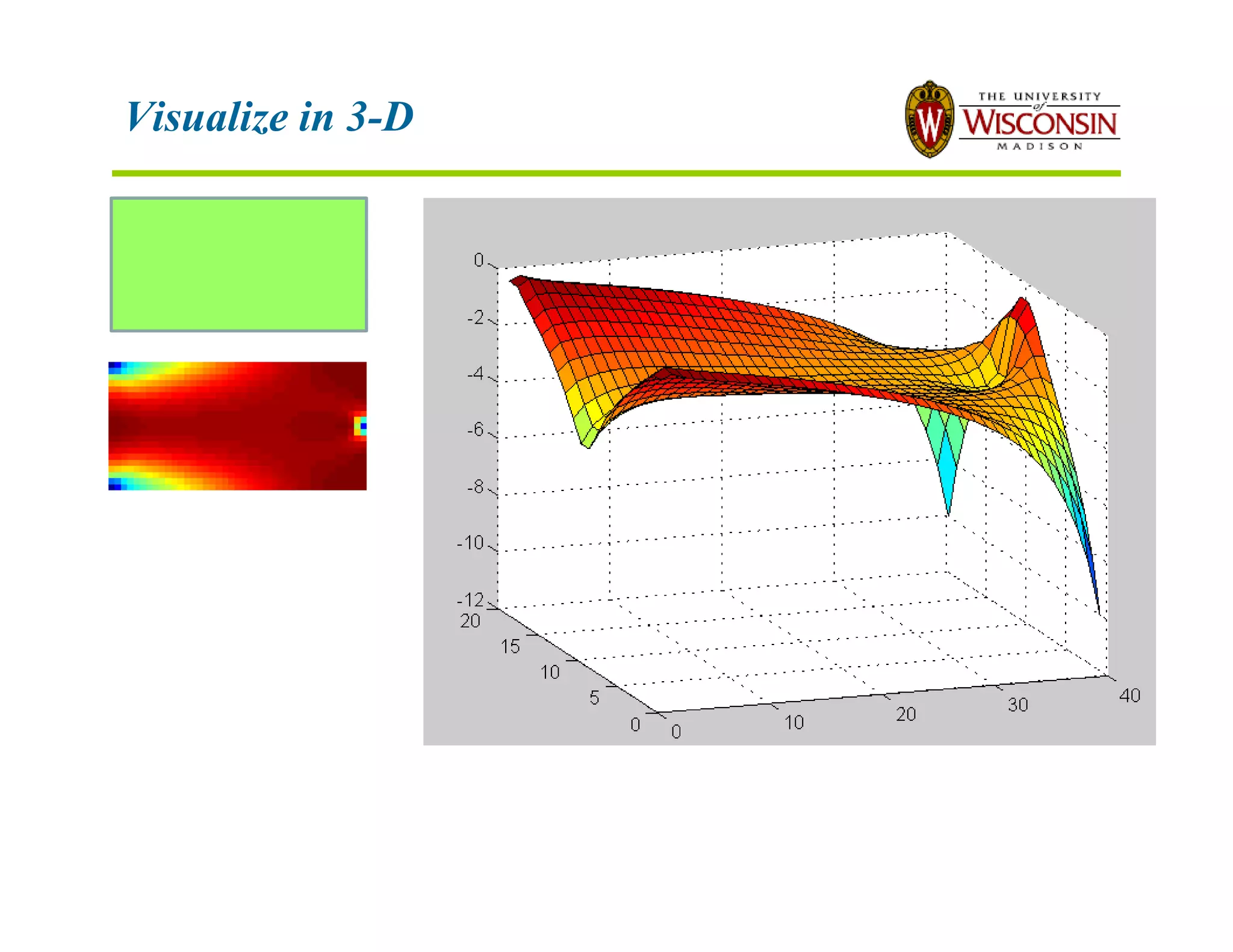

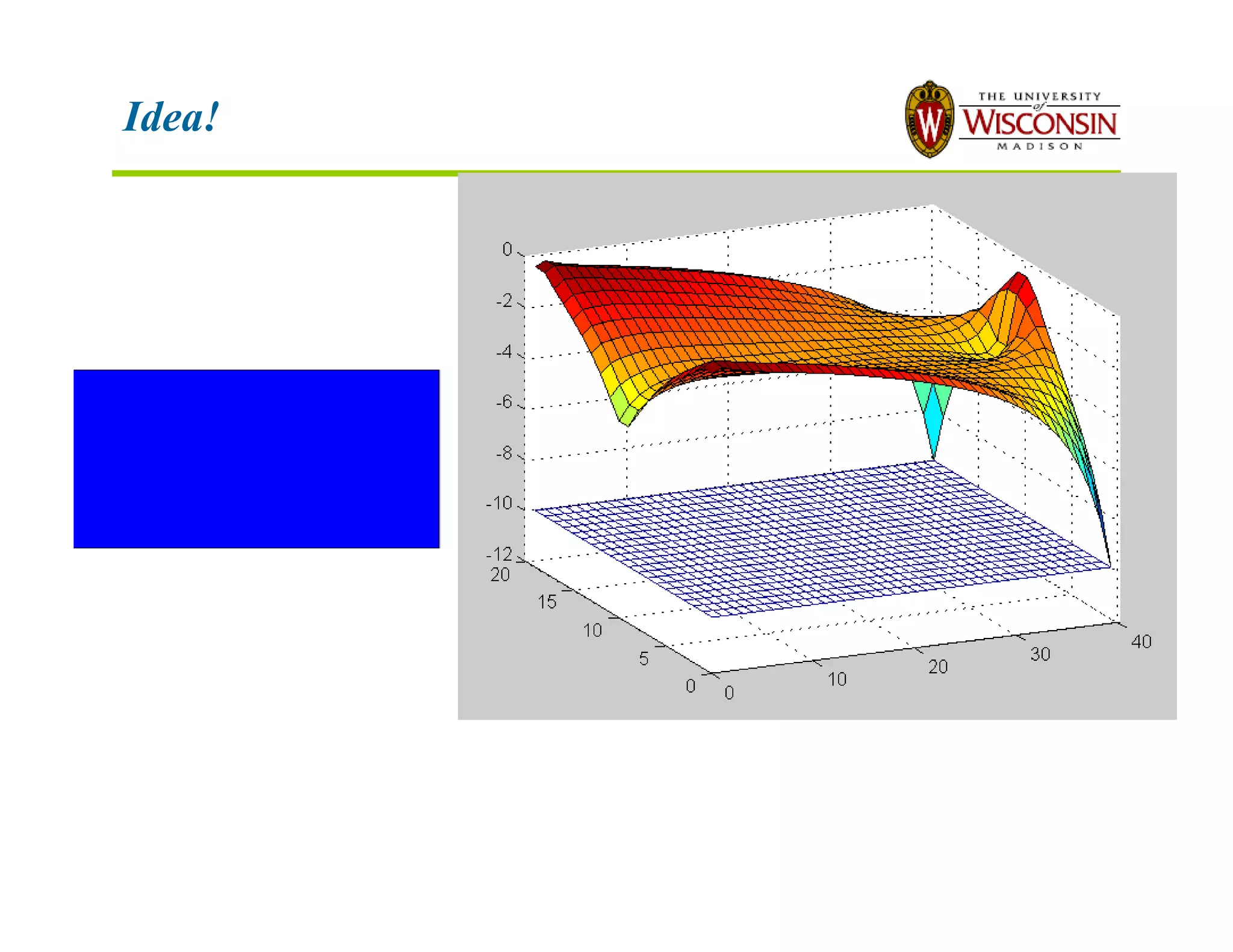

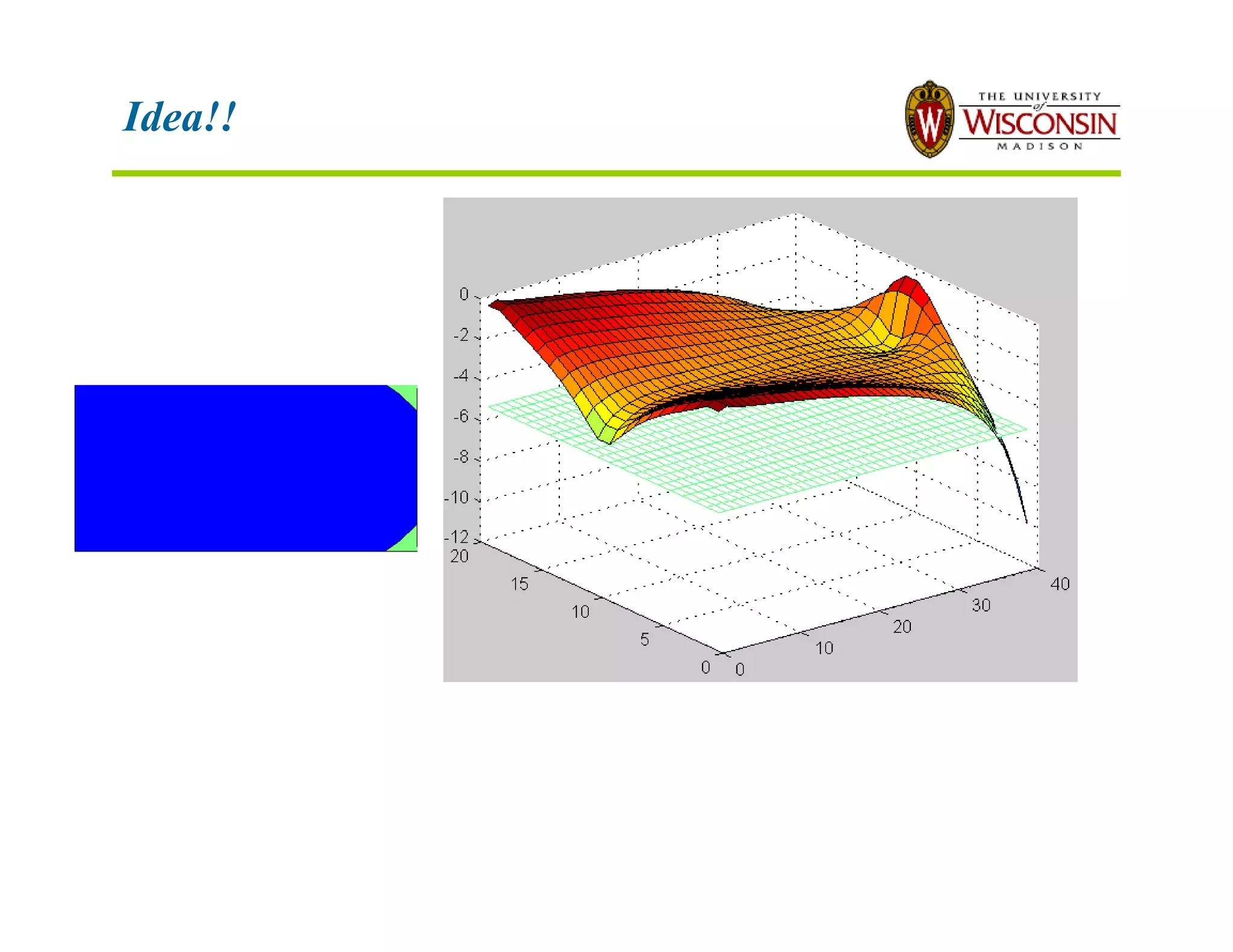

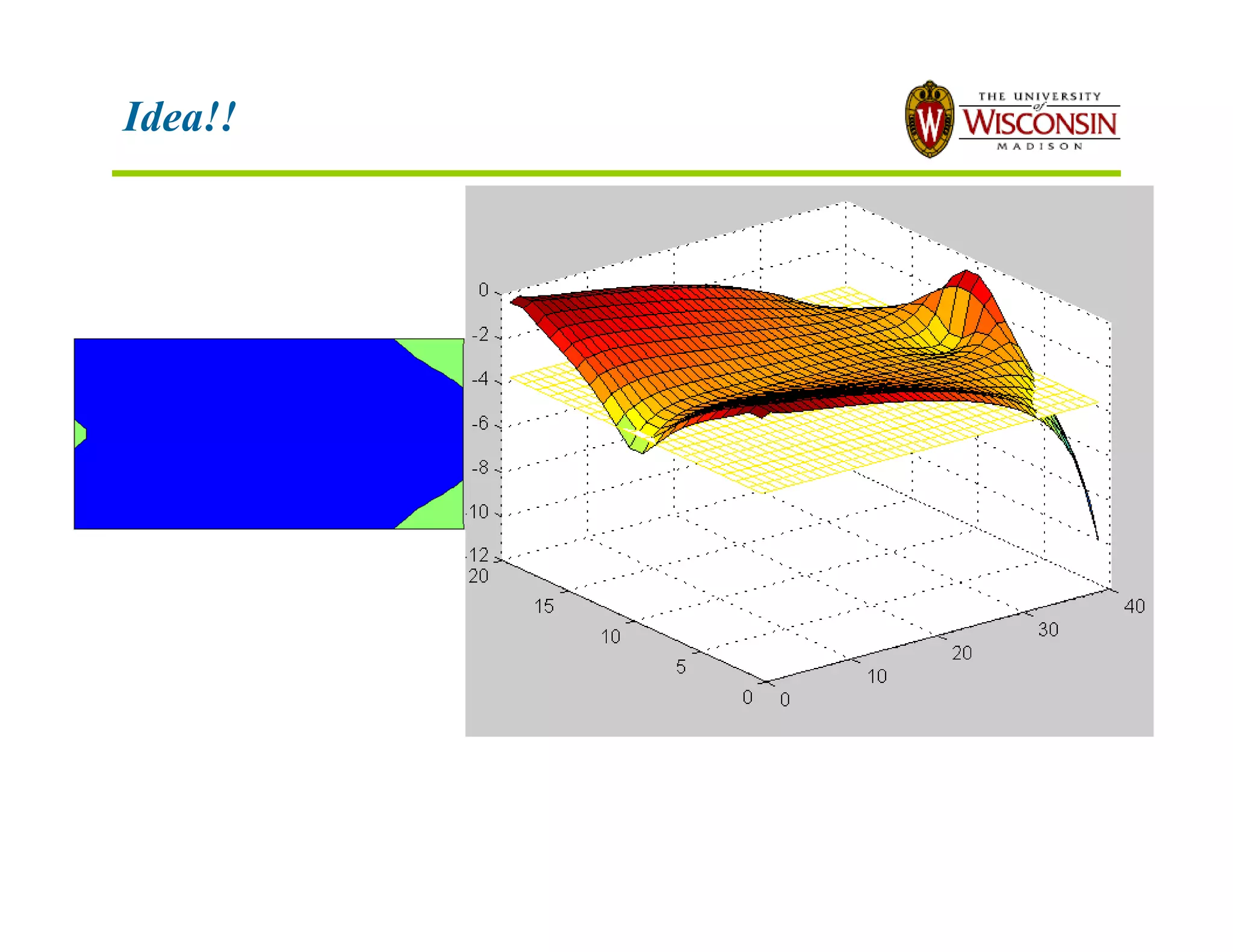

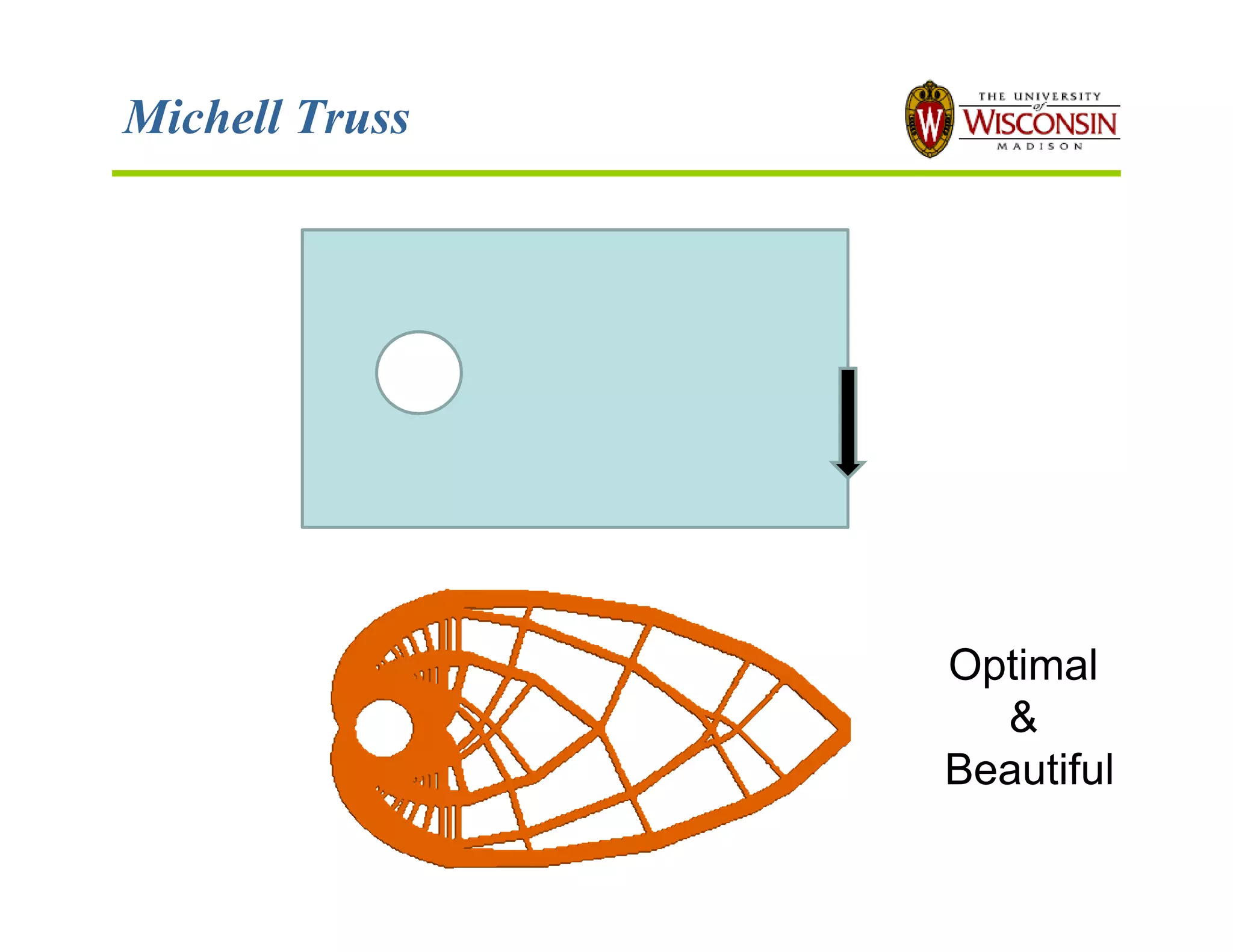

