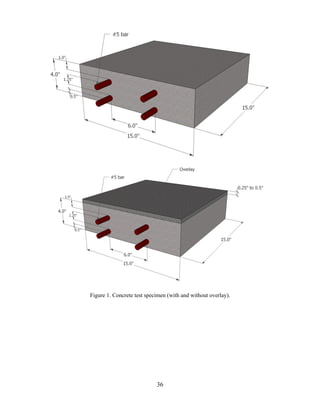

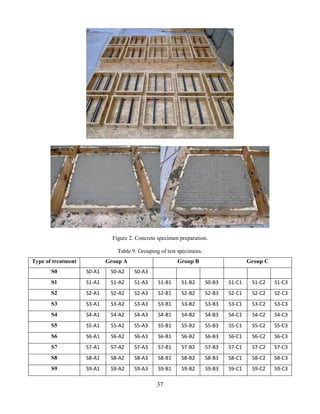

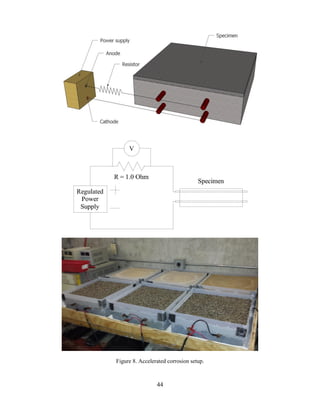

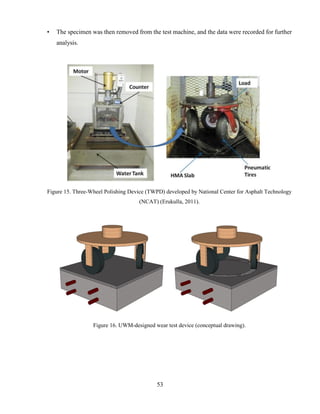

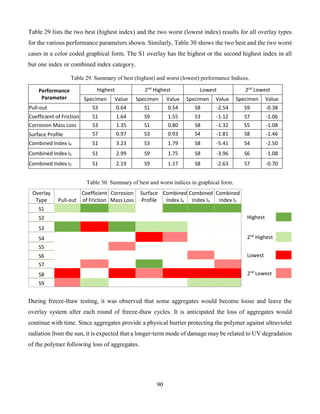

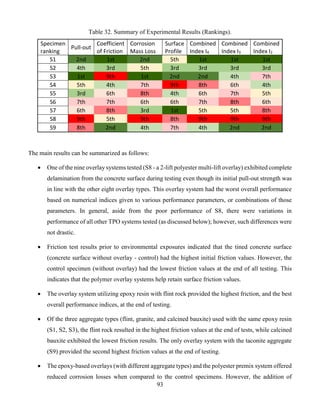

This document evaluates nine thin polymer overlay systems for bridge decks. Laboratory specimens were subjected to accelerated corrosion, freeze-thaw cycling, heat/UV/rain exposure, and tire wear tests. The best performing overlay was an epoxy resin with flint rock aggregate, based on friction coefficient, corrosion mass loss, pull-out strength, and surface deformation resistance. The polyester multi-lift overlay delaminated in all specimens. High chloride contamination levels reduced corrosion protection from overlays. Recommended maintenance guidelines are provided.