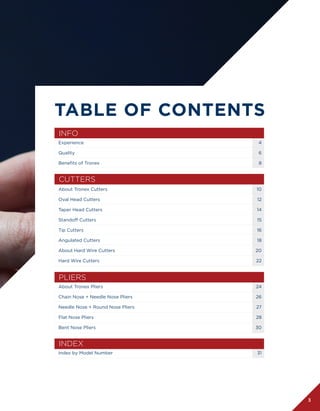

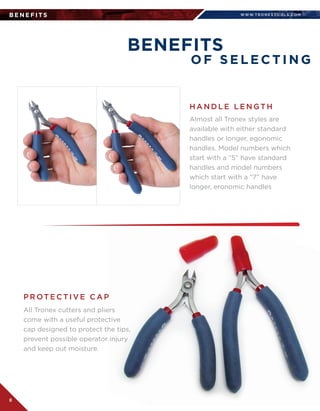

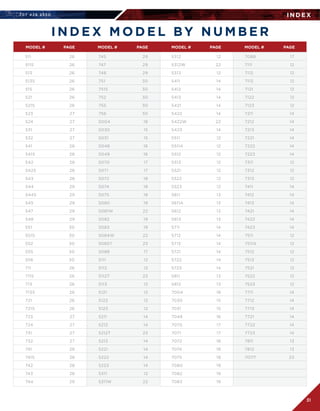

The document is a catalog from Tronex Tools that provides information about their cutting and plier products. Tronex has been a leader in precision hand tools for over 35 years. The catalog includes details about Tronex's history and manufacturing process to ensure high quality. It also provides specifications and descriptions of their various cutter and plier models for different applications.