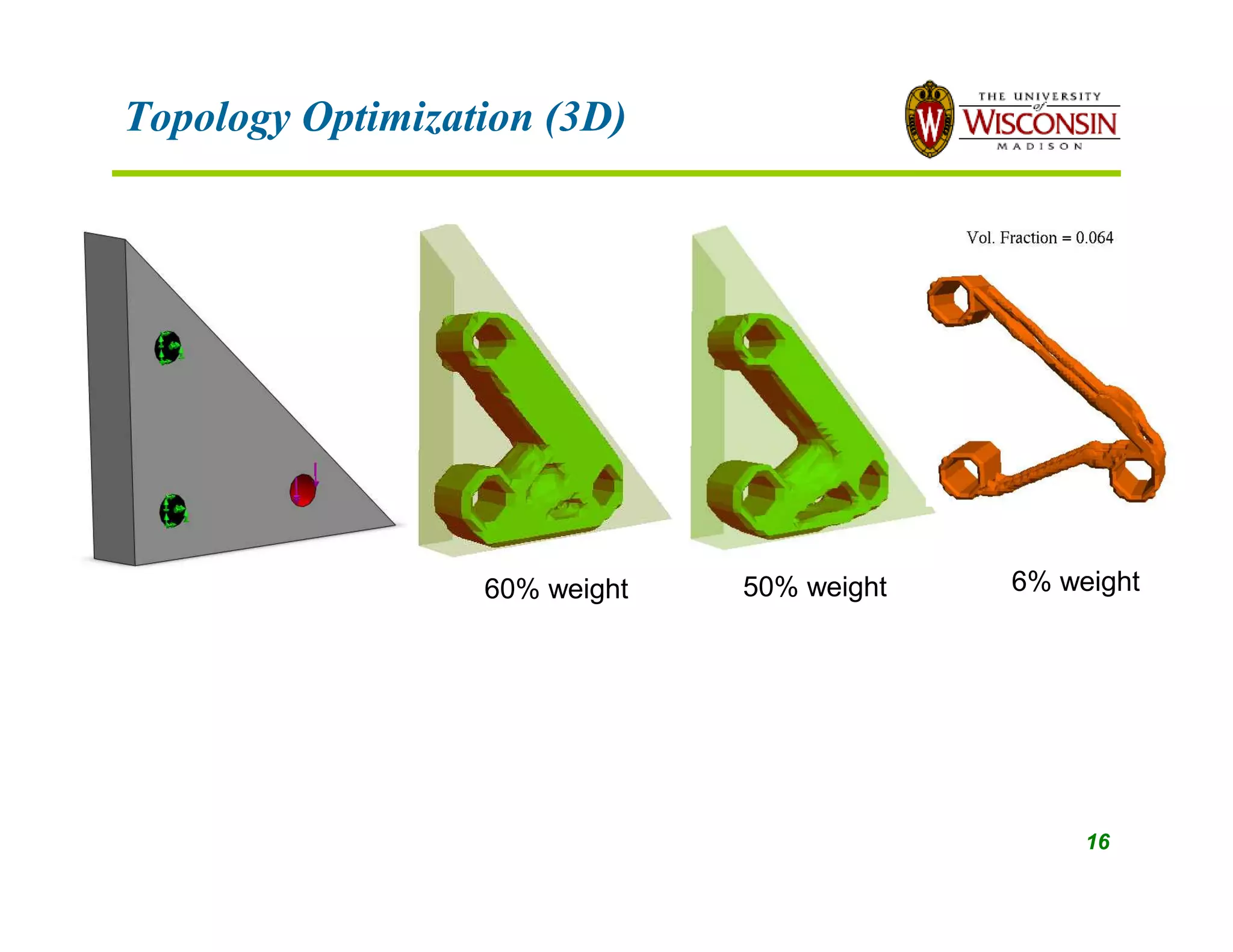

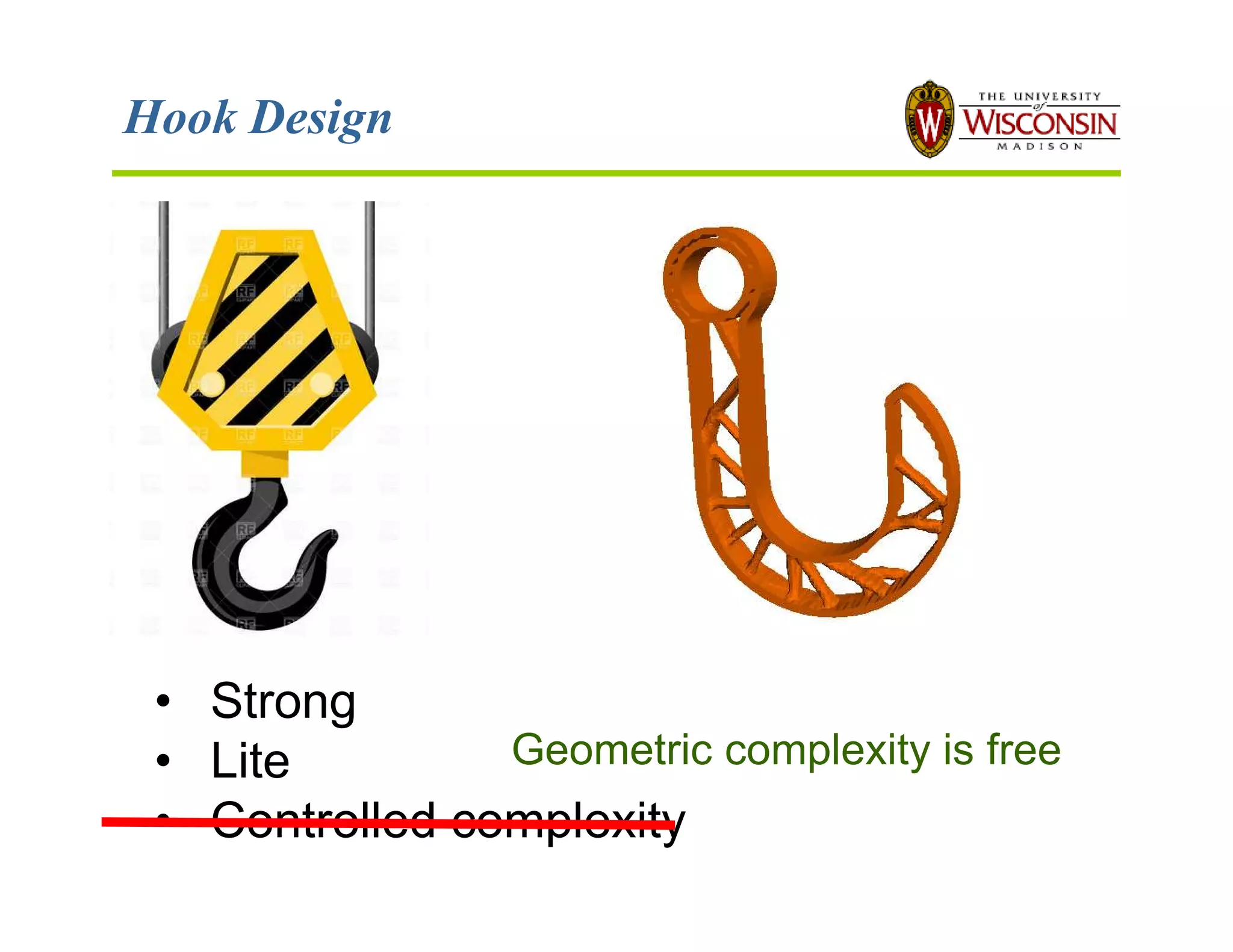

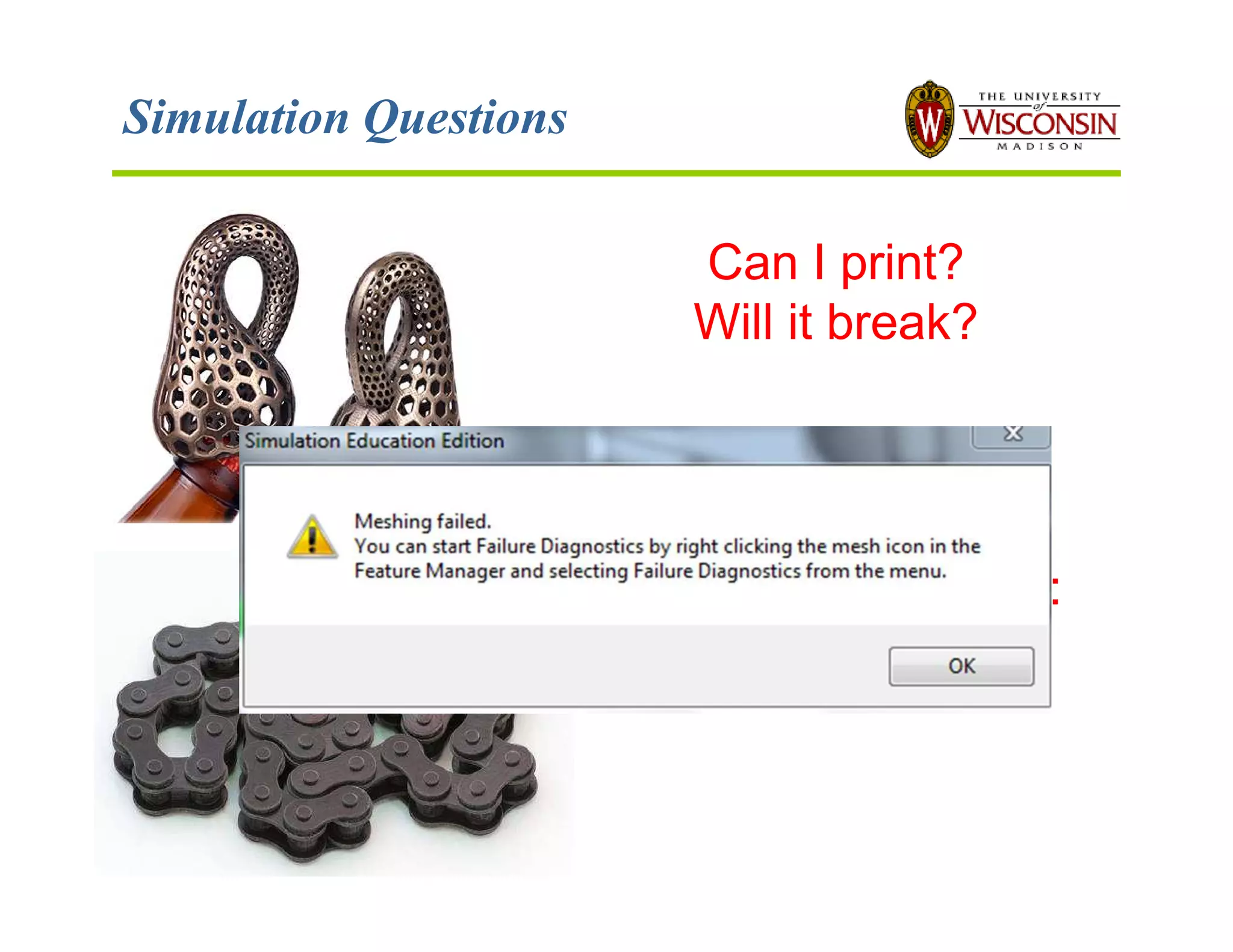

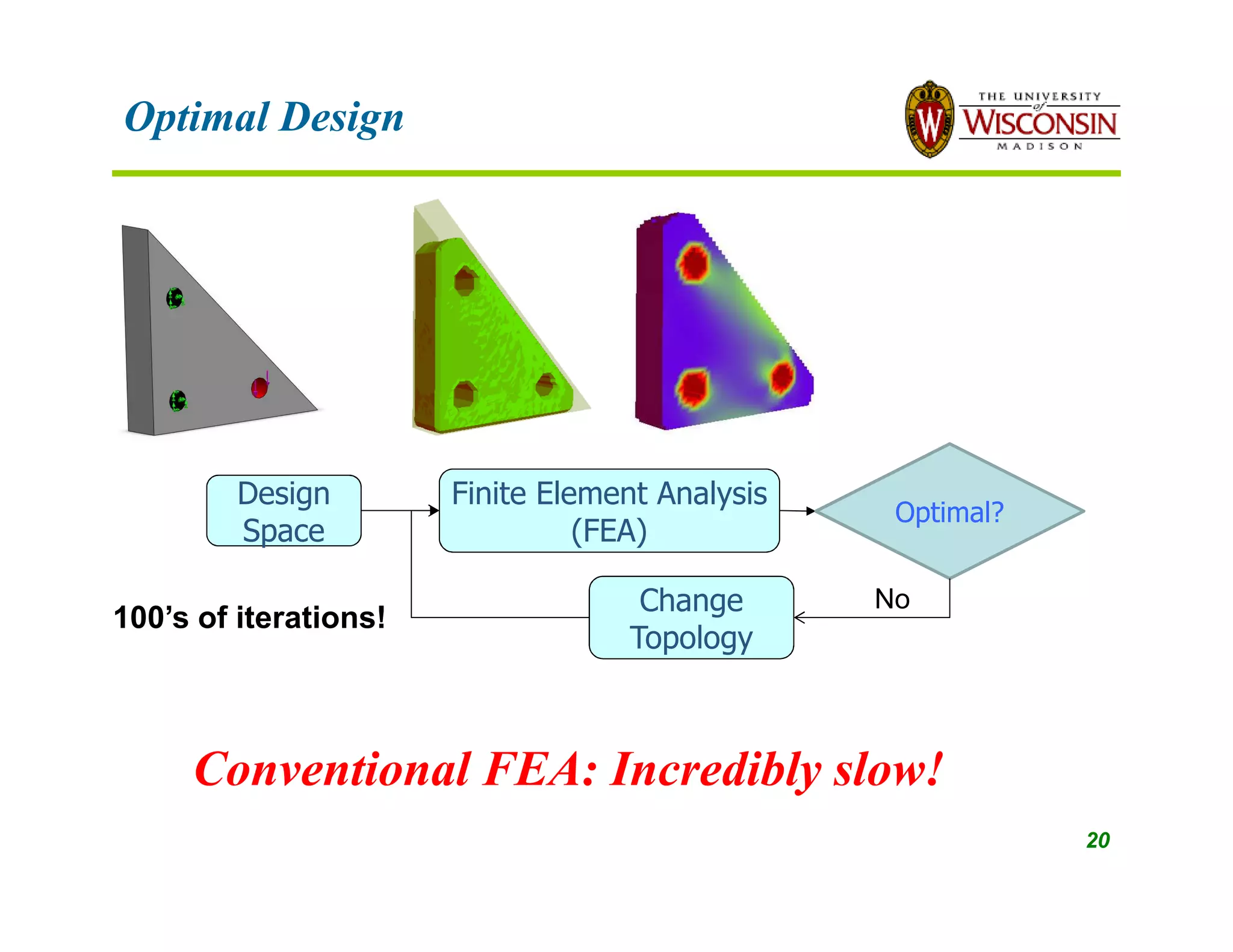

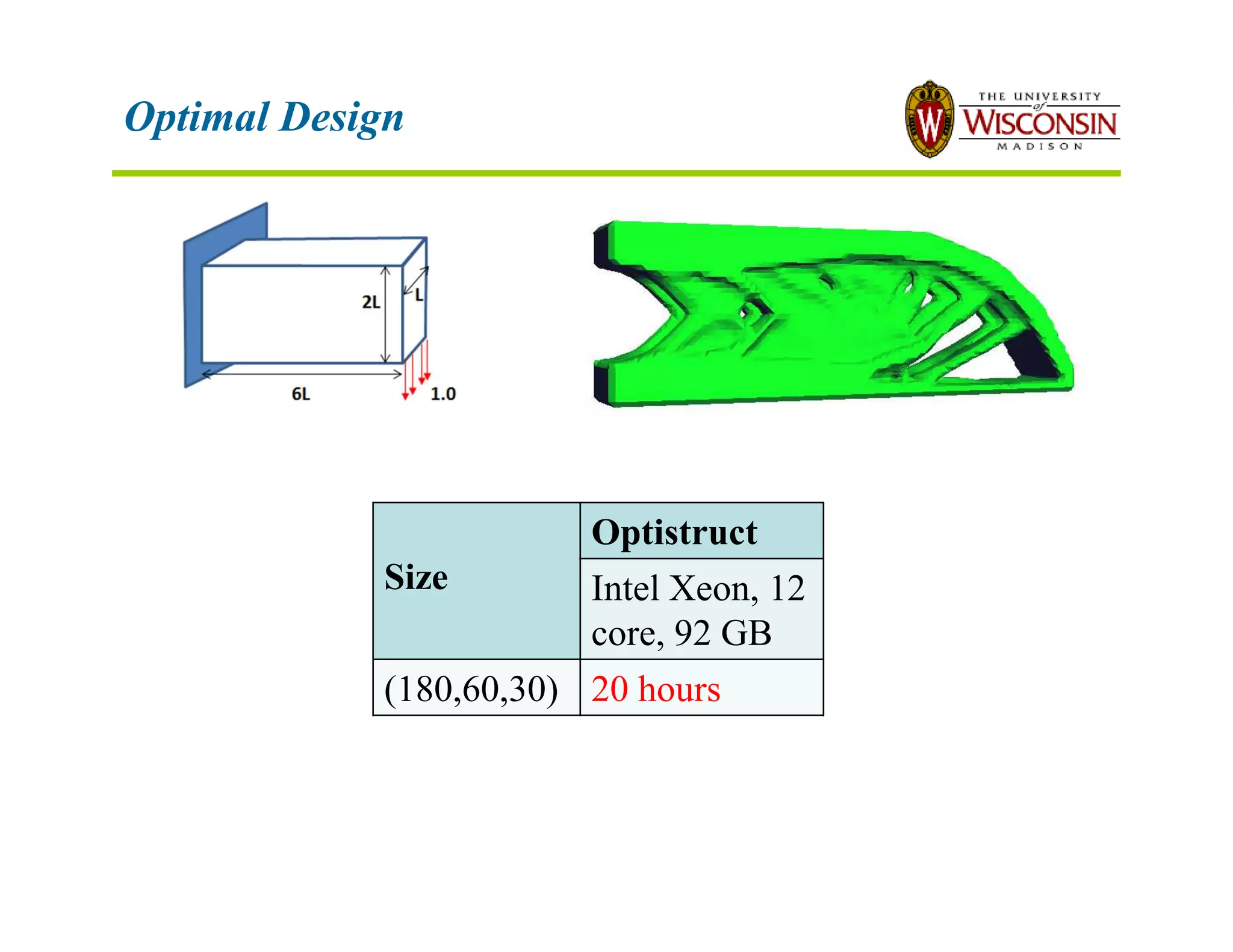

