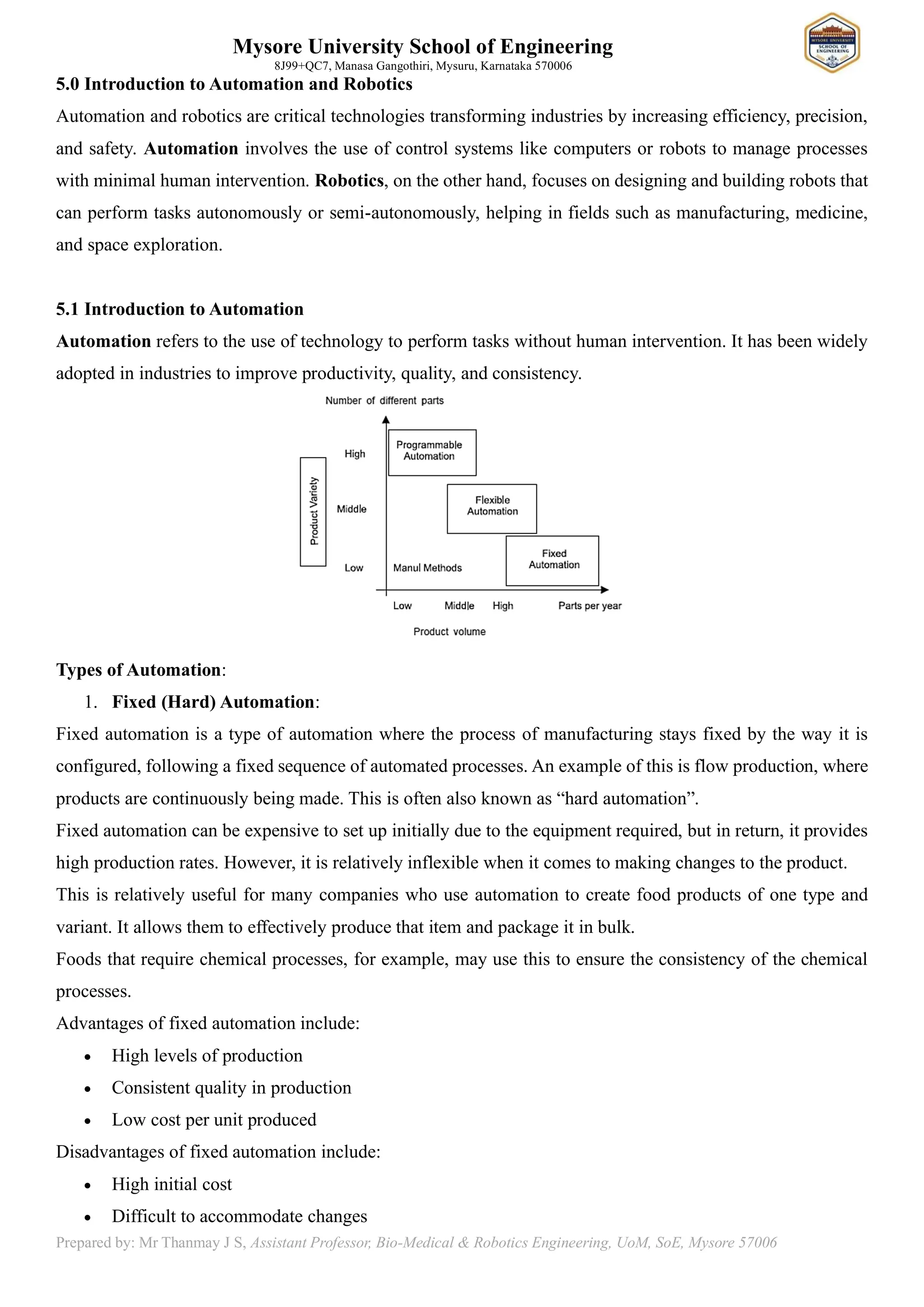

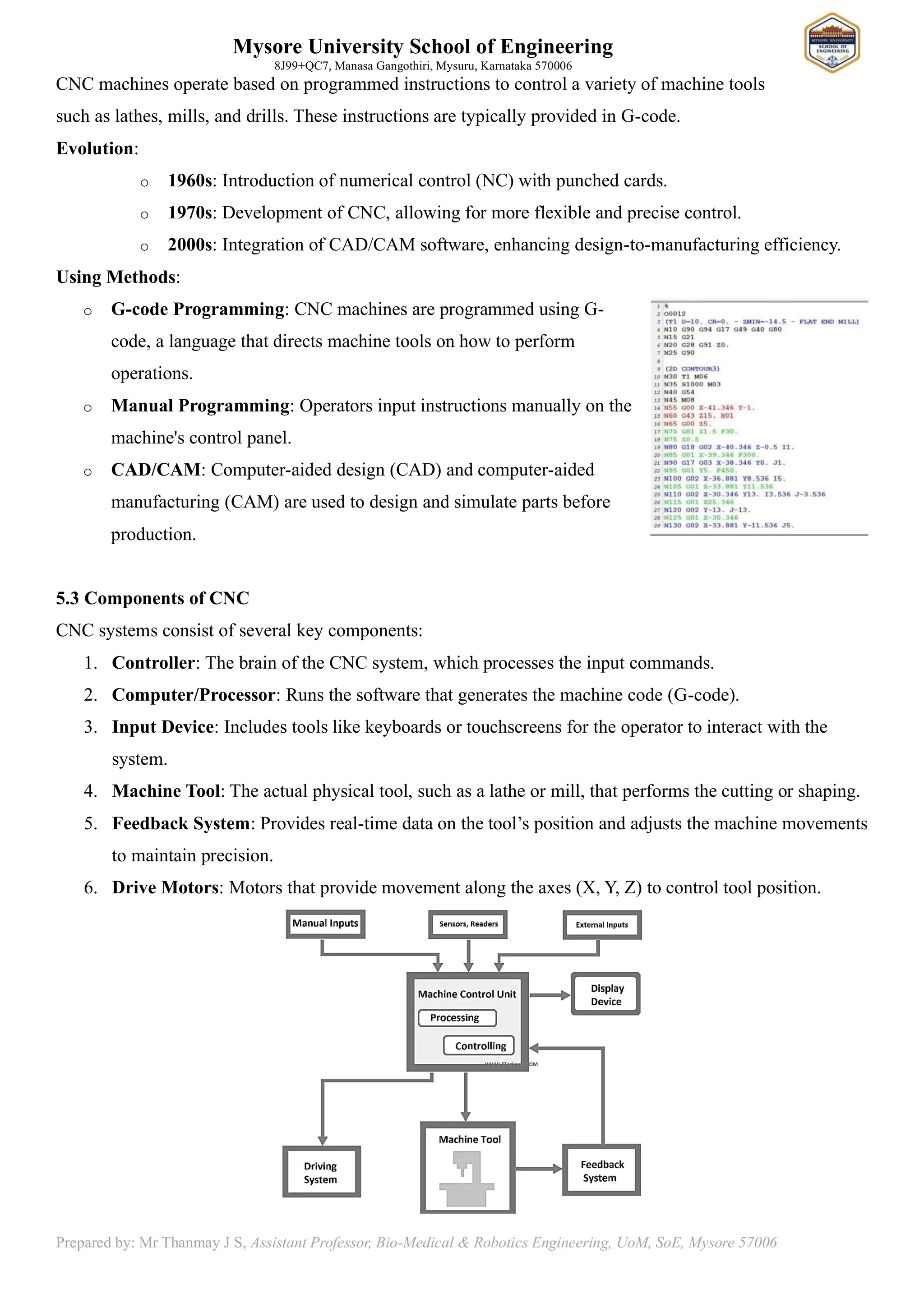

Automation and Robotics: Automation: CNC-

