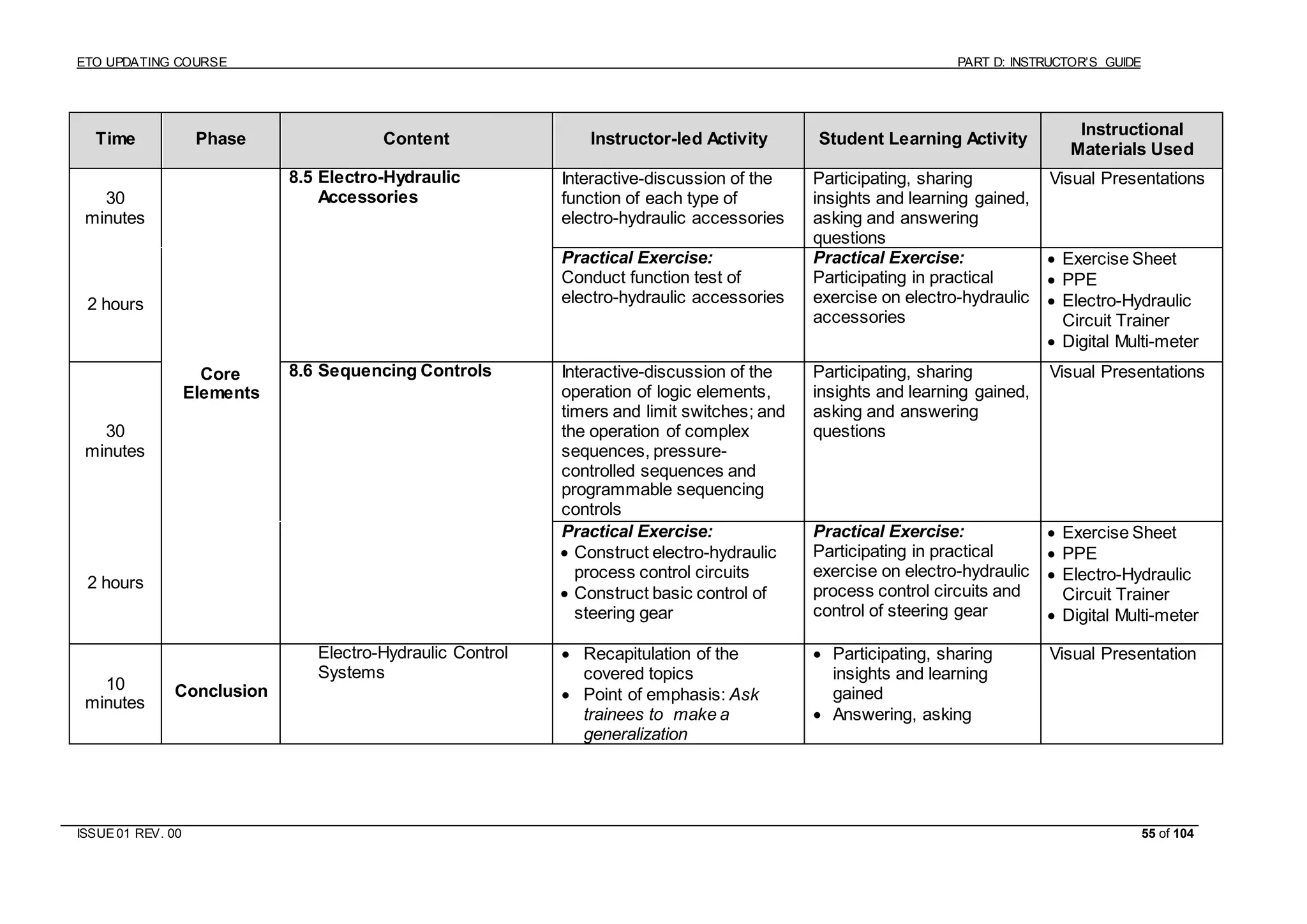

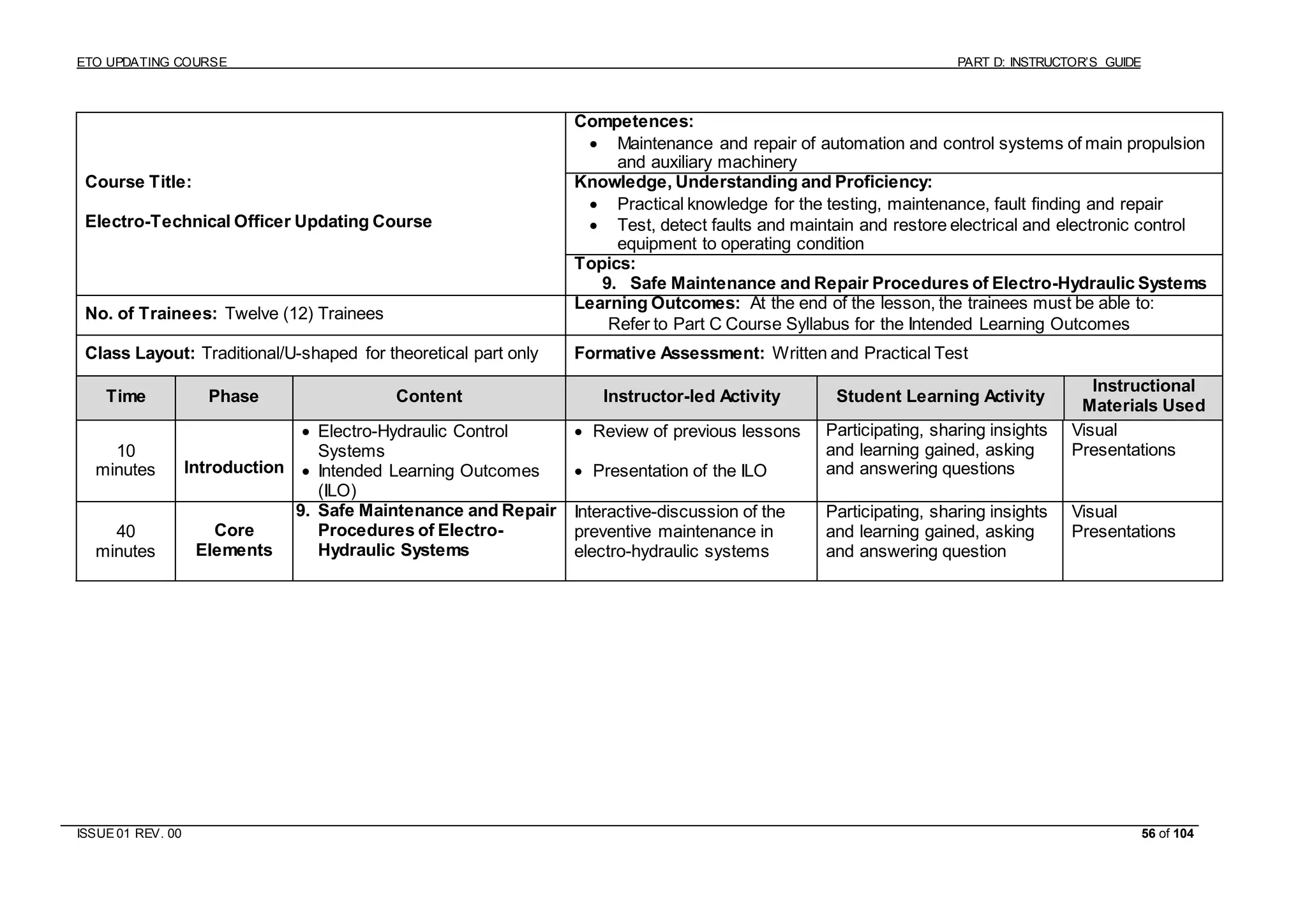

This document outlines an instructor's guide for an Electro-Technical Officer Updating Course. The course focuses on monitoring electrical, electronic and control systems, as well as automatic control systems for propulsion and auxiliary machinery. One module involves electro-hydraulic control systems and covers fundamental principles, hydraulic pumps, control valves, actuators, accessories, and sequencing controls. Practical exercises are included to teach function testing and maintenance of electro-hydraulic equipment. Another module addresses safe maintenance and repair procedures for electro-hydraulic systems through discussion and practical exercises involving fault detection, equipment repair, and performance testing.