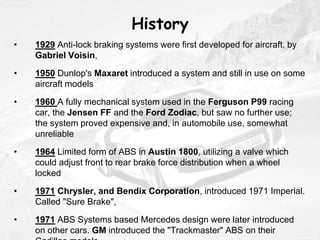

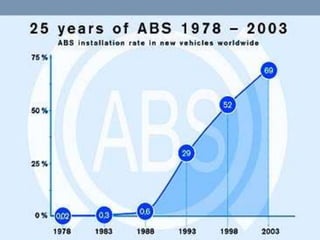

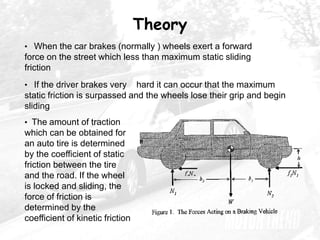

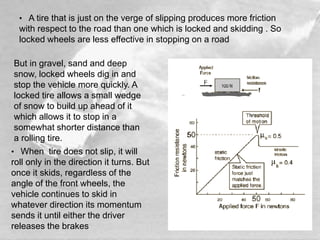

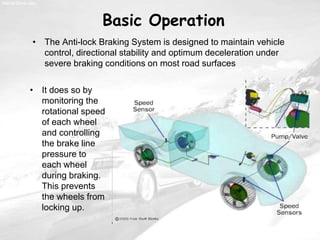

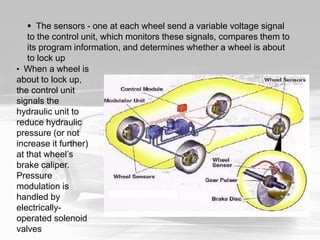

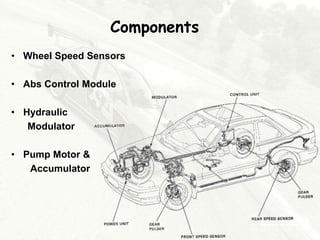

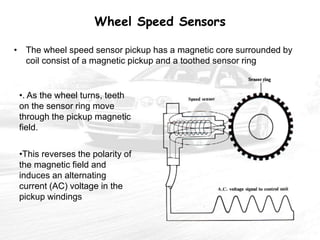

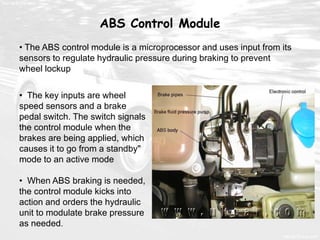

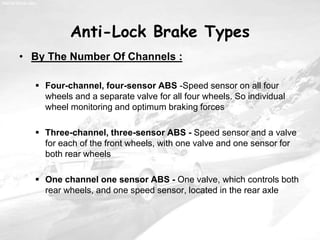

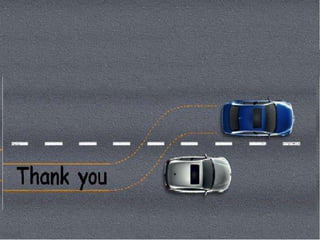

This document discusses anti-locking brake systems (ABS). It begins with an introduction that defines ABS and describes how it works to prevent wheel lockup during braking. It then discusses the history of ABS, including early aircraft applications in the 1920s-1960s and automotive applications starting in the 1970s that have led to ABS becoming standard on most vehicles today. The document also covers the basic theory behind ABS and how it modulates brake pressure to maintain traction. It describes the key components of ABS including wheel speed sensors, control modules, hydraulic modulators, pumps and accumulators. It concludes by discussing different types of ABS systems and some disadvantages.