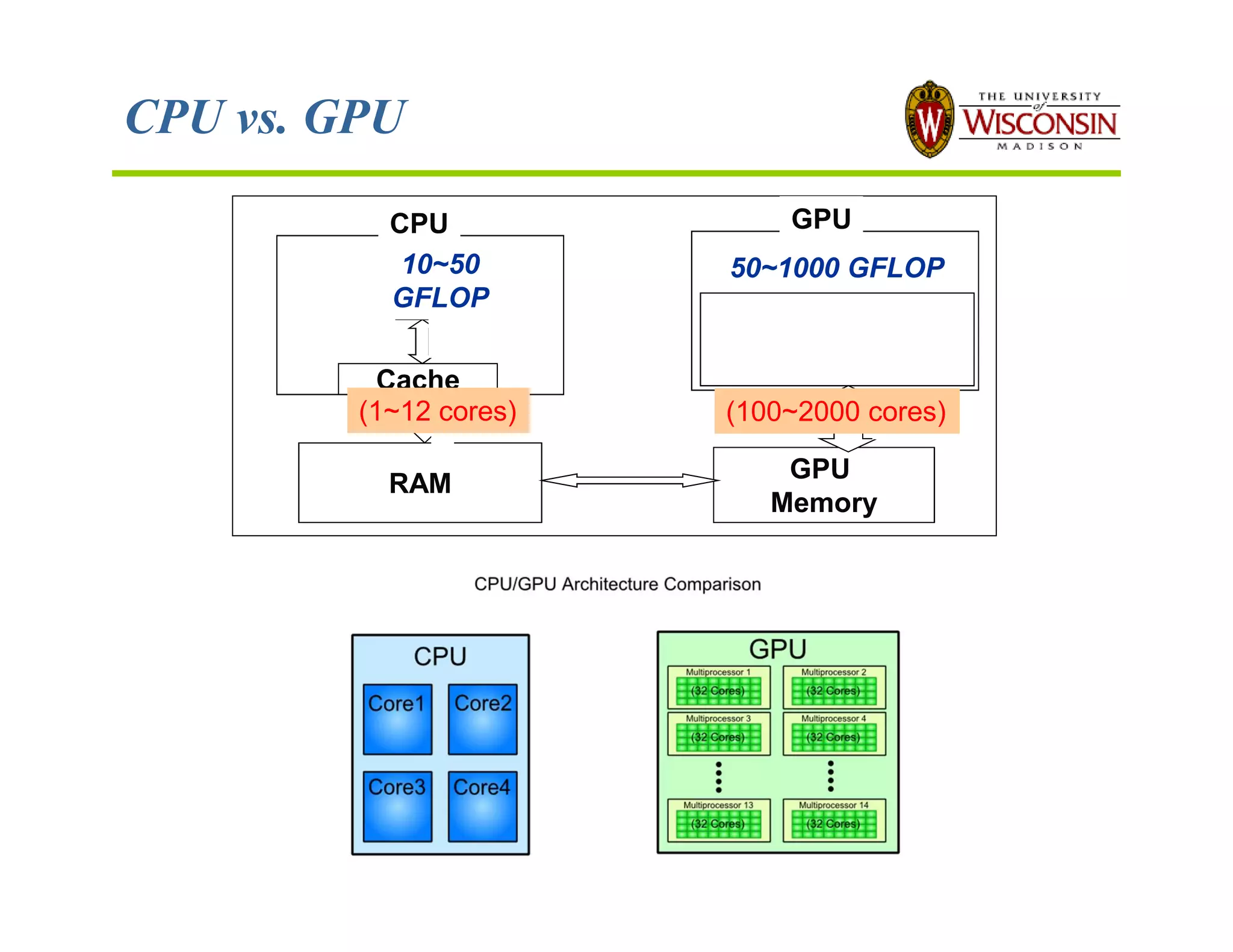

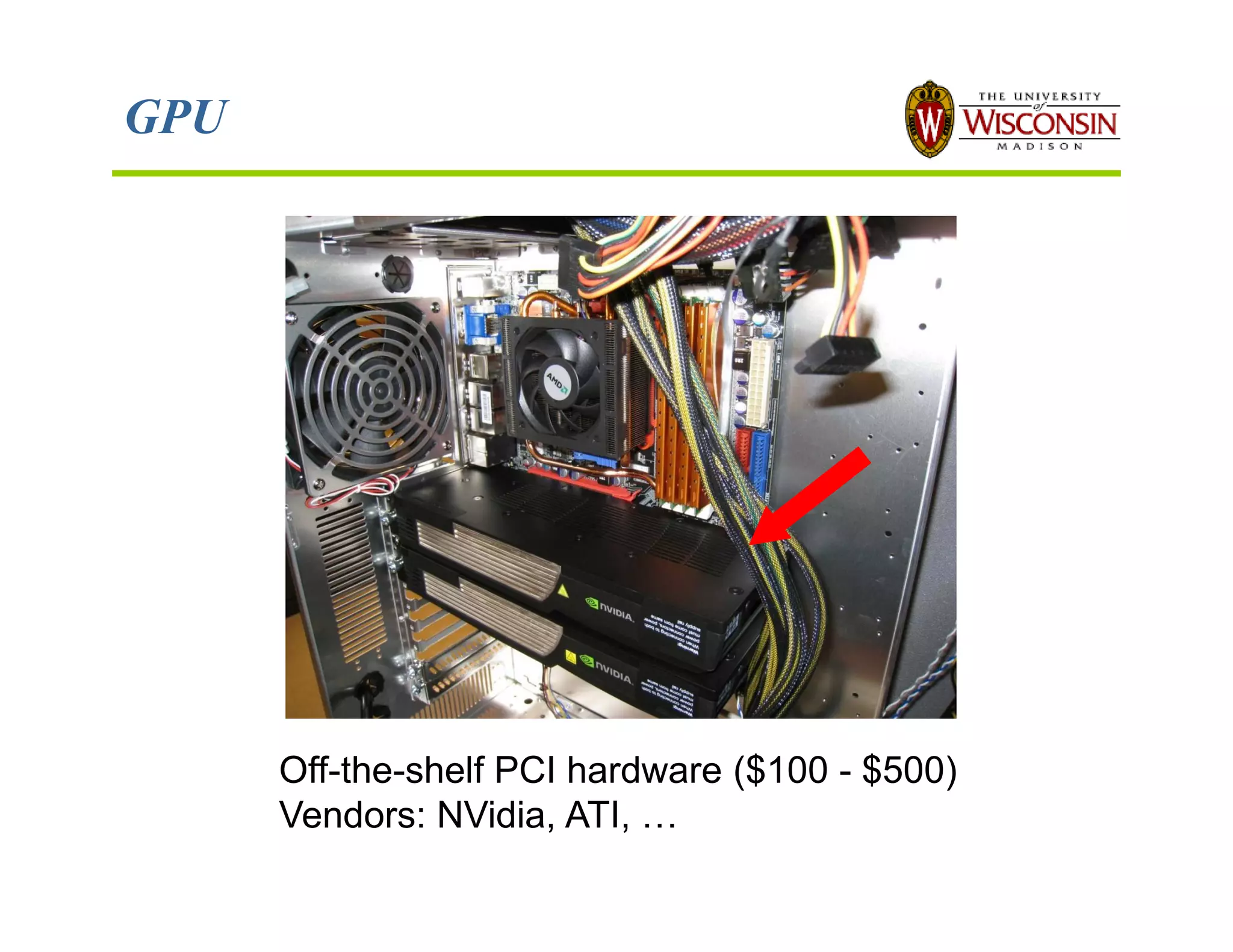

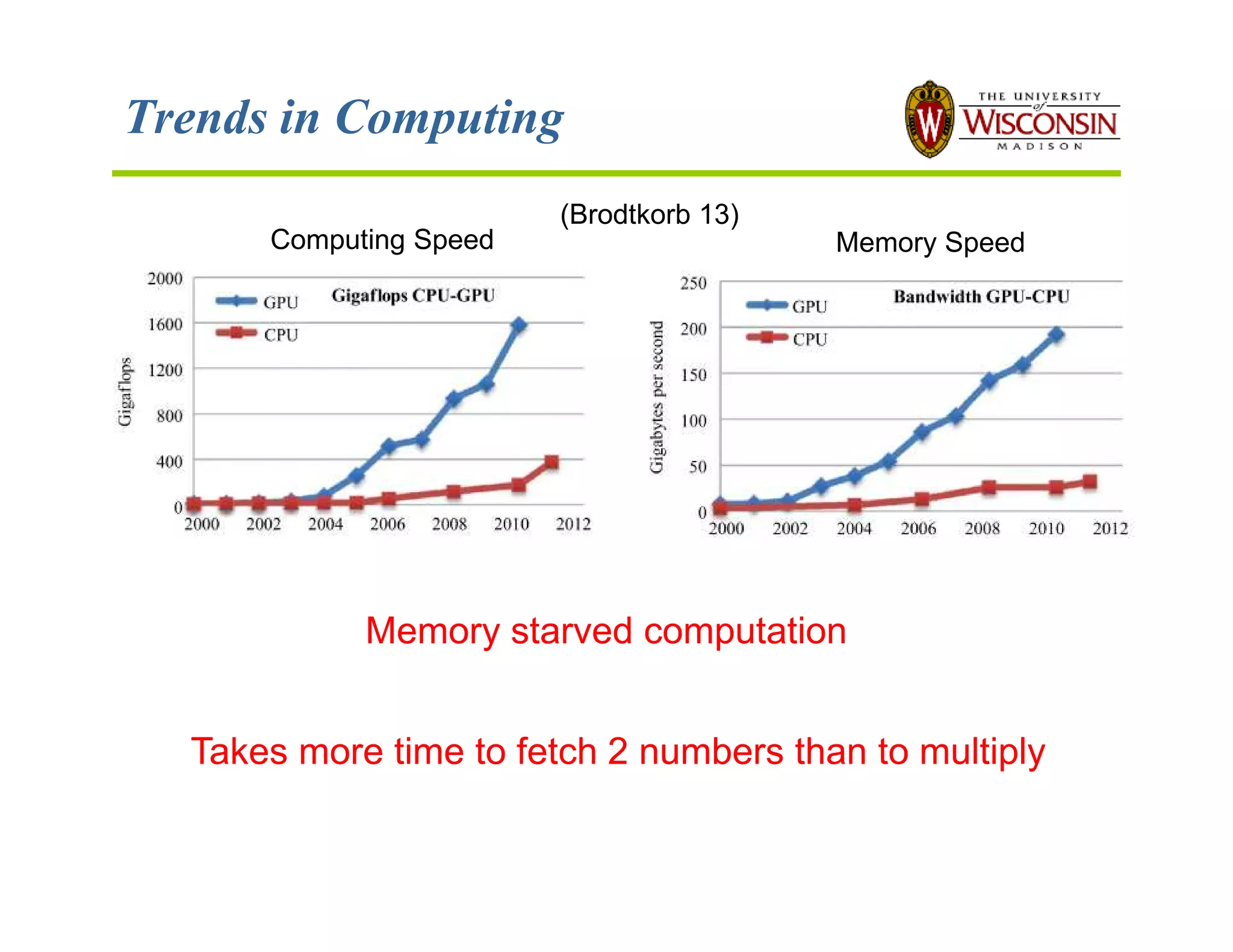

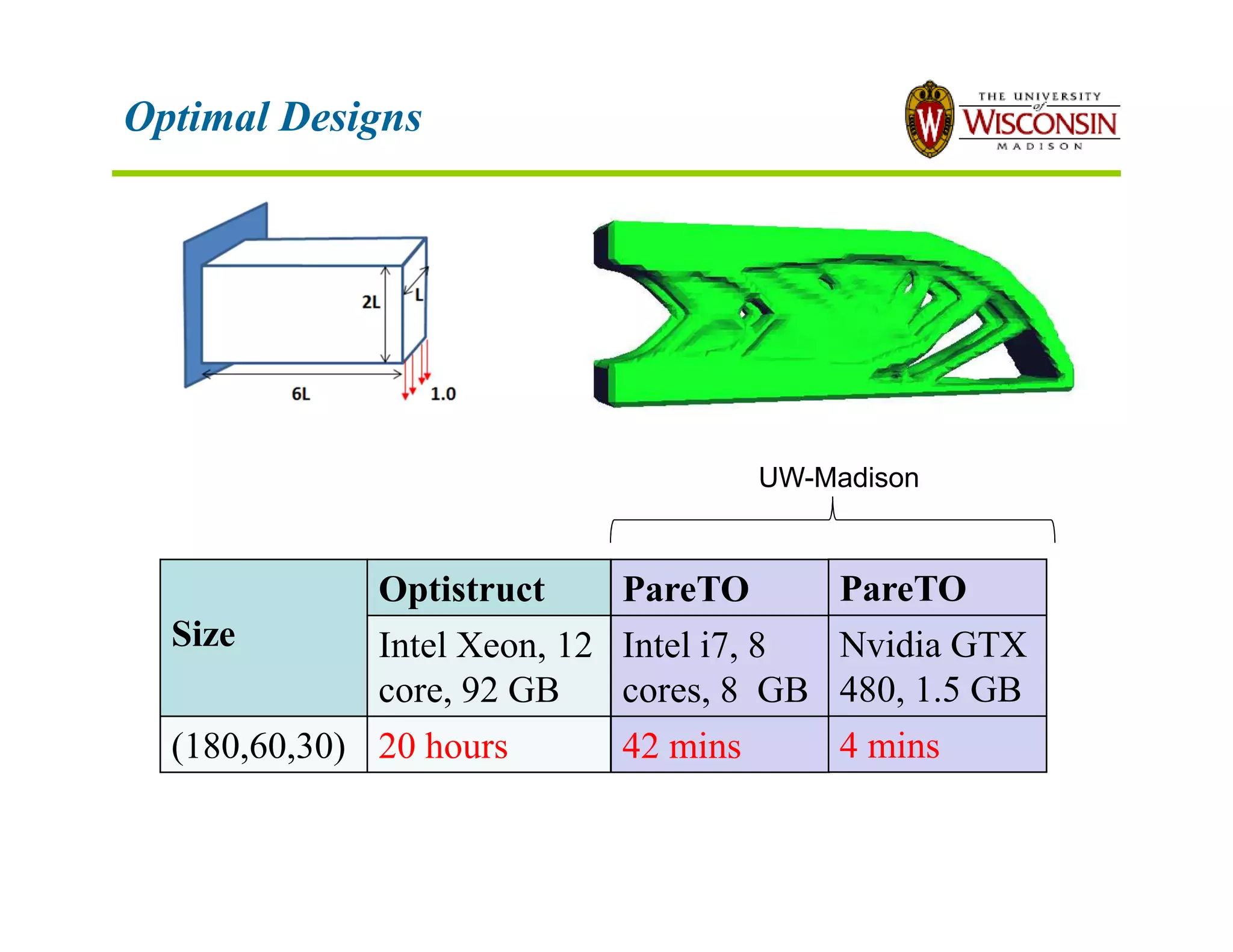

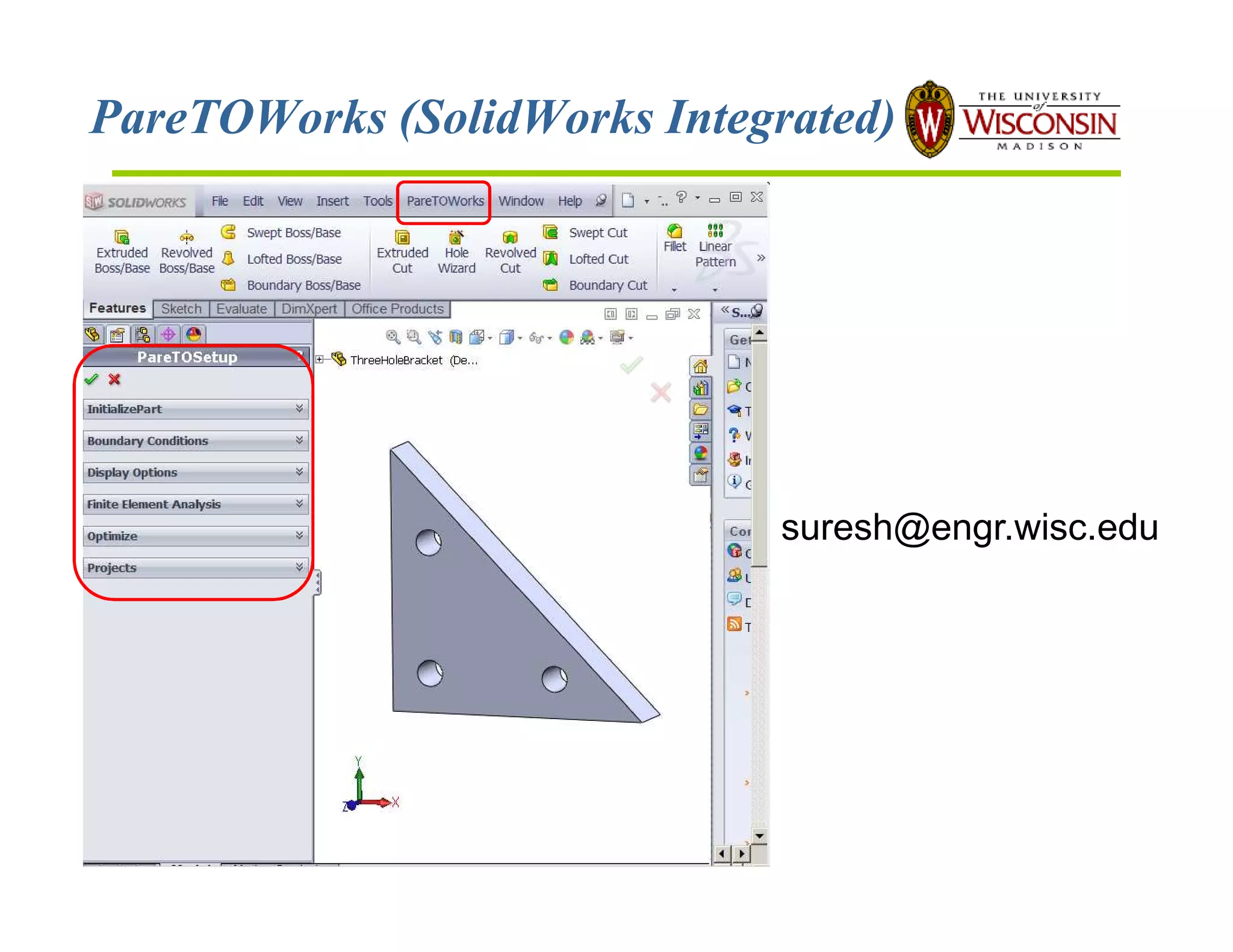

