1993 Honda Prelude Service Repair Manual.pdf

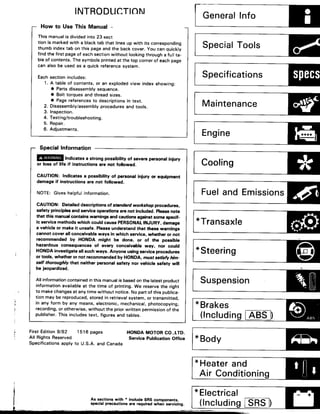

- 1. I - L ' _ _ _ INTRODUCTIONI How to Use This Manual - This manualis dividedinto 23 sect tion is markedwith a blacktab that lin€sup with its co.responding thumb indextab on this paqeandthe backcover.you can auicklv tindthe tirstpageof eachsectionwithout lookingthrougha full ta- bleof contents.Thesymbolsprintedat the top cornerof eachpage can alsobe used as a quick reference system. Eachsectionincludes: 1. A table of contents,or an explodedview indexshowing: a Partsdisassemblv sequence. a Bolt torquesand threadsizes. a Pagereterences to descriptions in text. 2. Disassembly/assembly procedures and tools. 3. Inspection. 4. Testing/troubleshooting. 5. Repair. 6. Adjustments. SpecialInformation @@ tnai""tes a strong possibilityot sevorop€rsonalinjury or losa of lite it instluctions ar€ not tollowed. CAUTION: Indicates a possibility of poBonal iniury ol oquipmont damage if instructions aro not tollowed. NOTE: Giveshelpfulinformation. CAUTfON: Detaifoddescriptionsol st ndard wo*shop procedures, satety p nciplesand servic€opalationsaro not includod.pleasonot6 that this manualcontainswamingsandcautionsagainstsomsspocit- ic s€rvicemethodswhich could causePERSONAL lNJURy, d8mag6 a vahicl€or mako it unsafe. Pleaaaund€ratandthat thos6 warnings cannot cover all conc€ivableways in which sorvice,whethgr 01not recommended by HONDA might b6 dono, or of tho possible hazardous consequences of evely conceivablo way, no. could HONDAinvostigateallsuch ways. Anyono usingsorvicsproceduros 01toofs.whetheror not rocommendedby HONDA,must satjslyhim- sel, thoroughly that ngithor p€r3onal aatety nor vohicl€ s8fety will be jsopardized. All informationcontainedinthis manualis basedon the latestDroduct info.mationavailable at the time of printing.We reservethe right to makechanges at anytime withoutnotice.Nopartof thispublica- tion may be reproduced, storedin retrievalsystem.or transmitted, in any form by any means,electronic.mechanical, photocopying, recording, or otherwise,withoutthe priorwrittenpermission oJthe publisher. This includestext, figuresand tables. FirstEdition9/92 1516 pages All Rights Reserved Specilications applyto U.S.A.and Canada HONDAMOTORCO..LTD. Seruic€PublicationOffics As soctions with * includ6 SRScomDononrs. sp€cialpiocautions aro roquiradwhoit so.vicing. General lnfo Specifications f,|tr Maintenance t Engine ll= Cooling I t ri! FuelandEmissions ZZ *Steering If." r *Body *Heaterand Air Conditionin * Electrical (lncluding - + *Transaxle *Brakes (lncludin

- 2. GeneralInformation Chassis andPaintCodes................. 1-2 ldentification Number Locations ....... 1-4 Warning/Caution Labels.................. 1-s Lift and SupportPoints Lift ........... ................ 1-9 Floor Jack ................. 1-10 Safety Stands ............ 1-11 Towing .......1-12 ServicePrecautions Handlingof SpecialNuts and Bolts 1 - 1 3 '!. 7t

- 3. Chassisand PaintCodes U.S. Model VehicleldentificationNumbel and FederalMotor Vehicle Safety Standard Certification' EngineNumber EngineType F22A1; 2.2 / SOHCSequential Multi- port Fuel-injectedengine H22A1t2-2, DOHCVTECSequential MultiportFuel-iniected engane H23A1t2.3, DOHCSequential Multi- port Fu€l-injectedengine EmiesionGroup lOO: Califolniawith H22A1 engine 130: 49ST with H22A1 engine 2OO:California with H23A1 engine 23O: 49ST with H23A1 engine 920: Calilorniawith F22A1 engine 923: 49ST with F22A1 engine Serial Numbel Paint Code COLOR B-64P ii ir i[ i F22A1-9200001 JHMBA814'PCOOOOol Type of Vehicle JHM: HONDAMOTOR CO.,LTD. HONDA,Passenger Car BA8: Prelude2.2 / BBl : Prelude2.2 t VfEC BB2: Prelude2.3 / Body and TransmissionTYPe 1: 2-doors-sDeed Manual 2t 2-doot 4-speedAutomatic Vehicle Grade 4: PreludeS 5: Prelude Si 6: PreludeSi 4WS 7: Prelude Si VTEC Chock Digit Model Yoat P:, '1993 M2F4- 1000001 M2F4: Manualwith H22A1 engine M2L5: Manualwith F22Al engine M2S4:Manualwith H23A1 engine M2F4: l OOOOO1 - ExceotM2F4: 20OOOO1 - FrescoBlue Pearl BrittanyBlueMetallic GranadaBlsckPeatl SeablingSilverMetallic Frost White MiranoRed

- 4. CanadaModel VehicleldentificationNumber JHMBA814* PC800001 JHM: HONDAMOTORCO..LTD. HONDA,Passenger Ca. BA8: Prelude2.2 / B B 1 :P r e l u d e 2 . 2 . l E C BB2: Ptelude 2.3 I Body and T.ansmissionType 1: 2-doors-sDeed Manual 2',2-doot4-speedAutomatic Vehicle Glade 4: Prelude 5: Prelude SR 6: Prelude SR 4WS 7: PreludeSR-V Check Digit Model Y6at P : 1 9 9 3 C: SaitamaFactoryin Japan F22A1: 2.2 / SOHCSequential Multi port Fuefinjected engine H22A'l:2.2 / DOHCVTECSeouential MultiportFuel-injected engine H23A1:2.3 / DOHCSequential Multi- pon Fuel-injected engine F22A1 engine;928OOO1 - H22A1 engine:l TOOOO l - H23A1 engine:27OOOO1 - M2F4- 1000001 M2F4: Manualwith H22A1 engine M2L5: Manualwith F22Al engine M2S4:Manualwith H23A1 engine M2F4: l OOOOO l - ExceptM2F4: 2OOOO01 - VehicleldentificationNumbe] and CanadianMotor Vohicle Safety Standard Certification. PaintCode COLOR 8,64P F esco Blue Pearl Brittany Blue Met8llic GranadaBlack Pearl SeablingSilverMetallic Frost White MiranoRed 1-3