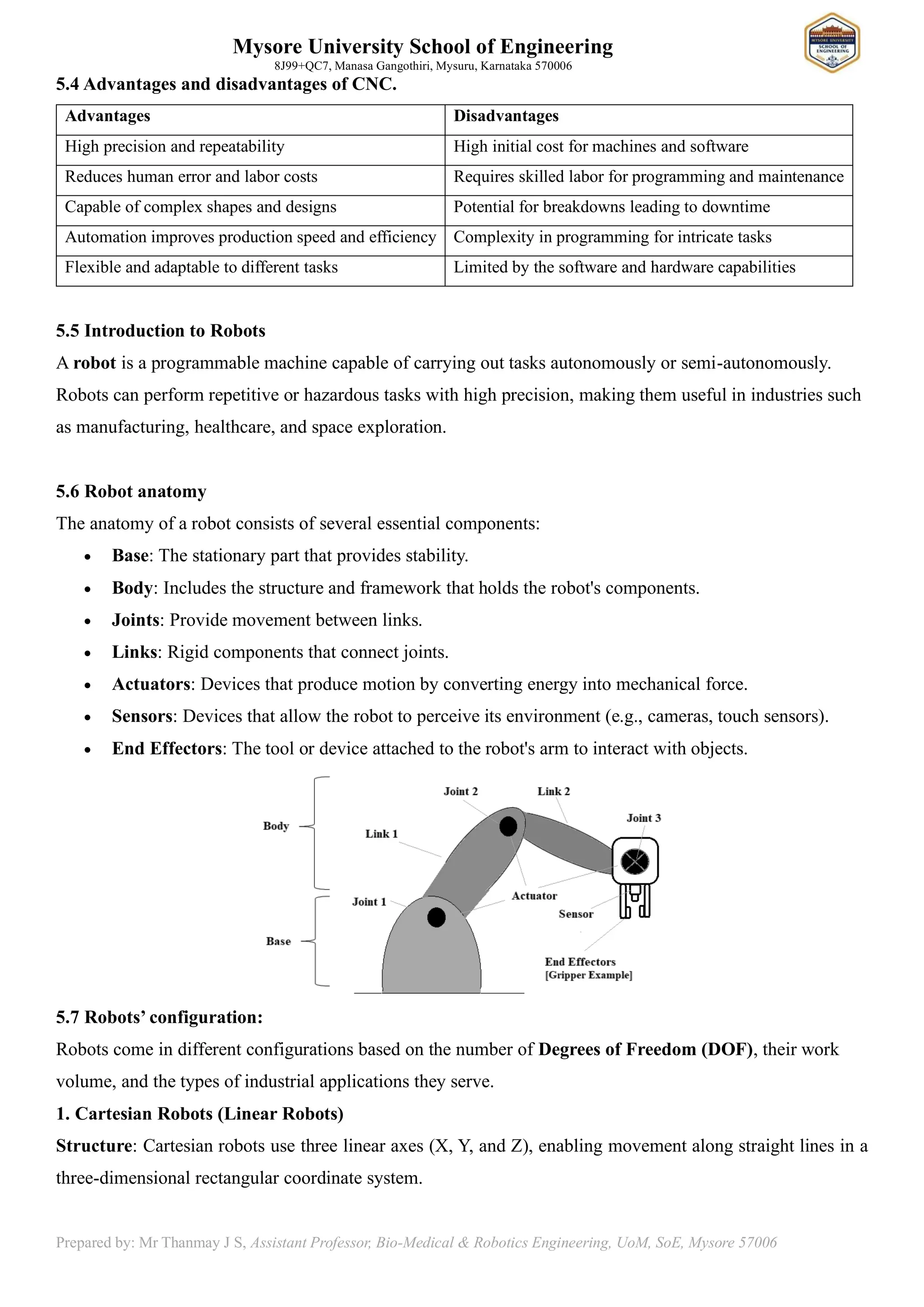

Introduction, components of CNC, Advantages and

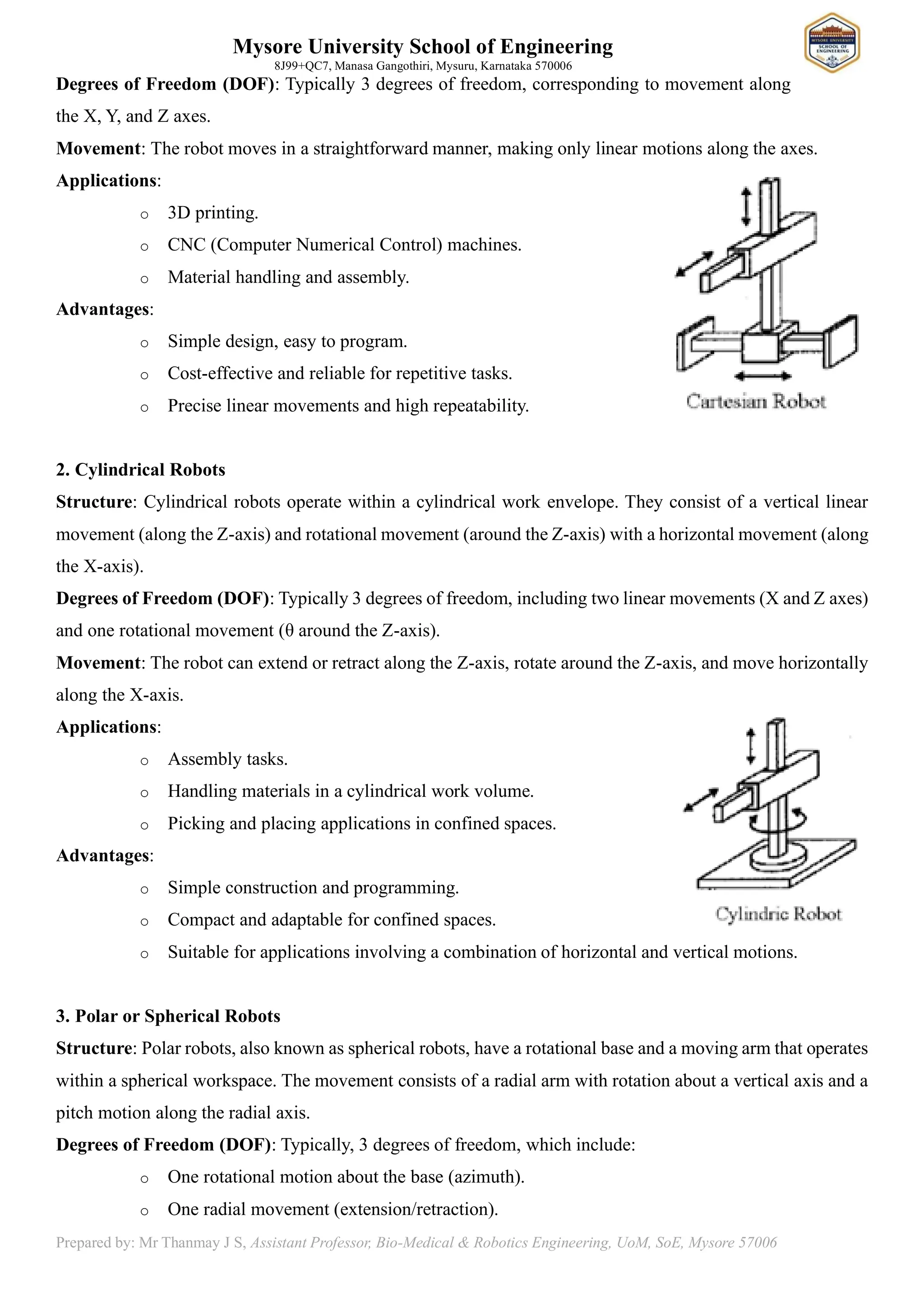

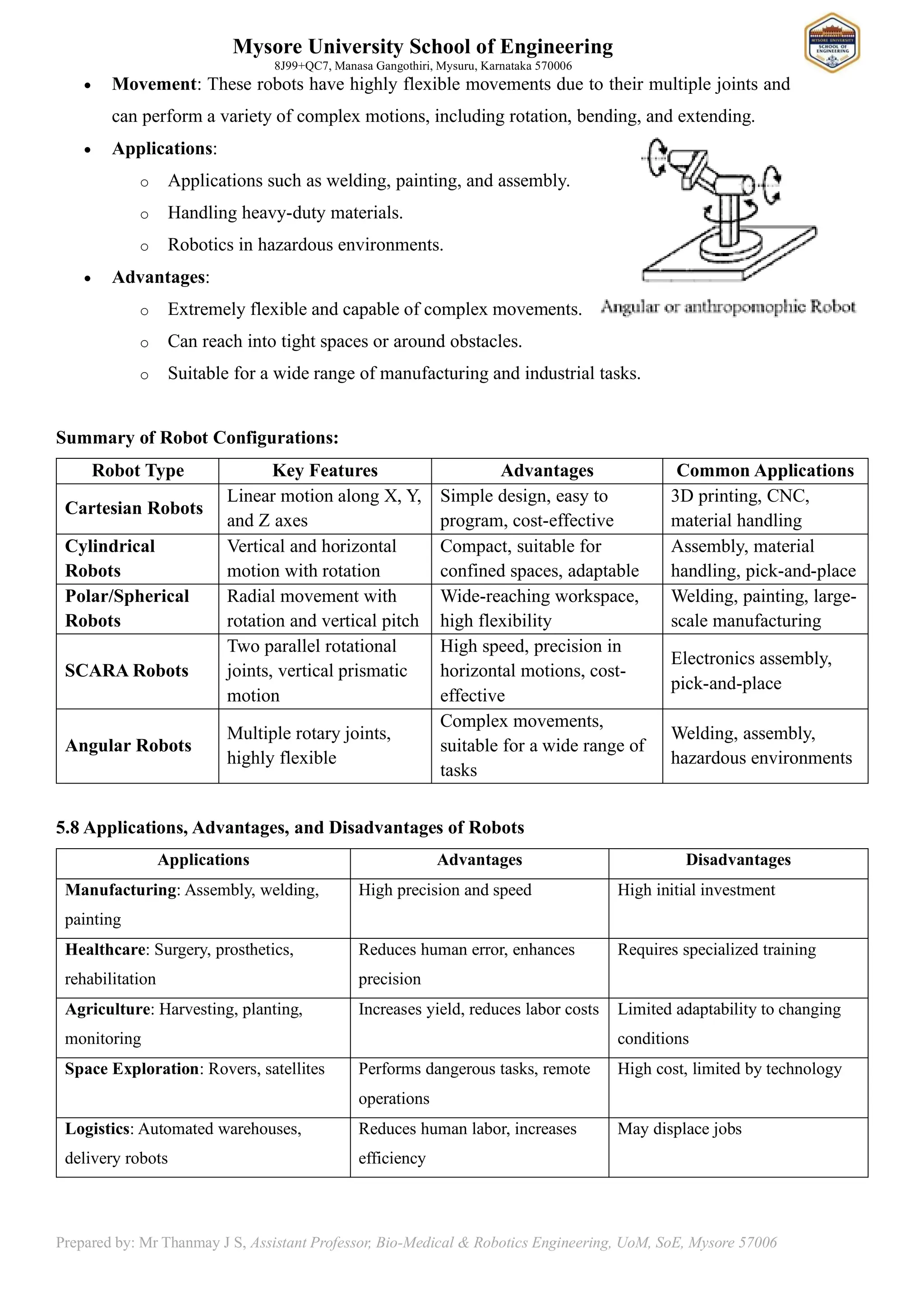