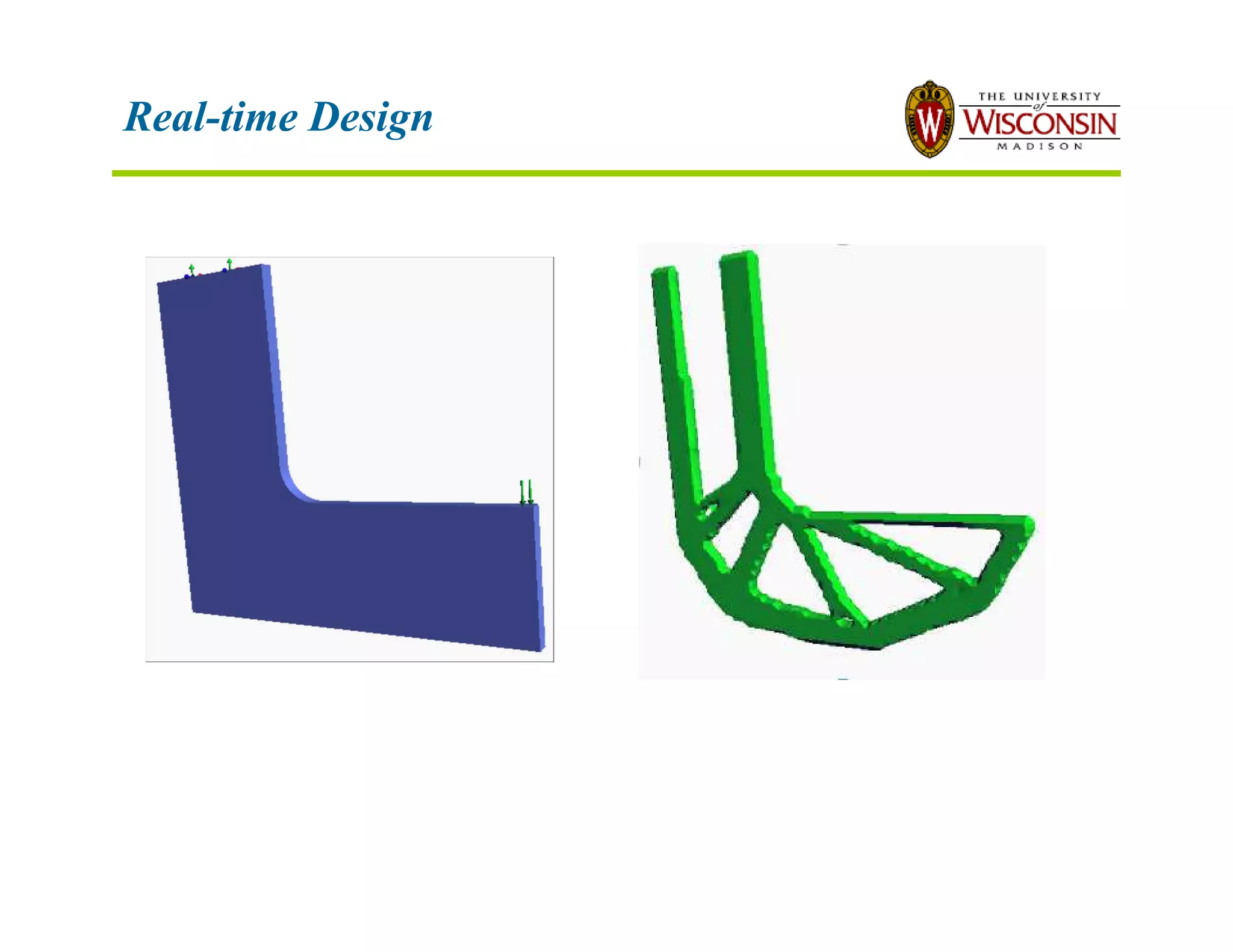

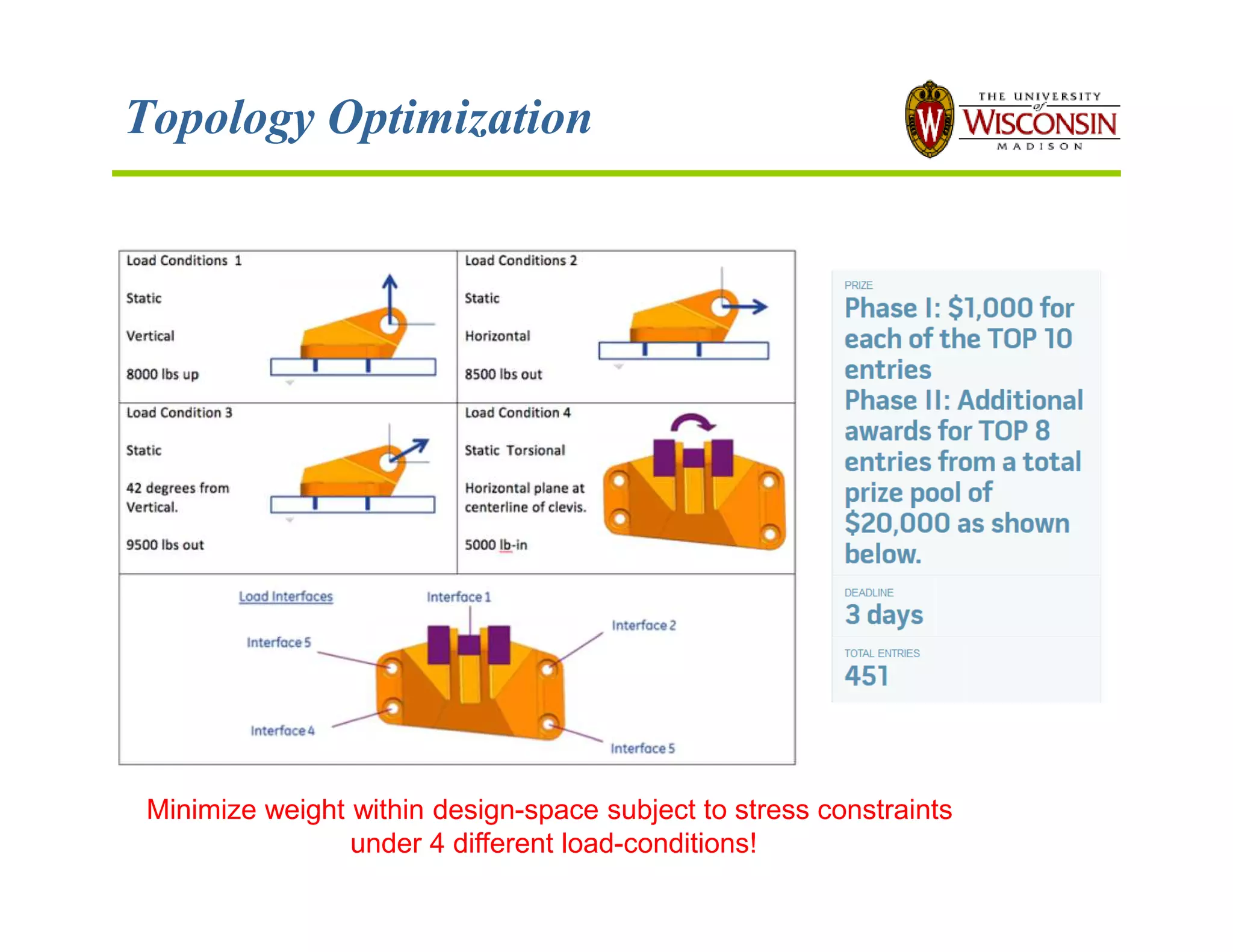

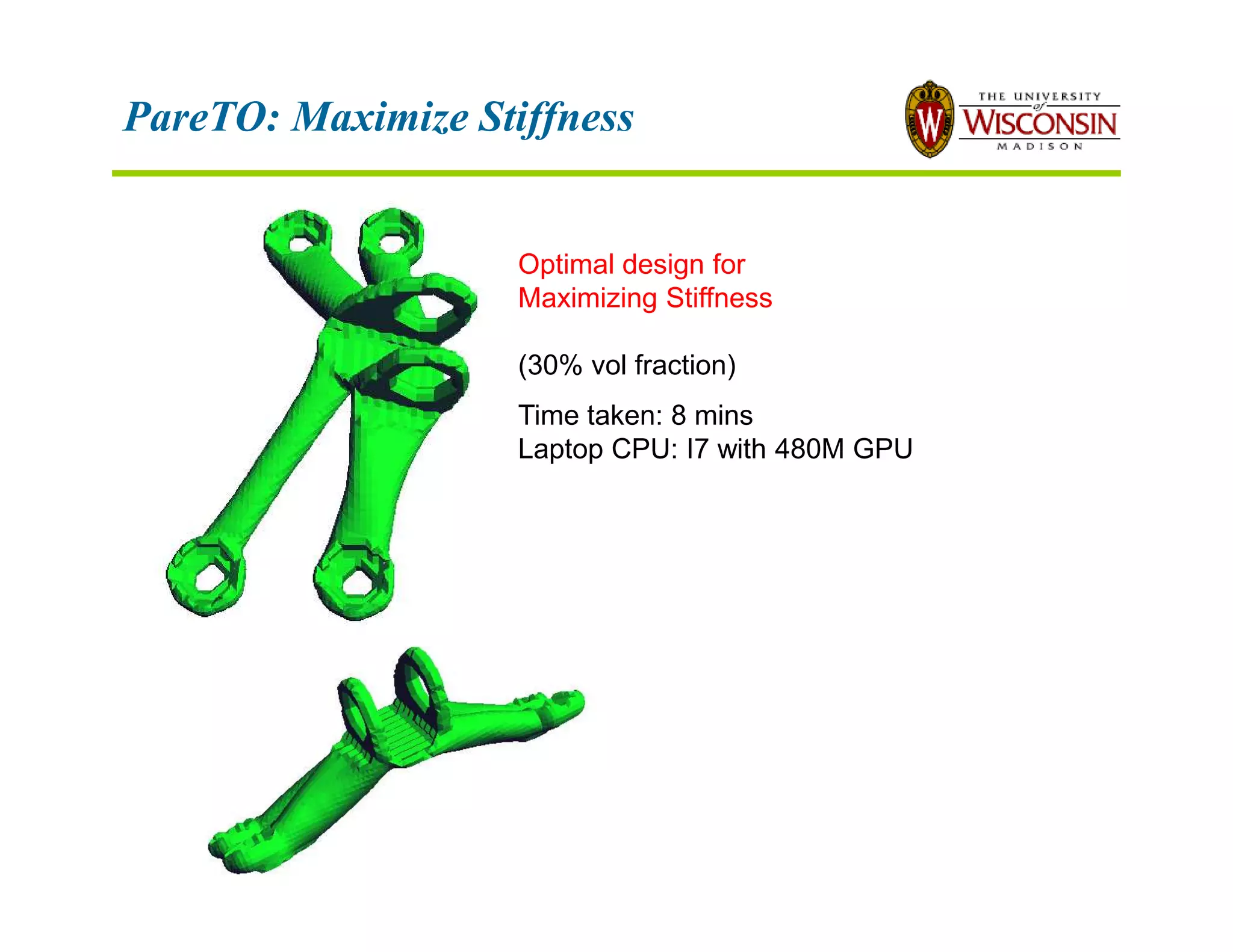

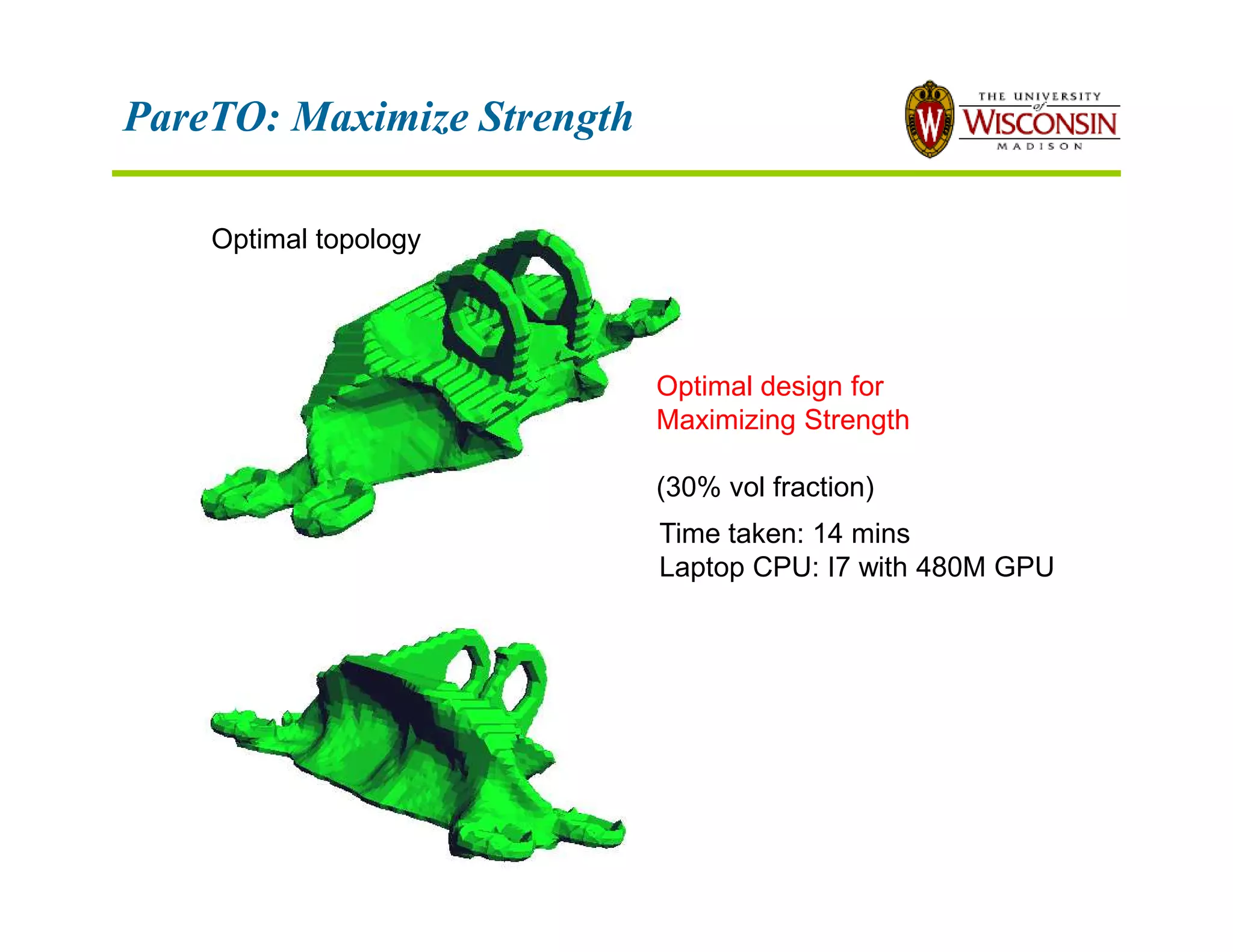

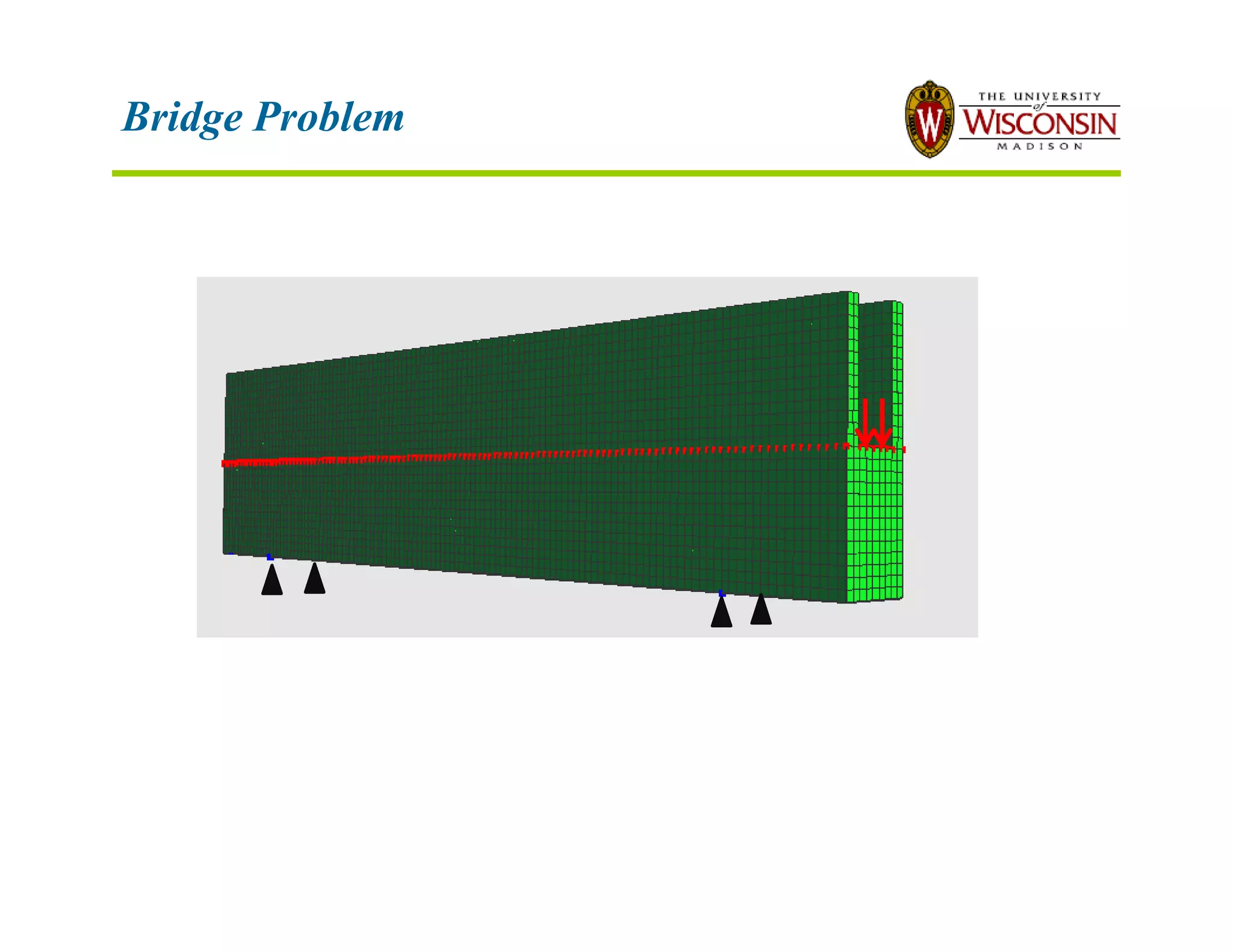