- 5. https://www.aservicemanualpdf.com/ My Dear Friend! Thank you very much for visiting. Full manual if required, please enter the following URL into your browser. https://www.aservicemanualpdf.com/

- 6. ldentification NumberLocations Vehicle ldentif ication Number V.hicl€ ldontitication Numbo. TransmissionNumber (Automaticl TiansmissionNumber lManual) t l , ' i , l

- 7. Warning/Caution LabelLocations A: CABLEREELCAUTIONA D: DRIVER MODULE WARI{|]{G CAUTION: ISRSI BEFORE INSTA-I.IING CABLEREEL: . CENTERTHE FRONTWHEELS. . ALIGNTHE MARKS. . READSERVICEMANUAL. A WARI{ING THEAIRBAG I'{FLATOR ISEXPLOSIVE AND,IFACCIDEN. TALLYDEPLOYED, CAt{ SERIOUSLY HURTOFKILLYOU. . DOI{OI USEELECTRICAL TESTEOUIPMENT ORPNOB- II{G DEVICES.THEY CAN CAUSE ACCIDENTAL DEPTOYI'EI{T. . NO SERVICEABLE PARTSINSIDE,DO OT DISAS. SEMBLE. . PLACE AIRBAG UPf,IGHT WHEI{BEMOVED. a Fou.ow sERvtcE MAI{UAL |]{STRUCT|O]{S CAREFULLY. B: CABL€ REELCAUTIONB cAUTtOt{: NO SERVICEABLE PARTSINSIDE;DO NOTDISASSEMBLE OR TAMPER. C: DRIVERMODULEDANGER E: I FLATORWARNINGTAG A DANGER EXPLOSIVE/FLAMMABLE CONTACTWITHACID,WATERORHEAVYMETALSSUCH AS COPPER. LEADOR MEFCURYMAY PRODUCE HARM- FUL AND IRRITATING GASES OR EXPLOSIVECOM- POUNDS.STORAGE TEMPERATURES MUSTI{OT EXCEED 2OO"F{1OOOCI. FORPROPER HANDLII{G,STORAGE AND DISPOSALPROCEDURES REFERTO SERVICEMANUAL, SRSSUPPI.EMENT. POTSON COI{TAINSPOISONOUS SODIUMAZIDEAND POTASSIUM NITRATE, FIRSTAIO IFCONTENTS ARESWALLOWED. II{DUCEVOMITING.FOR EYE CONTACT, FLUSH EYES WITH WATER FOR 15 MINUTES.IF GASES(FROMACID ORWATERCONTACT) ABE INHALED,SEEI(FRESHAIR. IN EVERYCASE, GET PROMPTMEDICALATTENTION. KEEPOUT OF REACHOF CHILDREN. A WARNING ACCIDENIAL AIRBAG DEPLOYMEI{I CA]T SERIOUSLY HURTORKILLYOU.II{STALLTHEREDSERVICE CONNEC- IOB WHENTHEINFLATORHARITESS IS DISCONNECTED. F: STEERING WHEELt{OllCE NOTICE IMPROPER STEERING VYHEEL REMOVALORII{STALLATION CAN DAMAGE SRSCOMPOT{EI{TS. FOLLOWSERVICEMA UA! INSTRUCTION CAREFULLY. (cont'd) 1 - 5