disadvantages of CNC. Robotics: Introduction, Robot

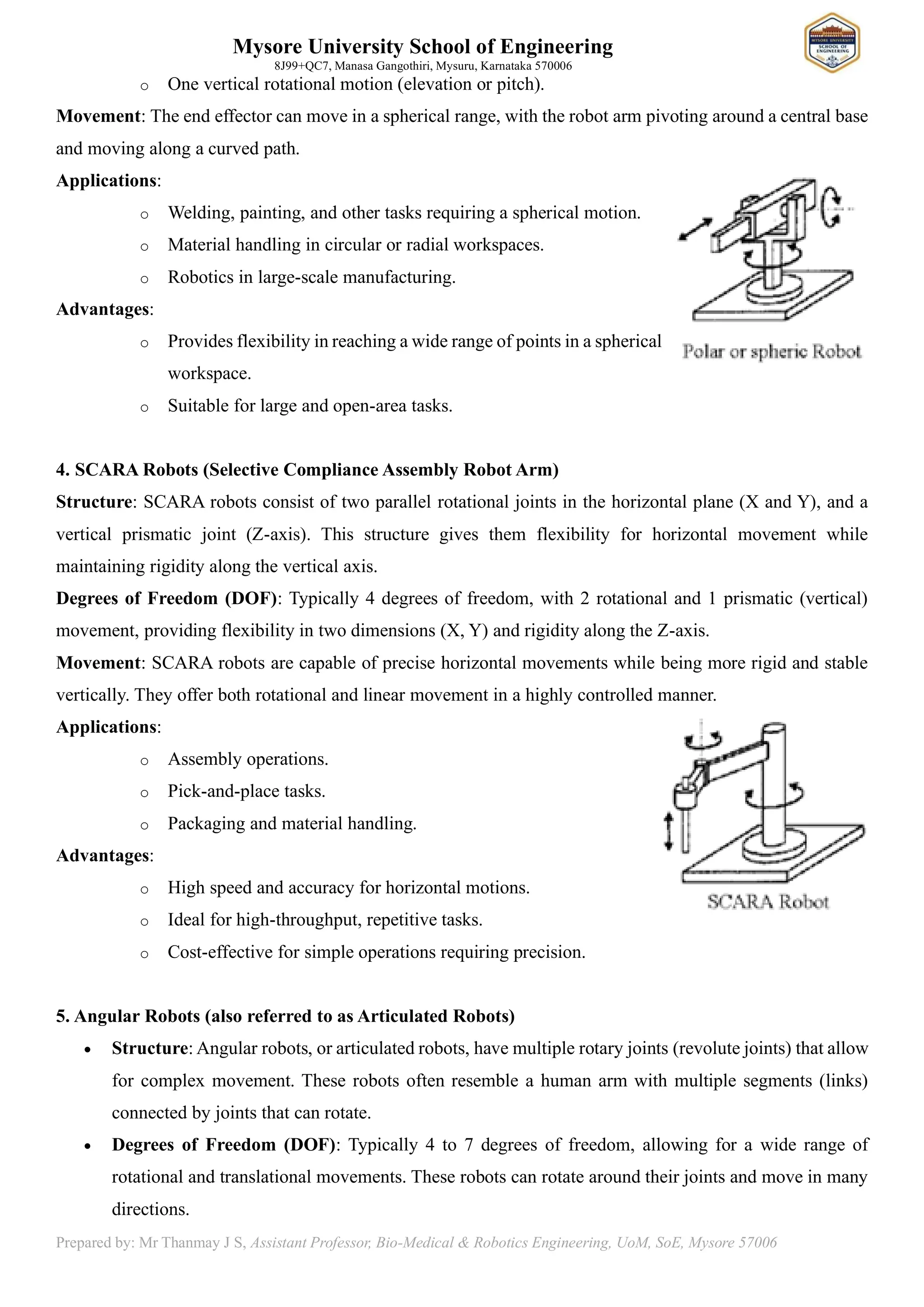

anatomy, Robots configuration- Polar, cylindrical, Cartesian

coordinate and spherical. Applications, Advantages, and

disadvantages.

Engineering Materials: Properties, Composition and

Industrial Applications of engineering materials Metals –

Ferrous: cast iron, tool steels and stainless steels and Non-

ferrous: aluminium, brass, bronze.

Polymers - Thermoplastics and thermosetting

polymers. Ceramics - Glass, optical fiber, glass, cermet’s.