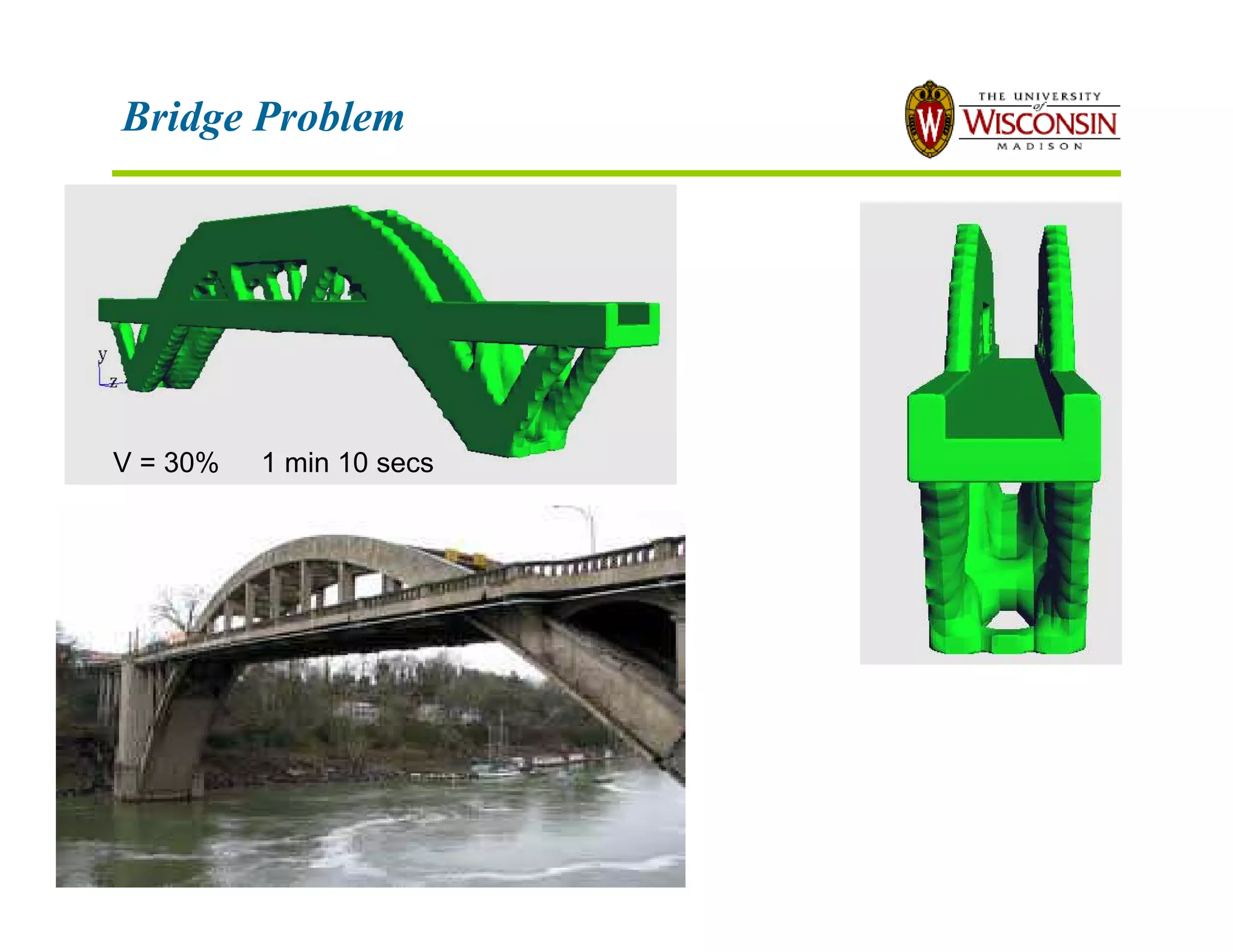

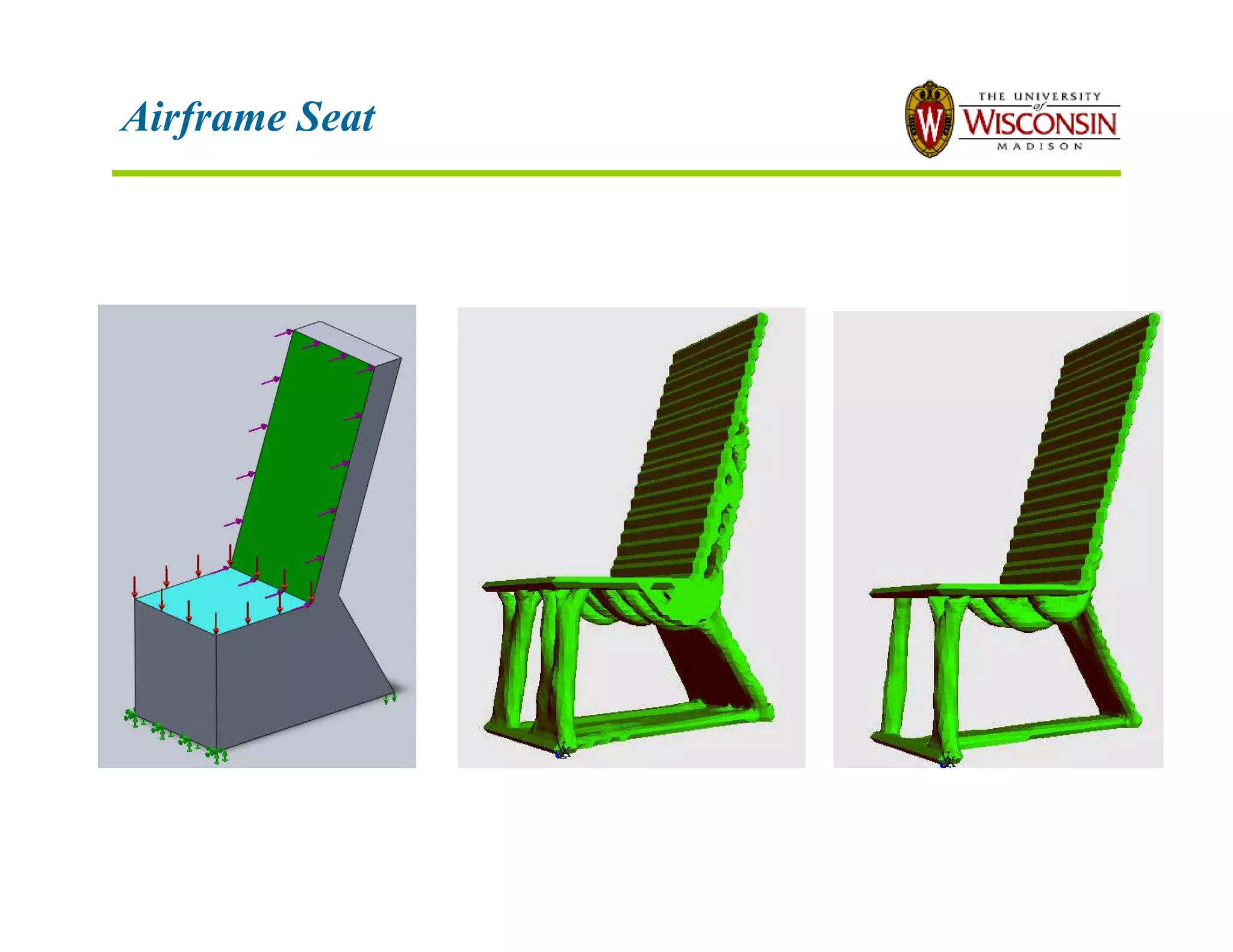

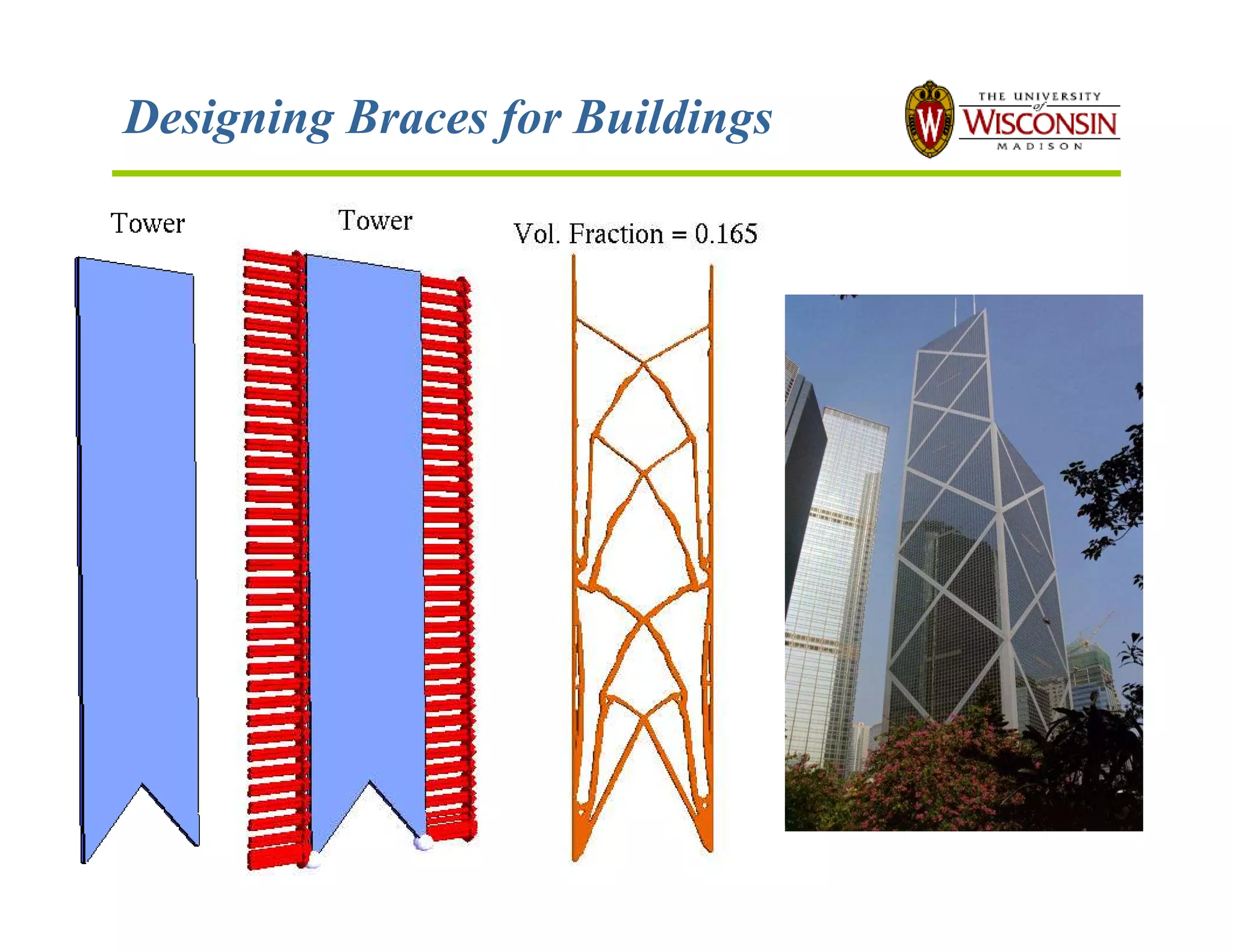

This document discusses new design paradigms enabled by 3D printing. It notes that 3D printing allows for geometric complexity at no added cost, unlike traditional manufacturing. This enables optimal and aesthetically complex part designs that may be stronger yet lighter. However, new design tools are needed to create such optimal complex parts. The document presents topology optimization as one such new tool that can design parts with minimum weight subject to stress constraints. It also discusses how GPU-based simulation can enable real-time topology optimization designs for 3D printing. In conclusion, 3D printing coupled with new design and simulation tools will lead to greater design freedom and more optimal lightweight complex parts.