- 9. SUPPLEMENTAL RESTRAIIIIT SYSTEMISRS) THIS VEHICLEIS EOUIPPED WITH DRIVERAND FRONT SEATPASSENGEB AIRBAGSAND FRONTSEATBELTTEN. SIONERSYSTEMS. ALL SRS ELECTRICAL WIRINGAND CONNECTORS ARE COLOREO YELLOW. TAMPERING WITH, DISCONNECTING ORUSINGELECTRI- CAL TESTEOUIPMENT ON THE SRSWIRINGCAN MAKE THESYSTEMINOPERATIVE ORCAUSEACCIDENTALFIR- ING OF THE INFLATOR. A WARNING THEAIRBAGINFLATORIS EXPLOSIVE AND. IF ACCIDE . TALLYOEPLOYED. CANSERIOUSLY HURTYOU. FOLLOW SERVICEMANUAL INSTRUCTIONS CAREFULLY. G: SRSWARNING{ENGINE HOOOI H: STEERING COLUMNCAUTION CAUTION ISRS To AvotD DAMAGIIGrHE sRs CABLE oB REE|-. wHtcH COULDMAKETHESYSTEM INOPERATIVE, REMOVE THE STEERING WHEELB€FORE REMOVING THE STEERING SHAFTCONNECTOR BOLT. l: FRONTSEATPASSENGER AIRBAGMODULEDANGER *This versionof the labelis usedon cars with lront passenger airbag. A DANGER EXPLOSIVE/FLAMMABLE CONTACTWITHACID,WATERORHEAVYMETALSSUCH AS COPPER, LEADOR MERCURYMAY PRODUCE HARM. FUL AND IRRITATING GASES OR EXPLOSIVECOM- POUNDS.STORAGE TEMPERATURES MUSTNOTEXCEED 2OOOF (lOOOC} FORPROPEB HANDLING, STORAGE ANO DISPOSALPROCEDURES REFERTO SERVICEMANUAL, SRSSUPPLEMEI'T. POISON CONTAINSPOISONOUS SOOIUMAZIDEAND POTASSIUM NITRATE. FIRSTAID IFCONTENTS ARESWALLOWED, INOUCE VOMITING.FOR EYE CONTACT, FLUSH EYES WITH WATER FOR T5 MINUTES. IFGASESIFROMACIDORWATERCONTACTI ABE INHALED,SEEKFRESHAIR. IN EVERYCASE, GET PROMPTMEDICALATTENTION. KEEPOUT OF REACHOF CHILDREI'. A WARNING THEAIRBAGINFLATORIS EXPLOSIVE AND, IFACCIDEN. TALLY DEPLOYED, CAN SEBIOUSLY HURTOR KILLYOU. . DO NOTUSEELECTRICAL TEST€OUIPMENT ORPROB- ING DEVICES. THEY CAN CAUSE ACCIDENTAL DEPLOYMENT. . NO SERVICEABLEPARTS INSIDE. DO NOT DISAS- SEMBLE. . PLACEAIRBAG UPRIGHTWHEN BEMOVED. . F O L L O W S E R V I C E M A N U A I - I N S T R U C T I O N S CAREFULLY. 1-7 DRIVER'SAIREAG INFORMATION . SUPPLEMENTAL RESTRAINT SYSTEMISRSICAN PRO- VIDEAOOITIONALPROTECTION FORTHEDRIVERINA FRONTAL COLLISION. A FUNCTIONAL DESCRIPTION OF THE SRSIS IN YOUROWNER'SMANUAL. . THESYSTEMMUST BEINSPECTED TENYEARSAFTER DATEOFMANUFACTURE, AS NOTEDONTHECERTIFI- CATION PLATE. . ANY REPAIR, INSPECTION ORNEARBY ACCESSORY II{. STALLATIONSHOULD8E DONEBY AN AUTHORIzED HONDADEALER. . IF YOURSRS INDICATOR: . LIGHTSWHILE DRIVINGOR FLASHES; . FAILSTO LIGHTORSTAYSON AFTERTHEIGNITION IS FIRSTTURNEDON: SEEYOURAUTHORIZEDHONDA DEALER. K: DRIVER INFORMATION ISUNVISOB) ALWAYWEARYOURSEATBELT CAR IS EOUIPPED WITH A DRIVER AIRBAGAS A SUPPLEMENTAL RESTRAINTSYSTEM{SRSI. . IT IS OESIGNED TO SUPPLEMENT THE SEAT BELT. . BEFORE ORIVING READLABELINSIDE THEGLOVEBOX. 'K: DRIVER INFORMATION ALWAYWEARYOURSEATBELT CAR IS EOUIPPEO WITH A DBIVERAIRBAGAND A FRONT SEATPASSENGER AIRBAGAS A SUPPIEMEN- TAL RESTRAINTSYSTEMISRS). . IT IS DESIGNED TO SUPPLEMENT THE SEAT BELT. . BEFORE DRIVING REAOLABELINSIDE THEGLOVEBOX. L: GLOVEBOX INFORMATION 'L: GLOVEBOXINFORMATION M: SRSUNITCAUTION CAUTIONi . NO SERVICEABLE PARTSINSIOE. . DO NOT OISASSEMELE OR TAMPER. . DO NOT DROP. . STORE IN A CLEAN,DRYAREA, (cont'd) DRIVER'S AND FORMATION FRONTSEAT PASSENGER'S AIRBAG IN- . SUPPLEMENTAL RESTRAINT SYSTEM{SRSICAN PRO. VIDEADDITIONALPROTECTION FORTHEDN|VER AND FRONTSEATPASSENGER IN A FRONTALCOLLISION. A FUNCTIONAL DESCRIPTION OFTHESRSIS IN YOUR OWNER'SMANUAI.. . THESYSTEMMUSTBEINSPECTEO TENYEARSAFTER DATEOFMANUFACTURE, AS NOTEDONTHECERTIFI- CATION PLATE. . ANY REPAIR, INSPECTION ORNEARBYACCESSORY IN- STALLATIONSHOULDBE DONEBY AN AUTHORIZEO HONDADEALER. . IF YOURSRSINDICATOR: . LIGHTSWHII-EDRIVINGOR FLASHES; . FAII.STO LIGHTORSTAYSON AFTERTHEIGNITION I rs FrRsTTUBNEDON; . SEEYOURAUTHORIZED HONDAOEALER.

- 10. t: I I I . Warning/Caution LabelLocations AIR CLEAI{ERELEMEI{T, OIL FILTEB,RECOMMENDATIOI{ ENGINEOll- and SPARKPLUG tl i-l atl ;DZ"N RAOIATORCAP CAUTION 1-8 ..

- 11. Lift and SupportPoints @Q wnen heavy real components such as suspension,fuel tank. spare tile and trunk lid are to be removed, plac€ additional weight in tha trunk betole hoisting. When substantialweight is removedtrom the lear of th6 cal, the center of gravity may change and can causs the car to tip forward on tho hoist. NOTE: Sinceeachtire/wheelassemblyweighsapproximately 30 lbs {14 kg), placingthe front wheelsin the trunk can assistwith weight dist.ibution. 1. Placethe lift blocksas shown. 2. Raisethe hoist a few inches(centimeters) and .ock the car to be sureit is firmly supponed. 3. Raisethe hoistto tull heightand inspectlift pointsfor solidsupport. (cont'd) DH REARSUPPORT POINT 1-9

- 12. Lift and SuPPortPoints FloorJack Setthe parkingbrakeandblockthe wheelsthat are not being lifted. When liJtingthe rearof the car, put the gearshift leverin reverse{Automatictransmission in @ po- sition). Raisethe ca. highenoughto insertthe safetystands' Adjustandplacethe satetystandsasshownon page 1-11 sothe car will be approximately level,then low- er the car onto them. @ o Always uso sal€ty stands when wolking on or undor any vehiclo that is supponed only by a jack. a N€veratt€mpt to use a bumpel iack for lifting ol supporting tho cat. CENTER BEAM Centerthe iacking bracket in the middle of the jack lilt Platform. PLATFORM Centerthejacking bracketin the middle ol the iack lift Platform LIFTPLATFORM 1 - 1 0

