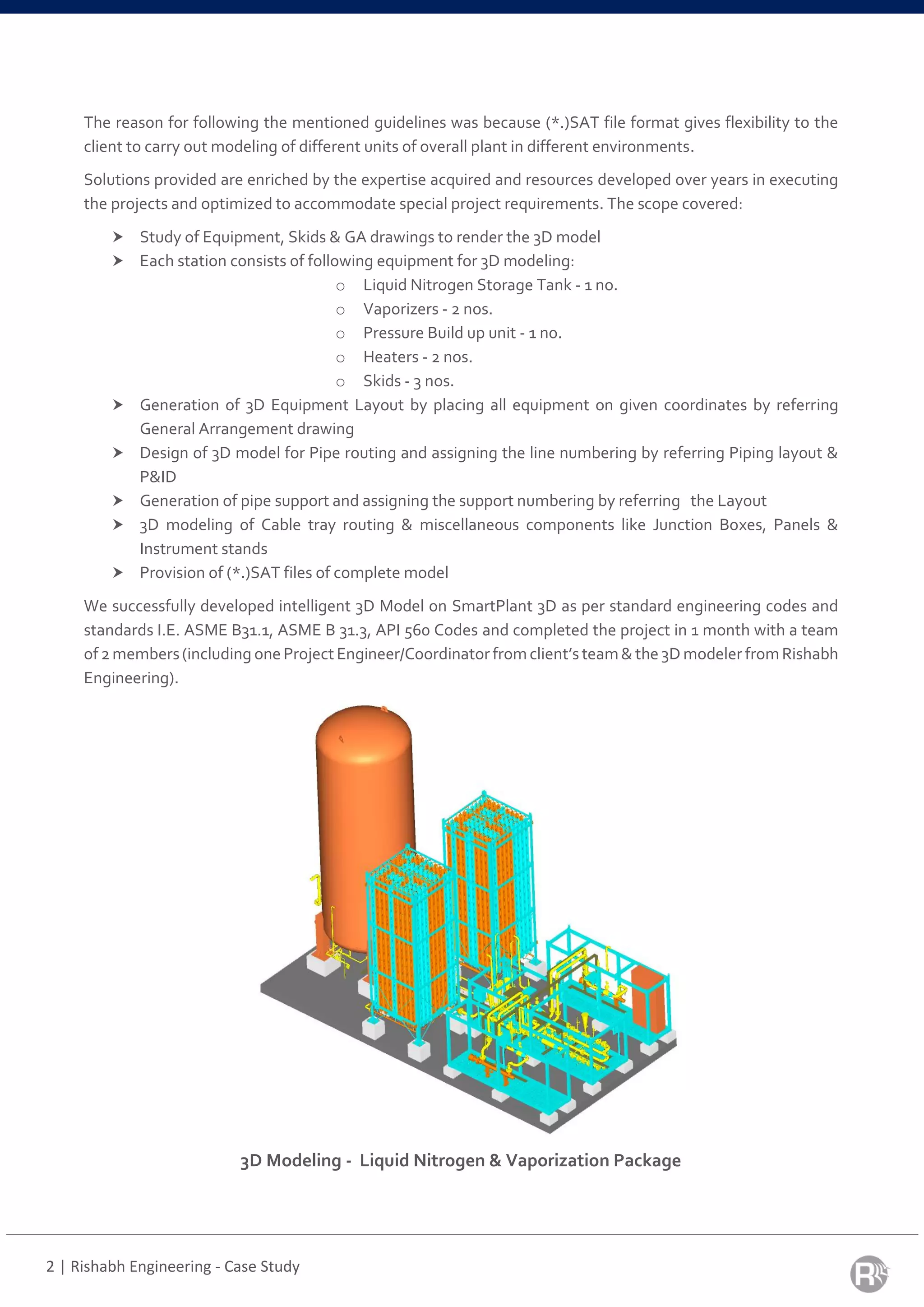

Rishabh Engineering was tasked with creating detailed 3D models for two liquid nitrogen storage and vaporization stations for a global leader in cryogenic storage solutions, completing the project in one month. Key challenges included ensuring the model files were in SAT format and limited to under 5 MB for optimal performance, which required innovative approaches to file compartmentalization. The project utilized Intergraph SmartPlant 3D technology and involved modeling various components, achieving 99.9% accuracy while adhering to engineering standards.