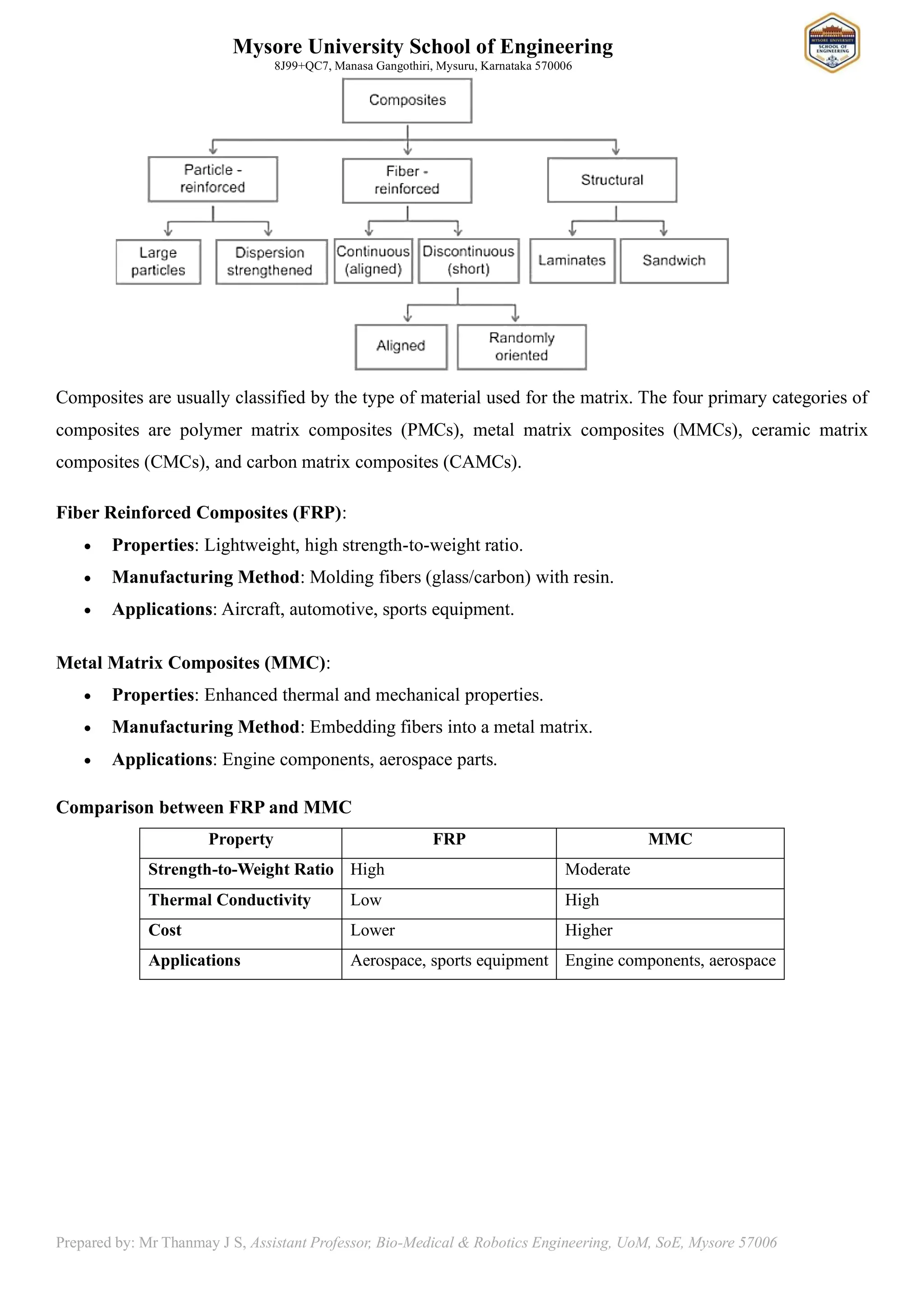

Composites - Fiber reinforced composites, Metal Matrix

Composites