- 13. SafetyStands DH FRONTSUPPORTPOINT SAFEW STANDS REARSUPPORTPOINT 1-11 j

- 14. Towing ll the car needsto be towed. calla proJessional towing service.Nevertow the car behindanothercar with just a roDeor chain.lt is verYdangerous EmelgencyTowing Thereare three popularmethodsof towing a car: Flat-bed Equipment- Theoperator loadsthe caron the backol a truck.Thisis the bestway of transponingthe car. Wheel Litt Equipmont- The tow truck usestwo plvor- ing armsthat go underthe tires {trontor rear)and lifts them otf the ground.The othertwo wheelsremainon the ground. Sling-type Equipmont - The two truck uses metal ca- bles with hookson the ends.Thesehooksgo around Dartsof the trameor suspension andthe cableslift that endof the caroft the ground.Thecar'ssuspension and bodycanbeseriously damaged if thismethodof towing is attempted. lf the carcannotbetransported by flst-bed,it shouldbe towed with the front wheelsoff the ground.lf due to damage,the car must be towed with the front wheels on the ground,do the following: 5-spe6d Manual Tlansmission a Release the Parkingbrake. a Shift the transmission to Neutral. Automatic Tlansmission a Release the Parkingbrake. a Startthe engine. a Shift to @ position,then @ position. a Turn off the engine. NOTICE: lmpropertowing preparation will damagethe transmission. Followthe aboveprocedure exactly.It you cannotshift the transmission or startthe engine(auto- matictransmission), your car must be transponedon a flat-bed. a lt is best to tow the car no farther than 50 miles (8okm),andkeepthespeedbelow35 mph(55 km/hl' NOTICE: Tryingto lift or tow the carby the bumpers will causeserious damage. Thebumpers arenot designed to suooortthe car's weight. TtEDOWIIHOOKS TOWING HOOK .-) t : f 'l . 1-12

- 15. 1 - 1 3 ServicePrecautions Handlingof SpecialNuts and Bolts Becausethe tront subframesectionson this car a.e con- structed with aluminumalloys. use only the special "Dacro" type nuts and bolts recommended by Honda. NOTE: a Dacrofinishcan be identitiedby gray plating. a Some Dacrotinish bolts have a greencoating on the th.eadsectionof the bolt for easielapplica- tion.Thistype ot boltis calleda "Torqu6r" bolt, a Useof othertypes ot nuts and boltsmay cause electrolvsis and corrosion,which in turn could caus€the bolt to loosen. l . When replacingnuts and bolts, use only the same type. Tightenthe nuts and bolts with I torqua wrench to ths specifications providedin this manual. Cleanall thread ridges with a non wire type bristle brush. Foroignmatter in the threadsmay causethe bolt to loosen. S€ctionson this car requiringthe use of Dacronuts and boltswill be indicated bv a l* I in this manual. J . 4. Gray Grcon coating on tha thraad! of ao|lro bolta. Gray plsting:"Dacro" type Gray plating + Greencoatingon the threads: "Torquer" type

- 17. Standardsand ServiceLimits ''l: CHUOHATSUJOmanulactured valvesprrng. '2: NIHONHATSUJOmanulactllred valvespring 6 I CytinderHead/ValveTrain {F22A1 engine}- Section 6 I TTaEASuREMENT J sraruolnotruewt I senvtce umtr Compression 25O rpm and Nominal wide openthrottle Minimum kPa{ks/cm2, psi) r49l'm!Il9!919! 1.250 112.5, 1781 950{9.5,135) 200 12.0.2al Cylind€rhead Warpage Hoight 99.95-100.05 (3.935-3.939) 0.o5(0.002) Camshaft End play Camshalt-to-holder oil clearance Total runout Cam lobeheight I N EX o.05-o.1 5 (0.002-0.006) 0.o50-0.089 (o.oo20-o.oo35) 0.03 {0.0o1) max. 38.526 (1.5168) 3a.77a11.52671 o.5 {0.02) 0.15(0.006) o.06 (0.002) Valveclearance Valvestem O.D. Stem-to-guideclearance EX IN EX IN EX IN o.23-0.28 (0.o09-0.o1 1) 0.27-0.30 (0.01 1'0.01 3) 5.485-5.495 10.21 59-0.21 63) 5.450-5.460 (0.2146-0.21 50) 0.o20-0.045 {o.0008-o.oo20) 0.055,0.o80 {0.0022-o.oo3'l ) ooss ro.: Ioet 5.4201o.21341 0.08(o.oo3) o.1 2 (0.oo5) Valve seat width Stem installedheight I N EX I N EX 1.25-1.55 (0.049-0.061 ) 1.25-1.55 (O.049-0.061 ) 48.245-48.7 15 (1.8994-1.91 79) 50.31 5-50.785 (1.9809-1,9994) 2.0 {0.08) 2.0 10.08) 48.965 t1.92781 51.035 (2.00921 Valvespring EX Freelength lN 2 2 54.8112.158) 54.82(2.r 58) 56.26{2.215) 56.2A12.2161 Valveguide I N E X I N E X t . D . Installed height 5.51 5,5.53010.217 1-0.217 7| 5.51 5-5.5301o.211 1-O.21771 23.75-24.25 (O.91 5-0.954) 15.05-' 1 5.55{O.593-0.61 2) 5.53(0.218) 5.53{0.2181 Bocksrarm I N EX Arm-to-shaft clearance o.o1 7-o.050 l0.oo07'o.oo20) o.o1 8-0.054 (0.ooo7-o.0021 ) 0.08 (0.003) o.08 {o.oo3)

- 18. I .l CylinderHead/ValveTrain (H23A1 enginel - Section 6 MEASUREMENT Unit of tength:mm (in) srAr{DARD tt{Ewl I stnvtce urirr Compression 250 rpm and Nominal wide openthrottle Minimum kPa lkg/cm2, psi) Maximumvaiation 1,250112.5, 1181 950{9,5,135} 200 12.o,2al Cylinderhead Warpage Heighr 131.95-132.05 (5.195,5.1 99) 0.o5{0.oo2) Camshatt Endplay Camshaft-to-holder oil clearance Total runout Cam lobeheight I N EX 0.050.15 (0.oo2-o.006) o.050-0.089 (o.0020-o.oo35) *1 0.100,o. 139 (o.0039-0.0055)*2 0.O3(0.O011 max. 33.661 {1.3252} 33.725 t1.327 8) o.5 {0.02} o.15{0.006).1 0.20 (o.oo8)*, 0.06 (0.oo2l Valve clearance Valvestem O.D. Stem to-guide clearance IN EX IN EX IN EX o.07-0.1 1 (0.003-0.004) o.15-0.19 t0.oo6 0.007) 6.580-6.590 (O.2591 -0.2594) 6.550-6.560 (O.2579-0.2583) o.o2-o.05 (o.oo1 -0.002) 0.o5-o.08 (o.oo2-0.o031 6.55(O.258) 6.32 t0.257l 0.08{o.oo3) 0.11(O.OO4) Valve seat Widrh Stem anstalled height IN EX IN EX 1.25-1.55 (0.049-0.061 ) 1.25-'1.55 (0.049,O.061 ) 39.365-39.835 t'1.5498-1.5683) 39.195,39.635 (1.5431 -1.5604t 2.0 (o.081 2.0 (0.081 40.085{1.5781) 39.885 {1.5703) Valvospring Freelength lN EX 4 7 . 1 41 1 . 8 5 6 1 4 7 . r 4 ( 1 . 8 5 6 ) Valveguide I N EX I N EX t.D. Installed height 6.61-6.63 (O.260-0.261 I 6.61,6.63 (0.260-0.261 ) 13.25-1 3.75 1O.522-0.541 | 13.75-1 4.25(O.541 -0.561 ) 6.70 to.264l 6.70{0.264) ' 1: ExhaustNo. 5 journal. '2: ExceptexhaustNo. 5 journal. {cont'd) 3-3

