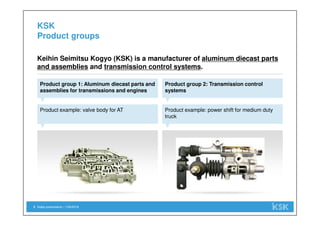

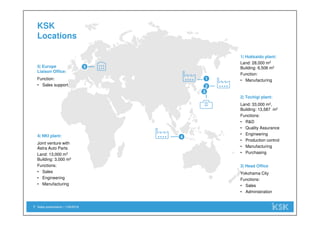

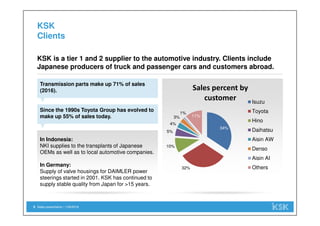

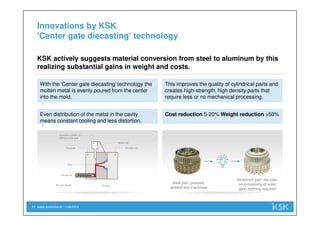

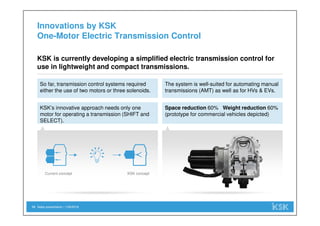

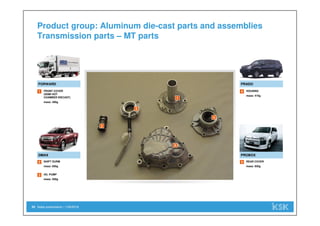

KSK is a Japanese manufacturer of aluminum die-cast parts and transmission control systems established in 1960. The document provides an overview of KSK's products, processes, locations, certifications, clients, and innovations. It details KSK's two main product groups of aluminum die-cast parts and transmission control systems, highlighting example parts and specifying production technologies like semi-hot chamber diecasting. Sales figures from 2016 and a breakdown of clients by percentage are also presented.