- 19. Standardsand ServiceLimits CHUOHATSUJOmanufactured valvespr'ng' NIHONHATSUJOmanufactured valvespring' , 2 | ii ii CylinderHead/ValveTrain (H22A1 engine)- Sectit MEASUREMENT 6 STANDARD tNEwl I sERvlcELlMlr )n Compression 250 rpm and Nominal wide openthrottle Minimum kPa (kg/cm2,psi) Maximumvarlatron 1,30O(13.0,185) 950 {9.5, 135) 200 (2.o, 28) Cvlinderhead Warpage Heisht 141.95 142.05 {5.589-5.593) o.o5{0.002} Camshaft Endplay Camshalt-to_holder oil clearance Total runout Cam lobeheight lN Primary Mid Secondary EX PrimarY Mid Secondary o.o5-o.1 5 {O.OO2-0.006} o.050-0.o89 (o.o020-o.oo35) 0.03(O.001 | max 34.04' 1 {1.3402) 36.856 (1.4510) 34.971 {r.3768} 33.745 {1.3285) 36.323 (1.43001 34.683 (1.3655) 0.5(0.02) o.15(0.006) 0.06 {o.oo2) 0.15-O.1 9 (0.006-0.oo7) o.170.21(O.OO7-O.OO8| 5.475-5.485 1O.2' l 56'0.21 59) 5.475-5.485 (0.21 56-0.21 59) o.025-0.055 (0.001 0-0.oo22) o.o5o-0.080 {0.0020-0.0031 ) i.oou to.z'tool 5.445{0.2144) 0.08(0.003) 0.11 (0.oo4) Valveclearance lN EX Valvestem O.D. lN EX Stem-to-guide clearance lN EX Valve seat widrh Steminstalled height IN EX I N EX 1.25-1.55 (0.049-0.061 ) 1.25-1.55 (0.049-0.061 ) 37.465-37.935 (1.4750-' |.4935) 37.165-37.635 (1.4632-1.481 7) 2.0 10.079) 2.0 t0.079) 38.185 (1.5033) 3 7 . 8 8 5 { 1 . 4 9 1 5 } Valvespring Freelength lN Outer lnner EX Outer tnner 4 5 . 1 6( 1 . 7 7 8 ) ' r 45.76 (1.802)'2 4 1 . 7 8{ 1 . 6 4 5 ) ' 1 41.75 11 .6441'2 46.72 (1.839)-r 46.74 11.8401 '2 39.32 (1.548)*r 39.28 (1.546)'2 Valveguide t . D . Installed height I N EX I N EX 5.51o-5.530 1O.21 69-0.2177| 5.535-5.555 (0.21 79'0.21 87) 12.55-1 3.O5(O.494-0.5141 12.55-13.O5(O.494-0.51 4) 5.55(0.219) 5.60{O.220) 13.30{O.524} 13.30(0.524) Rockerarm IN EX Arm-to-shaft clearance 0.025-0.052 (O.OO1 0'0.0020) o.025-o.052 (O.001 0 0.oo20) 0.o8(o.003) o.08i0.oo3) 3-4

- 20. _]] -'] EngineBlock Section Unit of length:mm linl '1: Measured at 2l.O mm (O.83inl on F22A1 engineand 15.0 mm (0.59 in) on H23A1. H22A1 enginesborh from bottom o{ skirt. '2: TEIKOKU PISTON RINGmanufactured pisronring. '3: RIKENmanufactured pistonring. MEASUREMENT STANDARD{NEW} I SERVICE LIMIT Cylinderblock Warpageof deck surtace BorediameterF22A1 engine H23Al, H22A1engines Bore taper Reboring limit F22A1 engine H23A1, H22A1 engines 0.0710.003) max. 85.01 0 85.020 (3.3468,3.3472) 85.000,85.010 (3.3465 3.3468) 87.O'f 0-87.020 3.4256-3.4260) 87.OOO 87.01013.4252 3.42561 0.1010.0041 85.0713.349) 87.O7t3.4281 0.o5 (0.002) 0.50(0.020) 0.2510.010) Piston Skirt O.D.*1 F22At engine No Letter(A) Letter B H2341, H22A1 enginesNo Letter{A} Letter B Cfoarancein cylinder F22A1 engine H234'1, H22A1engines Groovewidth F22A1 engine Top {for ring} Second oil H23A1,H22At engines Top Second oil 84.980-84.990 {3.3457-3.3461 ) 84.970 84.980 {3.3453 3.3457) 86.990-87.003 13. 424A-3.42531 86.980-86.993 13.4244-3. 42491 0.020-0.o40 (0.ooo8,0.001 6) o.007-0.030 (0.0003-0.001 2) 1.220-1. 230{O.0480 0.0484) 1.220-1. 230{O.0480,0.0484) 2.405-2.420 (O.1 104-0.1 1101 '1.230- 1.245{0.0484-0.0490t 1.230- 1.245t0.0484-O.0490) 2.405-2.820 (0.1104-0. 1110) 84.970 (3.3453) 84.960(3.3449) 87.980(3.4638) 87.97013.4634) 0.05{0.002) o.04{o.002) 1.25(0.049) 1.25(0.049) 2.85(0.1 12) 1.265{0.0498) 1.265{0.0498) 2.85tO.112l Pistonring Ring-to-groove clearance Top Second 0.035-0.060 (o.001 4-0.0024) 0.030-0.055 to.oo1 2-o.oo22l 0.13(0.oo5) 0.13(0.005) Ringend gap F22Al engine Top Second oil H23A1,H22A1engines Top Second oil 0.20-o.35 (0.008-0.01 4) 0.40-o.ss(0.o1 6-0.022) 0.20-0.70 (0.0080.028) o.25-0.35 {0.01 0-o.014) 0.60,0.75 (o.0240.o30) 0.20-o.50 {0.008-0.o20) *2 0.20-0.70 (0.oo8-0.0281 *3 0.60{0.024) 0,70 {0.028) o.80(0.031) o.60 (0.024) 0.90(0.035) 0.6010.024) 0,80(o.031) Piston Pin o.D. Pin-to-pistonclearance F22A1 engine H23Al, H22A1 engines 21.994-22.OOO (0.8659-0.866 1) o.o1 2-0.o24 {o.0005-o.ooo9} 0.01 2-0.026 to.0005-0.0o10) Connectingrod Pin-to-rodinterlerence Small end bore diameter Largeend borediameter Nominal €nd playinstalled on crankshaft Srhallend bore-tolargeend boreparallelism 0.o1 3-o.o32 (o.ooo5-o.001 3l 21.968-21.981 (0.8649-O.8654) 5 1 . 0{ 2 . O 1 ) o. 15-0.30 (0.006-0.01 2) 0.12 (0.O05)/100 max. 0.40(o.o16) 0.15 (0.oo6y100 Crankshaft Mainjournaldiameter No. 1 and 2 journals No. 3 journal No. 4 journal No. 5 journal Rodjournaldiameter Taper Out-of-round Endplay Total runoul 49.976-50.000 (1.9676-1.9685) 49.97249.996 (1.9674,1.96831 49.984-50.008 (1.9679-1.9688) 49.988-50.01 2 (1.9680-1.9690) 47.97649.000{1.8888- 1.8898) 0.005 (0.0002)max. 0.OO5(O.0002)max. o.10,o.35 (0.oo4,0.01 4l O.03 {0.OOl ) max. 0.006(0.0002) 0.006{0.0002) 0.45{O.018) o.04 {o.002) Eearings Mainbearing-to-journal oil clearance N o . 1 a n d 2 j o u r n a l s _ No. 3 journal No. 4 iournal No. 5 journal Rodbearing-to-journal oil clearance F22A1 engine H23A1,H22At engines 0.021 -0.045(o.0008 0.001 8) 0.025-0.049 (0.0o10-0.001 9) 0.013-0.037(0.ooo5-o.001 5) 0.009-0.033 (0.0004,0.001 3) 0.021 -0.049{o.0008-0.oo20) 0.027-0.055 (o.001 'l-0.oo22) 0.050(0.0020) 0.055(0.0022) 0.050{0.0020) 0.040{o.0016) 0.055(0.oo22) 0.060(0.o024t 3-5

- 21. Standardsand ServiceLimits Engine Block - Section 7 (cont'd) MEASUREMENT STANOARD INEW} I SERVICE LIMIT Balancershatl Journaldiameter No. 1 iournal(lront) No. 1 journal(rear) No. 2 journals No. 3 iournals Journaltaper Endplay Front Rear Total runout Oil clearance No. 1 journallrear) No. 1 (front)and No 3iournal No. 2 iournals 42.7 22-42.734 (1.6820'1.68241 20.938-20.950 {O.8243-0.8248) 3A.712-3A.7 24 11.5241 -1.52461 34.7 22-34.7 34 (1.3670-1.3675) 0.005(0.0002) 0.10,0.35(O.OO4-0.O14) o.06-0. 18 to.002-0.o07) 0.02(o.oo1) o.050-0.075 to.oo20-0.0030) 0.066-0.1 18 (0.0026-0.0046) o.o76-0 i 2a {o.oo30-0.0050) 42.7' l{1,689} 20.92Q.A24l 38.70(1.524) 34.71{1.367) o.os ro.oot t o.09{o.oo4) 0.12(O.005) 0.13{0.005) Balancer shalt beanng LO. No. 1 journal(frontl No. 1 journal{rear) No. 2,ournals No. 3 iournals 42.AOO-42.820 {1.6850-1.6958) 21.000-2 1.01 3 {0.8268-0.8273) 38.800-38.820 11.527 6-1.52431 34.8OO-34.82O (1.3701-1.3709) 42.83(1.686) 21.O2@.A2Al 38.S3 (1.529) 3 4 . 8 3 ( 1 . 3 7 1 ) EngineLubrication- Section8 MEASUREMENT STAI{DARD (IIEW} I SERVICE LIMIT Engineoil Capacity t (USqt, Imp qt) F22A1 engine H23A1 engine H22A1 engine 4.9 {5.2, 4.3} for engineoverhaul 3.8 14.0,3.3) for oil change,including lilte. 5.4 (5,7, 4.81for engineov€rhaul 4.0 (4.2, 3.5) lor oil change,including lilter 5.9 (6.2, 5.2) for engineoverhaul 4.A $i, 4.21tor oil ch€nge,including filter Oil p'rmp Displacement ? IUSqt, lmp qtl/min @rpm 73.5 177.7,64.7) @6,000 lnner-toouter rotorradialclearance Pumpbody-toouterrotor radialclearance Pumpbody-to-rotor axialclearance o.02-0. 16 10.001 -o.006) 0.10,0.1 9 (0.004-0.007) o.02-0.07 (o.oo1 -0.003) o.20 (0.008) 0.21 (O.OO8) 0.12(0.005) Flelief valve Pressure settingat oil termperature 176oF (80oC) kPa (kg/cm2,psi) at idle at 3,0OOrpm 70 {0.7, 1O}min. 350 (3.5, 50) min. o i ; I ! Ir I i , l ' t I Cooling- Section MEASUREMENT STAI{OARD (NEW} Radiator ReservoircapacitY Enginecoolantcapacity F22A1 engine including engine, heater,cooling lineand reservoir { (USqr, lmp qt) H23A1 engine H22A1 engine M/T: 7.1 (7.5, 6.2) for overhaul 3.5 (3.7, 3.1) for coolantchange AlTt 7.O 17 .4, 6.2) tor ovorhaul 3.4 (3.6, 3.0) for coolantchange MlTt 7.4 17.9,6.5)for overhaul 3.8 (4.0, 3.3) for coolantchange All: 7.3 17 .7, 6.4) lor overhaul 3.7 (3.9, 3.3) lor coolantchange M/T: 7.8 (8.2, 6.9) Ior overhaul 4.2 14.4,3.7)for coolantchange o.6(o.6, o.5) Badiatorcap Openingpressure kPa {kg/cm2,Psi) 95-125(0.95-1.25, 13.5'17.8) Thermostat Startto open oF {oc) Fullyopen 'F {oC) Valvelifi at Iully open 169-177 {76-80) 194 (90) 8.O1O.31) min. Waler pump Displacement F22A1 engine f {USqt. lmp qt)hin @rpm H23Al engine H22A1 engine 165(174,145)@6,000 1s91168, 140)@6,000 163(172,143)@6,000 Radialorfan ECTswitch"ON" F22A1,H23A1engines temperature H22AI engine ECTswitch "OFF" tempetatureoF (oC) 194,205(90,96) 198-208(92-98) Subtruct 4'13 {l-7} tfomactual "ON" temperature

- 22. -]'] _]]] l Fueland Emission- Section 11 Unil ol lengthimm (in STANDARD(NEW) MEASUREMENT Fuelpump Displacement cc {USoz, lmp oz} in 10 seconds 205 (6.93, 7.221tnin. Pressureregulator Pressure with regulator vacuumhosedtsconnected kPa{kg/cm2, psi} F22A1,H23A1engines H22A1 engine 255-305(2.55,3.05, 36-43) 230-280{2.3-2.8. 33-40) Fuel tank Capacity{ {USgal, lmp gal) 60 (15.9, 13.2) Engine Fastidlerpm 1,400 ldlespeedrpm with headlightand cooling fan ott 700 150 (M/T:neurral) 7OO150 {A/T:E o. E position) ldle CO % 0.1 max. Clutch Section 1 2 ManualTransmission Section 1 3 MEASUREMENT STANDARD INEWI I SERVICE LIMIT Clutchpedal Pedalheight ro ttoor Stroke Pedalplay Disengagement height to floor 2 0 8( 8 . 1 1 ) 1 3 5 - 1 4 5 ( 5 . 3 1 - 5 . 7 1 ) 1.0-7.0 (0.O4-O.28) 94 {3.70) min. Flywheel Clutchsurlacerunout 0.05{O.002} max. o.15 (0.006) Clutchdisc Rivet head depth Surface runout Thickness 'l.3 (0.O51) min. O.8(0.03)max. 8.4-9.1 (O.331-0.3s8) o.2 1 . O 6.O (0.008) (0.04) (0.2361 Clutch cover Pressureplate warpage 0.03(O.0011 max. o.15(0.06) MEASUREMENT STANDARo {NEw} I sERvIcELIMIT Transmissionoil Capacity t (uS qt, lmp qt) 1.9 12.O, 1.71foroil change 2.O 12.1,1.Al tor overhaul Mainshaft Endplay Diameterot ball bearingcontact area Diameter of third gearcontactar€a Diameterol ball bearingcontact area Runout 0. 10-0.16 {0.0039-0.0063) 27.977 -27.990(1.1015 1.1020) 37.984-38.OOO 11.49541.4961 ) 27.987 -28.OOO (1.1018-1.1024) 0.02 (0.0008)max. Adjustwitha shim. 27.94 11.1001 37.93(1.493) 27.94(1.100) 0.o5 (0.0021 Mainshatt3rd and fourth gears L D . Endplay Thickness 3rd gearM2L5, M2S4 M2F4 4th gearM2L5, M2S4 M2F4 43.OO9-43.025 (1.6933,1.6939) 0.06,0.21(0.0024,O.0083) 32.42-32. 47 tl.27 6-1.27 8l 34.92-34.97 11.37 5-1.3771 30.92-30.97 11.217 -1.2191 31.42-31.47 11.237-1.2391 43.080 {1.6961) o.30(0.o12) 32.3(1.2721 34.811.3701 3 0 . 8( 1 . 2 1 3 ) 3 1 . 3{ 1 . 2 3 2 ) Mainshaltsth gear t . D . Endplay Thickness 43.009 43.025 {1.6933- 1.6939} 0.06-0.21 (o.0024,0.oo83) 30.92-30.97 11.217 -1.21 9l 43.080(1.6961) 0.30{0.012} 3 0 . 8( 1 . 2 1 3 ) Countershaft Endplay Oiameter of needlebearingcontactarea Diameter of ball bearingand needlebearing conlactarea Diameter ot low gearcontactarea Runout 0.05,0.40 (0.0019-0.0157) 38.OOO-38.O1 5 {1.496'1 -1.4967) 24.947-25.OOO (O.9837-0.9845) 39.984-40.OOO 11.57 42-1.574al O.02 {O.0OO8) max. o.50{o.02) 37.95(1.494) 24.94lO.982l 39.93{1.572} o.05 (o.oo2) Countershalt lsl gear t.D. Endplay 46.009-46.025 {1.81 14-1.81 20} 0.04,0.10 (o.002 0.oo4) 46.08 (1.8't4) Adiustwith a washer. Countershatt2nd gea( LD. Endplay Thickness 47.OO9-47 .O25 (1.8507 1.8514) o.04-0. 10 {0.002-o.004) 28.922a.97(1.'t 39,1.141) 47.08 ('t.854) Adjustwith a collar. 2 8 . 8( 1 . 1 3 ) (cont'd) 3-7

- 23. Standardsand ServiceLimits dl ManualTransmission- Section 13 (cont MEASUREMENT STANOARDINEW) I SERVICELIMIT Spacercollar lCountershaft 2nd gear) LD. o.D. Length B 36.48-36.49 {1.4362-1.4366) 41.989-42.O00 {1.6531 -1.6535) 29.O2-29.O4 (1.1 425-1. 1433) 29.O7 -29.09(' |.144-1. 145) 36.50(1.4371 4 1 . 9 4 ( 1 . 6 5 2 ) Spacecollar (Mainshaft 4th and 5th gear) L D . o.D. Length B -Jo a - la 31.002-31.01 2 (1.2205-1.2209) 37.989-38.OOO (1.4956-1.4961 ) 56.45,56.55 12.222-2.2261 26-03-26.08 (1.0248-1.0268) 31.06(1.223) 37.94(1.494) Reverse idlergear L D . Gear-lo reverse gearshaltclearance 20.o1 6-20.O43 (0.7880-0.7891 l 0.036-0.084 {o.oo1 4-0.00331 20.09(o.7909| 0.160to.ooo6l Syncroring Ring-to gearclearance (ringpushedagainst gearl o.85-1.10 (0.034-0.043) 0.40{o.o16l Dualcone sYncnro nng Clearance (ringpushedagainstgear) Outersynchroringto_gear Innersynchroring-togear Outersynchroring-tosynchrocone 0.95-1.68 (0.037-0.066) o.5-1.O (0.02-0.04) o.5-1.O (0.02-O.041 0.6(0.024) o.3(0.o11 0.3(0.01) Shift fork Fingerthickness M215, M2S4 M2F4 Forkto syncrosleeveclearance 6.2,6.41O.244-0.2521 7.4,7.6 (O.291-0.299) o.35-0.65 t0.01 4-0.026) 1.O(0.039) Reverseshitt fork a t A a t B a t A a t B Pawlgroovewidth ri'w, srouvc w,uu, A Fork'to reverse idle gear clearance I Groove width Fork-to-tifth/ B reverseshift shalt clearance 13.0-13.3 (0.51-0.52) 0.5-1.1 (0.02-0.431 7.O5-7.2510.27 a-O.25541 7.4-7 .7 tO .29-O .301 o.o5-0.35 10.002-o.o14) 0.4,o.8{o.02-0.03) 1.8(0.07) o.5to.02l 1.0{o.04) Shift arm L D . Shift arm-to-shaft clearance Shift tork diameterat contactarea Shift-arm-ro-shaft lork shaf t clearance 15.973-1 6.000{O.6289-0.6299) o.005,0.059 to.ooo2-o.oo23) 12.9-1 3.O(0.508-0.51 2) 0.2-o.5to.ol-o.02l Selectlever Pinsizeof contactarea Selectleverto-shittpeiceclearance Shaftouterdiameler Shift arm cover clearance 7.9,8.O(O.31 1-0.3' I 5) o.o5 0.25 10.002-o.o10) 15.41-15.68 (0.607-0.617) 0.032-o.102 (0.OO1 3-0.0040) o.5(0.o20) Shift arm lever o.D. Tlansmission housingclearance 15.941-15.968 {0.6276-0.62871 0.027-0.139 (O.001 1-O.OO55) lntedock Eorediameter Shitt arm lever clearance 16.00-1 6.O510.630'0.632) 0.032-0. 109 (0.001 3-o.oo43) I {r I

- 24. Automatic Transmission- Section 14 MEASUREMENT STANDARD{NEWI Unit of lengthmm (in) SERVICELIMIT Transmission tluid Capacityf (USqt, lmp qt) 6.0 (6.3, 5.3) Ior overhaul 2A 12.5,2.11torlluidchange Hydraulic pressure (F22A1engine) kPa lkg/cm2, psr, LineDressure at 2.OO0rom i n E o r E p o s i t r o n 800t8.0,1141 throftleIully-closed I 850(8.5,121) lhrottle morethan3/16open 73O11.5, 1O7l throttle morethan3/16 open 4th clutchoressure at 2.000 rom in @ position 530 (5.3, 75) throttle fully,closed I 8 5 0 ( 8 . 5 . ' 1 2 1 ) throttle more than 3/16 open 480 (4.8, 68) throttte lully-closed I 750 17.5,1071 throttle morethan3/16 open 3rd and 2nd clutchpressure at 2,000 rpm in E posrtion 5 0 0{ 5 . 0 , 7 1 ) throttleIullv-closed I 850(8.5,121) throttlo morethan3/16open 450 (4.5, 64) throttle fully-closed I 750 (7.5,107) throttlemorethan 3/16 open 2nd clutchpressure at 2,OOO rpm in Lzl position 800-850 (8.0-8.5. 114-1211 75017.5, 1O7l 1st and 1st-holdclutchpressure at 2.000 rpm in LLI position 800-850{8.0-8.5, 114-121} 750 17.5,1071 Throttle B pressure Throttle fully closed Throttle fully open 0 (0.o) 800-850 t8.0-8.5. 114-1211 750 17.5,107) Hydraulic pressure (H23A1engine) kPa {kg/cm2, pst, Linepressure at 2.000 rom in E or E]position 850(8.5,121) thro le tully-closed I 900 (9.o,129) throttlemorethan3/16 open 8O0(8.0.t 14l throttlemorothan3/16 open 4rd clutch pressureat 2.OOOrDm in @ positron 5 3 0( 5 . 3 , 7 5 ) throttle fully-closed I 900 (9.o,128) throttle morethan3/16open 48O (4.8, 68) throtte tully-closed I 800 (8.0,114) throttlemorethan 3/16 open 3rd and 2nd clutchpressure at 2,0OOrpm in E position 5OO(5.0.71) throtlletullv-closed I 900 (9.o,128) throttle morethan3/16open 450 {4.5, 64) rhrottlefully-closed I 800{8.0,114} throttle morethan3/16 open 2nll_glutchpressrueat 2,OOOrpm in L2l position 850,90018.5-9.O. 121-1 28) 800 {8.0, 114} 1st and 1st-holddutch pressure at 2,000 rpm in Lll posirion 850-900{8.5-9.0, 121-128) 800 {8.0,114) Throttle I pressure Throttle fully closed Throtttefully open o (o,o) 850-900(8.5-9.0, 121-128) 800(8.0.114) Stalf speed rpm F22A1 engine {Checkwith car on levelground) H23A1 engine 2,350-2,650 2,600-2,900 {cont'd) 3-9

- 25. Thank you very much for your reading. Please Click Here Then Get More Information.

- 26. https://www.aservicemanualpdf.com/ My Dear Friend! Thank you very much for visiting. Full manual if required, please enter the following URL into your browser. https://www.aservicemanualpdf.com/